Professional Documents

Culture Documents

Engineering Tips-Cooling Tower

Uploaded by

Sharon LambertOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Tips-Cooling Tower

Uploaded by

Sharon LambertCopyright:

Available Formats

Engineering Tips The Challenge of Cooling Tower Pumping

Tower pumping does not present

great difficulty in terms of good pump application. This is because of a normally high order of application safety factors. Troubles do occur occasionally, however. So, lets take a look at these potential troubles and see how to solve them.

Pump Head e!uirements

The pumping head determination procedure for the "open# tower piping loop differs from the conventional "closed# loop piping circuit used for most hydronic $heat%cool& applications. The difference concerns consideration of "open# loop static heads. The closed loop circuit has no need for consideration of static heads for pump selection because of a balance or cancellation of static heads between the supply and return risers. Static head lost by water flow to any height in the supply piping is cancelled by a static head "regain# as water flows down the return piping. The only pump head re!uirement for the "closed# loop is that due to flow%friction pressure drop, $'ig (&. The "open# or tower circuit is different from the "closed# loop circuit in that all static heads are not cancelable. )n the open piping circuit, the pump must raise fluid from a low reference level to a higher level* this re!uires pump work, and open statics becomes an important consideration for pump selection. )n 'ig. +, the re!uired pump head will be the pipe flow%friction loss from , to - plus the energy head $Hs& re!uired to raise water from the lower to higher level. The cooling tower circuit differs slightly from the basic "open# circuit in that the discharge piping is seldom connected directly to a discharge tank. The tower discharge is generally to the atmosphere and then into a distribution pan. 'or the tower piping circuit, the pump must overcome the piping flow friction loss. piping, condenser, valves, etc. )t must also provide the energy head necessary to raise water from a low to a higher static head level. /ost discussions concerning tower and0or open piping circuits would simply define the re!uired pump static energy head as Ho $see 'ig. 1&2the "open# height of the piping circuit. This is, however, an over%simplified assumption which may or may not be true depending on whether or not a "siphon draw# is established in the downcomer return piping, -3. The nature of the downcomer siphon draw and its limitations should be evaluated.

-owncomer Siphon -raw

)n 'ig. 1, water is being discharged at 3 to the atmosphere. Pressure at - must be e!ual to e4it loss plus flow%friction loss -3 and minus the static pressure reduction caused by downcomer

return static height Hr.

Pressure reduction to - as caused by static height Hr will generally, but not always, permit cancellation of height Hr as a part of the re!uired pump head. This is because of a resultant siphon draw action in the downcomer. 5iven that the "siphon draw# does indeed occur, the re!uired pump head will become.

The pump head selection statement shown above is commonly accepted as a truism. )t has limitations, however, and will not apply under certain circumstances. These circumstances should be understood if unnecessary cost and embarrassment are to be avoided by the consultant. 34it loss and flow%friction loss in the downcomer will generally be less than the downcomer height Hr. 'or this circumstance, the downcomer must operate at sub%atmospheric pressure when the siphon draw is established. )f the downcomer vacuum is broken, the e4pected siphon draw will not occur, and the estimated pump head may be inade!uate. The e4pected downcomer return siphon draw vacuum can be broken by any of three basic application circumstances. (. Top%vented downcomer. +. )nade!uate downcomer flow rates* bottom%vented downcomer. 1. 'luid vapor pressure or flash considerations.

Top%6ented -owncomer

, downcomer vent will break the siphon draw vacuum. The vent may be a simple loose pipe connection, or it may be a mechanical vent purposefully applied at the downcomer return high point. 6ents are sometimes applied to establish known reference pumping conditions when downcomer return siphon draw conditions propose stability problems, as with a very high downcomer, when fluid boiling is a probability, or when start%up downcomer flow rates are anticipated as inade!uate for the siphon draw. 5iven a top%vented downcomer, the pump must raise water from the pump suction pan water

level to the highest vented point in the downcomer. Considering this point to occur at - in 'ig. 1, the re!uired pump static head will become Ho 7 Hr or Hs. The total pumping head to point - will become Hs plus the flow%friction loss -elta h $,-&. Separate consideration must now be given to the downcomer return. Since the pump has raised water to level "-,# it provided a fluid head e!ual to Hr to overcome flow%friction loss in the downcomer. There are two different pumping possibilities* fluid head Hr greater than downcomer flow%friction loss $-elta h -3& and the reverse. Hr less than -elta h $-3&. The usual pumping circumstance will be the condition of Hr greater than -elta h $-3&. This is because the available fluid head Hr is the e!uivalent of (88 ft.0(88 ft. pipe friction loss rate. -owncomer piping flow%friction loss will generally be to the order of 9 ft.0(88 ft. Since the pump has already provided the necessary fluid head to flow the downcomer, Hr : -elta h $-3&* friction%flow loss in the downcomer is not a part of the re!uired pump head, and total pump head becomes.

High downcomer pressure drops can be caused by control valves or tower spray no;;les. <hen this pressure drop plus the downcomer pipe flow%friction loss e4ceeds fluid head Hr, the pump head must be increased by the difference -elta h $-3& minus Hr. Total pump head then becomes.

=ottom%6ented -owncomer

-owncomer flow rates can be so low, relative to pipe si;e, as to allow air to enter at the pipe discharge, causing the downcomer to become vented and will prevent formation of the necessary siphon draw vacuum. Tests conducted at =ell > 5ossett indicate the siphon draw will not be established when the actual flow%friction loss rate is less than the order of (0(88 based on clean pipe pressure drop evaluation. Pump head re!uirements for the bottom%vented downcomer will be as previously noted for the top%vented circumstance. ,n unfortunate operational se!uence can occur during pump start%up when the pump energy head is devoted towards simply raising water from the low level pan to the highest part of the system. -uring this start%up period, flow rates can be so low as to cause "bottom venting# and prevent $sometimes forever& formation of siphon draw circumstances and full design flow rates. , water% legged discharge or discharge reducer will provide automatic siphon draw establishment so long as minimum "start%up# flow velocity in the downcomer is to the order of ( ft.0sec. )n 'ig. 9, air entry into the pipe discharge is prevented. The minimum flow velocity pulls air bubbles down the piping, finally evacuating the downcomer of air and establishing the siphon draw condition2downcomer pipe full of water and operating at sub%atmospheric pressure.

?nusual application circumstances will sometimes establish such a low start%up flow rate $less than l0sec. velocity& that air bubbles are not carried down the piping. The downcomer cannot then be emptied of air and e4pected siphon draw will never occur. 'or this circumstance, it is necessary to separately fill the downcomer with water. This can be accomplished by valve closure at the piping e4it in combination with a top vent. -uring start%up, the e4it valve is closed and the vent opened. ,fter the piping is filled, the vent is closed and the e4it valve opened.

Siphon -raw @imitation

5iven sufficiently low sub%atmospheric pressure, any fluid will flash or boil. 'luid pressure in the downcomer piping cannot be less than the pressure at which the fluid boils. 'luid vapor pressure thus provides a siphon draw limitation. Theoretical cancelable downcomer return static height $due to sub%atmospheric siphon draw& will vary dependent on fluid vapor or boiling pressure and on atmospheric pressure as this changes from sea level. The variation for water as affected by water temperature and height above sea level is shown in Table ). Table (. /a4imum theoretical downcomer return cancelable static height because of siphon draw. water only. <ater temperature A' Height above sea level 8 (,888 +,888 1,888 9,888 B,888 C,888 E,888 D,888 F,888 Cold 19 1+.D 1(.C 18.+ +F.+ +D +C.F +B.D +9.C +1.9 (8B 1(.D 18.( +F.( +D.+ +E +B.C +9.C +1.9 ++.+ +(.+ (+8 18 +F +D +C.D +B.C +9.9 +1.+ ++.+ +( (F.D (98 +E.C +C.9 +B.1 +9.( +1 +(.D +8.C (F.9 (D.+ (E.( (C8 +1.9 ++.+ +( (F.F (D.E (E.B (C.9 (B.+ (9 (+.F (D8 (E (B.D (9.C (1.B (+.+ ((.( (8 D.D E.C C.9 +88 E.E C.9 B.+ 9.81 +.D+ (.C( .9D

(8,888

++.+

(F.F

(D.C

(B.F

((.E

B.+

'ig. B illustrates an e4ample tower schematic for an installation located at C,888 ft. elevation. The tower is to be used to dissipate heat from (D8A water* what is the re!uired pump headG

$The figures shown in 'ig. B correspond to available fluid head over and above vapor pressure for the water temperature shown.& eference to Table ) shows that the cancelable siphon draw height for C,888 ft. elevation and (D8A water is only (8, while downcomer return static height is 18 ft. )f conventional pump selection practice were to be followed, the pump selection would be.

This pump selection provides a perfect e4ample of low start%up flow rates* the pump head will Hust be enough to raise water to the system top. Start%up flow rate will be insignificant. 3ven given the special application precautions previously stated, the pump selection wont work because water flash in the downcomer will prevent establishment of the presumed 18 siphon draw head. )n this instance, water would flash because the downcomer return static height e4ceeds the cancelable siphon draw head $see Table ). C,888 ft. at (D8A I (8&. <hen downcomer return height e4ceeds cancelable siphon draw head, it is necessary to separately evaluate downcomer needs. 'or these circumstances the summation of cancelable siphon draw static height plus downcomer return flow friction loss must e4ceed downcomer return height* the e4cess providing anti%flash pressuri;ation. The necessary downcomer flow%friction loss would generally be established by a balance valve positioned close to the outlet $3&. This valve will now provide the necessary "back pressure# to maintain downcomer fluid pressure at above its boiling or vapori;ation point. 'or the particular e4ample, a valve pressure drop e!ual to the order of +1 ft. would establish an overall downcomer return flow%friction loss of +B ft. $+1 7 + I +B&.

, +B downcomer flow%friction loss added to the theoretical cancelable height of (8 ft. will establish a pressure over and above boiling of B ft. at "-.#

The correct pump head selection now becomes.

'or this particular e4ample, a simpler solution could apply an open vent at "-,#eliminating need for the downcomer balance valve and its setting. )n this case, the pump provides an "available# head at - of 18. This fluid head is available for downcomer flow and is greater than flow%friction loss in the downcomer $-elta h -3& of +. -owncomer return flow%friction loss can then be neglected since downcomer fluid will be in "free fall.# e!uired pump head would then become.

3ither correct solution will provide re!uired design flow rates. -esign flow rates would not and could not be established by the "conventional# head selection of 98 ft. This is an abridged version of an article based on =ulletin Jo. T3H%(8EB, "Cooling Tower Pumping > Piping# that appeared in the Jovember (FFD issue of Service > Contracting.

eprinted from TechTalk Kanuary (FFF Copyright 1999 by ITT Industries eturn to the ?niversity Press Page eturn to the 'luid Handling ?niversity Homepage

You might also like

- HVAC Chilled Water Distribution SchemesDocument56 pagesHVAC Chilled Water Distribution SchemesJenson Joy100% (5)

- Shock and Vibration PDFDocument211 pagesShock and Vibration PDFEnrique Lopez De ArroyabeNo ratings yet

- MD He Tema Asme v0.1Document31 pagesMD He Tema Asme v0.1Sharon Lambert100% (1)

- MD He Tema Asme v0.1Document31 pagesMD He Tema Asme v0.1Sharon Lambert100% (1)

- O & M Manual of Cooling Tower-TMDocument11 pagesO & M Manual of Cooling Tower-TMpiyushsingh788102060% (5)

- Cooling TowerDocument10 pagesCooling TowerKeshav Rao100% (1)

- Equivalent Length Calculator - RevADocument10 pagesEquivalent Length Calculator - RevArkrajan1502No ratings yet

- Flexible ConnectionsDocument118 pagesFlexible ConnectionsMuzaffarNo ratings yet

- Calculating Sump VolumeDocument2 pagesCalculating Sump VolumeSharon LambertNo ratings yet

- Terminal Points for Main Plant EquipmentDocument6 pagesTerminal Points for Main Plant Equipmentpunitg_2No ratings yet

- Cooling TowerDocument8 pagesCooling TowerNeal JohnsonNo ratings yet

- DS32 01 Pump Stations Borehole MechanicalDocument71 pagesDS32 01 Pump Stations Borehole MechanicalZerathan OmaeNo ratings yet

- HVAC Duct Sizing GuideDocument91 pagesHVAC Duct Sizing GuidePrabir Bhowmik100% (1)

- Gestra Condensate ManualDocument172 pagesGestra Condensate ManualGeorge ClaessenNo ratings yet

- Pressure Drop Calculation Equations For PIPING and PIPELINEDocument3 pagesPressure Drop Calculation Equations For PIPING and PIPELINETiano BaLajadia100% (4)

- AST Emergency Vent Flow Rates ChartDocument3 pagesAST Emergency Vent Flow Rates ChartSharon LambertNo ratings yet

- Expansion LoopDocument54 pagesExpansion Loopsteepa22No ratings yet

- SEA WATER COOLING TOWER OPERATIONDocument32 pagesSEA WATER COOLING TOWER OPERATIONnivasssvNo ratings yet

- CTI Test Summary Report (Advent IT Park) T43A 178 16A 2016Document9 pagesCTI Test Summary Report (Advent IT Park) T43A 178 16A 2016nagrajuNo ratings yet

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Document8 pagesAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraNo ratings yet

- Vertical pumps-II PDFDocument8 pagesVertical pumps-II PDFjagadeesanNo ratings yet

- 31-SAMSS-006 - 2 July 2019 ERDocument15 pages31-SAMSS-006 - 2 July 2019 ERjulius100% (1)

- Oppenheimer TranscriptDocument54 pagesOppenheimer TranscriptRatkoMRNo ratings yet

- Project (Exergy Analysis of Steam Power Plant)Document76 pagesProject (Exergy Analysis of Steam Power Plant)Shashi Bhushan Patel88% (8)

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsFrom EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahNo ratings yet

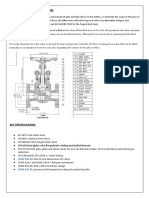

- Globe Valve Bs 1873 and Api 602: ASME B16.10Document7 pagesGlobe Valve Bs 1873 and Api 602: ASME B16.10swapnil PATILNo ratings yet

- BAC-Cooling Tower Pumping & PipingDocument46 pagesBAC-Cooling Tower Pumping & PipingRCYABO100% (1)

- Pipe and Fitting Calcs MasterDocument8 pagesPipe and Fitting Calcs MasterSharon LambertNo ratings yet

- Winterization Systems Design RequirementsDocument7 pagesWinterization Systems Design RequirementsAnonymous v5uipHNo ratings yet

- Electrode BoilerDocument7 pagesElectrode BoilerBrijendra MathurNo ratings yet

- Recommended velocities and pressure drops for common process pipelinesDocument5 pagesRecommended velocities and pressure drops for common process pipelinesger80100% (1)

- Control Valve & Actuator Sizing27012004173744Document23 pagesControl Valve & Actuator Sizing27012004173744Raju NaiduNo ratings yet

- Duct SilencersDocument125 pagesDuct SilencersesagcojrNo ratings yet

- Ma05m Centrifugal Pumps SpecificationDocument21 pagesMa05m Centrifugal Pumps SpecificationandyNo ratings yet

- Castable-Free Fired HeaterDocument4 pagesCastable-Free Fired HeaterchemengseliemNo ratings yet

- E-Pr-330 COMPRESSED AIR SYSTEMSDocument28 pagesE-Pr-330 COMPRESSED AIR SYSTEMSFabian Andrey DiazNo ratings yet

- PIPING PLAN SUMMARYDocument9 pagesPIPING PLAN SUMMARYMohit MundraNo ratings yet

- Internal Epoxy Coating in Surface CondenserDocument14 pagesInternal Epoxy Coating in Surface CondenserChaudhari SanketNo ratings yet

- Heller System PPT 3 Cooling SystemsDocument34 pagesHeller System PPT 3 Cooling SystemsShrey DattaNo ratings yet

- Vacuum Breaker ValveDocument2 pagesVacuum Breaker ValveRaghunath YeturiNo ratings yet

- ERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerDocument18 pagesERT 318/4 Unit Operations SEMESTER 1 (2013/2014) : Water Cooling TowerNorzaifee NizamudinNo ratings yet

- TechSheet109 - Corrosion in DeaeratorsDocument1 pageTechSheet109 - Corrosion in DeaeratorsrinthusNo ratings yet

- Apollo Tyres Ltd Stock Cooling Tower Optimization with 3DTrasarDocument13 pagesApollo Tyres Ltd Stock Cooling Tower Optimization with 3DTrasarEBINESARNo ratings yet

- Automatic Recirculation ValveDocument3 pagesAutomatic Recirculation ValveIsares PodkohNo ratings yet

- Instrument Air Dryer and Instrument Air ReceiverDocument4 pagesInstrument Air Dryer and Instrument Air ReceiverAzizul HakimNo ratings yet

- Bhel Ref No: PW / TSX /hindalco/ Hindalco Mahan, 6X150 MW: ObjectiveDocument2 pagesBhel Ref No: PW / TSX /hindalco/ Hindalco Mahan, 6X150 MW: ObjectiveVenkat RamanNo ratings yet

- Flash Steam SystemDocument4 pagesFlash Steam SystemAnonymous CX51waINo ratings yet

- Area 1Document16 pagesArea 1Camille LachicaNo ratings yet

- Turbine Bypass System - HORADocument11 pagesTurbine Bypass System - HORAhozipekNo ratings yet

- API BB1 vs BB2: Radially split pumps better for H2S, high pressureDocument1 pageAPI BB1 vs BB2: Radially split pumps better for H2S, high pressurebomthanhphuNo ratings yet

- Reducing Steam Header PressureDocument1 pageReducing Steam Header Pressuresj_scribdNo ratings yet

- Cooling Water Flushing Block C.Document4 pagesCooling Water Flushing Block C.Krishna VachaNo ratings yet

- HPAC - Evaluating Deaerator OperationDocument5 pagesHPAC - Evaluating Deaerator Operationghostamir100% (1)

- Monitoreo de BombasDocument6 pagesMonitoreo de Bombasroberdani12No ratings yet

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087No ratings yet

- Compressor Inlet Piping - Compressed Air Best PracticesDocument10 pagesCompressor Inlet Piping - Compressed Air Best PracticesBehroozRaadNo ratings yet

- JCCP BoierWaterDocument74 pagesJCCP BoierWaterwaheed2286No ratings yet

- Service Activity Reports Complete PS3-PS4Document45 pagesService Activity Reports Complete PS3-PS4Mohamed MusaNo ratings yet

- Overview Plant Utility SystemDocument7 pagesOverview Plant Utility SystemMuhammad Nur Fahmi NaimemNo ratings yet

- ONIK ENTERPRISES Offers 1000LPH RO PlantDocument11 pagesONIK ENTERPRISES Offers 1000LPH RO PlantALPHA AND OMEGA SYSTEMSNo ratings yet

- Whrs ManualDocument41 pagesWhrs ManualAKHLESH JHALLARENo ratings yet

- 1 MW KKK Siemens Backpressure Steam Turbine CFR5 G5Document2 pages1 MW KKK Siemens Backpressure Steam Turbine CFR5 G5muhammadnain100% (1)

- Comprimo® Sulfur Solutions: ApplicationsDocument1 pageComprimo® Sulfur Solutions: ApplicationsPrasad ChakkarapaniNo ratings yet

- POWER PLANT RAW WATER SYSTEMDocument21 pagesPOWER PLANT RAW WATER SYSTEMAniesh MahajanNo ratings yet

- Excess FLow ValveDocument9 pagesExcess FLow ValvechloeNo ratings yet

- Minimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunityDocument7 pagesMinimum Submergence Required For Vortex Breaker - Industrial Professionals - Cheresources - Com CommunitySHINo ratings yet

- Service and District Regulator ConsiderationsDocument52 pagesService and District Regulator ConsiderationsRohan Sharma100% (1)

- Presentation On Utilities & Offsite Iffco, ParadeepDocument22 pagesPresentation On Utilities & Offsite Iffco, ParadeepSOCRATESNo ratings yet

- Air Cooled CondenserDocument7 pagesAir Cooled Condensermoreds1983No ratings yet

- Equivalent Length of A Reducer - Google SearchDocument3 pagesEquivalent Length of A Reducer - Google SearchzoksiNo ratings yet

- 3082-ET-A-005 - Diverter Damper System ManufacturingDocument137 pages3082-ET-A-005 - Diverter Damper System Manufacturingmanh hung leNo ratings yet

- Air Cooled CondensersDocument6 pagesAir Cooled CondensersruchiajmerNo ratings yet

- 182268644-CW-Pump-CalculationDocument18 pages182268644-CW-Pump-CalculationPinak ProjectsNo ratings yet

- Equipment Specification Project - RFQ - #: XXXXXX XXXXX ES-223116Document17 pagesEquipment Specification Project - RFQ - #: XXXXXX XXXXX ES-223116Calin SeraphimNo ratings yet

- 20170706140756729Document36 pages20170706140756729Sharon LambertNo ratings yet

- Hvac BasicsDocument73 pagesHvac BasicsSharon LambertNo ratings yet

- 20170706140654483Document66 pages20170706140654483Sharon LambertNo ratings yet

- Hvac Basics 4Document74 pagesHvac Basics 4Sharon LambertNo ratings yet

- JournalofBuildingPhysics 2012 Younes 267 302Document37 pagesJournalofBuildingPhysics 2012 Younes 267 302Sharon LambertNo ratings yet

- Fundamentals of Water Distribution: TopicsDocument89 pagesFundamentals of Water Distribution: TopicsRonald Kahora0% (1)

- HVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationDocument4 pagesHVAC Expansion Tanks: Plain Steel vs. Bladder-Type: Air Control or Air EliminationSharon LambertNo ratings yet

- Commercial Kitchen Design PDFDocument21 pagesCommercial Kitchen Design PDFRocky WidjajaNo ratings yet

- AHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetDocument17 pagesAHRI Standard 885 2008 Duct Discharge Calculation SpreadsheetbinishNo ratings yet

- REQ 15 Sizing of Oil and Grease TrapsDocument40 pagesREQ 15 Sizing of Oil and Grease TrapsSharon LambertNo ratings yet

- Background Noise Rating Calculator: InstructionsDocument29 pagesBackground Noise Rating Calculator: InstructionsSharon LambertNo ratings yet

- Test different beam configurations for bending stressDocument3 pagesTest different beam configurations for bending stressSharon Lambert100% (1)

- Temperature Expansion PipesDocument2 pagesTemperature Expansion PipesSharon LambertNo ratings yet

- Grease Trap Calculator 03Document2 pagesGrease Trap Calculator 03Sharon LambertNo ratings yet

- Pertes de Charge (Fluide Compressibles) V2Document20 pagesPertes de Charge (Fluide Compressibles) V2Sharon LambertNo ratings yet

- Wap 3 Ventilation WksheetDocument7 pagesWap 3 Ventilation WksheetSharon LambertNo ratings yet

- Piping Pressure Drop Functions by Stephen Hall, PE: Pipe DataDocument4 pagesPiping Pressure Drop Functions by Stephen Hall, PE: Pipe DataSharon LambertNo ratings yet

- The Importance of Drying Compressed Air - Paerker BalstonDocument12 pagesThe Importance of Drying Compressed Air - Paerker Balstonppluis90No ratings yet

- Heating Mechanism Analysis. General OverviewDocument4 pagesHeating Mechanism Analysis. General OverviewVlad TampizaNo ratings yet

- IB EXtended Essay-Modeling The Variation in Specific Heat of A 4'-Octyl-4-Biphenyl-Carbonitrile Liquid Crystal Due To Phase TransitionDocument43 pagesIB EXtended Essay-Modeling The Variation in Specific Heat of A 4'-Octyl-4-Biphenyl-Carbonitrile Liquid Crystal Due To Phase TransitionAndrewNo ratings yet

- GV240 Series: Advanced Switching SolutionsDocument7 pagesGV240 Series: Advanced Switching SolutionsBiagio PadulaNo ratings yet

- Power System Transmission and Security: DR Nuraddeen MagajiDocument68 pagesPower System Transmission and Security: DR Nuraddeen MagajiNuraddeen MagajiNo ratings yet

- UnifacDocument3 pagesUnifacapi-294011342No ratings yet

- fle, Tii,:v,' Jy ' TR Ijf, Q D, 4cto'r:.,ma, Ri:al' :1j::"""Document4 pagesfle, Tii,:v,' Jy ' TR Ijf, Q D, 4cto'r:.,ma, Ri:al' :1j::"""Ovidijus RučinskasNo ratings yet

- 10 Electric CurrentDocument12 pages10 Electric Currentömer aydınNo ratings yet

- Problems CH 2Document7 pagesProblems CH 2Oec EngNo ratings yet

- Static Electromagnetic Fields in Matter Chapter 7 SummaryDocument7 pagesStatic Electromagnetic Fields in Matter Chapter 7 Summaryekosatria0040% (1)

- BM 502 Microcontrollers and Bioelectronics Module 5: Introduction To BioelectronicsDocument3 pagesBM 502 Microcontrollers and Bioelectronics Module 5: Introduction To BioelectronicsVeena mitraNo ratings yet

- Ce6306 QBDocument9 pagesCe6306 QBAbhishek KumbalurNo ratings yet

- Biological Computation PDFDocument7 pagesBiological Computation PDFmanoj_rkl_07No ratings yet

- Chapter 7 Fourier Series: 1 Learning OutcomesDocument12 pagesChapter 7 Fourier Series: 1 Learning OutcomesMorsaleen ChowdhuryNo ratings yet

- November 2012 Question Paper 22 Physics Past PaperDocument20 pagesNovember 2012 Question Paper 22 Physics Past PaperGeorge PapoutzasNo ratings yet

- This PDF Is The Sample PDF Taken From Our Comprehensive Study Material For IIT-JEE Main & AdvancedDocument13 pagesThis PDF Is The Sample PDF Taken From Our Comprehensive Study Material For IIT-JEE Main & Advancedannu technologyNo ratings yet

- ME 218 - Spring 2018 - Week05 HandoutDocument7 pagesME 218 - Spring 2018 - Week05 HandoutNitin BhatiNo ratings yet

- Direct and Min Total PE FormulationDocument12 pagesDirect and Min Total PE FormulationMansoorNo ratings yet

- Heat Exchanger Design CHE 311 Final Project MSUDocument15 pagesHeat Exchanger Design CHE 311 Final Project MSUnefoussiNo ratings yet

- Thermodynamic Principles and Ideal Gas FunctionsDocument17 pagesThermodynamic Principles and Ideal Gas FunctionsLê Xuân NamNo ratings yet

- Science 8 - Week 3 - Lesson 2 PDFDocument10 pagesScience 8 - Week 3 - Lesson 2 PDFLizaNo ratings yet

- Turning-Moment Diagrams and FlywheelDocument35 pagesTurning-Moment Diagrams and FlywheelKartik BhararaNo ratings yet

- Determine Amount of Oxygen in Tank from Pressure and TemperatureDocument3 pagesDetermine Amount of Oxygen in Tank from Pressure and Temperatureyeng botzNo ratings yet

- SEMIKRON DataSheet SKKE 15 07170871 PDFDocument4 pagesSEMIKRON DataSheet SKKE 15 07170871 PDFVinicius Veiverberg DillNo ratings yet

- S.Y. B.SC - PDF - VNSGU 2006-07Document8 pagesS.Y. B.SC - PDF - VNSGU 2006-07drharshalpatel1986No ratings yet

- Physics Project On ThermoelectricityDocument10 pagesPhysics Project On ThermoelectricityAbdul SamiNo ratings yet

- Ruta Al Caos PDFDocument33 pagesRuta Al Caos PDFDiego VilchesNo ratings yet

- Material Engineering in CompositesDocument31 pagesMaterial Engineering in CompositesCaryl Alvarado SilangNo ratings yet