Professional Documents

Culture Documents

ATI Product Info1

Uploaded by

johnj_ramirezOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ATI Product Info1

Uploaded by

johnj_ramirezCopyright:

Available Formats

NEW IMPROVED ATI DRILLSTRING THREAD

INSPECTION SYSTEM

T

S

C

I

N

S

P

E

C

T

I

O

N

S

Y

S

T

E

M

S

TSCs improved Automated Thread Inspection (ATI) drillstring thread

inspection system uses the Amigo ACFM inspection instrument and

special array probes to provide rapid and reliable inspection of

drillstring threads. The method is field proven in the North Sea and is

now included in the latest North Sea Drilling Inspection Standard (Ref

1). Compared to conventional inspection methods, ATI provides a

number of significant benefits, including:

Based on TSCs ACFM inspection method.

Reduced cleaning requirement compared to MT, PT.

Works on magnetic and non-magnetic components

Improved inspection reliability by reducing reliance on operator

Provides information of crack location, length and depth

Operates under Windows environment for easy interface to

other applications

All data is stored for audit, replay or review

Easy transfer of data in electronic form for review off-site if

required

Same instruments and software will accept probes for

inspection of non-threaded areas, including welds, stress relief

features, etc.

FEATURES OF THE ATI SYSTEM

The new ATI system comprises a master control unit, based around TSCs

rugged, battery-powered Amigo ACFM instrument. This is significantly lighter

than the previous system, and also supports use of a higher operating

frequency for increased sensitivity on non-ferrous components. The system is

controlled by a standard laptop PC, which can be supplied as a rugged version

if required.

ATI ARRAY PROBES

ATI array probes are available to cover a wide range of common drillstring

connection sizes. Pictured below is a probe suitable for 4tpi tapered threads.

With appropriate adapters fitted this probe can be used to inspect a variety of

pin and box threads and has been used successfully on NC38, NC 46, NC50, 4

IF, 6

5

/

8

Reg, 7

5

/

8

Reg and HT40 connectors. Probes for other thread forms

or pitches are also available.

Adapters are fitted to either side of the probe to position the thread sensors

correctly for the thread size (Pin or Box) to be inspected. Integral stainless steel

scrapers engage in the thread and closely follow the thread profile. The

scrapers remove dirt and contaminants from the thread and prevent wear to the

thread sensors which are held close to but not in contact with the thread.

4 tpi array probe with adaptors for 3.5 pin connector

Pin Threads

When the ATI probes are deployed on a pin thread, an elasticated strap can be

used to hold the probe in contact with the thread. This allows a stationary drill

pipe or tool to be inspected so no rotation of the thread is required. The

operator moves the probe by hand through one revolution around the thread to

inspect the 12 most highly loaded thread roots. An encoder tracks the probe

movement. When an inspection has been completed, the data is analysed

automatically, and any defects found are reported to the operator. Full details

of the inspection are recorded for detailed analysis or audit purposes. The

inspection cycle, end to end, takes around three minutes.

4 tpi probe inspecting 4.5 pin

Box Threads

By changing scrapers, the same ATI array probes can be used to inspect box

threads. Again the twelve most highly loaded threads are inspected. Process

indicators and controls are on the rear of the probe which allows correct use

whilst the probe is within the box thread. The ATI probes can inspect

components with or without bore-back.

4 tpi probe fitted with adaptors for box probe

4 tpi probe inspecting 3.5 box

4 tpi probe on sectioned 4.5 box

CONTROL SOFTWARE

The ATI system has been designed to reduce the requirement for skilled

operators and to allow drillstring thread inspection data to be available for audit.

One of the key features of the ATI system is its ability to detect, locate and size

defects without the need for operator interpretation. This is achieved by the use

of an advanced version of TSCs ASSIST software, which interprets the

inspection data automatically.

The software controls the data acquisition process, maintains the quality of the

data and provides the operator with a simple result detailing all defects found.

The system also provides management reports in the form of shift summaries

detailing all the inspections conducted and the result. The software also

provides for input from an inspection specialist who can set reporting thresholds

and review the detailed data not available to the site operator.

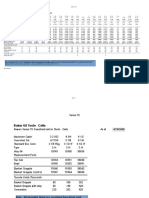

Software screen showing auto-detected and sized defects

OTHER AREAS

In addition to providing automated data interpretation using specialist probes,

the hardware and software can be configured to accommodate simple hand

held probes. These probes rely more on the operator and the data requires

interpretation by the operator. However, this can provide a very flexible

inspection capability and can be used to inspect shoulder areas, stress relief

grooves, weld areas, bearing grooves etc.

Universal thread probe with plastic shoe (left) and shoes for pin and box threads (right)

SPECIFICATION

Amigo Instrument Weight: 4.5kg

Instrument Size: 206 x 292 x 127 mm

Probe Cable Length: 5 metres standard, up to 20m by special request.

Serial Communications Cable up to: 30 metres

Operating Temperature: -20 + 40C

Environment Protection: IP54 rated. Not Ex-rated.

Battery Life*: >5 hours continuous operation with array probe, >10

hours with a single probe

Recharge Time: 4 hours

Laptop Requirements: Windows 2000 or XP. Serial comms port (or USB to

serial adapter). CD-rom drive. Floppy disc drive (or

means of transferring probe files from floppy discs).

* Note that system can be run continuously from mains supply.

For further information, please contact:

TSC Inspection Systems

6 Mill Square, Featherstone Road

Wolverton Mill, Milton Keynes, MK12 5RB

UNITED KINGDOM

Tel No: +44 (0) 1908 317444

Fax No: +44 (0) 1908 220959

Email: sales@tscinspectionsystems.com

Web: www.tscinspectionsystems.com

ACFM is a registered trademark of Technical Software Consultants Ltd

Please Note: As part of its continuing programme of product improvement, TSC

reserve the right to alter specifications without prior notice.

TSC Inspection Systems is a trading name of Technical Software Consultants Ltd.

You might also like

- Inspection Report for JS-04 Rig UnitDocument52 pagesInspection Report for JS-04 Rig Unitjohnj_ramirezNo ratings yet

- JS3Document58 pagesJS3johnj_ramirezNo ratings yet

- UK-SPEC Third EditionDocument48 pagesUK-SPEC Third EditionRahul PatelNo ratings yet

- Vibration-Induced Fatigue - A Risk-Based ApproachDocument25 pagesVibration-Induced Fatigue - A Risk-Based Approachjohnj_ramirezNo ratings yet

- SIA 9 CompositesDocument0 pagesSIA 9 Compositesjohnj_ramirezNo ratings yet

- Corrosion Guidelines (California DOT) PDFDocument51 pagesCorrosion Guidelines (California DOT) PDFtylerlhsmithNo ratings yet

- 18Document8 pages18Mohamed WahidNo ratings yet

- Danfoss LPV Pump PDFDocument32 pagesDanfoss LPV Pump PDFjohnj_ramirezNo ratings yet

- CSWIP ISO NDT 11 93 R 8th Edition February 2016Document23 pagesCSWIP ISO NDT 11 93 R 8th Edition February 2016Brandon EricksonNo ratings yet

- LRFD Beam Load Tables PDFDocument75 pagesLRFD Beam Load Tables PDFjohnj_ramirezNo ratings yet

- SIA 3 Mechanical PropertiesDocument0 pagesSIA 3 Mechanical Propertiesjohnj_ramirezNo ratings yet

- Stuctural SafteyDocument38 pagesStuctural SafteySanthosh ReddyNo ratings yet

- Overpressure CaseDocument33 pagesOverpressure Casejohnj_ramirezNo ratings yet

- MICROBIALLY INFLUENCED CORROSIONDocument0 pagesMICROBIALLY INFLUENCED CORROSIONAnky FadharaniNo ratings yet

- 9-Appendix 1 Part 4 Radiographic Interpreter 4th Edition June 2011Document6 pages9-Appendix 1 Part 4 Radiographic Interpreter 4th Edition June 2011johnj_ramirezNo ratings yet

- SIA 1 Stress ConcentrationDocument0 pagesSIA 1 Stress Concentrationjohnj_ramirezNo ratings yet

- ACPD MkIV Product InfoDocument0 pagesACPD MkIV Product Infojohnj_ramirezNo ratings yet

- Fracture MechanicsDocument18 pagesFracture Mechanicsjalali007No ratings yet

- Corrosion Guidelines (California DOT) PDFDocument51 pagesCorrosion Guidelines (California DOT) PDFtylerlhsmithNo ratings yet

- Thermo Scientific Niton Xl3t Goldd XRF Analyzer ADocument1 pageThermo Scientific Niton Xl3t Goldd XRF Analyzer Ajohnj_ramirezNo ratings yet

- Xlgo 6130 System ADocument2 pagesXlgo 6130 System Ajohnj_ramirezNo ratings yet

- Pressure Vessel Inspections Using Ultrasonic Phased ArraysDocument13 pagesPressure Vessel Inspections Using Ultrasonic Phased ArraysCemal NergizNo ratings yet

- API Test Taking TipsDocument6 pagesAPI Test Taking TipsSripathyNo ratings yet

- AB-520 Finite Element Analysis (FEA) RequirementsDocument4 pagesAB-520 Finite Element Analysis (FEA) Requirementsjohnj_ramirezNo ratings yet

- Alberta eye exam reportDocument1 pageAlberta eye exam reportjohnj_ramirezNo ratings yet

- AB-012 Pressure Vessel Inspection ReportDocument1 pageAB-012 Pressure Vessel Inspection Reportjohnj_ramirez50% (2)

- 4 - 2 - Public Safety and Hazardous MaterialsDocument49 pages4 - 2 - Public Safety and Hazardous Materialsjohnj_ramirezNo ratings yet

- Comparacion HT y ET PDFDocument6 pagesComparacion HT y ET PDFAndres Camilo Peña SanchezNo ratings yet

- Ab-59 Ice SyllabusDocument44 pagesAb-59 Ice SyllabuscoxshulerNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Project Report GPKP YugandherDocument52 pagesProject Report GPKP Yugandherapi-440402079No ratings yet

- Steam System Spirax SarcoDocument12 pagesSteam System Spirax Sarcoashwinmoi100% (1)

- MSDS EvaDocument3 pagesMSDS EvasunitaNo ratings yet

- Glazing TerminologyDocument4 pagesGlazing TerminologyDaliPotter100% (1)

- CIVE 265 - Lab 2 - Tensile Testing of MeDocument6 pagesCIVE 265 - Lab 2 - Tensile Testing of MeRebecca ChungNo ratings yet

- Pressure GaugeDocument22 pagesPressure GaugeSandi Aslan100% (2)

- PERFORMANCE TEST ON VAPOUR COMPRESSION REFRIGERATION SYSTEM USING R290 & R134a MIXTUREDocument7 pagesPERFORMANCE TEST ON VAPOUR COMPRESSION REFRIGERATION SYSTEM USING R290 & R134a MIXTUREJASH MATHEWNo ratings yet

- Chapters Page No.: AcknowledgementDocument7 pagesChapters Page No.: AcknowledgementBrian FreemanNo ratings yet

- O3plus Brochure 2Document6 pagesO3plus Brochure 2Jalindar SawaseNo ratings yet

- Acoplamento de Tambor MalmedieDocument20 pagesAcoplamento de Tambor MalmedieFelipe Bianchi Ambrosio100% (1)

- Magnum PartsDocument77 pagesMagnum PartsNestor Marquez-DiazNo ratings yet

- lnt26 EngDocument1 pagelnt26 EngVVan TanNo ratings yet

- Build your own Continuous Rotation Servo with Encoder LabDocument8 pagesBuild your own Continuous Rotation Servo with Encoder LabGoran MiljkovicNo ratings yet

- TALIS Desalination Solutions 2019 WebDocument16 pagesTALIS Desalination Solutions 2019 WebSakir ZakNo ratings yet

- Structural Analysis Is A: Science, Having Definite ValueDocument34 pagesStructural Analysis Is A: Science, Having Definite ValueRamanathan SenthilNo ratings yet

- Fixed Steel Ladders: Cotterman CoDocument4 pagesFixed Steel Ladders: Cotterman CoNguyen Quoc VuNo ratings yet

- TC 36" Standard Cone CrusherDocument1 pageTC 36" Standard Cone CrusherEddo CarrionNo ratings yet

- Carrier HAP Systems Design ReportDocument30 pagesCarrier HAP Systems Design ReportEngineering WavesNo ratings yet

- 1 Theory of HPLC IntroductionDocument16 pages1 Theory of HPLC IntroductionaugustoxavierNo ratings yet

- Narrow Vein Mining: Mini-Machines From FranceDocument2 pagesNarrow Vein Mining: Mini-Machines From FranceCristian Quelmis Vilca HuarachiNo ratings yet

- Capsules Deduster: The PTGDocument2 pagesCapsules Deduster: The PTGRafael ZavalaNo ratings yet

- Automotive CableDocument46 pagesAutomotive CableDanu MamlukatNo ratings yet

- Tensile StrengthDocument19 pagesTensile StrengthAshraful Himel100% (2)

- Closed House Broiler Enclosure PLC AutomationDocument125 pagesClosed House Broiler Enclosure PLC AutomationRizki El AkbarNo ratings yet

- Materials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFDocument50 pagesMaterials For Cryogenic Service - Engeering Properties of Aus - Decrypté PDFGOUAREF SAMIRNo ratings yet

- Concrete Repair SpecificationDocument30 pagesConcrete Repair Specificationalejandraoy9No ratings yet

- Flexible Polyurethane Foam A PrimerDocument7 pagesFlexible Polyurethane Foam A PrimerirwanchemNo ratings yet

- Amorphous Metal TransformersDocument17 pagesAmorphous Metal TransformersAnjeri PhelestusNo ratings yet

- All OvershotsDocument25 pagesAll OvershotsnjileoNo ratings yet

- Shaft AlignmentDocument8 pagesShaft Alignmentrafiee100% (1)