Professional Documents

Culture Documents

Drying Beds

Uploaded by

Taufiq Ur RahmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drying Beds

Uploaded by

Taufiq Ur RahmanCopyright:

Available Formats

Drying Beds

http://www.sswm.info/print/1302?tid=764

Drying Beds Published on SSWM (http://www.sswm.info)

Compiled by:

Dorothee Spuhler (seecon international gmbh)

Drying beds are either planted or unplanted sealed shallow ponds filled with several drainage layers and designed for the separation of the solid from the liquid fraction of (faecal) sludge from latrines, septic tanks, biogas reactors, trickling filters, etc. Sludge is dried naturally by a combination of percolation and evaporation. When plants are present, evaporation is enhanced by transpiration (evapotranspiration). The percolate still contains pathogens and needs to be collected for treatment or controlled reuse. After treatment in planted drying beds (humification beds), the dried sludge, a nutrient-rich soil amendment, can be directly used in agriculture. If unplanted sludge drying beds are used, additional treatment by composting may be foreseen. Unplanted drying beds need to be desludged before fresh sludge is applied, while humification beds can be filled up intermittently requiring desludging only once ever 5 to 10 years. Drying beds are relatively easy to construct and simple to maintain, although large surface areas and man- or mechanical power is required for regular desludging.

In Faecal Sludge Out Compost (for further off-site composting), Soil, Treated Water, Fertigation Water or Water requiering further treatment

All organic degradation processes produce sludge (SASSE & BORDA 1998). Sludges from wastewater collection or treatment units are of variable consistency (from septic tanks, small and large scale anaerobic digesters, anaerobic digesters for organic waste, anaerobic baffled reactors, wastewater stabilisation pond systems, etc.). Generally, they do not have a higher solids content than 2 to 10 % and can therefore not be transported easily with simple equipment. Apart from this, sludge is contaminated and occupies large volumes for storage (SASSE & BORDA 1998). Therefore it is better to dry or dewater sludge before further use or dumping. Sludge drying beds are one of the simplest and oldest techniques for sludge dewatering (SANIMAS 2005). They are a simple means to reduce the volume of the sludge and prepare reuse as fertiliser. Sludge drying beds are basically impermeable beds filled with different layers of gravel and sand. Drainage pipes are incorporated in the bottom of the beds.

Indiscriminate disposal of faecal sludge, Ouagadougou. Source: EAWAG/SANDEC (2008)

1 of 7

16/09/2012 7:07

Drying Beds

http://www.sswm.info/print/1302?tid=764

Lettuce farm fertilised with safe compost made out of faecal sludge treated in drying beds at Gyenyasi farmers association in Kumasi. Source: ERIKSEN-HAMEL & DANSO (2008)

Sludge is applied in layers on top of the gravel beds and is naturally dried. The bed can be either planted or unplanted. After treatment in planted drying beds (humification beds), the dried sludge, a nutrient-rich soil amendment (or biosolid), can be directly used in agriculture. If unplanted sludge drying beds are used, additional treatment by composting may be foreseen. This allows to stabilise the sludge and to return nutrients and organic matter into the soil for agriculture. The percolate contains pathogens and is collected in the drainage pipes. It can be reused, but then requires treatment.

Unplanted and planted drying bed. Source: TILLEY et al. (2008)

A traditional sludge drying bed can be used for dewatering and drying of faecal sludge and anaerobic digester residue. Anaerobic sanitation systems (e.g. latrines, septic tanks, aqua privies, anaerobic baffled reactors, biogas reactors) produce less sludge than aerobic treatments (e.g. from trickling filters, activated sludge) and anaerobic sludge also dries better and results in fewer odours as it is more stabilised. Sludge is dewatered by percolation, while the solid fraction remains on the filter surface and is dried by natural evaporation. In planted drying beds, the plants enhance evaporation by transpiration. This process is called evapotranspiration. In principle the construction of unplanted and planted sludge drying beds is similar to gravel/sand filters, starting with an impermeable shallow pond, drainage pipes in the bottom (perforated PVC pipes or hollow blocks), and different drainage layers. The bed frame is usually made from concrete or a plastic liner with the bottom surfaces slightly sloped in order to facilitate percolation and drainage. The lowest layer of the bed consists of a drainage stratum made of coarse gravel. Upper layers consist of different sand and gravel with finer grain size at the top. For the sludge application, a splash spate may be used to avoid sputtering.

Unplanted Sludge Drying Beds

2 of 7

16/09/2012 7:07

Drying Beds

http://www.sswm.info/print/1302?tid=764

Crosscut of an unplanted drying bed. Source: STRAUSS & MONTANGERO (2002)

Unplanted sludge drying beds are simple sand and gravel filters on which batch loads of sludge are dewatered. Indication about the diameter of the medium and the height of the different gravel and sand layers vary depending on the source (SASSE & BORDA 1998; STRAUSS & MONTANGERO 2004). Generally, the coarse gravel layer (grain diameter: 15 to 50 mm) is within 20 to 30 cm of height. A gravel layer (diameter of 7 to 15 mm) of 10 to 15 cm follows this layer. This layer can be followed of a similar one of slightly lower diameter (see picture below, STRAUSS & MONTANGERO 2002), but this is not compulsory (SASSE 1998). There should be a final sand layer of 25 to 30 cm. As some sand will be lost each time the sludge is manually removed, it may be higher (STRAUSS & MONTANGERO 2004; TILLEY et al. 2008).

Unplanted drying beds in Ghana (left) and rain protected unplanted drying bed at the Arcata wastewater treatment plant, USA (right). Source: EAWAG/SANDEC (2008); HUMBOLDT EDU (2008)

The sludge is applied in a batch mode about once per week intervals in layers of no more than 20 to 30 cm. About 50 to 80 % of the initial volume is removed by percolation (STRAUSS & MONTANGERO 2002), resulting in total solid (TS) content of 20 to 70 % (STRAUSS & MONTANGERO 2004) depending on the local weather conditions and climate. In regions with frequent rainfall, contour bounds can prevent surface runoff to enter the ponds and covering the drying beds with a roof may be considered. Drying induces partial pathogen removal. However, the dried sludge still may contain pathogens, particularly Helminth eggs, and should therefore be handled carefully and receive further treatment such as composting or prolonged storage before use in agriculture. The percolate from dewatering contains also pathogens, mainly bacteria and viruses and has to be further treated as well (STRAUSS et al. 1997). In the case of frequent application of sludge and to enhance retention times, two or more drying beds can be constructed in parallel and used alternately. On an annual basis, about 100 to 200 kg TS/m2 can be applied on a drying bed. Drying takes 10 to 20 days. Land requirements are 0.05 m2 per capita for a 10 days cycle (STRAUSS & MONTANGERO 2002). Before fresh sludge is applied, dried sludge needs to be desludged and brought to a composting site, what makes it a rather laborious treatment option.

Planted Sludge Drying Bed (Humification Bed)

3 of 7

16/09/2012 7:07

Drying Beds

http://www.sswm.info/print/1302?tid=764

Crosscut of a planted drying bed. Source: STRAUSS & MONTANGERO (2004)

Pilot beds of the VFCW developed for faecal sludge dewatering study in sub-Saharan countries. Source: KONE & KENGE (2008)

Planted sludge drying beds, also designated as reed beds or constructed wetlands, could minimise the need for frequent removal of dried sludge as they can be operated for several years before sludge removal becomes necessary. Source: EAWAG/SANDEC (2008)

As for unplanted beds, planted beds consist of an impermeable shallow pit filled with different layers of coarse to fine sand. Generally, there are three layers, starting with a large gravel layer (diameter of 20mm) of 25 cm height, followed by a fine gravel layer with granules of 5 mm in diameter (also 25 cm height) and finally covered with a sand layer of some 10 cm (EAWAG/SANDEC 2008). Unlike unplanted beds, planted beds do not need desludging before each new application as the root system of the plants maintains the permeability. The sludge is added intermittently once a week and only removed every 5 to 10 years (STRAUSS et al. 1997; STRAUSS & MONTANGERO 2002). Once the sludge is removed it is well mineralised and has a soil-like structure with a TS content of 40 to 70 % (STRAUSS & MONTANGERO 2002). Therefore, planted sludge drying beds are also called humification beds. It is best to stop applying sludge one or two years before removing it (while a parallel bed receives the sludge). In such a way, the humified sludge is nearly pathogen free and can be reused directly as biosolid in agriculture. Percolate quality also considerably improves by the presence of plants but may still require a polishing treatment (STRAUSS et al. 1997). Planted beds can receive about 250 kg TS/m2 per year (STRAUSS & MONTANGERO 2002).

Costs Considerations

4 of 7

16/09/2012 7:07

Drying Beds

http://www.sswm.info/print/1302?tid=764

The investment costs of sludge drying beds are moderate where land prices are low and filter material (gravel/sand) is locally available (SANIMAS 2005). However, the pond may needs to be made impermeable and expert skills are required for design. Operation costs are low as no energy or complicated equipment is required. However, desludging, particular for unplanted beds is laborious.

Operation and Maintenance

Operation and maintenance includes application of sludge, desludging, control of drainage system and the control of the secondary treatments for percolate or dried sludge. Even though experts are not compulsory for the operation and maintenance, a well-organised community group, which has experience in organic fertiliser use and preparation is required (SANIMAS 2005).

Health Aspects

Fresh sludge is generally highly pathogenic and should be handled with care. Also a certain distance to the installed beds (especially when sludge has been recently applied) should be respected. Percolates from sludge drying beds contain also pathogens and need to be further treated. Sludge from unplanted beds should be composted before reuse to enhance pathogen removal. Dried sludge from planted drying beds (if there was no fresh application of sludge during the past 1 to 2 years) is generally free from pathogens and can be used directly (STRAUSS et al. 1997).

At a Glance

Drying beds are simple sealed shallow ponds filled with several drainage layers. Sludge is applied on the top and dried by percolation and evaporation. In planted drying beds, the plants maintain the porosity of the soil and enhance the evaporation by transpiration (evaporation). Dried sludge can be used as biosolid in agriculture. Requires large land-surfaces and can cause odour; therefore generally installed in rural areas. Depends strongly on the local climate (rain, runoff); TS content of 20 to 70 % can be achieved. Some of NH4 is lost to air. Pathogen removal is moderate for unplanted beds with short retention time, but high for planted drying beds with long retention times. Moderate investment costs and low operation costs Can be produced with locally available material, but requires expert design. Operation is simple but staff/community should be trained. Application of sludge, desludging, control of drainage system and of the secondary treatment for percolate or dried sludge. Desludging for unplanted beds every one to several weeks and every 5 to 10 years for planted drying beds. High, if the area is kept dry (rain, runoff). Low-tech and no requirement of energy. Requires space; odour can occur; (and frequent desludging in the case of unplanted beds).

Working Principle

Capacity/Adequacy

Performance Costs Self-help Compatibility O&M Reliability Main strength Main weakness

Applicability

Sludge drying beds are a secondary treatment for all kinds of sludge, including faecal sludge from on-site sanitation systems, anaerobic digesters at community or large-scale level. But large surface areas are required and odour is frequent. Therefore, they should be constructed far away from housings. The method is simple but requires professional design and informed manpower for the operation. Drying beds are not adapted for regions with heavy rainfalls and frequent flooding or where the water table is

5 of 7

16/09/2012 7:07

Drying Beds

http://www.sswm.info/print/1302?tid=764

high. In any case, the ponds should be sealed to prevent infiltration of the pathogen containing percolate and a counter bound can prevent run-off to flow in.

Advantages

Dried sludge can be used as fertiliser (either directly in the case of planted beds or after composting in the case of unplanted beds) Easy to operate (no experts, but trained community required) High reduction of sludge volume Can achieve pathogen removal Can be built with locally available materials

Disadvantages

Requires large land area Requires treatment of percolate Only applicable during dry seasons or needs a roof and contour bund Manual labour or specialised equipment is required to remove dried sludge from beds Can cause odour problems

References

EAWAG (Editor); SANDEC (Editor) (2008): Fecal Sludge Management. Presentation. Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC). URL [Accessed: 18.02.2011]. EAWAG/SANDEC (Editor) (2008): Household Water Treatment and Safe Storage (HWTS). Lecture Notes. Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC). URL [Accessed: 08.04.2010]. PDF Lecture notes on the technical and non-technical aspects of sanitation household-level drinking water treatment and safe storage (HWTS) in developing countries. ERIKSEN-HAMEL, N.S.; DANSO, G. (2008): Urban Compost: A Socio-economic and Agronomic Evaluation in Kumasi, Ghana. In: REDWOOD, M. (Editor) (2008): Agriculture in Urban Planning: Generating Livelihoods and Food Security. . URL [Accessed: 23.06.2010]. HEINSS, U.; LARMIE, S.A.; STRAUSS, M. (1998): Solids Separation and Pond Systems for the Treatment of Faecal Sludges in the Tropics . Lessons Learnt and Recommendations for Preliminary Design. . Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC). URL [Accessed: 12.04.2010]. PDF The report sets out to provide guidelines for the preliminary design of faecal sludge treatment schemes comprising solids-liquid separation and stabilisation ponds. The document is based on the results of collaborative field research conducted by the Ghana Water Research Institute and SANDEC on full and pilot-scale faecal sludge (FS) treatment plants located in Accra, Ghana. KONE, D.; KENGE, I. (2008): Technology Transfer Forage Plants Used in Faecal Sludge Dewatering Beds in Sub-Saharan Africa. In: Sandec News 9. PDF In collaboration with the Asian Institute of Technology (AIT), Bangkok, Eawag has previously demonstrated that constructed wetlands, especially in Thailand, offer a viable solution for the treatment of faecal sludge. However, since the characteristics of sludge vary widely from one region to another, appropriate indigenous plants had to be identified so as to ensure successful operation of these facilities. SANIMAS (Editor) (2005): Informed Choice Catalogue. pdf presentation. BORDA and USAID. PDF This informed choice catalogue for community based wastewater treatment technologies helps to identify suitable sanitation options and facilitates the assessment of different sanitation system components with regard to stakeholder preferences. A powerful tool for technical bottom-up planning giving overall information about technical options at a "glance". SASSE, L. ; BORDA (Editor) (1998): DEWATS . Decentralised Wastewater Treatment in Developing Countries. Bremen: Bremen Overseas Research and Development Association (BORDA). PDF Exhaustive report on technological, operational and economic aspects of decentralised waste water treatment systems. Spreadsheet examples support the reader in designing and planning waste water treatment systems components. STRAUSS, M.; LARMIE, S.A.; HEINSS, U. (1997): Treatment of sludges from on-site sanitation Low-cost options. In: Water Science and Technology 6, 129-136. URL [Accessed: 23.06.2010]. PDF Published in 1997, this article gives an overview on current literature-based knowledge regarding faecal sludge treatment along with results and conclusions from field research.

6 of 7

16/09/2012 7:07

Drying Beds

http://www.sswm.info/print/1302?tid=764

STRAUSS, M.; MONTANGERO, A. (2002): FS Management Review of Practices, Problems and Initiatives. London and Duebendorf: DFID Project R8056, Capacity Building for Effective Decentralised Wastewater Management, Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC). URL [Accessed: 24.05.2012]. PDF A study on management and institutional aspects regarding the challenges and possible improvements in managing faecal sludge. MONTANGERO, A.; STRAUSS, M. (2004): Faecal Sludge Treatment. Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC). URL [Accessed: 10.06.2010]. PDF This document reviews current practices of faecal sludge management and treatment. TILLEY, E.; LUETHI, C.; MOREL, A.; ZURBRUEGG, C.; SCHERTENLEIB, R. (2008): Compendium of Sanitation Systems and Technologies. Duebendorf and Geneva: Swiss Federal Institute of Aquatic Science and Technology (EAWAG). URL [Accessed: 15.02.2010]. PDF This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies. HUMBOLDT EDU (Editor) (2008): Arcata's Wastewater Treatment Plant & The Arcata Marsh and Wildlife Sanctuary. Arcata: Environmental Resources Engineering, Humboldt State University. URL [Accessed: 22.05.2012].

For further readings, case studies, awareness raising material, training material, important weblinks or the related powerpoint presentation, see www.sswm.info/category/implementation-tools/wastewatertreatment/hardware/sludge-treatment/drying-beds

7 of 7

16/09/2012 7:07

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Purposive Comm 9-8-22Document26 pagesPurposive Comm 9-8-22Jazzyl ParanNo ratings yet

- Foundations For The Pan Pacific Hotel On Pinnacled and Cavernous Limestone, 1985, 8th SEAGC, MalaysiaDocument16 pagesFoundations For The Pan Pacific Hotel On Pinnacled and Cavernous Limestone, 1985, 8th SEAGC, MalaysiafreezefreezeNo ratings yet

- Marie Louise Von Franz Alchemy PDFDocument35 pagesMarie Louise Von Franz Alchemy PDFLFF57100% (1)

- Final Preboard for Civil Engineering Board ExamDocument7 pagesFinal Preboard for Civil Engineering Board ExamIcz Fuentes100% (1)

- (BS ISO 9403-2000) - Crude Petroleum. Transfer Accountability. Guidelines For Cargo Inspection.Document64 pages(BS ISO 9403-2000) - Crude Petroleum. Transfer Accountability. Guidelines For Cargo Inspection.ELYES CHOUCHENENo ratings yet

- Public Administration ThesisDocument4 pagesPublic Administration Thesisjosephineromeroalbuquerque100% (2)

- Teaching English in Jhs & Shs - Full Units 2019Document130 pagesTeaching English in Jhs & Shs - Full Units 2019jamafosuaNo ratings yet

- 01-Sieve Analysis Coarse and Fine Aggregate.Document7 pages01-Sieve Analysis Coarse and Fine Aggregate.gsv988No ratings yet

- Chapter 6 Operations Planning and ControlDocument36 pagesChapter 6 Operations Planning and Controlsam.geneneNo ratings yet

- Bonaventure ResumeDocument1 pageBonaventure Resumeapi-631877498No ratings yet

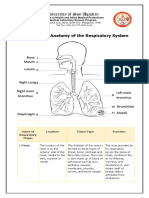

- Anatomy of The Respiratory SystemDocument4 pagesAnatomy of The Respiratory SystemMayden Grace GayatgayNo ratings yet

- Basic Electronics Lab Exp 4-6-pdf Ayush Anshuman Supakar (118MN0579)Document10 pagesBasic Electronics Lab Exp 4-6-pdf Ayush Anshuman Supakar (118MN0579)Ayush Anshuman SupakarNo ratings yet

- Evidence Research PaperDocument6 pagesEvidence Research PaperMichael James Madrid MalinginNo ratings yet

- Shape Functions in Finite Element AnalysisDocument22 pagesShape Functions in Finite Element AnalysissyampnaiduNo ratings yet

- Ps3 Unit 8 Lesson 1 Period 2Document6 pagesPs3 Unit 8 Lesson 1 Period 2Quách Thi NhungNo ratings yet

- EMC Design GuideDocument42 pagesEMC Design GuideDe Raghu Veer KNo ratings yet

- CE 555 Hydraulics Lecture and Tutorial OverviewDocument5 pagesCE 555 Hydraulics Lecture and Tutorial OverviewbakrichodNo ratings yet

- 4 - Linguistic AnalogyDocument20 pages4 - Linguistic AnalogyAniala DequinaNo ratings yet

- The Use of 1% Nano-Fe3O4 and 1% Nano-TiO2 As Partial Replacement of Cement To Enhance The Chemical Performance of Reinforced Concrete StructuresDocument12 pagesThe Use of 1% Nano-Fe3O4 and 1% Nano-TiO2 As Partial Replacement of Cement To Enhance The Chemical Performance of Reinforced Concrete StructuresCamila Marçal GobiNo ratings yet

- Ils or Loc Rwy18: Apt Elev: Rwy18 THR Elev: Trans Level: Trans AltDocument1 pageIls or Loc Rwy18: Apt Elev: Rwy18 THR Elev: Trans Level: Trans AlttommyNo ratings yet

- MEIOSIS and MITOSISDocument4 pagesMEIOSIS and MITOSISHannaj May De GuzmanNo ratings yet

- Integration Procedure of Telecom System WHP andDocument53 pagesIntegration Procedure of Telecom System WHP andselamet riantoNo ratings yet

- An International Railway Project - A Project Management Case StudyDocument9 pagesAn International Railway Project - A Project Management Case StudySourav NathNo ratings yet

- Science 10 12.2 Worksheet 2Document2 pagesScience 10 12.2 Worksheet 2purajian041007No ratings yet

- Driven Too Holder With Coromant Capto 92856Document48 pagesDriven Too Holder With Coromant Capto 92856Prerak PatelNo ratings yet

- Functioning of Dr. Ambedkar Foundation: Ministry of Social Justice & Empowerment Government of IndiaDocument9 pagesFunctioning of Dr. Ambedkar Foundation: Ministry of Social Justice & Empowerment Government of IndiaVikramNo ratings yet

- 3 RdgradereadingcomprehensionpassageandquestionsetDocument7 pages3 Rdgradereadingcomprehensionpassageandquestionsetapi-369806954No ratings yet

- Alternative Health TherapiesDocument415 pagesAlternative Health TherapiesTris TanNo ratings yet

- A Safe Container For FearDocument3 pagesA Safe Container For FearMārs LaranNo ratings yet

- MC Sci 101 - Module 1Document12 pagesMC Sci 101 - Module 1Judith Valenzuela100% (2)