Professional Documents

Culture Documents

TC Manual Fluid Pumps

Uploaded by

vickersCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TC Manual Fluid Pumps

Uploaded by

vickersCopyright:

Available Formats

Page 1 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Temperature Control Manual

FLUID PUMPS

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 2 of 32

Temperature Control Manual Fluid Pumps

TABLE OF CONTENTS

Section

1 1.1 1.2 1.2.1 1.2.2 1.3 2 3 3.1 3.2 3.2.1 3.2.2 3.2.3 3.3 3.3.1 3.3.3 3.4 3.4.1 3.4.2 3.5 3.6 3.6.1 3.6.2 3.6.3 3.6.4 3.6.5 3.6.6 3.6.7 3.6.8 3.6.9 3.7 4

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Page

INTRODUCTION................................................................................................................ 3 Description........................................................................................................................ 3 Equipment......................................................................................................................... 4 Stationary Components................................................................................................ 4 Rotating Components .................................................................................................. 6 Applications...................................................................................................................... 8 TECHNICAL DATA ........................................................................................................... 9 INSTALLATION, OPERATION AND MAINTENANCE (IOM) ............................... 22 Introduction..................................................................................................................... 22 Installation ...................................................................................................................... 22 Location ..................................................................................................................... 22 Foundation ................................................................................................................. 22 Suction and Discharge Hoses .................................................................................... 22 Commissioning ............................................................................................................... 24 Priming ...................................................................................................................... 24 Starting the Unit......................................................................................................... 24 Operation ........................................................................................................................ 25 Operational Checks.................................................................................................... 25 Principal of Operation ............................................................................................... 25 Decommissioning ........................................................................................................... 26 Maintenance Procedures ................................................................................................. 26 Overhaul .................................................................................................................... 26 Change of Mechanical Seal ....................................................................................... 27 Leakage Test.............................................................................................................. 27 Examination of Internal Components........................................................................ 27 Lubrication................................................................................................................. 27 Spanner sizes and recommended torques .................................................................. 27 Service Reports.......................................................................................................... 27 Service Requirements for the Fluid Pumps ............................................................... 28 Maintenance Schedules ............................................................................................. 28 Troubleshooting .............................................................................................................. 31 ELECTRICAL ................................................................................................................... 32

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 3 of 32

Temperature Control Manual Fluid Pumps

1 1.1 INTRODUCTION Description

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Aggrekos Centrifugal Pumps are manufactured by Grundfos ISO LINE, Link Pumps and Regent Pumps. Difference between these types of pumps will be highlighted further in this document. Aggreko utilises six variations of flow rates with two different means of coupling. The pumps range from 3 litre/second to 125 litre/second pumps. These pumps, in particular the Grundfos ISO LINE are an end-suction, back pull out pump. This type of pump is interchangeable with other ISO pumps of the same size, which conforms to the international standard ISO 2858. a. Casing- The pump casing is a highly efficient volute type configuration. The design has been aided with computer technology for high stress resistance and maximum performance. The flanges have been drilled to AS2129 table E (standard) and include tapped connections for suction and pressure gauges. Impeller- The impeller is fully enclosed is hydraulically and dynamically balanced and features double curvature vanes for highly efficient suction performance. Back-plate- This features an O ring seal for positive leak proof connections with the pump casing. Positive location is maintained between the casing and the housing because of the metal to metal face contact thus ensuring that the pump is a rigid structured unit. Shaft- The shaft is a heavy duty 431 stainless steel, which provides maximum protection against deflection at high speeds. The shaft includes a taper mounted and keyed impeller for easy removal during servicing and positive locking during operation. Housing- It is a rigid single piece casting with a positive no gap location, with the casing and ensures accurate coupling alignment. Bearings- As a standard arrangement, sealed for the life greased packed, deep groove, single row ball bearings have been provided. Lip-seals are fitted to prevent the ingress of dust, etc.

Discharge Pressure Gauge

b. c.

d.

e. f.

Discharge Manifold

Discharge Butterfly Valve

Bearing Housing

Suction Manifold

Shaft Seal

Volute Casing

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 4 of 32

Temperature Control Manual Fluid Pumps

1.2 1.2.1 1.2.1.1 Equipment Stationary Components Casing

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

There are generally two types of casings, the volute type and the circular type. The volute casings build a higher head, whilst the circular casings are used for low head and high capacity. A volute is a curved funnel increasing in area to the discharge port. As the area of the cross-section increases, the volute reduces the speed and increases the pressure of the liquid. One of the main purposes of a volute casing is to balance the hydraulic pressure on the shaft of the pump, this occurs best at the manufactures capacity. Running volute-style pumps at a lower capacity than manufacturer recommendation can place lateral stress on the shaft and increase wear and tear on the seals, bearings and on the shaft itself. Double volute casings are used when the radial thrusts become significant at reduced capacities. Circular casings have stationary diffuser vanes surrounding the impeller periphery that convert velocity energy to pressure energy. Conventionally, the diffusers are applied to multi-stage pumps. The casings can be designed either as a solid or split casing. Solid casings imply a design in which the entire casing, including the discharge nozzle is all contained in one casting or fabricated piece. A split casing implies two or more parts are fastened together. When the casing parts are divided by a horizontal plane, the casing is described as horizontally or axially split. When the split is in the vertical plane perpendicular to the rotation axis, the casing is described as vertically or a radially split casing. Casing wear rings act as the seal between the casing and the impeller.

1.2.1.2

Suction and discharge Nozzles

The suction and discharge nozzles are part of the casings itself. They commonly have the following configurations; a. End Suction/ Top Discharge The suction nozzle is located at the end of, and concentric to the shaft, while the discharge nozzle is located at the top of the case perpendicular to the shaft. This pump is always of an overhung type and typically has a lower NPSHr (Net Positive Suction Head required), because the liquid feeds directly into the impeller eye. Top Suction/ Top Discharge The suction and discharge nozzles are located at the top of the case perpendicular to the shaft. This pump can either be an overhung type or between-bearing type but is always a radially split case pump.

b.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 5 of 32

Temperature Control Manual Fluid Pumps

1.2.1.3 Seal Chamber and Stuffing Box

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

The Seal Chamber and Stuffing Box both refer to a chamber which is either integral with or separate from the pump case housing. This forms the region between the shaft and casing and is where the sealing media are installed. When sealing is achieved by means of a mechanical seal, the chamber is commonly referred to as a Seal Chamber. When the sealing is achieved by means of a packing, the camber is referred to as a Stuffing Box. Both the seal chamber and the stuffing box have the primary function of protecting the pump against leakage at the point where the shaft passes through the pump pressure casing. When the pressure at the bottom of the pump is below atmospheric, it prevents air leakage into the pump and when the pressure is above atmospheric, the chamber prevents liquid leakage out of the pump. The seal chambers and stuffing boxes are also provided with cooling or heating arrangements for proper temperature control. The diagram below depicts an externally mounted seal chamber and its parts.

1.2.1.4

Gland

The gland is a very important part of the seal chamber or stuffing box. It gives the packing or the mechanical seal the desired fit on the shaft sleeve. It can be easily adjusted in the axial direction. The gland comprises of a seal flush, quench, cooling, drain and vent connection ports.

1.2.1.5

Throat Bushing

The bottom or inside end of the chamber is provided with a stationary device called a throat bushing that forms a restrictive close clearance around the sleeve (or shaft) between the seals and the impeller.

1.2.1.6

Throttle Bushing

This refers to a device that forms a restrictive close clearance around the sleeve (or shaft) at the outboard end of the mechanical seal gland.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 6 of 32

Temperature Control Manual Fluid Pumps

1.2.1.7 Internal Circulating Device

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

This is a device that is located in the seal chamber to circulate the seal chamber fluid through a cooler or barrier fluid reservoir. This is commonly known as a pumping ring.

1.2.1.8

Bearing House

The bearing housing encloses the bearings mounted on the shaft. The bearings keep the shaft or rotor in the correct alignment with the stationary parts under the action of radial and transverse loads. The bearing house also includes an oil reservoir for lubrication, constant level oiler and a jacket for cooling by circulating cooling water.

1.2.2

Rotating Components

There are three main rotating components in a centrifugal pump, these being; a. b. c. Impeller; Shaft; and Coupling.

1.2.2.1

Impeller

The impeller is the main rotating part that provides the centrifugal acceleration to the fluid. They are often classified in many ways; a. Based on major direction of flow in reference to the axis of rotation, b. Radial flow, Axial flow, Mixed flow. Single suction: liquid inlet on one-side, Double Suction: liquid inlet to the impeller symmetrically from both sides. Closed, shrouds or sidewall enclosing the vanes Open, no shrouds or wall to enclose the vanes, semi open or vortex type.

Based on suction types, -

c.

Based on mechanical construction (Fig 3.), -

Closed impellers require wear rings and these wear rings present another maintenance problem. Open and Semi-open impellers are less likely to clog, but need manual adjustment to the volute or back plate to get the proper impeller setting and prevent internal recirculation. Vortex pump impellers are great for solids and stringy materials but are up to 50 percent less efficient than conventional designs. The number of impellers determines the number of stages in the pump. A single stage pump has a single impeller and is best for low head services. A two stage pump has two impellers in a series for medium head service. A multi-stage pump has three or more impellers in series for high head service.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 7 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Wear rings provide an easy and economically renewable leakage joint between the impeller and the casing. If clearance becomes too large, the pump efficiency will be lowered causing heat and vibration troubles. Most manufacturers require that you disassemble the pump to check the wear ring clearance and replace the rings when this clearance doubles.

1.2.2.2

Shaft

The basic purpose of a centrifugal pump shaft is to transmit the torques encountered when starting and during operation, while supporting the impeller and other rotating parts. It must do this job with a deflection less than the minimum clearance between the rotating and stationary parts. Shafts are usually protected against erosion, corrosion, wear at the seal chambers, leakage joints, internal bearings and the waterways by a component called a renewable sleeve. Unless otherwise specified, a shaft sleeve, where there is an issue with the above conditions, shall be provided to protect the shaft. The shaft shall be sealed at one end. The shaft seal assembly shall extend beyond the outer face of the seal gland plate. Leakage between the shaft and the sleeve should not be confused with leakage through the mechanical seal.

1.2.2.3

Coupling

This component can compensate for axial growth of the shaft and transmit torque to the impeller. Shaft couplings can be broadly classified into two groups, rigid and flexible. a. b. Rigid couplings are used in applications where there is absolutely no possible room of misalignment Flexible shaft couplings are more prone to selection, installation and maintenance errors. Flexible shaft couplings can be divided into two basic groups, elastomeric and non-elastomeric. Elastomeric couplings use rubber or polymer elements to achieve flexibility. These elements can either be in shear or compression. Tire and rubber sleeve designs are elastomer in compression couplings.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 8 of 32

Temperature Control Manual Fluid Pumps

-

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Non-elastomeric couplings use metallic elements to obtain flexibility. These can be one of two type; lubricated or non-lubricated. Lubricated designs accommodate misalignment by the sliding action of their components, hence the need for lubrication. The non-lubricated designs accommodate misalignment through flexing. Gear, grid and chain couplings are examples of non-elastomeric, lubricated couplings. Disc and diaphragm couplings are non-elastomeric and non-lubricated.

1.3

Applications

The Grundfos ISO LINE single stage centrifugal pump is suitable for a wide range of applications including; a. b. c. d. e. Water supply Boosting Circulation of Hot and Cold water Transfer, circulation and boosting of water/glycol mixture (up to 50 percent) solution or glycol based anti-freeze with similar physical and chemical properties. Other thin, non-explosive and non-oleaginous liquids.

While pumping liquids with densities higher than water, motors with corresponding higher outputs should be used.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 9 of 32

Temperature Control Manual Fluid Pumps

2 TECHNICAL DATA

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

08.10.2001

Revision:

Page 9 of 32

Document number

Fluid Pumps

FP 3

au5.3

1.

INTRODUCTION Liquid pumps are used in the refrigeration industry to circulate chilled water or brine. Aggreko has a complete range of centrifugal pumps, adapted to the chiller and air handler rental fleet. Quick camlock fluid connections ensure easy and leakage free connections. The pumps are mounted in a heavy galvanised frame.

2.

KEY-DATA Design Flow Design Pressure head Absorbed Power at duty point Installed Motor Rating Dimensions Length Width Height Weight 3. LAYOUT 3l/s 30 m 3.5 kW 5 kW 1710 mm 530 mm 1210 mm 284 kg

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 10 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

08.10.2001

Revision:

Page 10 of 32

Document number

Fluid Pumps

FP 3

UNITS Regent l/s m m l/s kPA C C

au5.3

VALUE 40-320 D132M 3 30 32 5 No 1400 -15 / 95 -15 / 40 Cast Iron Bronze 416 Stainless kW kW 1rpm V A A Male Socket dB(A) dB(A) 3.5 5 5.5 1450 9.5 57 Clipsal 32A 63 70

4.

TECHNICAL SPECIFICATIONS

ITEM Performance Data Pump Type Motor Type Design Flow 1) Design Head Pressure 1) Maximum Head Pressure 50Hz / 60 Hz Maximum Flow50 Hz / 60 Hz Self Suction Maximum Working Pressure Minimum / Maximum Fluid Temperature Minimum / Maximum Ambient Temperature Pump Material Casing Impeller Pump Shaft Electrical Data Absorbed Power At Duty Point 1) Installed Power Pump RPM Supply Voltage 3 phase Maximum Current Starting Current Cable Connection Noise Data Sound Pressure Level at 1 Metre Sound power level Physical Data Overall Length Overall Width Overall Height Weight Fluid Connections

mm mm 1mm kg mm / inch

1710 530 1210 284 50 / 2" Camlock

NOTE: Contact Technical Department If Application Conditions Differs From Design Conditions1) Design conditions at 1460 RPM, 50 Hz supply

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 11 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.04.1999

Revision:

Page 11 of 32

Document number

Fluid Pumps

FP 10

au5.2

1.

INTRODUCTION Liquid pumps are used in the refrigeration industry to circulate chilled water or brine. Aggreko has a complete range of centrifugal pumps, adapted to the chiller and air handler rental fleet. Quick camlock fluid connections ensure easy and leakage free connections. The pumps are mounted in a heavy galvanised frame.

2.

KEY-DATA Design Flow Design Pressure head Absorbed Power at duty point Installed Motor Rating Dimensions length Width Height Weight 10 l/s 30 m 6.5 kW 7.5 kW 1710 mm 530 mm 1210 mm 335 kg

3.

LAYOUT

aggre

TC Manual Fluid Pumps.doc Aggreko Australia Pacific

Page 12 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

ko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.04.1999

Revision:

Page 12 of 32

Document number

Fluid Pumps

FP 10

UNITS Southern Cross l/s m m l/s kPA C C

au5.2

4.

TECHNICAL SPECIFICATIONS ITEM Performance Data Pump Type Motor Type Design Flow 1) Design Head Pressure 1) Maximum Head Pressure 50Hz / 60 Hz Maximum Flow 50 Hz / 60 Hz Self Suction Maximum Working Pressure Minimum / Maximum Fluid Temperature Minimum / Maximum Ambient Temperature Pump Material Casing Impeller Pump Shaft Electrical Data Absorbed Power At Duty Point 1) Installed Power Pump RPM Supply Voltage 3 phase Maximum Current Starting Current Cable Connection Noise Data Sound Pressure Level at 1 Metre Sound power level Physical Data Overall Length Overall Width Overall Height Weight Fluid Connections

1)

VALUE 10x50-315 D132M 10 30 43 12.5 No 1400 -15 / 95 -15 / 40 Cast Iron Zinc Free Bronze 416 Stainless

kW kW rpm V A A Male Socket dB(A) dB(A) mm mm mm kg mm / inch

6.5 7.5 1450 415 14.1 84.6 Clipsal 32A 63 70 1710 530 1210 335 100 / 4"

NOTE: Contact Technical Department If Application Conditions Differs From Design Conditions

Design conditions at 1460 RPM, 50 Hz supply

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 13 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.04.1999

Revision:

Page 13 of 32

Document number

Fluid Pumps

FP 30

au5.1

1.

INTRODUCTION Liquid pumps are used in the refrigeration industry to circulate chilled water or brine. Aggreko has a complete range of centrifugal pumps, adapted to the chiller and air handler rental fleet. Quick camlock fluid connections ensure easy and leakage free connections. The pumps are mounted in a heavy galvanised frame. 2. KEY-DATA 30 l/s 30 m 11.8 kW 15.0 kW 1710 mm 620 mm 1210 mm 493 kg

Design Flow Design Pressure head Absorbed Power at duty point Installed Motor Rating Dimensions length Width Height Weight 3. LAYOUT

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 14 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.04.1999

Revision:

Page 14 of 32

Document number

Fluid Pumps

FP 30

UNITS Southern Cross l/s m m l/s kPA C C

au5.1

VALUE 80 - 160 D160L 30 30 33.5 45 No 1400 -15 / 95 -15 / 40 Cast Iron Zinc Free Bronze 416 Stainless kW kW rpm V A A Male Socket dB(A) dB(A) mm mm mm kg mm / inch 11.8 15 1450 415 27.7 166.2 Clipsal 32A 63 70 1710 610 1210 493 100 / 4"

4.

TECHNICAL SPECIFICATIONS

ITEM Performance Data Pump Type Motor Type Design Flow 1) Design Head Pressure 1) Maximum Head Pressure 50Hz / 60 Hz Maximum Flow 50 Hz / 60 Hz Self Suction Maximum Working Pressure Minimum / Maximum Fluid Temperature Minimum / Maximum Ambient Temperature Pump Material Casing Impeller Pump Shaft Electrical Data Absorbed Power At Duty Point 1) Installed Power Pump RPM Supply Voltage 3 phase Maximum Current Starting Current Cable Connection Noise Data Sound Pressure Level at 1 Metre Sound power level Physical Data Overall Length Overall Width Overall Height Weight Fluid Connections

1)

NOTE: Contact Technical Department If Application Conditions Differs From Design Conditions

Design conditions at 1460 RPM, 50 Hz supply

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 15 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

08.10.2001

Revision:

Page 15 of 32

Document number

Fluid Pumps

FP 50

au5.4

1.

INTRODUCTION Liquid pumps are used in the refrigeration industry to circulate chilled water or brine. Aggreko has a complete range of centrifugal pumps, adapted to the chiller and air handler rental fleet. Quick camlock fluid connections ensure easy and leakage free connections. The pumps are mounted in a heavy galvanised frame.

2.

KEY-DATA Design Flow Design Pressure head Absorbed Power at duty point Installed Motor Rating Dimensions length Width Height Weight 50 l/s 30 m 18.8 kW 22.0 kW 1770 mm 620 mm 1210 mm 624 kg

3.

LAYOUT

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 16 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

08.10.2001

Revision:

Page 16 of 32

Document number

Fluid Pumps

FP 50

au5.4

4.

TECHNICAL SPECIFICATIONS

ITEM UNITS Regent l/s m m l/s kPA C C VALUE 125 - 320 D160L 50 30 33.5 65 No 1400 -15 / 95 -15 / 40 Cast Iron Zinc Free Bronze 416 Stainless kW kW rpm V A A Male Socket dB(A) dB(A) mm mm mm kg mm / inch mm / inch 18.8 22 1450 415 38.2 229.2 Clipsal 50A 63 70 1770 610 1210 624 100 / 4" male camlock 2 X 100 / 4 female camlock

Performance Data

Pump Type Motor Type Design Flow 1) Design Head Pressure 1) Maximum Head Pressure 50Hz / 60 Hz Maximum Flow 50 Hz / 60 Hz Self Suction Maximum Working Pressure Minimum / Maximum Fluid Temperature Minimum / Maximum Ambient Temperature

Pump Material

Casing Impeller Pump Shaft

Electrical Data

Absorbed Power At Duty Point 1) Installed Power Pump RPM Supply Voltage 3 phase Maximum Current Starting Current Cable Connection

Noise Data

Sound Pressure Level at 1 Metre Sound power level

Physical Data

Overall Length Overall Width Overall Height Weight Fluid Connections

:Discharge :Suction

NOTE: Contact Technical Department If Application Conditions Differs From Design Conditions

1)

Design conditions at 1460 RPM, 50 Hz supply

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 17 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.08.2000

Revision:

Page 17 of 32

Document number

Fluid Pumps

FP 75

au5.5

1.

INTRODUCTION Liquid pumps are used in the refrigeration industry to circulate chilled water or brine. Aggreko has a complete range of centrifugal pumps, adapted to the chiller and air handler rental fleet. Quick camlock fluid connections ensure easy and leakage free connections. The pumps are mounted in a heavy galvanised frame.

2.

KEY-DATA Design Flow Design Pressure head Absorbed Power at duty point Installed Motor Rating Dimensions length Width Height Weight 75 l/s 30 m 35.0 kW 45.0 kW 2270 mm 800 mm 1490 mm 910 kg

3.

LAYOUT

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 18 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

14.08.2000

Revision:

Page 18 of 32

Document number

Fluid Pumps

FP 75

UNITS Regent CMG l/s m m l/s kPA C C

au5.5

4.

TECHNICAL SPECIFICATIONS

ITEM Performance Data Pump Type Motor Type Design Flow 1) Design Head Pressure 1) Maximum Head Pressure 50Hz / 60 Hz Maximum Flow 50 Hz / 60 Hz Self Suction Maximum Working Pressure Minimum / Maximum Fluid Temperature Minimum / Maximum Ambient Temperature Pump Material Casing Impeller Pump Shaft Electrical Data Absorbed Power At Duty Point 1) Installed Power Pump RPM Supply Voltage 3 phase Maximum Current Starting Current Cable Connection Noise Data Sound Pressure Level at 1 Metre Sound power level Physical Data Overall Length Overall Width Overall Height Weight Fluid Connections :Discharge VALUE 150 - 320 SGA 225m-4 75 30 32 120 No 1400 -15 / 95 -15 / 40 Cast Iron Zinc Free Bronze 416 Stainless

kW kW rpm V A A Cable box m12 dB(A) dB(A) mm mm mm kg mm / inch

35 45 1450 415 78 350 3 phase + E 63 70

2270 800 1490 HOLD 2X 100 / 4" male camlock :Suction mm / inch 3 X 100 / 4 fmale camlock NOTE: Contact Technical Department If Application Conditions Differs From Design Conditions 1) Design conditions at 1460 RPM, 50 Hz supply

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 19 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

08.10.2001

Revision:

Page 19 of 32

Document number

Fluid Pumps

FP100

au5.6

1.

INTRODUCTION Liquid pumps are used in the refrigeration industry to circulate chilled water or brine. Aggreko has a complete range of centrifugal pumps, adapted to the chiller and air handler rental fleet. Quick camlock fluid connections ensure easy and leakage free connections. The pumps are mounted in a heavy galvanised frame.

2.

KEY-DATA Design Flow Design Pressure head Absorbed Power at duty point Installed Motor Rating Dimensions length Width Height Weight 100 l/s 30 m 35.0 kW 45.0 kW 2270 mm 800 mm 1490 mm 947kg

3.

LAYOUT

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 20 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Adam Hentschel

Date:

08.10.2001

Revision:

Page 20 of 32

Document number

Fluid Pumps

FP100

UNITS Regent CMG l/s m m l/s kPA C C

au5.6

4.

TECHNICAL SPECIFICATIONS

ITEM Performance Data Pump Type Motor Type Design Flow 1) Design Head Pressure 1) Maximum Head Pressure 50Hz / 60 Hz Maximum Flow 50 Hz / 60 Hz Self Suction Maximum Working Pressure Minimum / Maximum Fluid Temperature Minimum / Maximum Ambient Temperature Pump Material Casing Impeller Pump Shaft Electrical Data Absorbed Power At Duty Point 1) Installed Power Pump RPM Supply Voltage 3 phase Maximum Current Starting Current Cable Connection Noise Data Sound Pressure Level at 1 Metre Sound power level Physical Data Overall Length Overall Width Overall Height Weight Fluid Connections :Discharge VALUE 150 - 320 SGA 225m-4 75 30 32 120 No 1400 -15 / 95 -15 / 40 Cast Iron Zinc Free Bronze 416 Stainless

kW kW rpm V A A Cable box m12 dB(A) dB(A) mm mm mm kg mm / inch

35 45 1450 415 78 350 3 phase + E 63 70

2270 800 1490 HOLD 3 X 100 / 4" male camlock :Suction mm / inch 4 X 100 / 4 fmale camlock NOTE: Contact Technical Department If Application Conditions Differs From Design Conditions 1) Design conditions at 1460 RPM, 50 Hz supply

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 21 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

aggreko

Prepared by: Discipline: Section:

Date:

08.10.2001

Revision:

Page 21 of 32

Document number

Fluid Pumps

FP125

au5.7

1.

INTRODUCTION Liquid pumps are used in the refrigeration industry to circulate chilled water or brine. Aggreko has a complete range of centrifugal pumps, adapted to the chiller and air handler rental fleet. Quick camlock fluid connections are available to ensure easy and leakage free connections. The pumps are mounted in a heavy painted steel frame. 2. KEY-DATA Design Flow 125 l/s Design Pressure head 30 m Absorbed Power at duty point 40.0 kW Installed Motor Rating 45.0 kW Dimensions length 1930 mm Width 830 mm Height 1560 mm Weight 912kg

3.

LAYOUT

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 22 of 32

Temperature Control Manual Fluid Pumps

3 3.1

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

INSTALLATION, OPERATION AND MAINTENANCE (IOM) Introduction

Installation of our pumps is of utmost importance. The operating life will be greatly determined on how the pumps are positioned. The ground must be compact and level and various factors must be considered ie: if the discharge hoses have not been secured to the main frame and carry their own weight. This will place added radial stress on the shaft and will also wear bearings and shaft seals causing premature breakdown of the units.

3.2 3.2.1

Installation Location

The pump should be located in a dry, well ventilated and frost free area. The unit should be as near as possible to the source of the liquid that is being pumped, which is to involve the smallest suction lift and the shortest length of suction hose. Care should be taken to ensure that the pump module is at least 150mm (6) clear of obstructions and that adequate air supply reaches the motor casing cooling fan.

3.2.2

Foundation

A solid foundation is required for the positioning of the unit. A suitable level base, be it concrete, compacted gravel or soil should be sought. If the unit is required to be situated at an elevated position, the structure should be able to support at least 1 times the accumulated weight (this includes associated piping and fluid).

3.2.3

Suction and Discharge Hoses

All hose/pipe-work should be adequately supported so that there is no external load imposed on the pump body as shown below. The shaft must be free to turn after the pump has been installed and the hoses/ pipe-work connected. Suction piping must be free from air leaks and should be short as possible. The hoses should be rigid and the internal roughness of the hose should be minimal. They should gradually fall away from the pump to the liquid source to maintain suction pressure efficiency. Discharge piping should be selected of a size suitable to carry the required capacity, such that the friction head created is not excessive.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 23 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Try and keep the hoses straight as possible. Bends are not to be aggressive.

Fluid Pump

Minimise Head Pressures Try and keep the suction hose length short as possible

This will minimise the load on the shaft and shaft seal.

Secure discharge hoses here.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 24 of 32

Temperature Control Manual Fluid Pumps

3.3 Commissioning

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Prior to a Fluid Pump being brought on line, the flex hose associated with the unit, should be flushed through (where possible). This will clear any deposits that may of accumulated in the hose from the previous job or from transport. If this is not accomplished, there may be a possibility of damaging the impeller or shaft seal.

3.3.1

Priming

Centrifugal pumps must not be run dry or part full. The fine internal clearances depend upon the pumped liquid for lubrication. If this occurs, galling or seizure of internal components can result. The mechanical seal will also be severely damaged by any dry running. The pumps are not a self priming unit, and therefore require the following before starting the unit; a. b. Once all hoses are connected, open all vent cocks whilst filling to expel trapped air in the water system. Where possible, the pump shaft should be rotated slowly to expel air trapped in the casing/ impeller. It should not be necessary to re-prime the pump before subsequent starts if the integrity of the suction line remains intact. Where rotation of the shaft is not possible, jogging the unit (as for the direct-drive units) will accomplish the same as hand rotation.

c.

3.3.3

Starting the Unit

Prior to starting the unit, the following pre-start checks are required to be carried out; a. Ensure the priming procedures have been carried out correctly. NOTE: To avoid damage, do not run the pump with the discharge valve in the fully closed position for pro-longed periods b. c. d. Ensure the discharge valve is fully closed. Apply power to the unit. Test all emergency stops, alarm trips and inter-locks are operational and set to correct values. Ensure that the direction of rotation conforms with directional arrow located on pump casing.

Once all pre-start checks have been completed the unit can be started. When the pump reaches full speed, slowly open the discharge valve until the desired capacity is reached. If there is no delivery of fluid shut-down the pump immediately. CAUTION- Opening the discharge valve too quickly may result in over-loading of the pump driving unit, especially if the pump is discharging into an empty system, as the delivery pressure may fall below the designed pressure.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 25 of 32

Temperature Control Manual Fluid Pumps

3.4 3.4.1 Operation Operational Checks

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Once the unit is in operation, it is important to carry out the following checks; a. b. c. Ensure pump is not generating less than its rated delivery pressure. Listen for abnormal noise and visually inspect mechanical shaft-seal for leaks. Record pressures, temperature of bearings and ammeter readings on rounds sheets. NOTE: The Ideal running temperature of a bearing is 40-60deg C. This can be slightly exceeded providing that the temperature is steady and not rising, however the temperature is not to exceed 80 deg C. d. e. Complete a thorough visual inspection of all hose connections for leaks. Check emergency stop action

3.4.2

Principal of Operation

All centrifugal pumps use an impeller and volute to create the partial vacuum and discharge pressure necessary to move water through the casing. The impeller and volute form the heart of the pump and help determine its flow, pressure and solid handling capability. In order for a centrifugal pump, or self priming, pump to attain its initial prime the casing must first be manually primed or filled with water. Afterwards, unless it is run dry or drained, a sufficient amount of water should remain in the pump to ensure quick priming the next time it is needed.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 26 of 32

Temperature Control Manual Fluid Pumps

3.5 Decommissioning

The decommissioning procedure is as follows: a. b. c. d. e. f.

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Start to close the discharge valve until it is 75% closed. This will reduce the load on the unit. Leave for a few minutes. Stop the unit. When the pump has come to rest, fully close the discharge valve. Fully close the suction valve (where fitted, or isolate buffer tank). Slowly drain water. Cap all suction inlets and discharge outlets when hoses have been disconnected.

3.6 3.6.1

Maintenance Procedures Overhaul

NOTE: If spacer type coupling has been fitted between the pump and the driver, the pump casing can remain bolted to the suction and the discharge pipes. The following is required for a complete overhaul: a. b. Remove the back-plate to casing bolts. Jacking screw holes are provided in the back-plate to facilitate removal of the bearing housing shaft element; Unscrew the impeller nut (two turns should be sufficient, but can vary), drive a pair of wooden or metal wedges gently between the impeller and back-plate to prevent distortion of the impeller. Using a soft-face hammer, hit the impeller nut in order to spring the impeller from the taper. Remove impeller nut and sealing washer and lift off impeller. Lift out impeller key and slide the moving section of the mechanical seal from the shaft. Remove the bearing housing to back-plate bolts and remove the back-plate. NOTE: Some pumps do not have separate housing to back-plate bolts and these would have been removed in Step 1. d. e. Remove stationary face of mechanical seal by tapping out gently with a piece of wood. Remove the bearing cover to bearing housing bolts. By tapping the shaft on the drive end with a piece of wood the shaft/bearing assembly and bearing cover can be removed.

c.

A pump that has become worn in the body, impeller or back-plate may be repaired by fitting bronze wear rings. These rings, with full instruction for machining the pump parts and fitting rings are obtainable from the nearest GRUNDFOS sales office or dealer. NOTE: Unnecessary removal of the bearings should be avoided as frequent removal can cause deterioration of the interference fit. Bearings should only be removed if they need closer inspection.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 27 of 32

Temperature Control Manual Fluid Pumps

3.6.2 Change of Mechanical Seal

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

If a leak of 1-2 drops per minute or more is found in the seal, it will have to be replaced. This type of seal is not adjustable, and therefore a leak is a sign of a damaged seal.

3.6.3

Leakage Test

After the assembly is complete, fill the pump with water and connect to the pressure network (max 10bar) to check for leakage.

3.6.4

Examination of Internal Components

With the pump and rotating element dismantled, the internal components and the clearances can be checked. a. Casing Wear Ring- Use an internal micrometer to measure the bore of the casing wear ring, taking measurements at intervals around the circumference to check for uneven wear. Compare dimensions with the impeller neck and refer to the allowable clearances. New wear rings can be fitted in order to restore design dimensions and obtain the design hydraulic performance. Impeller- Inspect the impeller for mechanical damage, corrosive pitting and cavitation. If damage is extensive the impeller may need replacing. Examine the eye at neck portion for grooving. Slight grooving is acceptable, however deep or profuse grooving is not, and requires machining of the impeller and then fitting the neck ring. Shaft- This should be checked for mechanical damage and corrosion. If the shaft is not true within 0.1mm TIR, it should be replaced or repaired.

b.

c.

3.6.5

Lubrication

The bearings are grease packed and sealed for life and need no further lubrication.

3.6.6

Spanner sizes and recommended torques

a. No. 1 Shaft Module: Pump Driven End Diameter 24mm. 13mm, 17mm and 19mm AF spanner and a 19mm Socket for the impeller Nut. Impeller Nut torque 30nm. No. 2 Shaft Module: Pump Driven End Diameter 32mm. 13mm, 17mm, 19mm and 24mm AF Spanners and a 5/8 Whit socket for the Impeller Nut. Impeller Nut torque 74nm. No. 3 Shaft Module: Pump Driven End Diameter 42mm. 17mm, 19mm, 30mm AF Spanners and a 3/4 Whit socket for the Impeller Nut. Impeller Nut torque 144nm.

b.

c.

3.6.7

Service Reports

Service reports play a very important role in monitoring machinery, developing trends and enabling proper planning of corrective maintenance. The deterioration of the equipment will become inevitable without monitoring the service reports.

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 28 of 32

Temperature Control Manual Fluid Pumps

3.6.8 Service Requirements for the Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

The service for the fluid pumps is an A service. This is to be conducted every three (3) calendar months (where possible) and on return to depot after hire. Before commencing, complete a review of the most recent service reports for any abnormalities or defects. CAUTION Ensure that the pump is isolated from its electrical supply before commencing with the shutdown inspections. A Danger Tag should be fitted to all machinery that work is being conducted on.

3.6.8.1

Operation

The service requirements for the operation are as follows: a. b. c. d. Complete thorough leak search; Record motor current in full operation; Observe for any abnormal sound or vibration; and Check Emergency stop action.

3.6.8.2

Shutdown

The service requirements for the shutdown of the units are as follows: a. b. c. d. e. f. g. h. i. j. Complete thorough cleaning of pump housing and frame; Check for any visual damage; Inspect and grease bearing/s as required; Check control panel wiring; Check safety inter-locks; Inspect condition of contactors; Confirm contactor over load settings; Confirm contactor action; Flush through and clean drain valve; and Complete full wash down of unit.

3.6.9

Maintenance Schedules

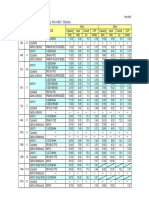

The following are the Maintenance Schedules for the Aggreko Fluid Pumps:

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 29 of 32

Temperature Control Manual Fluid Pumps

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Maintenance Schedule for Aggreko's Centrifugal Liquid Handling Pumps No: FP3, FP10, FP30, FP50, FP75, FP100 and FP125:

Item No. Operation and Maintenance Instructions

On Hire and Installation Monthly or at 750 Hours 6-Monthly or at 4300 Hours Completion of Hiring and Decomm. At 36 Cumulative Months of Operation

Note: for detail descripttion of installation, commissioning, start-up, trouble-shooting, etc., please refer to Installation and Operating Instructions booklet of Grundfos Pumps contained in this IOM manual. For the placement & installation of the modular pump assembly choose a horizontal and well-ventilated site free from debris, dust, water, obstructions, etc. Ensure to allow access for installation and connection of suction and discharge piping, power supply cabling, and drainage. Allow access and space for service & maintenance at all times. Check and ensure that all safety warning signs and instructions are intact and clearly visable to the occupants in the vicinity and to the authorised technicians to work on the pump assembly. Prior to starting the pump check and ensure that: 1. protective safety guards are securely in place. 2. pump coupling is aligned and tightened. 3. all shaft bearings are properly lubricated. 4. pump priming is properly carried out. 5. discharge valve is closed. 6. suction valve is fully open. 7. power supply for the electric motor is available 8. all electrical contactors, relays, alarm trips, indicators,circuit breakers, etc., are operational and set to their correct operating values and tolerances. 9. direction of the electric motor shaft rotation is the same as the direction of arrow on the pump. Start the pump only upon after checking, inspecting, and ensuring proper and safe operation of the pump and the other equipment in the system set-up. When the pump reaches full speed, open the discharge valve gradually until the desired liquid flow rate is reached. If no liquid is being pumped, shut down the unit immediately. Upon reaching specified full flow rate and stable running, check and ensure that: 1. pump is delivering not less than its rated delivery pressure. 2. discharge pressure gauge andf suction and discharge pressure differential pressure gauge are both showing normal or specified operating conditions. 7 3. no excessive vibrations generated by the motor-pump assembly. 4. no excessive heating generated by the pump seals and the motor bearings. 5. no exceptional noise generated by the pump seals and the motor bearings. 6. no leaks from suction and discharge valves. 7. leaks from valve glands and/ or connections are stopped. 8 Check full load amps against nameplate rating. X X X X

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 30 of 32

Temperature Control Manual Fluid Pumps

Item No.

On Hire and Installation Monthly or at 750 Hours 6-Monthly or at 4300 Hours

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Operation and Maintenance Instructions

Completion of Hiring and Decomm.

At 36 Cumulative Months of Operation

9 10 11 12

Check and ensure that pump and associated pipeworks are vented and free of any air entrapment. Check the pressure gauge readings and ensure that the strainer is clean. Clean pump strainer by physically removing basket. Inspect pump gland adjust the leakage to one drop per minute. If the packing cannot be adjusted any further replace the gland to pump manufacturer's recommendation. Check and ensure that the gland well and the gland drain line are clear of any obstructions. With pump running, lightly lubricate bearings for pump and motor, as necessary. Check, clean, and lubricate/ grease pump and motor bearings. Check pump-motor coupling buffer material and replace if worn. Clean pump generally. Check and readjust pump and motor alignment. Megger motor windings. Check coupling bushes for wear. If worn, replace bushes and check pump-motor alignment. Inspect exposed surfaces for corrosion, repair paintwork, as necessary. Apply complete overhauling by dismantling, inspecting, repairing, replacing, reassembling, and testing. Please see overhauling procedures of Installation and Operating Instructions booklet of Grundfos Pumps in this IOM manual.

X X

X X X X

13 14 15 16 17 18 19 20 21

X X

X X

X X X X X X X X

X X X X X X X

22

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 31 of 32

Temperature Control Manual Fluid Pumps

3.7 Troubleshooting

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

Problem

Failure to deliver water or operating below rated capacity Suction and discharge piping Pump

Possible Cause

Long suction, short delivery (Minimum discharge head of 1.5m will help emilinate) Obstruction in line (closed valve, suction strainer blocked, low water level, loss in pipes Air leaks in suction piping or joints, worn or damaged mechanical seal Pump not properly primed Speed too low Discharge head beyond pumps rating. Excessive suction lift Incorrect rotation direction Impeller blocked Air or gas in liquid handling Incorrect alignment of coupling Unsupported pipes adding stress to pump Bent shaft Worn Bearings Total head lower then estimated (causing too much water) Therefore need to throttle capacity using a gate valve Pump speed too high Density of liquid greater then water Bent shaft Pump jammed Misalignment Misalignment Foundation not rigid Impeller blocked Worn bearings Unbalanced coupling or pulley Cavitations from air or gases in liquid Abrasion caused by solid particles Corrosive action of liquid pumped Foreign body jammed in impeller or body Impeller binding in body Pump not primed Cavitations noise

Hot Bearings

Power consumption too high

Excessive Vibration

Excessive internal wear of Pump

Noisy operation

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

Page 32 of 32

Temperature Control Manual Fluid Pumps

4 ELECTRICAL

Version 0.1 Date: 1/02/2007 Prepared By: Justin Day Engineering Department

The following schematics are based on the latest supply of the fluid pumps (3l/s, 10l/s, 30l/s, 50l/s, 75l/s and 100l/s) Note: The 75l/s and 100 l/s pumps have the same drawing as the motors are the same size. The 75 l/s and below are capable of operating on 50 or 60Hz power, where the 100l/s is strictly 50Hz. The combined panel drawings for Aggrekos fluid pumps are as follows; a. b. c. d. e. f. 3 l/s pump 5.5kW Starter NHP Drg No MCL10443 Rev 0 10 l/s pump 7.5kW Starter - NHP Drg No MCL10444 Rev 0 30 l/s pump 18.5kW Starter - NHP Drg No MCL10445 Rev 0 50 l/s pump Awaiting from manufacturer. 75 l/s pump 45kW Starter NHP Drg No MCL10085 Rev 1 100 l/s pump 45kW Starter - NHP Drg No MCL10085 Rev 1

TC Manual Fluid Pumps.doc

Aggreko Australia Pacific

You might also like

- ASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFDocument74 pagesASHRAE Testing-Adjusting-Balancing-HVAC-Systems PDFvickers100% (1)

- Alarms and Fault CodesDocument5 pagesAlarms and Fault CodesRaghavendra KaleNo ratings yet

- Centrifugal Pumps CourseDocument108 pagesCentrifugal Pumps CoursefotopredicNo ratings yet

- Vertiv Liebert PCW Brochure With PH 250Document8 pagesVertiv Liebert PCW Brochure With PH 250Asad Nizam100% (1)

- Chiller Types and ApplicationsDocument73 pagesChiller Types and Applicationsvickers100% (3)

- TC Manual Water Cooled ChillersDocument24 pagesTC Manual Water Cooled Chillersvickers100% (1)

- McQuay BrochureDocument24 pagesMcQuay BrochureAna Gil Pinto BrásNo ratings yet

- ZF 665 Series: Product DetailsDocument4 pagesZF 665 Series: Product DetailsJhonAlexRiveroNo ratings yet

- Install and Prepare CompressorsDocument36 pagesInstall and Prepare CompressorsArief Budiman Hermani100% (7)

- Danfoss Facts Worth Knowing About ACDrivesDocument208 pagesDanfoss Facts Worth Knowing About ACDrivesvickersNo ratings yet

- PLC Vs ControllerDocument4 pagesPLC Vs ControllerththeeNo ratings yet

- Installation Operation Maintenance: Air-Cooled Scroll ChillersDocument276 pagesInstallation Operation Maintenance: Air-Cooled Scroll ChillersCésarVanegasNo ratings yet

- Chiller Installation InstructionsDocument36 pagesChiller Installation InstructionsIsaias RamirezNo ratings yet

- 518 STD Usa Centrifuge Manual Part 90 90 061 Reva21 PDFDocument109 pages518 STD Usa Centrifuge Manual Part 90 90 061 Reva21 PDFChemist - Aban DD8No ratings yet

- Simpson - Boiler Feed Pump Turbine Case StudyDocument11 pagesSimpson - Boiler Feed Pump Turbine Case Studyvinothenergy100% (1)

- 9852 2462 01 Maintenance Instructions COP 1838HDDocument26 pages9852 2462 01 Maintenance Instructions COP 1838HDMario AS100% (4)

- Danfoss Banana Ripening Application BrochureDocument6 pagesDanfoss Banana Ripening Application BrochurevickersNo ratings yet

- CDM6225 (MBB) 零件图册Document159 pagesCDM6225 (MBB) 零件图册Emmanuel Silvestre MonserratNo ratings yet

- Maintenance of Electrical Motors 1.5Document9 pagesMaintenance of Electrical Motors 1.5Sayed NagyNo ratings yet

- Rooftop Trane Voyager tch180 tch150 tch240Document108 pagesRooftop Trane Voyager tch180 tch150 tch240Leandro P SilvaNo ratings yet

- Start-Up Checklist For Chiller SystemsDocument4 pagesStart-Up Checklist For Chiller SystemsPraveenkumar Kashyab0% (1)

- Pump Iso13709 Api610 bb3 Multistage DVMX Marelli Maintenance Manual EnglishDocument25 pagesPump Iso13709 Api610 bb3 Multistage DVMX Marelli Maintenance Manual EnglishJuan Pablo Chumba Lara100% (1)

- Electrical Nomenclature 02-07Document4 pagesElectrical Nomenclature 02-07Nebur Mtza100% (2)

- SM MultiV IV Air Outdoor Units 4 15 - 20150414080917Document150 pagesSM MultiV IV Air Outdoor Units 4 15 - 20150414080917Gino Waximinguirijillo Santana100% (3)

- AnnuallyDocument70 pagesAnnuallyFloreidNo ratings yet

- TC Manual Air Cooled Chillers PDFDocument26 pagesTC Manual Air Cooled Chillers PDFhandy repair general0% (1)

- AERCO Boiler Benchmark 3.0Document129 pagesAERCO Boiler Benchmark 3.0hfdadl100% (1)

- Technical Specifications For LPG Tank TruckDocument11 pagesTechnical Specifications For LPG Tank TruckDayo Idowu100% (2)

- MD Reading 3 4Document96 pagesMD Reading 3 4asapamoreNo ratings yet

- The Power & Temperature Rental Leader's 497 kW Air Cooled Fluid ChillerDocument5 pagesThe Power & Temperature Rental Leader's 497 kW Air Cooled Fluid ChillerMateen YounasNo ratings yet

- WSHP SVX01P en - 01202016Document128 pagesWSHP SVX01P en - 01202016Jesus LizarazoNo ratings yet

- Chiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonDocument152 pagesChiller CGA MInstallation, Operation, Air-Cooled Scroll Chillers 20-130 TonvickersNo ratings yet

- 150RZGDocument4 pages150RZGJorge Andre Olivera Aranibar100% (1)

- Read This Manual Before Installation and Operation Make Sure That It Is Well Kept For Later ReferenceDocument32 pagesRead This Manual Before Installation and Operation Make Sure That It Is Well Kept For Later Referenceelshan_asgarov100% (1)

- Operation and Maintenance Manual: Maxp Series AnsiDocument40 pagesOperation and Maintenance Manual: Maxp Series AnsiCarlos GomezNo ratings yet

- Frequency of Maintenance TestingDocument5 pagesFrequency of Maintenance TestingIsmael AhmedNo ratings yet

- Building Sustainability AnalysisDocument25 pagesBuilding Sustainability AnalysisvickersNo ratings yet

- Geared Variable-Speed Couplings for Precise Control of Maximum PowersDocument14 pagesGeared Variable-Speed Couplings for Precise Control of Maximum Powers050678No ratings yet

- Maintenances Schedules (LHB)Document11 pagesMaintenances Schedules (LHB)Parthaprotim Nath100% (3)

- CatalogoWEG Completo de Motores WegDocument362 pagesCatalogoWEG Completo de Motores WegJoseph Villamar Manrique100% (1)

- C0210101-02-11-EN Installation - manuals - Generale - EN - 印刷 PDFDocument20 pagesC0210101-02-11-EN Installation - manuals - Generale - EN - 印刷 PDFNhật Phong NguyễnNo ratings yet

- HFCC D Iom 03Document16 pagesHFCC D Iom 03geovany_villagraNo ratings yet

- Replacement For DWM Compressors PDFDocument13 pagesReplacement For DWM Compressors PDFssgrunfNo ratings yet

- Induction MotorDocument14 pagesInduction Motoraryans143sNo ratings yet

- Liebert ACTech ManualDocument52 pagesLiebert ACTech ManualMohamed Abou El hassanNo ratings yet

- Snag List-Hyatt House Hvac and Chiller System Valve Pakage CD Fa Duct Rooms or Areas Fcu and Duct ConnectionDocument10 pagesSnag List-Hyatt House Hvac and Chiller System Valve Pakage CD Fa Duct Rooms or Areas Fcu and Duct ConnectionriyasudheenmhNo ratings yet

- Chiller Carrier 30XA-400Document26 pagesChiller Carrier 30XA-400edwin ramirezNo ratings yet

- 38aks016 CarrierDocument138 pages38aks016 CarrierYolanda Borbon100% (1)

- DocumentDocument5 pagesDocumentBahrowi Adi WijayaNo ratings yet

- Checklist FasilitiesDocument2 pagesChecklist FasilitieszaindinNo ratings yet

- A-W and A-F Oil SeparatorsDocument1 pageA-W and A-F Oil SeparatorstribleprinceNo ratings yet

- D81 1 N - 1009 enDocument68 pagesD81 1 N - 1009 enbotondh77No ratings yet

- Service parts for 74mm screw compressorsDocument1 pageService parts for 74mm screw compressorsPrince RajaNo ratings yet

- MotorDocument165 pagesMotorare_reeNo ratings yet

- Asy Iom MCS PDFDocument140 pagesAsy Iom MCS PDFMohammed IsmailNo ratings yet

- Datasheet WEG MOTORDocument1 pageDatasheet WEG MOTORThiago ColzaniNo ratings yet

- Midea High-Temperature Direct-Heating Heat Pump Water Heater Technical ManualDocument47 pagesMidea High-Temperature Direct-Heating Heat Pump Water Heater Technical ManualCésar Tejos ElizondoNo ratings yet

- 38CKC Product DataDocument26 pages38CKC Product DataCarlos Enrique Godoy Sifontes0% (1)

- 160.49-PW14york Solid State StarterDocument4 pages160.49-PW14york Solid State StarterAwo Orumila Giraldolegra0% (1)

- Catalogo CopelandDocument320 pagesCatalogo CopelandFranklin Avendaño Carbajal100% (1)

- Pressure Vacuum BleedersDocument4 pagesPressure Vacuum BleedersGustavo AlcaNo ratings yet

- Abb UpsDocument16 pagesAbb Upsbiya saraNo ratings yet

- MXL IQ Manual PDFDocument218 pagesMXL IQ Manual PDFJosé María Rodríguez RiveraNo ratings yet

- Weishaupt Valve Proving System VPS 504S2Document6 pagesWeishaupt Valve Proving System VPS 504S2diab ali100% (1)

- 1bjn26abc 635421 PDFDocument40 pages1bjn26abc 635421 PDFWilliam MartinezNo ratings yet

- Installation Manual: Heat Pump and Heat Recovery Outdoor VRF Condensing UnitsDocument204 pagesInstallation Manual: Heat Pump and Heat Recovery Outdoor VRF Condensing UnitsJohn SimitzisNo ratings yet

- DWM Copeland Semi-HermeticDocument17 pagesDWM Copeland Semi-HermeticMohammad Amer75% (4)

- 16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Document16 pages16280x Eaton MV Autovar PFC Capacitor Bank Specifications Oct112013Ahmed Said GhonimyNo ratings yet

- Service and Maintenance Instructions 48HC PDFDocument130 pagesService and Maintenance Instructions 48HC PDFRenan Gonzalez0% (1)

- Hisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgDocument34 pagesHisense Corporation: AS-09UR4SVNVG1 AS-12UR4SVNVG1 As-12Ur4Svgvg As-18Ur4Stvvg As-24Ur4SqjvgRajesh SoniNo ratings yet

- ELSMT01Document7 pagesELSMT01dennisplazaNo ratings yet

- VCV WesperDocument12 pagesVCV Wesperciperu55No ratings yet

- TTR SeriesDocument6 pagesTTR SeriesppuchihaNo ratings yet

- Preventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForDocument2 pagesPreventive Maintenance of Diesel Generator Sets Daily:: Specimen Check-List ForAndrewNo ratings yet

- Hankison H-Unit March06Document40 pagesHankison H-Unit March06SAUL OSPINONo ratings yet

- Compressor Model Number System GuideDocument46 pagesCompressor Model Number System GuidemoceNo ratings yet

- 30XA Product Data PDFDocument36 pages30XA Product Data PDFanoopkumar1231150100% (2)

- Butterfly Valve Maintenance ManualDocument14 pagesButterfly Valve Maintenance Manualtiago_mozartNo ratings yet

- EB D G C: Esign Uide YlindersDocument11 pagesEB D G C: Esign Uide YlindersJonathan CunninghamNo ratings yet

- 8.1 Turbine Mechanical Systems DescriptionDocument13 pages8.1 Turbine Mechanical Systems DescriptionSatyasheel Tyagi100% (1)

- Chillers and Heat Pumps Control-EngDocument4 pagesChillers and Heat Pumps Control-EngvickersNo ratings yet

- Thermal Applications CategoryDocument19 pagesThermal Applications CategoryvickersNo ratings yet

- McQuay MCW-C-H Technical Manual EngDocument20 pagesMcQuay MCW-C-H Technical Manual EngCarlos Can PootNo ratings yet

- Replacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)Document10 pagesReplacement Guideline For (ZR90K3, ZR11M3, ZR12M3, ZR16M3 and ZR19M3)vickersNo ratings yet

- Direct Expansion (DX) and Secondary Loop (SN) SystemsDocument2 pagesDirect Expansion (DX) and Secondary Loop (SN) SystemsvickersNo ratings yet

- Copeland Scroll Designation 2005Document1 pageCopeland Scroll Designation 2005vickersNo ratings yet

- Sanyo ScrollDocument24 pagesSanyo Scrollworker359567No ratings yet

- Chilled Beam Design GuideDocument46 pagesChilled Beam Design GuiderjchpNo ratings yet

- Comparative Table of ScrollsDocument11 pagesComparative Table of ScrollsvickersNo ratings yet

- NTC Thermistor Temperature to Resistance ChartDocument1 pageNTC Thermistor Temperature to Resistance ChartvickersNo ratings yet

- 6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandDocument10 pages6 Adjustable Tripping Settings of A Circuit Breaker You MUST UnderstandvickersNo ratings yet

- Basics of HVACDocument119 pagesBasics of HVACUmar FarooqNo ratings yet

- Cooling Load Temperature Difference Calculation MethodDocument3 pagesCooling Load Temperature Difference Calculation Methodvickers50% (2)

- Cypetherm SuiteDocument72 pagesCypetherm SuitevickersNo ratings yet

- CC - Quick Load CalculationsDocument2 pagesCC - Quick Load CalculationsvickersNo ratings yet

- CC - Rapid Load Calculator PDFDocument1 pageCC - Rapid Load Calculator PDFvickersNo ratings yet

- Refrigerant Charge CalculatorDocument1 pageRefrigerant Charge CalculatorBala Krishna GallaNo ratings yet

- ZB Scroll Compressors ManualDocument70 pagesZB Scroll Compressors ManualJavier AffifNo ratings yet

- INT69 KRIWAN Diagnosis SystemDocument6 pagesINT69 KRIWAN Diagnosis Systemvickers100% (1)

- ThermostatCatalog 570-280Document12 pagesThermostatCatalog 570-280vickersNo ratings yet

- Supco TimersDocument7 pagesSupco Timersvickers100% (1)

- Multi V Water PDB (08.04.10 - ) Final PDFDocument123 pagesMulti V Water PDB (08.04.10 - ) Final PDFMaxiaires RefrigeracionNo ratings yet

- T Series CouplingsDocument4 pagesT Series CouplingsiradocajNo ratings yet

- Dampers & De-Tuners: Reducing Vibration of Marine Engines: Facebook Twitter Google+ Linkedin PinterestDocument5 pagesDampers & De-Tuners: Reducing Vibration of Marine Engines: Facebook Twitter Google+ Linkedin PinterestrajishrrrNo ratings yet

- Fenaflex CouplingsDocument6 pagesFenaflex CouplingsRachid KerdidiNo ratings yet

- Select the Correct Bell-Housing and Drive CouplingDocument26 pagesSelect the Correct Bell-Housing and Drive CouplingFernando FernandezNo ratings yet

- Shaft Coupling Design and Software PDFDocument7 pagesShaft Coupling Design and Software PDFAbdulrahman AlkhowaiterNo ratings yet

- Equipment Professional Brochure enDocument228 pagesEquipment Professional Brochure enAnonymous yNhYxMJeYO0% (1)

- FormulasDocument11 pagesFormulasAbdelrhman Essam AttiaNo ratings yet

- ReportDocument20 pagesReportMoaaz KhanNo ratings yet

- Catalogo Centaflex Serie ADocument15 pagesCatalogo Centaflex Serie ACarlos Gallardo LagosNo ratings yet

- Load Sharing in AC Drive PDFDocument12 pagesLoad Sharing in AC Drive PDFsrmohapatra5086No ratings yet

- Crane Kits Specifications CSL1003 0206Document28 pagesCrane Kits Specifications CSL1003 0206JESUSCALVILLONo ratings yet

- Jaw-Flex Coupling Product ManualDocument35 pagesJaw-Flex Coupling Product Manualmallick099No ratings yet

- Chapter 10Document22 pagesChapter 10Nebiyou KorraNo ratings yet

- HRC™ Couplings: SelectionDocument2 pagesHRC™ Couplings: SelectionSh.nasirpurNo ratings yet

- CW, CWR & CWX Pumps Installation, Operation and Maintenance ManualDocument20 pagesCW, CWR & CWX Pumps Installation, Operation and Maintenance ManualNadeemNo ratings yet

- A Textbook of Machine Design R.S.khurMI and J.K.guptA 14ed - 11Document1 pageA Textbook of Machine Design R.S.khurMI and J.K.guptA 14ed - 11Muruganantham MajesticNo ratings yet

- Shaft Lectures - Class4Document21 pagesShaft Lectures - Class4Atalelew ZeruNo ratings yet