Professional Documents

Culture Documents

Practical Problems of Highway Construction in Black Cotton Soil Area PDF

Uploaded by

MosesGraceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practical Problems of Highway Construction in Black Cotton Soil Area PDF

Uploaded by

MosesGraceCopyright:

Available Formats

Practical Problems of Highway Construction in Black Cotton Soil Area

http://www.nbmcw.com/articles/roads/307-practical-problems-of-highwa...

LOGIN

CREATE AN ACCOUNT

HOME ABOUT US CONTACT US

ADVERTISE WITH US

MAGAZINES

NEWS

ARTICLES

PRODUCTS

EQUIPMENTS

REPORTS

INTERVIEWS

SUBSCRIPTION

PEOPLE WATCH

EVENTS

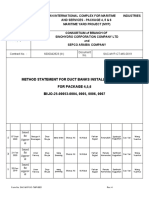

Practical Problems of Highway Construction in Black Cotton Soil Areas and In-Place Remedial Measures: A Case Study

Search.....

Dr. S.S.Seehra, Chief Pavement SpecialistcumMaterials and Geotechnical Engineer, Span Consultants Pvt. Ltd. (Member of the SNCLAVALIN Group Inc.) and (Former DirectorGrade Scientist and Head, Rigid Pavements Division, CRRI), New Delhi. Black cotton soils are inorganic clays of medium to high compressibility and form a major soil group in India. They are characterized by high shrinkage and swelling properties. This Black cotton soils occurs mostly in the central and western parts and covers approximately 20% of the total area of India. Because of its high swelling and shrinkage characteristics, the Black cotton soils (BC soils) has been a challenge to the highway engineers. The Black cotton soils is very hard when dry, but loses its strength completely when in wet condition. It is observed that on drying, the black cotton soil develops cracks of varying depth. Figure 1 shows the typical cracks in Black cotton soils (BC soils) in a dried state. As a result of wetting and drying process, vertical movement takes place in the soil mass. All these movements lead to failure of pavement, in the form of settlement, heavy depression, cracking and unevenness. This article covers highway construction in Black cotton soils (BC soils) and also describes a case history of highway construction in highway construction in Black cotton soils. Black Cotton Soil Peculiar Characteristics Black cotton soil (BC soil) is a highly clayey soil. It is so hard that the clods cannot be easily pulverized for treatment for its use in road construction. This poses serious problems as regards to subsequent performance of the road. Moreover, the softened sub grade has a tendency to up heave into the upper layers of the pavement, especially when the sub-base consists of stone soling with lot of voids. Gradual intrusion of wet Black cotton soil (BC soil) invariably leads to failure of the road. The roads laid on Black cotton soil (BC soil) bases develop undulations at the road surface due to loss of strength of the sub grade through softening during monsoon. The black color in Black cotton soil (BC soil) is due to the presence of titanium oxide in small concentration. The Black cotton soil (BC soil) has a high percentage of clay, which is predominantly montmorillonite in structure and black or blackish grey in color. The physical properties of Black cotton soil (BC soil) vary from place to place. Its engineering properties are given in Table 1. 40 to 60% of the Black cotton soil (BC soil) has a size less than 0.001 mm. At the liquid limit, the volume change is of the order of 200 to 300% and results in swelling pressure as high as 8 kg/cm / to 10 kg/cm . As such Black cotton soil (BC soil) has very low bearing capacity and high swelling and shrinkage characteristics. Due to its peculiar characteristics, it forms a very poor foundation material for road construction. Soaked laboratory CBR values of Black Cotton soils are generally found in the range of 2 to 4%. Due to very low CBR values of Black cotton soil (BC soil),

2 2

LATEST ISSUES

1 of 6

6/24/2013 12:07 AM

Practical Problems of Highway Construction in Black Cotton Soil Area

http://www.nbmcw.com/articles/roads/307-practical-problems-of-highwa...

View Online Download Issue (PDF) Previous Issues

excessive pavement thickness is required for designing for flexible pavement. Research & Development (R&D) efforts have been made to improve the strength characteristics of Black cotton soil (BC soil) with new technologies. Problems of Highway Construction in Black Cotton Soil Areas Problems Arising out of Water Saturation It is a well-known fact that water is the worst enemy of road pavement, particularly in expansive soil areas. Water penetrates into the road pavement from three sides viz. top surface, side berms and from sub grade due to capillary action. Therefore, road specifications in expansive soil areas must take these factors into consideration. The road surfacing must be impervious, side berms paved and sub grade well treated to check capillary rise of water. It has been found during handling of various road investigation project assignments for assessing causes of road failures that water has got easy access into the pavement. It saturates the sub grade soil and thus lowers its bearing capacity, ultimately resulting in heavy depressions and settlement. In the base course layers comprising of Water Bound Macadam (WBM), water lubricates the binding material and makes the mechanical interlock unstable. In the top bituminous surfacing, raveling, stripping and cracking develop due to water stagnation and its seepage into these layers. Generally, road construction agencies do not pay sufficient attention to the aspects of construction and maintenance of side berms. It is emphasized that road formation consisting of carriageway and berms must be considered as one single unit. In expansive soil areas, unpaved berms pose the maximum problem as they become slushy during rains, as they are most neglected lot. Fig 2 and Fig 3 show development of alligator cracks and extensive depression as well as upheavals respectively in bituminous surfacing in Black cotton soil (BC soil) areas.

Currently Online

We have 323 guests online

Alexa Rank

View Online Download Issue (PDF) Previous Issues

View Online Download Issue (PDF) Previous Issues

Design Problems in Black cotton soils In India, CBR method developed in USA is generally used for the design of crust thickness. This method stipulates that while determining the CBR values in the laboratory and in the field, a surcharge weight of 15 kg and 5 kg per 62 mm and 25 mm thickness respectively should be used to counteract the swelling pressure of Black cotton soils (BC soils). BC soils produce swelling pressure in the range of 20-80 tons/m and swelling in the range of 10-20%.Therefore, CBR values obtained are not rational and scientific modification is required for determining CBR values of expansive soil. Having heavy-duty traffic of 4500 commercial vehicles per day and msa 150 as generally found on our National Highways and taking CBR value of 2%, total crust thickness of flexible pavement works out to 830 mm which is practically an impossible preposition. It is felt that CBR design curves require modification for expansive soils. Assuming heavy traffic intensity of 4500 commercial vehicles per day and msa 150, crust thickness of rigid pavement works out approximately 300-320 mm, which is about one third of thickness needed for flexible pavement. Therefore, it sounds reasonable to adopt cement concrete pavement in Black cotton soil areas. This type of pavement may save the engineers from day to day maintenance problems also. Another approach to the problem can be in having semi rigid sub-bases. It is suggested that the CBR value of the BC soil be improved by giving a suitable treatment with the appropriate technology and then work out the crust thickness. This will substantially reduce the required crust thickness. Uncompacted berms without any treatment cannot withstand the traffic stresses. It is a common sight and experience that heavy vehicles get stuck up while overtaking and sometimes results in serious accidents. Development of separate specifications for berms need to be evolved. Technologies for Improving CBR of Black cotton soils Materials for Soil Stabilization The materials for Black cotton soil (BC soil) stabilization shall comprise lime or Ordinary Portland Cement (OPC)43 grade, moorum of approved quality, sand and Cohesive Non swelling Soil (CNS) having properties given below: a. The Black cotton soil (BC soil) having characteristics as given in Table 1. b. OPC 43 grade as per IS:8112- 1989. c. Well graded granular moorum having minimum 4 day soaked CBR of 10% and maximum laboratory dry unit weight when tested as per IS:2720 (Part-8) shall not be less than 17.50 kN/m3. d. The sand shall be as per IS:383-1970.

2

2 of 6

6/24/2013 12:07 AM

Practical Problems of Highway Construction in Black Cotton Soil Area

http://www.nbmcw.com/articles/roads/307-practical-problems-of-highwa...

e. The material for CNS soil should be good quality soil having laboratory dry unit weight when tested as per IS:2720 (Part-8) not less than 16kN/m3. Cement/ Lime-Soil Stabilization The engineering properties of Black cotton soil (BC soil) can significantly be improved with lime or cement treatment. This technology has been very common at global level and is in vogue for the last several years. Cement or hydrated lime in the range of 3 to 5 per cent brings remarkable improvement in the engineering characteristics of Black cotton soil (BC soil). The test results of typical Black cotton soil (BC soil) samples are given in Table 2 to indicate the improvement in its characteristics. Cement/ Limesoil stabilization technology has been found useful cost-effective and suited to manual methods of construction. This technology has been found 20-30% cheaper than conventional WBM construction. The cement or lime treatment is being utilized for the following purposes: a. To provide a pavement foundation of marginally weaker in strength than that of concrete pavement, but much improved strength than natural Black cotton soil (BC soil). b. To consolidate subgrades and base courses for concrete pavement in order to make them resistant to volume changes and displacement or erosion in the presence of moisture even under the rocking action of curled slabs, if any. c. To overcome the susceptibility of foundations to volume change and to increase their shearing resistance and bearing capacity. Pulverization and Mixing Methodology The method of pulverization of Black cotton soil (BC soil) and mixing with cement and moorum or lime and moorum shall be as follows: The Black cotton soil (BC soil) is dug from the ground where the embankment is to be constructed and clods broken with pick-axes so as to reduce them to a maximum size of 50 mm. Alternatively disc harrows with tractor could be employed. Soil clods are spread over the prepared and compacted surface of excavation and a smooth wheeled 8 tonne power roller passed over them a number of times, accompanied by frequent raking of the crushed material. About 8 passes of the roller combined with raking should normally be able to achieve the degree of pulverization. The degree of pulverization should be such that at least 80 per cent of soil passes through 475 micron sieve and there are no lumps larger than 25 mm size. The pulverized Black cotton soil (BC soil) is mixed uniformly in given proportion by weight with cement and moorum in-situ field conditions by using rotavator machine or motor grader. Portland cement or lime and Black cotton soil (BC soil) mixed at the proper moisture content has been used to build stabilized bases under concrete pavements for highways/ expressways and air fields .Cement/ lime-modified Black cotton soil (BC soil) is a mix that generally contains less than 5 per cent cement by volume. This forms a semi-rigid system, improves the engineering properties of the soil and reduces the potential of the soil to expand by absorbing water. OPC or lime, when mixed with pulverized Black cotton soil (BC soil) reduces the liquid limit (LL), the plasticity index (PI) and the potential for volume change. It increases the shrinkage limit and shear strength. Due to the strength increase incorporated by the use of cement, the Black cotton soil (BC soil) cement mixture can increase the subgrade bearing capacity and strength significantly. This technique is relatively cheap and quite effective. At the ingress of moisture in cement stabilized black cotton soil mix, the water increases the strength of cement matrix and imparts strength to the mix. Road Embankment Construction The methodology for improving the engineering characteristics of Black cotton soil (BC soil) for road embankment construction is as follows: a. After identifying the stretches where a treatment to strengthen the foundation embankment is required, the unsuitable Black cotton soil (BC soil) should be removed to the depth of 1600 mm below natural ground level (NGL). b. After excavation, the ground should be checked for density. In case the density is found to be less than 95 per cent of Max. Dry Density (MDD), a further depth of 225 mm should be loosened and recompacted at Optimum Moisture Content (OMC) till it attains the density of 95 percent of MDD and CBR of 5 per cent. c. Construction of embankment in layers of 200 mm compacted thickness or part thereof,

3 of 6

6/24/2013 12:07 AM

Practical Problems of Highway Construction in Black Cotton Soil Area

http://www.nbmcw.com/articles/roads/307-practical-problems-of-highwa...

should be continued up to 600 mm thickness with pulverized Black cotton soil (BC soil) (60% by wt.), cement (OPC) 43 grade or lime (3% by wt.) and moorum (37% by wt.) uniformaly mixed by using rotavator machine or by any other farm equipment and rolled to achieve density of 95 per cent of MDD and CBR of 5 percent. d. A layer of 225 mm thick sand filter should be provided over the stabilized Black cotton soil (BC soil) as given at (c) above and also to give uniform support. Over this a layer of 1000 mm thickcompacted moorum in layers of200 mm each should be provided. e. Compacted CNS soil of size 3000 mm in width and 2000 mm in depth should be provided at the edges of the compacted sublayers to prevent the entry of ground water to the sub-layers. f. Proper pucca drains on both sides of the road at the NGL along the embankment should be provided as per the standards. g. Construction details of the remaining upper layers should be as per pavement design based on the CBR results/ modulus of subgrade reaction. h. Use of good flyash in embankment construction should be permitted wherever available near the construction site. Flyash should be conforming to IS:3812 (Grade-1) and it should be ensured that availability of flyash is of consistent quality and in required quantity. Use of geo-textile fabric has found extensive application in highway engineering, particularly in expansive soil area. It was used in USA in early 70s and in India it is initial stage. Geo-textiles are manufactured from petroleum derivatives such as polypropylenes, polyesters, polyamides etc. These have high tensile strength, burst and puncture strength, permeability and abrasion resistance etc. The use of geotextile fabric is made to provide a separation barrier between subgrade and sub-base courses. This technique has tremendous potential for its application in Black cotton soil (BC soil) area, and it has further been found that this geo-textile layer acts as a reinforcing layer, acts and can also be used to combat reflective cracking in the pavement structure. Also with the use of geo-textile, a reduction in the thickness of the pavement has been predicted ranging from 10 to 25 per cent. The cost of the geotextile has been the stumbling factor for its wider application in India. However, in special areas, such as Black cotton soil (BC soil) area, geo-textile offers a solution to highway engineering problems. Use of moorum layer as a barrier between subgrade and subbase layer has been in practice in view of its costeffectiveness. Moorum of low plasticity index has been found effective and does not allow intrusion up of soft subgrade soil into the interstices of stone aggregates and ingress of water through it. It is a common old practice to provide about 225 mm thick sand blanket layer on soft soils as a barrier to stop intrusion of subgrade soil into interstices of granular base/ sub-base layer and serves as drainage layer, and also to give uniform support. Choice of Top Wearing Courses on Flexible Pavement In Black cotton soil (BC soil) areas, choice of bituminous surfacing on road crust is an important parameter in enhancing the life of the pavement. In order to eliminate the ingress of water into the pavement crust, it is preferred to adopt impervious surfacing of low void content, such as dense asphaltic concrete, premix carpet with liquid seal coat, bituminous macadam with seal coat etc. It has been found that open graded bituminous surfacings develop unevenness, waviness and depression during rainy season due to softening of subgrade caused by seeping of water through such open graded bituminous surfacings. In case of construction of new surfacings, it should be ensured that it is laid much before the monsoon season. It is felt that time slot of at least one month should be given between the end of construction and beginning of monsoon so that surface course gets additional compaction due to traffic. It ensures consolidationand compaction. Shoulders of roads need special treatment, as these are the vulnerable points for vehicles getting stuck up during overtaking. It is felt that special treatment is needed to make the berms paved and separate specifications should be formulated. Case History of Road Construction in Black Cotton Soil Areas 4 laning of National Highway No. 4 passing through Black cotton soil (BC soil) Area National Highway No. 4 (NH-4) connects Chennai and Mumbai via Bangalore. NH-4 is one of the four arms of the National Highway Network popularly known as the Golden Quadrilateral having length of about 6000 km as a component of National Highways Development Project (NHDP). The Ministry of Road Transport & Highways (MoRT&H) has authorized National Highways Authority of India (NHAI) to undertake the widening of the existing 2 lane stretch mostly passing through Black cotton soil (BC soil) area from Satara (km 725.00) to Maharashtra State Border Section of NH-4 (km 592.240), to 4-lane divided carriageway and strengthening of the existing 2-lane section through private sector participation on BOT basis. The Black cotton soil (BC soil) deposits existing on the road alignment were fully replaced with Cohesive Non- Swelling (CNS) soil having Plasticity Index (PI) value ranging between 5 to 15 and Free-Swelling Index (FSI) ranging between 7 to 35 in the entire length of new carriageway (Fig 4). Since the good quality CNS soil (moorum) was readily available in abundance from the nearby moorum quarries along the existing carriageway, therefore, no Black cotton soil (BC soil) stabilization was required to be carried out either with lime or cement. Fig 5 shows compaction of CNS soil (moorum) in the construction of embankment for the new 2 lane carriageway. Along this road, sampling of soil had been done at regular intervals of distance through test pitting and had been tested for FSI and Atterberg Limits to verify how much it was expansive. After that it was checked for other properties such as MDD/OMC, CBR and grain size analysis etc. Every borrow soil/ moorum other than Black cotton soil (BC soil) was used after

4 of 6

6/24/2013 12:07 AM

Practical Problems of Highway Construction in Black Cotton Soil Area

http://www.nbmcw.com/articles/roads/307-practical-problems-of-highwa...

testing their required properties as per codal specifications. Quality acceptance tests were carried out for common borrow embankment and subgrade materials. The methodology of embankment and subgrade construction where there was filling and cutting throughout the existing alignment is described under Case-I and Case-II respectively hereinafter. Methodology of Embankment Construction in Filling (Case-I) Where the stretches of highway embankment are in filling on Black cotton soil (BC soil) (Fig 6) and are above NGL, the methodology for improving the engineering characteristics of Black cotton soil (BC soil) was as follows: a. After location of the stretches where embankment was to be raised in filling, the formation level was prepared after clearing and grubbing to a depth of 150 mm. b. Construction of embankment in layers of 200 mm compacted thickness or part thereof, was continued upto thicknessh (Fig 6) with good soil other than Black cotton soil (BC soil) having FSI less than 50 per cent, PI less than 30, Field Dry Density (FDD) equal to 95 per cent of MDD and minimum CBR of 5 per cent. c. The remaining height of embankment would be layer of 500 mm thicknesscompacted CNS soil in two layers of 200 mm each and the remaining layer of 100 mm was provided over the compacted layer as given at (b) above, having zero FSI, FDD of 95 per cent of MDD and minimum CBR of 5 per cent. d. A further layer of 500 mm subgrade thickness of compacted CNS soil in two layers of 200 mm each and 100 mm was provided over the compacted layer as given at (c) above, having zero FSI, FDD of 97 per cent of MDD and minimum CBR of 8 per cent. e. The construction details of the remaining upper layers shall be as per pavement design based on the CBR results/ modulus of subgrade reaction. Methodology of Embankment Construction in Cutting (Case-II) Where the stretches of highway embankment are in cutting on Black cotton soil (BC soil) (Fig 7) and are below NGL, the methodology for improving the engineering characteristics of Black cotton soil (BC soil) for road embankment construction was as follows: a. After location of the stretches where embankment was to be raised in cutting, the formation level was prepared after excavation of the soil to a depth of 1600 mm below NGL. The formation level was checked for density. In case the density was found to be less than 95 percent of MDD, the soil would be loosened and recompacted at OMC till it attained the density of 95 per cent of MDD. Over this, a layer of 225 mm thick sand filter or blanket course consisting of non-plastic granular material or local sand was provided. b. Construction of embankment in layers of 200 mm compacted thickness or part thereof, was continued upto thicknessh (Fig 7) with good soil other than Black cotton soil (BC soil) having FSI less than 50 percent, PI less than 30, FDD equal to 95 per cent of MDD and minimum CBR of 5 per cent. c. The remaining height of embankment was layer of 500 mm thickness of CNS soil as described in para (c) of Case 1. d. A further layer of 500 mm subgrade thickness of compacted CNS soil in two layers of 200 mm thickness each and the remaining layer of 100 mm or two layers of 250 mm thickness each (as directed by the Engineer-in-Charge at site to reduce time of construction) shall be provided over the compacted layer as given at (c) above, having zero FSI, FDD of 97 per cent of MDD and CBR of 8 per cent. The construction details of the remaining upper layers shall be as per pavement design based on the CBR results/ modulus of subgrade reaction. Conclusion a. There is a need for providing the engineering characteristics of B.C. soil for road construction. b. Flexible pavement design method involving use of CBR method needs modification due to high swelling characteristics of Black cotton soil (BC soil). Rigid pavement construction can be employed to bring out overall economy in Black cotton soil (BC soil) areas. c. Use of lime-soil stabilization technology has a great potential in Black cotton soil (BC soil) areas. Use of moorum layer as a barrier between subgrade and sub-base layer has been in practice in view of its cost-effectiveness. Moorum of low PI has been found effective and does not allow intrusion up of soft subgrade soil into the interstices of stone aggregates and ingress of water through it. d. Use of 225 mm thick sand filter layer on soft soils as a barrier to stop intrusion of subgrade soil into interstices of granular base/ sub-base layer and serve as drainage layer, and to give uniform support. e. Incorporation of geo-textile fabric between subgrade and sub-base layer is an emerging technology. It not only stops seepage of water but also brings reduction in thickness. f. Dense bituminous surfacings are essential to stop the ingress of water from top surfacing. g. Roadside berms require pucca treatment including use of primer and stone grafting; a steep camber of 1:36 is recommended. h. A layer of 1000 mm thick compacted moorum should be provided over the sand filter layer as given at (d.) above. The compacted CNS soil of size 3000 mm in width and 2000 mm in depth should be provided at

5 of 6

6/24/2013 12:07 AM

Practical Problems of Highway Construction in Black Cotton Soil Area

http://www.nbmcw.com/articles/roads/307-practical-problems-of-highwa...

the edges of the compacted sub-layers to prevent the entry of ground water to the sub-layers. References 1. Chen, F. H (1998): Foundationson Expansive Soils, American Elsevier Science Publication, New York. 2. CRRI Report (1980): Investigation of certain stretcheson NH-3 near Biora in Madhya Pradesh. 3. Dunn I. S., Anderson, L. R. & Kiefer, F.W. (1980): Fundamentals of Geotechnical Analysis, John Wiley & Sons, Inc. New York. 4. John Nelson, D & Debora Millar. J (1991): Expansive Soils, John Wiley & Sons, Inc. New York. 5. National Gettogether on Road Research and its Utilization, CRRI, October 1987, Basic Document. 6. Road Research Paper No. 149: Lime Requirement in Soil- Stabilization. 7. Technical Specifications (Package-IV): Four-laning of SataraKolhapur upto Maharashtra State Border Section of NH-4 (km 592/240 to km 725/000), Vol. 3.

NBMCW March 2008

< Prev

TERMS & CONDITIONS PRIVACY POLICY

Next >

CANCELLATION/R EFUND POLICY DISCLAIMER

Copyright 2010 NBM Media Pvt. Ltd. All Rights Reserved.

6 of 6

6/24/2013 12:07 AM

You might also like

- Hydraulic Design of Highway CulvertsDocument410 pagesHydraulic Design of Highway CulvertsMosesGraceNo ratings yet

- Highway Materials & Mix Design Ppt. MMHDocument35 pagesHighway Materials & Mix Design Ppt. MMHMd Mehedi HasnatNo ratings yet

- 27 Minutes To MidnightDocument45 pages27 Minutes To MidnightMosesGrace100% (3)

- Flexible Pavement DistressDocument13 pagesFlexible Pavement DistressrajudeenNo ratings yet

- Strength of Materials - MCQDocument11 pagesStrength of Materials - MCQsudheer92100% (2)

- Design of low-cost river crossings for developing nationsDocument8 pagesDesign of low-cost river crossings for developing nationsMosesGraceNo ratings yet

- Bituminous Mix Design & Superpave MixesDocument53 pagesBituminous Mix Design & Superpave Mixesjaffna100% (9)

- Lesson 4: Hot Mix Asphalt - Mix Design: CEE 595 Construction Materials Winter 2008Document37 pagesLesson 4: Hot Mix Asphalt - Mix Design: CEE 595 Construction Materials Winter 2008akmeez100% (1)

- Method StatementDocument31 pagesMethod StatementMuneeb KhanNo ratings yet

- D 2397 - 02 RdizotcDocument3 pagesD 2397 - 02 RdizotcFlorencia MüllerNo ratings yet

- Mechanistic Design of Overlay Based On Benkelman Beam Deflection TechniqueDocument8 pagesMechanistic Design of Overlay Based On Benkelman Beam Deflection TechniqueNilay BhavsarNo ratings yet

- Methods of Soil and Base StabilizationDocument82 pagesMethods of Soil and Base StabilizationSunil Bose100% (1)

- Stabilization of Black Cotton SoilDocument44 pagesStabilization of Black Cotton SoilBhavya N Kotian100% (9)

- Bitumen TestDocument13 pagesBitumen TestAnupam Verma100% (1)

- Flexible Pavement DistressesDocument4 pagesFlexible Pavement DistressesSivakumar M100% (1)

- Pavement and Materials Design Manual 1999 - CHAPTER 8Document12 pagesPavement and Materials Design Manual 1999 - CHAPTER 8Kisali Sarakikya100% (2)

- Research and Application of Hot In-Place Recycling Technology for Asphalt PavementFrom EverandResearch and Application of Hot In-Place Recycling Technology for Asphalt PavementNo ratings yet

- Flexible Pavement Design - AashtoDocument17 pagesFlexible Pavement Design - AashtoFarhanah Binti Faisal0% (1)

- Neca 409-2009 - Installing and Maintaining Dry Type TransformersDocument42 pagesNeca 409-2009 - Installing and Maintaining Dry Type TransformersJosé Luis FalconNo ratings yet

- Boq - Fencing EstimateDocument2 pagesBoq - Fencing EstimateAugustine Believe100% (3)

- Quality Control in Concrete ConstructionDocument123 pagesQuality Control in Concrete ConstructionJustice ArjonaNo ratings yet

- Superpave Mix Design - Pavement InteractiveDocument7 pagesSuperpave Mix Design - Pavement InteractiveHoracio Reyes de la Rosa100% (1)

- Rigid Pavement DesignDocument11 pagesRigid Pavement DesignAjit P. SinghNo ratings yet

- Bituminous MixesDocument13 pagesBituminous MixesRanjit SinghNo ratings yet

- Current Approach To Pavement DesignDocument25 pagesCurrent Approach To Pavement DesignApril IngramNo ratings yet

- 3.3 Road Note No. 4-1Document40 pages3.3 Road Note No. 4-1Asad Choudhary100% (1)

- Pavement Design ReportDocument7 pagesPavement Design ReportYaselaNo ratings yet

- Highway Maintenance 2003Document80 pagesHighway Maintenance 2003Pranesh Gr100% (1)

- Surface DressingDocument34 pagesSurface DressingNyangoe Joel100% (1)

- Settlement BH-02 WaingapuDocument225 pagesSettlement BH-02 WaingapuAlifiya Malika ZahraNo ratings yet

- AASHTO Road Test Pavement Design GuideDocument3 pagesAASHTO Road Test Pavement Design GuideLenana KoikaiNo ratings yet

- Beam Block BrochureDocument7 pagesBeam Block BrochurehemendraengNo ratings yet

- Comparison of Marshall and Superpave Asp PDFDocument7 pagesComparison of Marshall and Superpave Asp PDFwillypraviantoNo ratings yet

- CBR Improvement of Clayey Soil With Geogrid ReinforcementDocument4 pagesCBR Improvement of Clayey Soil With Geogrid Reinforcementbkollarou9632No ratings yet

- A Guide To Good Quality Control Practices OnAsphalt Production and ConstructionDocument59 pagesA Guide To Good Quality Control Practices OnAsphalt Production and ConstructionAmirrudin Johari100% (1)

- Comparing Flexible and Rigid Pavement Costs for Soil and TrafficDocument10 pagesComparing Flexible and Rigid Pavement Costs for Soil and TrafficMano DragonNo ratings yet

- Unbound Aggregates in RoadsFrom EverandUnbound Aggregates in RoadsR.H. JonesNo ratings yet

- PFC - The Great CoolerDocument47 pagesPFC - The Great CoolerM.IBRAHEEM100% (1)

- IRC ProposalDocument50 pagesIRC ProposalashwinmjoshiNo ratings yet

- Determination of AASHTO Layer Coefficients For Granular MaterialsDocument12 pagesDetermination of AASHTO Layer Coefficients For Granular MaterialsSasana SanNo ratings yet

- Bitumen Modified With PlasticsDocument7 pagesBitumen Modified With PlasticsBeatrice KunguNo ratings yet

- Recycling of Asphalt Pavements: An OverviewDocument12 pagesRecycling of Asphalt Pavements: An OverviewProf. Prithvi Singh Kandhal100% (1)

- SS Seehra Black Cotton Soil Areas FinalDocument28 pagesSS Seehra Black Cotton Soil Areas FinalmanaliamitNo ratings yet

- Mix DesignDocument18 pagesMix Designawotina67% (3)

- Flexible Pavement Design Methods: Mechanistic, Empirical and Mechanistic-Empirical ApproachesDocument55 pagesFlexible Pavement Design Methods: Mechanistic, Empirical and Mechanistic-Empirical ApproachesShams KhattakNo ratings yet

- Standard Vs Modified ProctorDocument1 pageStandard Vs Modified ProctornickNo ratings yet

- Specification For Bituminous MacadamDocument13 pagesSpecification For Bituminous MacadamtdlongvraNo ratings yet

- Bituminous Material and Pavement DesignDocument35 pagesBituminous Material and Pavement Designmannie edetNo ratings yet

- Flexible Pavement (Bituminous Road) : Compacted Soil SubgradeDocument3 pagesFlexible Pavement (Bituminous Road) : Compacted Soil SubgradeDinesh Kumar PatelNo ratings yet

- Dense Bituminous MacadamDocument22 pagesDense Bituminous MacadamahmadsulNo ratings yet

- Concrete Roads Mix Design Per IRC CodeDocument11 pagesConcrete Roads Mix Design Per IRC CodeAnonymous MaSR3PNo ratings yet

- Bailey Method Achieving Volumetrics HMA Compactability Paper-1 PDFDocument25 pagesBailey Method Achieving Volumetrics HMA Compactability Paper-1 PDFDivya DeenuNo ratings yet

- Mechanistic Pavement DesignDocument9 pagesMechanistic Pavement DesignKulbir ThakurNo ratings yet

- Stabilization of Black Cotton Soil by Admixtures PDFDocument19 pagesStabilization of Black Cotton Soil by Admixtures PDFSantosh NaikNo ratings yet

- Plate Bearing Load TestDocument1 pagePlate Bearing Load TestTk Kendrick Lau100% (1)

- Design of Hot Mix Asphalt Using Bailey Method of GradationDocument8 pagesDesign of Hot Mix Asphalt Using Bailey Method of GradationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Mixing and Compaction Temp of Modified BindersDocument9 pagesMixing and Compaction Temp of Modified BindersreashmapsNo ratings yet

- Geotechnical LabDocument76 pagesGeotechnical LabJAZIRA BINTI JEFFRY -No ratings yet

- Meaning and Review of Jose Gatutura Thii Ukiamaga (Thiĩ Ũkĩũmaga) SongDocument1 pageMeaning and Review of Jose Gatutura Thii Ukiamaga (Thiĩ Ũkĩũmaga) SongMĩrĩng'ũ Wainaina100% (1)

- Black Cotton SoilDocument4 pagesBlack Cotton Soilibson045001256100% (2)

- Experimental Study on Permeable Concrete Pavement for Storm Water ManagementDocument28 pagesExperimental Study on Permeable Concrete Pavement for Storm Water ManagementVaidyanathan SivasubramanianNo ratings yet

- Pothole Repair Technology During Monsoon - by Prof. Prithvi Singh Kandhal, Jaipur, RajasthanDocument3 pagesPothole Repair Technology During Monsoon - by Prof. Prithvi Singh Kandhal, Jaipur, RajasthanVizag Roads100% (1)

- What Is Lean ConcreteDocument2 pagesWhat Is Lean Concreteadam dam jhegsNo ratings yet

- Proposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalDocument14 pagesProposed Revisions To MORTH Specifications For Roads (Fifth Edition Dated 2013) by Prof. KandhalProf. Prithvi Singh KandhalNo ratings yet

- Stabilization of Soil by Using Plastic Wastes: AbstractDocument6 pagesStabilization of Soil by Using Plastic Wastes: AbstractUmange Ranasinghe100% (1)

- Ultra Thin WhitetoppingDocument36 pagesUltra Thin WhitetoppingAnil Kumsr T B100% (1)

- Flexible PavementsDocument13 pagesFlexible PavementsAhmad NajiNo ratings yet

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- Steps To Improve Roads On Black Cotton SoilsDocument13 pagesSteps To Improve Roads On Black Cotton SoilsPerkresht PawarNo ratings yet

- MGT 613Document4 pagesMGT 613MosesGraceNo ratings yet

- P034 Governance ToolsDocument16 pagesP034 Governance ToolsMosesGraceNo ratings yet

- FrackingDocument3 pagesFrackingMosesGraceNo ratings yet

- Project Management and Organisational StrategyDocument12 pagesProject Management and Organisational StrategyfgdgdfgdfgNo ratings yet

- 12988-Wd-E - Tah Annex II Basic Guidelines For Road Classification StandardsDocument25 pages12988-Wd-E - Tah Annex II Basic Guidelines For Road Classification StandardsMosesGraceNo ratings yet

- 01 SCHOOL - 3 ClassroomsDocument11 pages01 SCHOOL - 3 ClassroomsMosesGraceNo ratings yet

- 1 - 470 - PA1302 - 1993 Diseño de Puentes PequeñosDocument7 pages1 - 470 - PA1302 - 1993 Diseño de Puentes Pequeñosmaush2009No ratings yet

- Rural Road CostingDocument11 pagesRural Road CostingMosesGraceNo ratings yet

- Renovation Report: Ramula Primary SchoolDocument8 pagesRenovation Report: Ramula Primary SchoolMosesGraceNo ratings yet

- Onshore UK Oil and Gas Exploration England Dec15Document49 pagesOnshore UK Oil and Gas Exploration England Dec15MosesGraceNo ratings yet

- Wcms 470460Document39 pagesWcms 470460MosesGraceNo ratings yet

- Procurement of Furniture1Document6 pagesProcurement of Furniture1MosesGraceNo ratings yet

- Unpriced BOQ Romula SchoolDocument35 pagesUnpriced BOQ Romula SchoolMosesGraceNo ratings yet

- Aamp Road Draft ContractsDocument1 pageAamp Road Draft ContractsMosesGraceNo ratings yet

- Measuring and Managing Cost EscalationDocument7 pagesMeasuring and Managing Cost EscalationLeo CalejaNo ratings yet

- Unpriced BOQ Romula SchoolDocument35 pagesUnpriced BOQ Romula SchoolMosesGraceNo ratings yet

- 1 Kings 18Document11 pages1 Kings 18MosesGraceNo ratings yet

- Box Culvert ConstructionDocument1 pageBox Culvert ConstructionMosesGraceNo ratings yet

- Revised Programme of Work - Pack-1-MACDOWL (Final)Document7 pagesRevised Programme of Work - Pack-1-MACDOWL (Final)MosesGraceNo ratings yet

- Tower TipsDocument122 pagesTower Tipsdion2110No ratings yet

- Foundations On Black Cotton Soil PDFDocument4 pagesFoundations On Black Cotton Soil PDFMosesGrace100% (1)

- Drilltech D75 LED Vs Halogen (26228)Document2 pagesDrilltech D75 LED Vs Halogen (26228)Oscar Acevedo MirandaNo ratings yet

- I Scarcely Perceptible: Intensity Scale DescriptionDocument15 pagesI Scarcely Perceptible: Intensity Scale DescriptionPete BasNo ratings yet

- LPR EquipmentDocument12 pagesLPR EquipmentsantoshgprNo ratings yet

- Corner Fitting Iso 1161 Type - Bottom Left (243000C-Bl)Document4 pagesCorner Fitting Iso 1161 Type - Bottom Left (243000C-Bl)mabuhamdNo ratings yet

- DIN-1092 Steel Flanges PN Standards DimensionsDocument4 pagesDIN-1092 Steel Flanges PN Standards DimensionsfitiranNo ratings yet

- Gs11m12a01 01e PDFDocument38 pagesGs11m12a01 01e PDFDhirender DagarNo ratings yet

- Heat Treatment GuideDocument33 pagesHeat Treatment GuidefethiaktuncNo ratings yet

- Typical Properties of Copper & AluminiumDocument5 pagesTypical Properties of Copper & AluminiumamoghnawatheNo ratings yet

- Erection Material List JGS320Document2 pagesErection Material List JGS320Rashid Mahmood JaatNo ratings yet

- DRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanyDocument1 pageDRAWING LIMIT N 9403.624: Saudi Arabian Oil CompanybillNo ratings yet

- Heat Transfer EquationsDocument163 pagesHeat Transfer Equationsdragon forceNo ratings yet

- Equipamentos E Processos Térmicos (Equipment and Thermal Processes) ERASMUS - Workgroup 2Document12 pagesEquipamentos E Processos Térmicos (Equipment and Thermal Processes) ERASMUS - Workgroup 2taha akbulatNo ratings yet

- Galambos Ravindra 1976Document103 pagesGalambos Ravindra 1976Eric NolascoNo ratings yet

- Methode Kerja Pondasi Bored Pile: A. Data Teknis: C. Squence of WorksDocument10 pagesMethode Kerja Pondasi Bored Pile: A. Data Teknis: C. Squence of WorksnadhifNo ratings yet

- Parkes-Series-Brochure ALTS Screen FA PDFDocument16 pagesParkes-Series-Brochure ALTS Screen FA PDFgio36No ratings yet

- Bloque de DistribuciónDocument10 pagesBloque de DistribuciónRoberto ArpNo ratings yet

- Heat Exchange Between Non-Black BodiesDocument5 pagesHeat Exchange Between Non-Black BodiesSubindas P KNo ratings yet

- 5 - Threaded Fasteners PDFDocument41 pages5 - Threaded Fasteners PDFViven Sharma100% (1)

- Knauf Product Catalogue Aug2019 WEBDocument28 pagesKnauf Product Catalogue Aug2019 WEBeka suryanaNo ratings yet

- Protective Concrete Coating GuideDocument3 pagesProtective Concrete Coating GuideTori SmallNo ratings yet

- Decor DepoDocument19 pagesDecor Depokh 9No ratings yet

- Steady Incompressible Flow in Pressure Conduits: Lecture - 10Document34 pagesSteady Incompressible Flow in Pressure Conduits: Lecture - 10Nawaz441No ratings yet

- Troubleshooting and Prevention of Cracking in Induction Hardening of Steels - Lessons Learned Part 2Document8 pagesTroubleshooting and Prevention of Cracking in Induction Hardening of Steels - Lessons Learned Part 2Rajesh GNo ratings yet

- Amp Qb.Document6 pagesAmp Qb.svkarthik83No ratings yet