Professional Documents

Culture Documents

Sanya Wedge Wire Factory

Uploaded by

zhanghuiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sanya Wedge Wire Factory

Uploaded by

zhanghuiCopyright:

Available Formats

Sanya Wedge Wire Factory

Welcome to Sanya Wedge Wire Factory Sanya Wedge Wire Factory is a professional factory which to produce all kinds of wedge wire products. Wedge wire is known as profile wire screen, V- wire screen, and wedge wire screen. And it is created by wrapping a profile wire cylindrical around longitudinal placed support rods. All wires and rods are resistance welded at each point of contact. The numerous combinations of profile wires and support rods, and the wide range of apertures between the wires and rods allows us to design a screen according your technical or cosmetic specification. t is custom made for the application. !aterials" gl#ani$ed steel, stainless steel %A S &'(,&)*+, #arnished low carbon steel. Applications" The features of this type of screen make it an attracti#e solution for separating solids from li,uids, rataining media, filtering, si$ing, dewatering, collecting and distributing. We manufacture all kind shapes of wedge wires" Welded Wedge Wire Screen, Flat Wedge Screen -anel, Water Well Screen, Wire screen, Vibrating Sie#e Screen, V- wire Screen, Sie#e .end Screen, Screen Support /rids, Wedge Wire for !ine, etc. ts products sell well in o#er &' countries and regions of 0urope, Amerrica, Asia and Africa. We ha#e e1cellent e,upments, perfect craftsship, scientific inspection skill. 0#ery product is strictly inspected according to its international standard. 0ach intersection of the wedge wire and support rod is welded. Various wedge wire 2 support rod combinations are a#ailable to produce the best design for your application.

Wedge wire screen series" cylinder wedge screen, sie#e bend screen and flat screen

Wedge Wire Screens Wedge wire screen is the most commonly using screen for filtration and separation in liquid/gas, water wasting, mining, food and so on. Then have flat type, cylinder type, basket type and slope type according to the screen type. Aslo called flat welded screen panel, cylinder wedge screen and sieve bend screen. They are aslo called woven wedge wire and welded wedge wire according to the weaving type, such as crimped wedge wire, welded wedge screen panels.

Wedge wire screens consist of profile wire and support rods with the materials of galvani ed steel, low carbon steel and stainless steel !"#, !$%. Wedge wire screen applications include using in chemical, oil, gas, food or beverage, waste water management, mining or coal separation. Whatever your situation calls for, we can provide you with a Wedge Wire screen designed to your own specifications manufactured from either grade !"# stainless steel or grade !$% stainless steel. &ength, width, shape and spacing of profile wire are made to meet your special application requirements. Welded wedge wire screens are made in panel or cylinder type,such as welded wedge screen panel Welded Wedge Wire Screens are made in panel or cylinder type from ' shaped profile wire, with an unique welding process, offering great strength, precision, long service life and a wide range of applications in the field of process, engineering such as sugar (uice filtration, waste water treatment, crude oil and natural gas production and vessel internals solving problems of solid / liquid and solid / gas separation, filtration of oils, greases, paints, food products, water, fuels, liquid cooling agents, chemicals etc. )lat welded wedge wire panels offer a perfectly flat and smooth surface with rectangular openings.This kind of wedge wire can replace traditional media like wire mesh cloth, perforated plate and other metal sifting materials as components for rotary screen, well screen, quarry screen, etc.

Wedge

Wire

Application"

Separating,

Si$ing3 Straining, 4e-watering, Filtering, 4rying, Water intake, !edia retention.

*ylinder wedge wire screens are available for both e+ternally,fed -flow from outside to inside. and internally feed applications. /+ternally,fed cylinders can be manufactured without requiring a weld seam up to about !% 01, larger diameters must be fabricated. 2nternally,fed cylinders are fabricated to customers requirements. $. /nd view of e+ternal,fed cylinder. 3. 2nternally,fed fabricated rotary screen cylinder. !. 2nternally,fed rotary screen cylinder. #. 4einforced e+ternally,fed rotary screen. 5. /+ternally,fed rotary screen with flanges.

%. 2nternally,fed rotary screen with flights. )eatures6 Self Supporting7 8igh Abrasion resistance7 &ow pressure drop7 8igh resistance to 'ibration. Applications6 *ylinder screen is used in food processing, waste water filtration, pulp and paper as well as mineral processing applications. Wedge wire or profile screen half cylinders can be added to an auger or screw press to separate solids from liquids in food, waste water, minerals and industrial grit/chips from coolant.

ntroduction of -!5 Sand 5ontrol Screen

9:* Sand *ontrol Screen 0ur factory can serve different specifications of 9:* sand control screen, which is a new efficient technology of mechanical sand control with e+cellent performance in practice by its high permeability, high strength, high deformation adaptive capacity, high reliability and good anti corrosion property. 9:* sand control screen mainly consists of base perforated pipe, 9:* sand control filtration (acket, and stainless steel outer protective shroud. The base pipe is of A92 casing or A92 tubing. The 9:* sand control filtration (acket is made of multilayer stainless steel precise micropore weaves. All parts of 9:* screen are welded together. 9:* Screen )eatures :aterials and Anticorrosion Ability6 $. )or common wells, oil engineering, the base pipe is A92 casing or tubing -;55, <=", etc... 9:* sand control filtration (acket and protective shroud are made of high quality stainless steel. 3. )or special wells in 83S, *03 or *$ corrosive environment, the base pipe is anti,corrosion casing or tubing, even is stainless steel tubing. 9:* sand control filtration (acket and protective shroud are made of high quality stainless steel. !. 8ave anti,corrosion ability to acid, alkali, or salts.

4escriptions V Wire Wrap Screen 6ew Specifications

' Wire Wrap Screen We offer different shapes and si es wire wrap screen. ' wire wrap screen is a common shape of this screen. ' wire wrap screen specifications6 :aterial6 SS!"# )itted on > 9'* base pipe Wire 1iameter6 !.5? Slot si e6 !""@m open area of screen6 $3A Shape69anel or round shape 9acking6 with pallets. &ength6 # , %m Special specifications can be required according to your needs.

4etailed 4escriptions 7auter Tun Screens Specifications

A wedge wire support grid provides a false bottom in a lauter tun in many breweries. The lauter tun screen sits on a ledge that is positioned on the inside diameter of the tank. 2t may also be necessary to have support beams depending on loading and tank diameter. &auter Tun screen description6 5B !/#? 01 made in 5 sections B!' wedge wire on ."C#? + !/#? support rods at $ $/3? centers <ominal slot openings6 "."!"? $/=? + $? banding around each sectionfour ,."C#? + $ $/3? seal strips -shipped loose.all Type !"# stainless steel

You might also like

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Y Strainer CatalogDocument2 pagesY Strainer CatalogLandung GumilangNo ratings yet

- Food & Beverage Processing: Bio-Fuels Corn Wet Milling Ethanol Malting Starch SugarDocument12 pagesFood & Beverage Processing: Bio-Fuels Corn Wet Milling Ethanol Malting Starch SugarHenry VergaraNo ratings yet

- Wedge Wire ScreensDocument5 pagesWedge Wire Screensamolthakur24No ratings yet

- Rotary Drum Wedge Wire Screens For Sugar IndustryDocument1 pageRotary Drum Wedge Wire Screens For Sugar IndustrysanjaymsNo ratings yet

- Screen SandDocument2 pagesScreen SandIng Jose BelisarioNo ratings yet

- Ajit RajakDocument14 pagesAjit Rajaktireless soulNo ratings yet

- GWWSL Products Presentation - Version '20 F Slide ShowDocument18 pagesGWWSL Products Presentation - Version '20 F Slide ShowThang HoangNo ratings yet

- SCC Cat 991aDocument12 pagesSCC Cat 991aEddy JorgeNo ratings yet

- DeZURIK Eccentric Plug ValveDocument8 pagesDeZURIK Eccentric Plug ValveArikan YuzbasiogullariNo ratings yet

- Project Report On Electroforged Steel Grating Manufacturing PlantDocument6 pagesProject Report On Electroforged Steel Grating Manufacturing PlantEIRI Board of Consultants and PublishersNo ratings yet

- Marbett Component Solutions For BeverageDocument48 pagesMarbett Component Solutions For Beverageabsalon_jarvNo ratings yet

- SAUNDERS Industrial Diaphragm ValvesDocument52 pagesSAUNDERS Industrial Diaphragm ValvesGohilakrishnan ThiagarajanNo ratings yet

- Large Generators WEBDocument16 pagesLarge Generators WEBHiep NguyenNo ratings yet

- Sam McCoy MFG - Catalogue 2004 - 2Document29 pagesSam McCoy MFG - Catalogue 2004 - 2Sam McCoy ManufacturingNo ratings yet

- Wedge Wire ScreensDocument6 pagesWedge Wire Screenscumpio425428No ratings yet

- Screens ENGDocument14 pagesScreens ENGSurendar Perumal100% (2)

- Internals For Down Flow ReactorsDocument12 pagesInternals For Down Flow Reactorsrodriguez.gaytanNo ratings yet

- Vtec Brochure2010Document6 pagesVtec Brochure2010Vicente Elías Venegas LunaNo ratings yet

- Fencing Catalogue UKDocument28 pagesFencing Catalogue UKVisoiu TiberiusNo ratings yet

- ANEXO 5 - Catalogo Sumideros JR Smith PDFDocument22 pagesANEXO 5 - Catalogo Sumideros JR Smith PDFCamilo VelásquezNo ratings yet

- Pipe SleeveDocument12 pagesPipe Sleeveparthasarathy2812No ratings yet

- Bollhoff Rivkle Blind Rivet NutsDocument40 pagesBollhoff Rivkle Blind Rivet NutsAce Industrial Supplies100% (1)

- Design FRP Tanks CatalogDocument72 pagesDesign FRP Tanks CatalogDavid Uribe86% (7)

- BUEHLER Guide To PetrographyDocument8 pagesBUEHLER Guide To PetrographyluciliarNo ratings yet

- Demco DM DTDocument30 pagesDemco DM DTGregory StewartNo ratings yet

- Series 900 BrochureDocument40 pagesSeries 900 BrochureLungisaniNo ratings yet

- Sheet pile capping systems guideDocument54 pagesSheet pile capping systems guideGabriel AmorimNo ratings yet

- CatalogDocument8 pagesCataloglangtu2011No ratings yet

- Wade ChannelDocument24 pagesWade ChannelAbdul NabiNo ratings yet

- Sheet Pile Capping Manual-DawsonDocument54 pagesSheet Pile Capping Manual-DawsonSankar CdmNo ratings yet

- BrocherDocument12 pagesBrochermustaqeem khanNo ratings yet

- Duplex StrainerDocument16 pagesDuplex StrainerKumaresan VasudevanNo ratings yet

- Viking Johnson Maxi FitDocument12 pagesViking Johnson Maxi FitTony GallacherNo ratings yet

- PVC Waterstop DatasheetsDocument2 pagesPVC Waterstop DatasheetssfgfhgfjNo ratings yet

- RFA-TECH Waterproofing BrochureDocument48 pagesRFA-TECH Waterproofing Brochuresilvereyes18No ratings yet

- Stainless Steel Standard Knife Gate ValvesDocument18 pagesStainless Steel Standard Knife Gate ValvescmontminyNo ratings yet

- Catalogo AisladorDocument28 pagesCatalogo AisladorEduardo LarenasNo ratings yet

- Safety On LathesDocument10 pagesSafety On Lathessaravanan_c1No ratings yet

- Valves Kvc07Document25 pagesValves Kvc07Dimas Anugrah MahardikaNo ratings yet

- Curve Jaw Type Coupling LOVEJOY PDFDocument17 pagesCurve Jaw Type Coupling LOVEJOY PDFRafo Vega GuerovichNo ratings yet

- Brochure Johnsons Screens® Water Well PVCDocument6 pagesBrochure Johnsons Screens® Water Well PVCMunshenNo ratings yet

- Sai Extrumech Alias Sai EngineeringDocument18 pagesSai Extrumech Alias Sai EngineeringsaiextrumechNo ratings yet

- REDCO™ Polyrthylene UHMWPEDocument8 pagesREDCO™ Polyrthylene UHMWPEDan AngheleaNo ratings yet

- Marco Full Product CatalogDocument54 pagesMarco Full Product Catalogjonathan1479No ratings yet

- ITW - Dynabolt Sleeve AnchorDocument3 pagesITW - Dynabolt Sleeve AnchorBai AdiNo ratings yet

- Carding: Card Clothing For Short Staple ApplicationsDocument20 pagesCarding: Card Clothing For Short Staple ApplicationsnashedisNo ratings yet

- Ceramic Packing and Internals: For Acidic ApplicationsDocument12 pagesCeramic Packing and Internals: For Acidic ApplicationsAndres VegaNo ratings yet

- Stop LogsDocument8 pagesStop LogsLakshmiWijayasiriNo ratings yet

- Datasheet Codeline OCTA 80S SeriesDocument4 pagesDatasheet Codeline OCTA 80S SeriesJulian Bocanegra ReyesNo ratings yet

- Technological Advancements in Wire RopesDocument6 pagesTechnological Advancements in Wire RopesMinaBasconNo ratings yet

- Oil Tempered WireDocument20 pagesOil Tempered WireGizem AkelNo ratings yet

- Surface Belt Structure: Cema C & D SeriesDocument8 pagesSurface Belt Structure: Cema C & D SeriesSari Ully SibaraniNo ratings yet

- Strahman Line Blinds PDFDocument11 pagesStrahman Line Blinds PDFGrandy Anantha SaktiNo ratings yet

- Drain CoilDocument12 pagesDrain CoilBerlinNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Family Handyman Do-It-Yourself Basics Volume 2From EverandFamily Handyman Do-It-Yourself Basics Volume 2Family HandymanRating: 5 out of 5 stars5/5 (2)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Cognos DispatcherDocument17 pagesCognos Dispatcherabdul87sNo ratings yet

- Rolls ModelsDocument186 pagesRolls ModelsapeirotanNo ratings yet

- Online Loan Application and Verification System AbstractDocument7 pagesOnline Loan Application and Verification System AbstractEdison Gregory100% (2)

- Kingstar Lighting InductionDocument8 pagesKingstar Lighting Inductionapi-194673166No ratings yet

- Work Experience: Kamble Arti Navnath MOB: (+91) 8830600972Document3 pagesWork Experience: Kamble Arti Navnath MOB: (+91) 8830600972KambleNo ratings yet

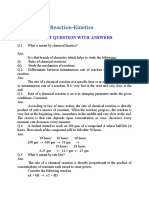

- Chapter 11 .Reaction-Kinetics: Short Question With AnswersDocument6 pagesChapter 11 .Reaction-Kinetics: Short Question With AnswersAasim AliNo ratings yet

- PDMS Support Design UsingDocument83 pagesPDMS Support Design UsingTien LeNo ratings yet

- 1 Bac Global Test (U - 2 & 3)Document2 pages1 Bac Global Test (U - 2 & 3)MouradFilaliNo ratings yet

- Datasheet SSA-X300 170629Document1 pageDatasheet SSA-X300 170629aparichithudooNo ratings yet

- Continuous Beam AnalysisDocument42 pagesContinuous Beam AnalysisMuhd MuqhreyNo ratings yet

- NCPWB August 2002Document6 pagesNCPWB August 2002Claudia MmsNo ratings yet

- Railway Overhead Conductors CatalogDocument14 pagesRailway Overhead Conductors CatalogsudhakarrrrrrNo ratings yet

- Screw ConveyorDocument3 pagesScrew ConveyorWalter EsquivelNo ratings yet

- Hull Survey MethodsDocument21 pagesHull Survey MethodsSanta Clara100% (2)

- Understanding Pressure: Units, Measurements, and CalculationsDocument2 pagesUnderstanding Pressure: Units, Measurements, and Calculationsirma elNo ratings yet

- D4B804B24C4 - GolfR - Engine Mechanical Fuel Injection and IgnitionDocument345 pagesD4B804B24C4 - GolfR - Engine Mechanical Fuel Injection and IgnitionJakeNo ratings yet

- States of Matter PoetryDocument20 pagesStates of Matter PoetrySaqib HussainNo ratings yet

- Marathon Special Products-601RJ 03-DatasheetDocument146 pagesMarathon Special Products-601RJ 03-DatasheetJoão Victor SarmieroNo ratings yet

- Proposal For A Cloud Computing Solution and Application in A Pedagogical Virtual OrganizationDocument10 pagesProposal For A Cloud Computing Solution and Application in A Pedagogical Virtual OrganizationloneislandNo ratings yet

- Kitchen Details by 0631 - DAGANTA PDFDocument1 pageKitchen Details by 0631 - DAGANTA PDFJay Carlo Daganta100% (1)

- en 20211124Document26 pagesen 20211124chaky212No ratings yet

- Calculation of Coefficients of Contraction, Velocity, and Discharge of A Circular Orifice Using A Hydraulic BenchDocument4 pagesCalculation of Coefficients of Contraction, Velocity, and Discharge of A Circular Orifice Using A Hydraulic BenchFran CarnaceNo ratings yet

- Marvelous College of Technology, IncDocument7 pagesMarvelous College of Technology, Incthirsty liquidNo ratings yet

- Trivalent Vs HexavalentDocument2 pagesTrivalent Vs HexavalentArvind KumarNo ratings yet

- Mooney M20R Ovation 2 GX - Pilot's Operating Handbook and Airplane Flight ManualDocument222 pagesMooney M20R Ovation 2 GX - Pilot's Operating Handbook and Airplane Flight Manuallegoulu100% (3)

- Dhanora To JamkhedDocument39 pagesDhanora To JamkhedSangram MundeNo ratings yet

- MPMC 32 Bit PDFDocument29 pagesMPMC 32 Bit PDFashok1683No ratings yet

- Product Brochure Industrial Regulators Mini Catalog Fisher en en 6033160Document24 pagesProduct Brochure Industrial Regulators Mini Catalog Fisher en en 6033160beepu bipNo ratings yet

- Understanding How OFDM Works in WiMAXDocument8 pagesUnderstanding How OFDM Works in WiMAXHarald KerresNo ratings yet

- Undergraduate Selected Applicants 2012-13 Part IDocument192 pagesUndergraduate Selected Applicants 2012-13 Part IchriszaidaNo ratings yet