Professional Documents

Culture Documents

HSA Stud Anchor

Uploaded by

Win ThanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSA Stud Anchor

Uploaded by

Win ThanCopyright:

Available Formats

HSA stud anchor

Features: - high loading capacity - force-controlled expansion - long thread - head marking for identification after setting - firestop assessment - pre-assembled with nut and washer time saving - cold formed Material: HSA: HSA-R: HSA-F: - carbon steel, zinc plated to min. 5 m - stainless steel, A4 grade; 1.4401 - carbon steel, hot dipped galvanised to min.35 m (M6-M16) and to min. 45m (M20)

Concrete Small edge distance / spacing Fire resistance Hilti Anchor programme Corrosion resistance

HSA / HSA-R / HSA-F

A4 316

Basic loading data (for a single anchor): HSA

All data on this page applies to concrete: as specified in the table no edge distance and spacing influence correct setting (See setting operations page 96) steel failure For detailed design method, see pages 97 102.

non-cracked concrete

Mean ultimate resistance, Ru,m [kN]: concrete C20/25

Anchor size Tensile, NRu,m Shear, VRu,m M6 M8 M10 Standard anchorage depth 12.5 20.1 20.6 8.4 15.5 22.4 M12 39.7 35.1 M16 62.5 63.3 M20 100.1 84.2 M6 9.2 10.6 M8 M10 M12 M16 Reduced anchorage depth 12.8 18.3 19.8 38.3 16.7 23.4 35.1 62.6 M20 44.4 84.2

Characteristic resistance, Rk [kN]: concrete C20/25

Anchor size Tensile, NRk Shear, VRk M6 M8 M10 Standard anchorage depth 6.0 12.0 16.0 5.5 9.5 16.0 M12 25.0 23.2 M16 38.9 39.3 M20 52.6 61.3 M6 5.0 5.5 M8 M10 M12 M16 Reduced anchorage depth 9.0 12.0 17.9 25.8 9.5 16.0 23.2 39.3 M20 34.7 61.3

Following values according to the

Concrete Capacity Method

Design resistance, Rd [kN]: concrete, fck,cube = 25 N/mm2

Anchor size Tensile, NRd Shear, VRd M6 3.3 4.0 M8 8.0 6.2 M10 10.7 9.9 M12 16.7 14.3 M16 25.9 26.7 M20 35.1 41.7 M6 2.8 4.0 M8 6.0 6.2 M10 8.0 9.9 M12 11.9 14.3 M16 17.2 26.7 M20 23.1 41.7 Standard anchorage depth Reduced anchorage depth

Recommended load, Lrec [kN]: concrete, fck,cube = 25 N/mm2

Anchor size Tensile, NRec Shear, VRec M6 M8 M10 Standard anchorage depth 2.4 5.7 7.6 2.9 4.4 7.1 M12 11.9 10.2 M16 18.5 19.1 M20 25.1 29.8 M6 2.0 2.9 M8 M10 M12 M16 Reduced anchorage depth 4.3 5.7 8.5 12.3 4.4 7.1 10.2 19.1 M20 16.5 29.8

Isssue 2005a

92

HSA stud anchor

Basic loading data (for a single anchor): HSA-R

All data on this section applies to concrete: as specified in the table no edge distance and spacing influence correct setting (See setting operations page 96) steel failure For detailed design method, see pages 97 - 102.

non-cracked concrete

Mean ultimate resistance, Ru,m [kN]: concrete C20/25

Anchor size Tensile, NRu,m Shear, VRu,m M6 M8 M10 Standard anchorage depth 11.2 17.2 20.1 8.7 20.0 24.0 M12 33.6 35.4 M16 52.3 62.2 M20 69.0 97.0 M6 9.2 9.5 M8 M10 M12 M16 Reduced anchorage depth 12.8 18.3 19.8 30.0 14.3 24.6 27.5 62.2 M20 43.0 97.0

Characteristic resistance, Rk [kN]: concrete C20/25

Anchor size Tensile, NRk Shear, VRk M6 M8 M10 Standard anchorage depth 6.0 12.0 12.0 6.0 11.0 17.0 M12 25.0 25.0 M16 38.7 51.8 M20 44.1 80.9 M6 7.1 6.0 M8 M10 M12 M16 Reduced anchorage depth 7.5 12.0 21.4 23.0 11.0 17.0 25.0 51.8 M20 33.0 80.9

Following values according to the

Concrete Capacity Method

Design resistance, Rd [kN]: concrete, fck,cube = 25 N/mm2

Anchor size Tensile, NRd Shear, VRd M6 M8 M10 Standard anchorage depth 3.3 6.7 6.7 4.0 7.3 11.3 M12 11.9 16.7 M16 21.5 31.4 M20 24.5 49.0 M6 1.9 4.0 M8 M10 M12 M16 Reduced anchorage depth 4.2 5.7 11.9 12.8 7.3 11.3 16.7 31.4 M20 18.5 49.0

Recommended load, Lrec [kN]: concrete fck,cube = 25 N/mm2

Anchor size Tensile, Nrec Shear, Vrec M6 M8 M10 Standard anchorage depth 2.4 4.8 4.8 2.9 5.2 8.1 M12 8.5 11.9 M16 15.4 22.4 M20 17.5 35.0 M6 1.4 2.8 M8 M10 M12 M16 Reduced anchorage depth 3.0 4.1 8.5 9.1 5.2 8.1 11.9 22.4 M20 13.2 35.0

93

Issue 2005a

HSA stud anchor

Basic loading data (for a single anchor): HSA-F

All data on this page applies to concrete: as specified in the table no edge distance and spacing influence correct setting (See setting operations page 96) steel failure For detailed design method, see pages 97 - 102.

non-cracked concrete

Mean ultimate resistance, Ru,m [kN]: concrete C20/25

Anchor size Tensile, NRu,m Shear, VRu,m M6 M8 M10 Standard anchorage depth 11.1 18.3 25.3 8.4 15.5 22.4 M12 38.3 35.1 M16 45.6 63.3 M20 64.4 84.2 M6 10.4 10.6 M8 M10 M12 M16 Reduced anchorage depth 14.2 20.8 26.8 39.8 16.7 23.4 35.1 62.6 M20 54.1 84.2

Characteristic resistance, Rk [kN]: concrete C20/25

Anchor size Tensile, NRk Shear, VRk M6 M8 M10 Standard anchorage depth 6.0 12.0 16.0 5.5 9.5 16.0 M12 25.0 23.2 M16 38.9 39.3 M20 52.6 61.3 M6 5.0 5.5 M8 M10 M12 M16 Reduced anchorage depth 9.0 12.0 17.9 25.8 9.5 16.0 23.2 39.3 M20 34.7 61.3

Following values according to the

Concrete Capacity Method

Design resistance, Rd [kN]: concrete, fck,cube = 25 N/mm2

Anchor size Tensile, NRd Shear, VRd M6 3.3 4.0 M8 8.0 6.2 M10 10.7 9.9 M12 16.7 14.3 M16 25.9 26.7 M20 35.1 41.7 M6 2.8 4.0 M8 6.0 6.2 M10 8.0 9.9 M12 11.9 14.3 M16 17.2 26.7 M20 23.1 41.7 Standard anchorage depth Reduced anchorage depth

Recommended load, Lrec [kN]: concrete, fck,cube = 25 N/mm2

Anchor size Tensile, NRec Shear, VRec M6 M8 M10 Standard anchorage depth 2.4 5.7 7.6 2.9 4.4 7.1 M12 11.9 10.2 M16 18.5 19.1 M20 25.1 29.8 M6 2.0 2.9 M8 M10 M12 M16 Reduced anchorage depth 4.3 5.7 8.5 12.3 4.4 7.1 10.2 19.1 M20 16.5 29.8

Isssue 2005a

94

HSA stud anchor

Setting details HSA standard anchorage depth HSA reduced anchorage depth

first mark: blue ring

second mark: thread end

Marking

df

Tinst

d0

Head marking

hmin

h ef h1

t fix

M10x108

M10x120 OK OK 120 G 72 70 50 59 50 57

Setting Details HSA-R available: HSA-F available: do [mm] Nominal dia. of drill bit I [mm] Anchor length Head Marking (letter code) IG [mm] Thread length Tinst [Nm] Torque moment* SW [mm] Width across nut flats df [mm] Clearance hole diameter h1 hef hnom tfix hmin h1 hef hnom tfix hmin [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] min. depth of drill hole effective embed. depth min. embedment depth max. fastenable thickness min. concrete thickness min. depth of drill hole effective embed. depth min. embedment depth max. fastenable thickness min. concrete thickness standard embedment

OK OK 50 A 15

OK OK 6 65 C 30 5 10 7

OK

OK OK 100 E 65 57 B 20

OK OK 75 C 35

85 D 50

OK OK 8 92 E 52 15 13 9

OK OK 115 G 75 137 H 97

OK OK 68 C 25

OK OK 90 E 42

OK 10 108 F 60 30 17 12

140 I 92

10 45 30 37

55 40 47 30 100

45

10

65 48 55 27 50 100 50 35 42 40 100 TE-CX-8

72

20

37 100 60 42 51 45 100 TE-CX-10

70

reduced embedment

20 100

40

55

23

63

85

25

77

Required drill bit

TE-CX-6

95

Issue 2005a

M10x140

M6x100

M8x115

M8x137

M10x68

M10x90

M6x50

M6x65

M6x85

M8x57

M8x75

M8x92

Anchor size

HSA stud anchor

M12x100 M12x120 M12x150 M12x180 M12x220 M12x240 M12x300 M16x100 M16x120 M16x140 M16x190 M16x240 M20x125 OK 20 240 P 170 125 G 45 30 22 130 103 115 30 210 200 170 K 85 L 120 1) 500 186.3 520 541 291.6 M20x170 OK OK M12x80 OK OK 80 D 30 Anchor size

Setting Details HSA-R available: HSA-F available: do I IG Tinst SW df h1 hef hnom tfix hmin h1 hef hnom tfix hmin standard embedment [mm] Nominal dia. of drill bit [mm] Anchor length [mm] Thread length [Nm] Tightening torque* [mm] Width across nut flats [mm] Clearance hole diameter [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] min. depth of drill hole effective embed. depth min. embedment depth max. fastenable thickness min. concrete thickness min. depth of drill hole effective embed. depth min. embedment depth max. fastenable thickness min. concrete thickness

OK OK

OK OK OK 12 180 220 L 50 19 14 O 125 165 OK 240 300 P S

OK OK

OK OK 16

OK OK

100 120 150 E 45 G 65 I 95

100 120 140 190 E G 50 I 70 100 24 18 115 84 95 25 75 170 90 64 75 45 130

Head Marking (letter code)

180 180 35

25

55

95 70 80 85 125 140

145 205

125

25

45

70 50 60 75 105 145 100 TE-CX-12

165 225

25

95

145

105 78 90 10 55 160 TEC-S 20 TE-Y 20

reduced embedment

Required drill bit

1)

TE-C-16 or TE-Y-16

* please note that the torque moment is the same for standard and reduced embedment thread length of HSA-R: 80 mm

Installation equipment

Rotary hammer (TE1, TE 2, TE5, TE6, TE6A, TE15, TE15-C, TE18-M, TE 35, TE 55, TE 76), drill bit, blow-out pump, torque wrench and hexagon drive socket appropriately sized for correct setting.

Setting operations

Drill hole with drill bit.

Blow out dust and fragments.

Install anchor.

Apply tightening torque.

Mechanical properties of the anchor bolt

Anchor size As fuk As,i fuk Wel [mm ]

2 2

HSA Stressed cross-section in thread Stressed cross-section in taper transition

2

M6 20.1 550 13.5 700 12.7 7.6

M8 36.6 520 25.5 650 31.2 18.7

M10 58.0 550 44.2 650 62.3 37.4

M12 84.3 550 62.2 650 109 71.9

M16 157.0 500 114.0 580 277 182.8

M20 245.0

[N/ mm ] Nominal tensile strength in thread [mm ] [mm ]

3 2

[N/ mm ] Nominal tensile strength of taper transition Elastic moment of resistance Design bending moment

1)

MRd,s [Nm]

Isssue 2005a

96

HSA stud anchor

Anchor size As fuk As,i fuk Wel [mm ]

2 2

HSA-R Stressed cross-section in thread Stressed cross-section in taper transition

2

M6 20.1 800 13.5 800 12.7 9.1

M8 36.6 700 25.5 800 31.2 18.7 M8 36.6 520 25.5 650 31.2 18.7

M10 58.0 700 44.2 800 62.3 37.4 M10 58.0 550 44.2 650 62.3 37.4

M12 84.3 700 62.2 800 109 65.4 M12 84.3 550 62.2 650 109 71.9

M16 157.0 650 114.0 800 277.0 166.2 M16 157.0 500 114.0 580 277 182.8

M20 245.0 700 186.3 600 540.0 324.0 M20 245.0 500 186.3 520 541 292.1

[N/ mm ] Nominal tensile strength of thread [mm ] [mm ]

3 2

[N/ mm ] Nominal tensile strength of taper transition Elastic moment of resistance Design bending moment

1)

MRd,s [Nm] Anchor size As fuk As,i fuk Wel [mm ]

2 2

HSA-F Stressed cross-section in thread Stressed cross-section in taper transition

2

M6 20.1 550 13.5 750 12.7 7.6

[N/ mm ] Nominal tensile strength of thread [mm ] [mm ]

3 2

[N/ mm ] Nominal tensile strength of taper transition Elastic moment of resistance Design bending moment

1)

MRd,s [Nm]

1)

The design bending moment is calculated from MRd,s = 1.2Welfuk/Ms where the partial safety factor Ms varies with anchor types and sizes.

Detailed design method - Hilti CC

(The Hilti CC method is a simplified version of ETAG Annex C.)

N rec,p/c/s

c

TENSION

The tensile design resistance of a single anchor is the lower of NRd,p : concrete pull-out resistance NRd,c : concrete cone resistance NRd,s : steel resistance NRd,p : Pull-out resistance

o NRd,p = NRd, p,sta./red. fBN

N0Rd,p,sta./red.: Design pull-out resistance

N N

Concrete compressive strength, fck,cube(150) = 25 N/mm2

HSA Standard anchorage depth Reduced anchorage depth HSA-R Standard anchorage depth Reduced anchorage depth HSA-F Standard anchorage depth Reduced anchorage depth M6 3.3 2.8* M6 3.3 1.9 M6 3.3 2.8* M8 8.0 6.0* M8 6.7 4.2* M8 8.0 6.0*

o

h

M10 10.7 8.0 M10 6.7 5.7 M10 10.7 8.0

o Rd,p

Anchor size

0 Rd,p,sta. 0 Rd,p,red.

M12 16.7 -** M12 11.9 -** M12 16.7 -**

o Rk,p

M16 -** -** M16 21.5 12.8 M16 -** -**

M20 -** -** M20 24.5 18.5 M20 -** -**

[kN] [kN]

Anchor size N N

0 Rd,p,sta. 0 Rd,p,red.

[kN] [kN]

Anchor size N N

0 Rd,p,sta. 0 Rd,p,red.

[kN] [kN]

The tensile design resistance is calculated from the tensile characteristic resistance N Rk,p by N varies Mp varies with anchor type and size (as per relevant approval). *Use is restricted to anchoring of structural components which are statically indeterminate. ** Pull-out is not decisive for the design.

=N

/Mp where the partial safety factor

97

Issue 2005a

HSA stud anchor

NRd,c : Concrete cone resistance

o NRd,c = NRd ,c,sta. / red. f T fBN f AN,sta. / red. fRN,sta. / red.

N0Rd,c,sta./red.: Design concrete cone resistance

N N

concrete compressive strength, fck,cube(150) = 25 N/mm2

HSA M6 M8 M10 M12 M16 M20

0 Rd,c,sta. 0 Rd,c,red.

Anchor size

[kN] [kN]

Standard anchorage depth Reduced anchorage depth

7.1 4.6*

11.2 7.0*

11.9 9.1

19.7 11.9

25.9 17.2

35.1 23.1

Anchor size

HSA-R

M6

M8

M10

M12

M16

M20

N N

0 Rd,c,sta. 0 Rd,c,red.

[kN] [kN]

Standard anchorage depth Reduced anchorage depth

7.1 3.9

9.3 7.0*

9.9 9.1

14.1 11.9

25.9 17.2

35.1 23.1

Anchor size

HSA-F

M6

M8

M10

M12

M16

M20

0 Rd,c,sta.

[kN]

Standard anchorage depth

7.1

11.2

11.9

19.7

25.9

35.1

0 4.6* 7.0* 9.1 11.9 17.2 23.1 N Rd,c,red. [kN] Reduced anchorage depth o o o The tensile design resistance is calculated from the tensile characteristic resistance N Rk,c by N Rd,c= N Rk,c/Mc,N where the partial safety factor varies Mc,N varies with anchor type and size (as per relevant approval). *Use is restricted to anchoring of structural components which are statically indeterminate.

fT : Influence of anchorage depth

h f T = act. h ef,red.

1 .5

Limits: hef,red. hact. hef,sta.

for HSA and HSA-F

fBN : Influence of concrete strength

Concrete strength designation (ENV 206) C20/25 C30/37 C40/50 C50/60 Cylinder compressive strength, fck,cyl [N/mm] 20 30 40 50

Cube compressive strength, fck,cube [N/mm] 25 37 50 60

fB

1 1.17 1.32 1.42

fBN

fc,cube = 25

0.4

Limits: 25N/mm2 fck,cube60N/mm2 for HSA-R fBN=1

fAN,sta. : Influence of anchor spacing on standard anchorage depth

Anchor spacing, s [mm] 40 50 55 75 90 105 120 130 144 150 180 210 230 252 280 300 309

M6 0.67 0.71 0.73 0.81 0.88 0.94 1.00 M8 HSA, HSA-R, HSA-F M10 M12 M16 M20

0.67 0.69 0.76 0.81 0.86 0.92 0.95 1.00

0.68 0.75 0.80 0.85 0.90 0.93 0.98 1.00

0.67 0.71 0.75 0.79 0.81 0.84 0.86 0.93 1.00

0.68 0.71 0.74 0.76 0.79 0.80 0.86 0.92 0.96 1.00

0.67 0.69 0.71 0.73 0.74 0.79 0.84 0.87 0.91 0.95 0.99 1.00

f AN,sta. = 0.5 +

Limits: s min s s cr,N

s 6 h ef ,sta.

s cr,N = 3 h ef,sta.

Isssue 2005a

98

HSA stud anchor

fAN,red. : Influence of anchor spacing on reduced anchorage depth

Anchor spacing, s [mm] 35 55 75 90 100 105 120 126 140 150 180 192 200 210 230 234

M6 0.68 0.78 0.89 0.96 1.00 M8 0.67 0.76 0.86 0.93 0.98 1.00 HSA, HSA-R, HSA-F M10 M12 M16 M20

0.72 0.80 0.86 0.90 0.92 0.98 1.00

0.83 0.85 0.90 0.92 0.97 1.00

0.76 0.77 0.81 0.83 0.86 0.89 0.97 1.00

0.71 0.72 0.76 0.77 0.80 0.82 0.88 0.91 0.93 0.95 0.99 1.00

fAN,red. = 0.5 +

Limits: s min s s cr,N

s 6 hef red.

s cr,N = 3 h ef,sta

fRN,sta.: Influence of edge distance on standard anchorage depth

Edge distance, c [mm] 50 60 65 72 75 90 105 120 125 144 150 154

M6 0.87 1.00 M8 HSA, HSA-R, HSA-F M10 M12 M16 M20

0.87 0.92 1.00

fRN,sta. = 0.22 + 0.52

c h ef ,sta.

0.90 0.97 1.00 0.89 1.00 0.87 0.96 0.99

Limits: c min c c cr,N

c cr,N = 1.5 h ef ,sta.

0.85 0.93 0.98 1.00 Note: If more than 3 edges are smaller than ccr, consult the Hilti technical advisory service.

fRN,red. : Influence of edge distance on reduced anchorage depth

fR,N=1.0

Anchor size HSA, HSA-F M6 40 M8 50 M10 55 M12 75 M16 90 M20 105

Standard effective anchorage depth, hef,sta. Reduced effective anchorage depth, hef,red.

Anchor size

smin [mm] cmin [mm] smin [mm] cmin [mm]

Min. spacing Min. edge distance Min. spacing Min. edge distance

HSA-R

50 35 38

M6 40

60 35 45

M8 50

65 55 65

M10 65

90 100 100

M12 75

105 100 100

M16 90

125 100 115

M20 105

Standard effective anchorage depth, hef,sta. Reduced effective anchorage depth, hef,red.

smin [mm] cmin [mm] smin [mm] cmin [mm]

Min. spacing Min. edge distance Min. spacing Min. edge distance

50 35 38

60 35 45

75 55 65

90 100 100

105 100 100

125 100 115

99

Issue 2005a

HSA stud anchor

NRd,s : Steel design tensile resistance

Anchor size M6 M8 M10 M12 M16 M20

NRd,s NRd,s NRd,s

[kN] [kN] [kN]

HSA HSA-R HSA-F

5.6 6.9 5.6

9.6 12.5 9.6

17.6 21.9 17.6

24.8 30.6 24.8

43.8 43.8 43.8

71.6 62.8 71.6

The design tensile resistance is calculated from the characteristic tensile resistance, NRk,s , using NRd,s= NRk,s /Ms, where the partial safety factor varies Ms varies with anchor type and size (as per relevant approval).

NRd : System design tensile resistance NRd = lower of NRd,p , NRd,c and NRd,s

Combined loading: Only if tensile load and shear load applied (See page 31 and section 4 Examples).

Detailed design method Hilti CC

(The Hilti CC method is a simplified version of ETAG Annex C.)

c2 > 1 .5 c

V rec,c/s

s

c2 > 1.5 c

SHEAR

The design shear resistance of a single anchor is the lower of VRd,c : concrete edge resistance VRd,s : steel resistance

VRd,c : Concrete edge design resistance

h>

1 .5

Note:

If the conditions for h and c2 are not met, consult your Hilti technical advisory service.

The lowest concrete edge resistance must be calculated. All near edges must be checked, (not only the edge in the direction of shear). The direction of shear is accounted for by the factor f,V.

o VRd,c = VRd ,c,sta. / red. f B f ,V f AR,V

V0Rd,c,sta./red. : Concrete edge design resistance

Concrete compressive strength, fck,cube(150) = 25 N/mm2 at minimum edge distance c min

HSA M6 M8 M10 M12 M16 M20

Anchor size

Rd,c,sta.

[kN]

Standard anchorage depth Reduced anchorage depth

2.6 2.2*

3.8 2.4*

4.8 4.6

8.8 9.6

12.5 11.0

18.2 15.1

V0Rd,c,red. [kN]

Issue 2005a

100

HSA stud anchor

Anchor size HSA-R M6 M8 M10 M12 M16 M20

Rd,c,sta.

[kN]

Standard anchorage depth Reduced anchorage depth

HSA-F

2.6 2.2

M6

3.8 2.4*

M8

5.9 4.6

M10

8.8 9.6

M12

12.5 11.0

M16

18.2 15.1

M20

V0Rd,c,red. [kN]

Anchor size

Rd,c,sta.

[kN]

Standard anchorage depth Reduced anchorage depth

2.6 2.2*

o

3.8 2.4*

o Rd,c

4.8 4.6 =V

o Rk,c

8.8 9.6

12.5 11.0

18.2 15.1

V0Rd,c,red. [kN]

The shear design resistance is calculated from the shear characteristic resistance V Rk,c by V safety factor Mc,V is equal to 1.5. *Use is restricted to anchoring of structural components which are statically indeterminate.

/Mc,V, where the partial

fB: Influence of concrete strength

Concrete strength designation (ENV 206) C20/25 C25/30 C30/37 C35/45 C40/50 C45/55 C50/60 Cylinder compressive strength, fck,cyl [N/mm] 20 25 30 35 40 45 50

Cube compressive strength, fck,cube [N/mm] 25 30 37 45 50 55 60

fB

1 1.1 1.22 1.34 1.41 1.48 1.55

fB =

fck,cube 25

Limits: 25 N/mm2 fck,cube(150) 60 N/mm2

Concrete cylinder: height 30cm, 15cm diameter

Concrete cube: side length 15cm

Concrete test specimen geometry

f,V : Influence of shear loading direction

Angle, [] 0 to 55 60 70 80 90 to 180

f,V

1 1.1 1.2 1.5 2

Formulae:

f,V = 1

f,V = 1 cos + 0.5 sin

V ... applied shear force

for 0 55 for 55 < 90 for 90 < 180

f,V = 2

fAR,V : Influence of edge distance and spacing

Formula for single-anchor fastening influenced only by edge

f AR,V =

c c min

c c min

results tabulated below

c 2,1 s n-1 s3 s2

Formula for two-anchor fastening valid for s < 3c

s1

f AR,V

3c + s = 6c min

c c min

Note:

c 2 ,2

c h >1,5 c

General formula for n-anchor fastening (edge plus n-1 spacing) only valid where s1 to sn-1 are all < 3c and c2 > 1.5c.

f AR ,V =

3c + s1 + s 2 + ... + s n 1 c 3nc min c min

It is assumed that only the row of anchors closest to the free concrete edge carries the centric shear load.

101

Issue 2005a

HSA stud anchor

fAR.V

Single anchor with edge influence, 1.0 s/cmin 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0 10.5 11.0 11.5 12.0

c/cmin 1.0 1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

3.2

3.4

3.6

3.8

4.0

1.00 1.31 1.66 2.02 2.41 2.83 3.26 3.72 4.19 4.69 5.20 5.72 6.27 6.83 7.41 8.00 0.67 0.75 0.83 0.92 1.00 0.84 0.93 1.02 1.11 1.20 1.30 1.03 1.12 1.22 1.32 1.42 1.52 1.62 1.22 1.33 1.43 1.54 1.64 1.75 1.86 1.96 1.43 1.54 1.65 1.77 1.88 1.99 2.10 2.21 2.33 1.65 1.77 1.89 2.00 2.12 2.24 2.36 2.47 2.59 2.71 2.83 1.88 2.00 2.13 2.25 2.37 2.50 2.62 2.74 2.87 2.99 3.11 3.24 2.12 2.25 2.38 2.50 2.63 2.76 2.89 3.02 3.15 3.28 3.41 3.54 3.67 2.36 2.50 2.63 2.77 2.90 3.04 3.17 3.31 3.44 3.57 3.71 3.84 3.98 4.11 2.62 2.76 2.90 3.04 3.18 3.32 3.46 3.60 3.74 3.88 4.02 4.16 4.29 4.43 4.57 2.89 3.03 3.18 3.32 3.46 3.61 3.75 3.90 4.04 4.19 4.33 4.47 4.62 4.76 4.91 5.05 5.20 3.16 3.31 3.46 3.61 3.76 3.91 4.05 4.20 4.35 4.50 4.65 4.80 4.95 5.10 5.25 5.40 5.55 5.69 3.44 3.60 3.75 3.90 4.06 4.21 4.36 4.52 4.67 4.82 4.98 5.13 5.29 5.44 5.59 5.75 5.90 6.05 6.21 3.73 3.89 4.05 4.21 4.36 4.52 4.68 4.84 5.00 5.15 5.31 5.47 5.63 5.79 5.95 6.10 6.26 6.42 6.58 6.74 4.03 4.19 4.35 4.52 4.68 4.84 5.00 5.17 5.33 5.49 5.65 5.82 5.98 6.14 6.30 6.47 6.63 6.79 6.95 7.12 7.28 4.33 4.50 4.67 4.83 5.00 5.17 5.33 5.50 5.67 5.83 6.00 6.17 6.33 6.50 6.67 6.83 7.00 7.17 7.33 7.50 7.67 7.83 8.00

These results are for a two-. Anchor fastening. For fastening made with more than 2 anchors, use the general formulae for n anchors the page before.

VRd,s : Steel design shear resistance

Anchor size M6 M8 M10 M12 M16 M20

VRd,s Anchor size VRd,s Anchor size VRd,s

[KN]

HSA

4.0

M6

6.2

M8

9.9

M10

14.3

M12

26.7

M16

41.7

M20

[KN]

HSA-R

4.0

7.3

11.3

16.7

31.4

49.0

M6

M8

M10

M12

M16

M20

[KN]

HSA-F

4.0

6.2

9.9

14.3

26.7

41.7

The design shear resistance is calculated from the characteristic shear resistance, VRk,s , using VRd,s= VRk,s /Ms, where the partial safety factor varies Ms varies with anchor type and size (as per relevant approval).

VRd : System design shear resistance VRd = lower of VRd,c,sta./red. and VRd,s

Combined loading: Only if tensile load and shear load applied (See page 31 and section 4 Examples).

102

You might also like

- Jeppesen CHAPTER 4 Aircraft Welding PDFDocument30 pagesJeppesen CHAPTER 4 Aircraft Welding PDFDavid SchkolnikNo ratings yet

- HILTI ExBar Rebar Design Soft WareDocument30 pagesHILTI ExBar Rebar Design Soft WareAline Tabet Abi SaadNo ratings yet

- Synthetic FibersDocument4 pagesSynthetic FibersKhaled Aldossari100% (1)

- Simple Connections ETOOLKITDocument27 pagesSimple Connections ETOOLKITLesego MatojaneNo ratings yet

- Notes On Hy-RibDocument20 pagesNotes On Hy-RibMohd Faizal100% (1)

- LCP Multideck® 90Document6 pagesLCP Multideck® 90GarfieldNo ratings yet

- Totten CatalogDocument19 pagesTotten CatalogxpertsteelNo ratings yet

- Design of Reinforced Concrete BeamsDocument38 pagesDesign of Reinforced Concrete BeamsZul AshraffNo ratings yet

- Chapter 22 - Formwork SystemDocument62 pagesChapter 22 - Formwork SystemshingkeongNo ratings yet

- C Purlin Technical Data SheetDocument6 pagesC Purlin Technical Data SheetAkhil VNNo ratings yet

- Design of Steel Structures BS 5950: Eng. Chamara Yapa Arachchi Civil EngineerDocument60 pagesDesign of Steel Structures BS 5950: Eng. Chamara Yapa Arachchi Civil Engineerpareen9No ratings yet

- SECTION 03490 Glass Fiber Reinforced Concrete (GFRC)Document17 pagesSECTION 03490 Glass Fiber Reinforced Concrete (GFRC)SunilNo ratings yet

- Group 7 - Block B (Up To 28 Floors) Building & Structural ElementDocument3 pagesGroup 7 - Block B (Up To 28 Floors) Building & Structural ElementChung ChanNo ratings yet

- Corporate Circular: Bridge Technical Direction Btd2013/01Document2 pagesCorporate Circular: Bridge Technical Direction Btd2013/01scribdarell100% (1)

- Comflor Floordecking PDFDocument39 pagesComflor Floordecking PDFing urbanNo ratings yet

- Axial Load Column CapacityDocument3 pagesAxial Load Column Capacityaditya2053100% (1)

- Limit state deflection and cracking in reinforced concrete structuresDocument17 pagesLimit state deflection and cracking in reinforced concrete structuresRadhikaNo ratings yet

- Checking Punching Shear Strength with Finite Element ModelsDocument1 pageChecking Punching Shear Strength with Finite Element ModelsDaniyal AhmadNo ratings yet

- 40 Ton Crane Tender DocumentDocument12 pages40 Ton Crane Tender DocumentJaay VelNo ratings yet

- Composite Bondek Specification PDFDocument9 pagesComposite Bondek Specification PDFGan Chin PhangNo ratings yet

- CCL PT Slabs Brochure Eng PDFDocument15 pagesCCL PT Slabs Brochure Eng PDFSharad BornarkarNo ratings yet

- RCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementDocument5 pagesRCC Beam With Different Choice of Design WSD For Singly & Doubly ReinforcementdsanandaNo ratings yet

- One Liberty Place - MSC PDFDocument40 pagesOne Liberty Place - MSC PDFpaninzynier100% (1)

- Chapter 3 FormworkDocument11 pagesChapter 3 FormworkSue IlaNo ratings yet

- ECCS Releases Fatigue Design ManualDocument2 pagesECCS Releases Fatigue Design ManualKoh Wei SangNo ratings yet

- Bolt Grip Length PDFDocument1 pageBolt Grip Length PDFmatthewwalls4386100% (2)

- Introduction To The Economics of Structural SteelworkDocument156 pagesIntroduction To The Economics of Structural SteelworkCharles AjayiNo ratings yet

- Hollow Core Tech DataDocument1 pageHollow Core Tech Datacr231181100% (1)

- Purlin DESIGNDocument10 pagesPurlin DESIGNMohamed NkNo ratings yet

- LECTURE 2 RCC StairsDocument40 pagesLECTURE 2 RCC StairsArsh Chaudhary100% (1)

- ASCE 7-95 Seismic CoefficientDocument1 pageASCE 7-95 Seismic Coefficientrina2369No ratings yet

- Table 15 Universal Beams - Dimensions and PropertiesDocument2 pagesTable 15 Universal Beams - Dimensions and PropertiesjdfdfererNo ratings yet

- Beam & Col FormulaeDocument9 pagesBeam & Col FormulaeAnonymous ciKyr0t100% (1)

- 05450-Pre Engineered Metal TrussesDocument4 pages05450-Pre Engineered Metal TrussesRamsey RasmeyNo ratings yet

- Scaffold Basic PartsDocument57 pagesScaffold Basic PartsSn Carbonel100% (1)

- Bab IV - Perhitungan Floor Deck (Ok)Document6 pagesBab IV - Perhitungan Floor Deck (Ok)Aditia Maulana ANo ratings yet

- Fixed Ladders. - 1910.27Document4 pagesFixed Ladders. - 1910.27Joe JacquatNo ratings yet

- Steel Chain-Link Fencing Materials Used in Detention and Correctional FacilitiesDocument2 pagesSteel Chain-Link Fencing Materials Used in Detention and Correctional FacilitiesMarcos Verissimo Juca de PaulaNo ratings yet

- Mcnichols Master CatalogDocument56 pagesMcnichols Master CatalogULISES MONTANONo ratings yet

- Hilti Manual For Bolt 1Document63 pagesHilti Manual For Bolt 1csengineer2No ratings yet

- Concretec Catalog Sample PDFDocument24 pagesConcretec Catalog Sample PDFseagull70No ratings yet

- ACI Punching ShearDocument9 pagesACI Punching ShearlonelyboyvnNo ratings yet

- MasterPort Portal Frame DesignDocument21 pagesMasterPort Portal Frame DesigncolbmNo ratings yet

- BookDocument620 pagesBookpiv0ter_betterNo ratings yet

- Parallel Flange Channels (ALL Sections) : DiagramDocument1 pageParallel Flange Channels (ALL Sections) : Diagramalvin_tanNo ratings yet

- Safe Load TablesDocument12 pagesSafe Load TablesdeviationzNo ratings yet

- Design of Steel BeamDocument19 pagesDesign of Steel BeamAnonymous tBhJoH5wgMNo ratings yet

- STEPOC 150dpiDocument6 pagesSTEPOC 150dpinick8081No ratings yet

- Column With Biaxial MomentDocument26 pagesColumn With Biaxial MomentRajanvmNo ratings yet

- Reinforcing bar sizes, grades, and standards in the United StatesDocument11 pagesReinforcing bar sizes, grades, and standards in the United StatesEvert AntoniazziNo ratings yet

- Foundation Example 9.7Document14 pagesFoundation Example 9.7Deana WhiteNo ratings yet

- Composite Beam IIDocument27 pagesComposite Beam IIStefan-Raluca AsavoaeNo ratings yet

- Bar Bending Schedule (Service BLDG)Document20 pagesBar Bending Schedule (Service BLDG)Rania SaiedNo ratings yet

- Everdure Waterstop - Page1Document1 pageEverdure Waterstop - Page1Jefferd AlicanNo ratings yet

- SWD-CSA-A23.3-04 Shear Wall Design ManualDocument82 pagesSWD-CSA-A23.3-04 Shear Wall Design ManualYohan LimNo ratings yet

- Concrete&baseplate PDFDocument18 pagesConcrete&baseplate PDFmitimas2003No ratings yet

- Concrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignFrom EverandConcrete-Filled Double-Skin Steel Tubular Columns: Behavior and DesignNo ratings yet

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesFrom EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeNo ratings yet

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Document1 pageBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNo ratings yet

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Document1 pageBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNo ratings yet

- First Floor PlanDocument1 pageFirst Floor PlanWin ThanNo ratings yet

- Design of Purlin CalculationDocument1 pageDesign of Purlin CalculationWin ThanNo ratings yet

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Document1 pageBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNo ratings yet

- Septic Tank Design Computation PDFDocument4 pagesSeptic Tank Design Computation PDFWin ThanNo ratings yet

- Design Information: 1. Type of Structure 3. Reference CodesDocument8 pagesDesign Information: 1. Type of Structure 3. Reference CodesWin ThanNo ratings yet

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Document1 pageBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNo ratings yet

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Document1 pageBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNo ratings yet

- TTDL PDFDocument1 pageTTDL PDFWin ThanNo ratings yet

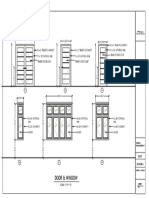

- Archi DWG - 2 ST Residential Buld - Hlaing TWP A-Xxx PL (A4)Document1 pageArchi DWG - 2 ST Residential Buld - Hlaing TWP A-Xxx PL (A4)Win ThanNo ratings yet

- 2ND To 12TH Floor Plan PDFDocument1 page2ND To 12TH Floor Plan PDFWin ThanNo ratings yet

- 09 ParkingDocument47 pages09 ParkingHarun SabljakovićNo ratings yet

- ST 21Document9 pagesST 21amarnath_jbbNo ratings yet

- RC Stair Design (EN1992)Document7 pagesRC Stair Design (EN1992)Win ThanNo ratings yet

- Glass Canopy 3D PDFDocument1 pageGlass Canopy 3D PDFWin ThanNo ratings yet

- Bolt Nut Connection DesignDocument12 pagesBolt Nut Connection DesignWin ThanNo ratings yet

- Mdy Glass CanopyDocument10 pagesMdy Glass CanopyWin ThanNo ratings yet

- L90X90X10 PropertyDocument1 pageL90X90X10 PropertyWin ThanNo ratings yet

- 19 PDFDocument1 page19 PDFWin ThanNo ratings yet

- NPT Residence Naypyitaw, Myanmar: Date 2019-08-5Document1 pageNPT Residence Naypyitaw, Myanmar: Date 2019-08-5Win ThanNo ratings yet

- NPT Residence Naypyitaw, Myanmar: Date 2019-08-5Document1 pageNPT Residence Naypyitaw, Myanmar: Date 2019-08-5Win ThanNo ratings yet

- ETABS 2016 16.2.0 3D View SoftwareDocument1 pageETABS 2016 16.2.0 3D View SoftwareWin ThanNo ratings yet

- 10 PDFDocument1 page10 PDFWin ThanNo ratings yet

- Gfl-1fl Plan UpdatedDocument1 pageGfl-1fl Plan UpdatedWin ThanNo ratings yet

- Owner's Roof Framing PlanDocument3 pagesOwner's Roof Framing PlanWin ThanNo ratings yet

- 18 PDFDocument1 page18 PDFWin ThanNo ratings yet

- Strap Footing Design: ASDIP Foundation 2.6.1Document4 pagesStrap Footing Design: ASDIP Foundation 2.6.1Win ThanNo ratings yet

- Calcs for Combined FootingDocument6 pagesCalcs for Combined FootingWin ThanNo ratings yet

- Drawing1 Layout1Document1 pageDrawing1 Layout1Win ThanNo ratings yet

- CH 13Document30 pagesCH 13Laurertan TavaresNo ratings yet

- Tube To Tubesheet Weld Joint Design & Welding Qualifications MicroDocument21 pagesTube To Tubesheet Weld Joint Design & Welding Qualifications MicroSiva baalanNo ratings yet

- Advanced Lab Course 50: PhotovoltaicsDocument18 pagesAdvanced Lab Course 50: PhotovoltaicsHamza OuerfelliNo ratings yet

- Closures Technical Manual 14nov2008Document37 pagesClosures Technical Manual 14nov2008jjescudero100% (1)

- SOP On LMO Tank 20210401 - USAID RISEDocument25 pagesSOP On LMO Tank 20210401 - USAID RISEBoke BelayNo ratings yet

- A Study of The Effect of Magnetite Additions To Shell Molds On THDocument106 pagesA Study of The Effect of Magnetite Additions To Shell Molds On THneel gajNo ratings yet

- In-Situ Rock StressesDocument16 pagesIn-Situ Rock StressesAslam KhanNo ratings yet

- DIY Homemade HHO Hydrogen Generator - RMCyberneticsDocument6 pagesDIY Homemade HHO Hydrogen Generator - RMCyberneticsharisaryono100% (1)

- Mechanical SealDocument64 pagesMechanical SealKhoh Kai ShengNo ratings yet

- Notes:: 6"-12" PIPE Flowline Removable AnchorDocument1 pageNotes:: 6"-12" PIPE Flowline Removable Anchornarutothunderjet216No ratings yet

- Asset Preservation MethodsDocument10 pagesAsset Preservation MethodsLuck Luqe67% (3)

- TemperatureDocument6 pagesTemperatureNur Khairiah Daimah SanupinNo ratings yet

- 3rd Summative TestDocument8 pages3rd Summative TestAngelica ValdezNo ratings yet

- Green Composites: An OverviewDocument11 pagesGreen Composites: An OverviewAyushNo ratings yet

- Alphawool 1600 Vacuum Formed Board Data SheetDocument2 pagesAlphawool 1600 Vacuum Formed Board Data SheetGurdeep Sungh AroraNo ratings yet

- ALLOTMENT DETAILS IN DA/DP EDAYARDocument30 pagesALLOTMENT DETAILS IN DA/DP EDAYARJoe Raj DaaluNo ratings yet

- PWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesDocument31 pagesPWA IAN 021 Rev A1 - Cycleways and Footways Pavement Design GuidelinesHenry TuganoNo ratings yet

- Chemical Formulae ExplainedDocument47 pagesChemical Formulae ExplainedZheng JoeyNo ratings yet

- Fan - 2009 - 8 - ECTC 2009 - 2 RahimDocument5 pagesFan - 2009 - 8 - ECTC 2009 - 2 RahimkraidonNo ratings yet

- GTU BE Semester V Mass Transfer Operations I Exam Summer 2016Document2 pagesGTU BE Semester V Mass Transfer Operations I Exam Summer 2016Shivam PanchalNo ratings yet

- 27 PsychrometryDocument16 pages27 PsychrometryPRASAD326100% (1)

- An Alternative To Additional SO3 Injection For Fly Ash ConditioningDocument7 pagesAn Alternative To Additional SO3 Injection For Fly Ash ConditioningmsoyoralNo ratings yet

- Chapter No-02-GT2Document5 pagesChapter No-02-GT2VikasPatilVickyNo ratings yet

- Tut 9 - PH 102 - 30052023Document1 pageTut 9 - PH 102 - 30052023PS SuryaNo ratings yet

- Propylene - Carbonate Data SheetDocument2 pagesPropylene - Carbonate Data SheetcNo ratings yet

- Items To Review at Hostel CHC ZAMKODocument1 pageItems To Review at Hostel CHC ZAMKOHumphrey OnyejegbuNo ratings yet

- Carbofill Dec08Document4 pagesCarbofill Dec08Cristian Andres Araya CisternasNo ratings yet

- Civil Engineering MCQDocument19 pagesCivil Engineering MCQSuhail RazaNo ratings yet

- Copper and It's AlloysDocument5 pagesCopper and It's AlloysReza MortazaviNo ratings yet