Professional Documents

Culture Documents

Tutorial On Machine Vice: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78

Uploaded by

Hareesha N GOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tutorial On Machine Vice: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78

Uploaded by

Hareesha N GCopyright:

Available Formats

Tutorial on Machine vice

Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78

11/27/2013

Hareesha N G, DSCE, Blore-78

Machine vice Assembly

11/27/2013

Hareesha N G, DSCE, Blore-78

Exploded view of machine vice

11/27/2013

Hareesha N G, DSCE, Blore-78

Exploded view of machine vice

11/27/2013

Hareesha N G, DSCE, Blore-78

Part 1: Body Step 1:Protrusion Sketch on front plane or XZ plane as shown in fig Symmetric protrusion distance 100 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

Step 2: Cut out Sketch on Top face or XY plane as shown in fig cut out depth 57 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

Step 3: Protrusion Sketch on Bottom face or XY plane as shown in fig protrusion distance 23 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

Step 4: Cut out Sketch on Top face or XY plane as shown in fig Cut out depth 23 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

Step 5: Protrusion Sketch on Side face or YZ plane as shown in fig protrusion distance 5 mm Mirror the above feature to the other face

11/27/2013

Hareesha N G, DSCE, Blore-78

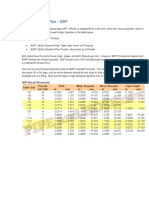

Step 6: Cut out Sketch on Bottom face or XY plane as shown in fig Cut out depth 10 mm for rectangle 60 X 165 Cut out depth 13 mm for rectangle 52 X 165

11/27/2013

Hareesha N G, DSCE, Blore-78

10

Step 7: Hole Create hole 1 of diameter 20 mm and depth 45 mm Create hole 2 of diameter 12 mm and depth 20 mm Create hole 3 of diameter 3 mm and depth 40 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

11

Part 2: Movable Jaw Step 1:Protrusion Sketch on front plane or XZ plane as shown in fig Symmetric protrusion distance 100 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

12

Step 2: Cut out Sketch on side face or YZ plane as shown in fig Cut out depth 50 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

13

Step 3: Hole Create hole 1 of diameter 20 mm and depth 50 mm Create hole 2 of diameter 5 mm(2 holes deep 10 mm) Create hole 3 of diameter 5 mm(2 holes deep 10 mm)

11/27/2013

Hareesha N G, DSCE, Blore-78

14

Part 3: Jaw Grip Sketch on Top plane or XY plane as shown in fig Symmetric protrusion distance 8 mm Create counter sink hole of diameter 6.3 mm, countersink dia of 12 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

15

Part 4: Screw M6 Step 1: Revolved protrusion Sketch on front plane or XZ plane as shown in fig Use revolve protrusion angle 1800

11/27/2013

Hareesha N G, DSCE, Blore-78

16

Step 2: Cut out Sketch on Top face or XY plane as shown in fig Use cut out depth of cut 1.9 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

17

Part 5: Screw Rod Step 1: Revolved Protrusion Sketch on front plane or XZ plane as shown in fig Use revolve protrusion angle 1800

11/27/2013

Hareesha N G, DSCE, Blore-78

18

Step 2: Cut out & Thread Sketch on Right plane or YZ plane as shown in fig Use symmetric cut out through all Create thread on cylindrical body

11/27/2013

Hareesha N G, DSCE, Blore-78

19

Part 6: Washer Create sketch on top plane or XY plane as shown in fig Symmetric protrusion distance 3 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

20

Part 7: Nut Create sketch on Top plane or XY plane as shown in fig Symmetric protrusion distance 8 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

21

Part 8: Nut Create sketch on Top plane or XY plane as shown in fig Symmetric protrusion distance 5 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

22

Part 8: Clamping Plate Create sketch on Top plane or XY plane as shown in fig Symmetric protrusion distance 8 mm Create countersink hole of dia 6.3 mm and countersink dia 12 mm

11/27/2013

Hareesha N G, DSCE, Blore-78

23

You might also like

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Tutorial On Tails Stock: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78Document19 pagesTutorial On Tails Stock: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78Hareesha N GNo ratings yet

- Tutorial Tails Stock ModelDocument19 pagesTutorial Tails Stock ModelKlevin GeorheNo ratings yet

- Machine Vice TutorialDocument25 pagesMachine Vice TutorialHareesha N GNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- Tutorial On IC Engine Connecting Rod: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78Document15 pagesTutorial On IC Engine Connecting Rod: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78Hareesha N GNo ratings yet

- Certified Solidworks Professional Advanced Sheet Metal Exam PreparationFrom EverandCertified Solidworks Professional Advanced Sheet Metal Exam PreparationRating: 5 out of 5 stars5/5 (4)

- Plummer Block TutorialDocument21 pagesPlummer Block TutorialHareesha N GNo ratings yet

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Tutorial On Screw Jack: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78Document15 pagesTutorial On Screw Jack: Hareesha N G Dept of Aeronautical Engg Dayananda Sagar College of Engg Bangalore-78Hareesha N GNo ratings yet

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsFrom EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNo ratings yet

- Screw Jack TutorialDocument16 pagesScrew Jack TutorialHareesha N GNo ratings yet

- Screw Jack Assembly DrawingsDocument17 pagesScrew Jack Assembly DrawingsSantosh RathodNo ratings yet

- NX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)From EverandNX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)No ratings yet

- 006 - Rear Radial SealDocument5 pages006 - Rear Radial Sealmax_simonsNo ratings yet

- Cordless Reciprocating Saw Technical SpecsDocument11 pagesCordless Reciprocating Saw Technical SpecsJose Sanchez100% (2)

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Top Drive PB169 - Blower - Motor - U-Bolt - SupportDocument6 pagesTop Drive PB169 - Blower - Motor - U-Bolt - SupportJoseMi Vacaflor Illanes100% (1)

- Machine Compatibility OEM Info Tools: Technical Instructions 1Document9 pagesMachine Compatibility OEM Info Tools: Technical Instructions 1servicerNo ratings yet

- Magic BowDocument13 pagesMagic BowSteve Dowell80% (5)

- D6 - Recoil DisassemblyDocument7 pagesD6 - Recoil DisassemblyrodriguezalejandrotucNo ratings yet

- Solidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingFrom EverandSolidworks 2018 Learn by Doing - Part 3: DimXpert and RenderingNo ratings yet

- SYS Bolt ManualDocument64 pagesSYS Bolt ManualNoppolNorasriNo ratings yet

- CATIA V5-6R2015 Basics - Part II: Part ModelingFrom EverandCATIA V5-6R2015 Basics - Part II: Part ModelingRating: 4.5 out of 5 stars4.5/5 (3)

- Installation Directions For The Presser Foot (Compact)Document6 pagesInstallation Directions For The Presser Foot (Compact)joecentroneNo ratings yet

- Guidelines For Collect DesignDocument24 pagesGuidelines For Collect DesignArun LeleNo ratings yet

- Presser Foot Stopper Roller-C SeriesDocument8 pagesPresser Foot Stopper Roller-C SeriesjoecentroneNo ratings yet

- NX 9 for Beginners - Part 3 (Additional Features and Multibody Parts, Modifying Parts)From EverandNX 9 for Beginners - Part 3 (Additional Features and Multibody Parts, Modifying Parts)No ratings yet

- Yx70 Viking Assembly ManualDocument0 pagesYx70 Viking Assembly ManualJulie LafranceNo ratings yet

- Parts: RoebuckDocument6 pagesParts: RoebuckCary BriefNo ratings yet

- Manual SumitomoDocument4 pagesManual SumitomoJorge A Vilal50% (2)

- Cadm 8th 2009 (1st)Document13 pagesCadm 8th 2009 (1st)viveksmartguyNo ratings yet

- 7 Horiz Tail 1Document8 pages7 Horiz Tail 1babumohallahNo ratings yet

- 3 in 1 Drill Press UpgradeDocument12 pages3 in 1 Drill Press UpgradeGermanHund100% (2)

- 2885B Air Compressor Inlet CompressedDocument10 pages2885B Air Compressor Inlet CompressedSsp VillalbaNo ratings yet

- Soundshield Assembly InstructionsDocument12 pagesSoundshield Assembly InstructionsChrisNo ratings yet

- Engine Hood & DoorDocument34 pagesEngine Hood & DoorMusat Catalin-MarianNo ratings yet

- P 51 DonalddDocument20 pagesP 51 DonalddNitu Iulian100% (3)

- Action Plan: SR - NO. Mould Name Supplier Name Part NoDocument4 pagesAction Plan: SR - NO. Mould Name Supplier Name Part NoYogesh KandalkarNo ratings yet

- Planos Router CNCDocument53 pagesPlanos Router CNCMiguel JaquetNo ratings yet

- Kreg Jig Potting Bench InstructionsDocument4 pagesKreg Jig Potting Bench InstructionsSteven Taylor100% (2)

- KP0800 Te PDFDocument8 pagesKP0800 Te PDFisaac grossiNo ratings yet

- Chapter 3 - Design of Mechanical JointDocument26 pagesChapter 3 - Design of Mechanical JointRaj KeeranNo ratings yet

- Bomba de Pistones Fan Armado InglesDocument18 pagesBomba de Pistones Fan Armado InglesAntony Armando Huaylla QuispeNo ratings yet

- 10 Ft. Square Steel Gazebo Assembly ManualsDocument9 pages10 Ft. Square Steel Gazebo Assembly ManualsgillerdoitNo ratings yet

- Drilling software casing design manualDocument29 pagesDrilling software casing design manualAnonymous ocBLoeAOh4No ratings yet

- Bar Bending Schedule For Pile Foundation With CalculationsDocument4 pagesBar Bending Schedule For Pile Foundation With CalculationsJustin MusopoleNo ratings yet

- Power SkivingDocument11 pagesPower SkivingahemerlyNo ratings yet

- BAI and ASI Syllabus For QP Setting Aug 2020Document6 pagesBAI and ASI Syllabus For QP Setting Aug 2020Hareesha N GNo ratings yet

- 15CS35 - Unix and Shell Programming-July 2018Document2 pages15CS35 - Unix and Shell Programming-July 2018Hareesha N GNo ratings yet

- 06CS36-Unix and Shell Programming-Jan 2009Document2 pages06CS36-Unix and Shell Programming-Jan 2009Hareesha N GNo ratings yet

- 06CS36-Unix and Shell Programming-Dec 2010Document1 page06CS36-Unix and Shell Programming-Dec 2010Hareesha N GNo ratings yet

- 06CS36-Unix and Shell Programming-July 2011Document1 page06CS36-Unix and Shell Programming-July 2011Hareesha N GNo ratings yet

- JET ENGINE FundamentalsDocument18 pagesJET ENGINE FundamentalsHareesha N GNo ratings yet

- 06CS36-Unix and Shell Programming-Jan 2014Document1 page06CS36-Unix and Shell Programming-Jan 2014Hareesha N GNo ratings yet

- 15CS35 - Unix and Shell Programming-Jan 2018Document2 pages15CS35 - Unix and Shell Programming-Jan 2018Hareesha N GNo ratings yet

- 10CS44 - Unix and Shell Programming-Dec 2012Document2 pages10CS44 - Unix and Shell Programming-Dec 2012Hareesha N GNo ratings yet

- 06CS36-Unix and Shell Programming-Jan 2010Document1 page06CS36-Unix and Shell Programming-Jan 2010Hareesha N GNo ratings yet

- 06CS36-Unix and Shell Programming-Dec 2011Document1 page06CS36-Unix and Shell Programming-Dec 2011Hareesha N GNo ratings yet

- 06CS36-Unix and Shell Programming-Jan 2008Document1 page06CS36-Unix and Shell Programming-Jan 2008Hareesha N GNo ratings yet

- Exam Question BankDocument1 pageExam Question BankHareesha N GNo ratings yet

- Practice Final SolutionsDocument41 pagesPractice Final SolutionsHareesha N GNo ratings yet

- MOM COsDocument1 pageMOM COsHareesha N GNo ratings yet

- File Identifier - StickersDocument50 pagesFile Identifier - StickersHareesha N GNo ratings yet

- PhaseII Final IITDocument26 pagesPhaseII Final IITHareesha N GNo ratings yet

- Modelling and Analysis Laboratory Manual VTU PDFDocument42 pagesModelling and Analysis Laboratory Manual VTU PDFHareesha N GNo ratings yet

- Phase1 Closure July 2004Document27 pagesPhase1 Closure July 2004Hareesha N GNo ratings yet

- Pert Chart MineDocument1 pagePert Chart MineHareesha N GNo ratings yet

- Chapter NumbersDocument11 pagesChapter NumbersHareesha N GNo ratings yet

- ARDB Rules - Grants PDFDocument38 pagesARDB Rules - Grants PDFHareesha N GNo ratings yet

- Sample Q and ADocument47 pagesSample Q and AHareesha N G100% (1)

- Application For Grant of Research/Development Project/Facilities Under Grants-In-Aid Scheme of Aeronautics R&D BoardDocument3 pagesApplication For Grant of Research/Development Project/Facilities Under Grants-In-Aid Scheme of Aeronautics R&D BoardHareesha N GNo ratings yet

- Alg LabDocument22 pagesAlg LabShobha KumarNo ratings yet

- Lab25 - Command Line InterfaceDocument22 pagesLab25 - Command Line InterfaceHareesha N GNo ratings yet

- Appendix: Where To Approach For R&D Funds?Document15 pagesAppendix: Where To Approach For R&D Funds?malini72No ratings yet

- 2015 Project TitlesDocument9 pages2015 Project TitlesHareesha N GNo ratings yet

- Database AwsDocument15 pagesDatabase AwsHareesha N GNo ratings yet

- Lab26 - Configure Endpoint and Access S3Document18 pagesLab26 - Configure Endpoint and Access S3Hareesha N GNo ratings yet

- ANSI Thread Series DesignationsDocument1 pageANSI Thread Series DesignationsAbby BurchNo ratings yet

- Bosch20182019 Catalog - Taps and DiesDocument8 pagesBosch20182019 Catalog - Taps and Diesrasim_m1146No ratings yet

- Austain Technical Information Sheet Imperial Tpi TableDocument1 pageAustain Technical Information Sheet Imperial Tpi Tablefra_salsaNo ratings yet

- TIEIG Catalog For Heavy Machinary 2022Document10 pagesTIEIG Catalog For Heavy Machinary 2022Hülya Kula ÇİÇEKÇİNo ratings yet

- Thread GaugesDocument7 pagesThread GaugesmutemuNo ratings yet

- Thread Identification Chart PDFDocument1 pageThread Identification Chart PDFashik asdNo ratings yet

- Whitworth Tapered Pipe Thread DIN EN 10226-1, DIN EN 10226-2 Formerly Known As DIN 2999 BSPT (British Standard Tapered Pipe)Document1 pageWhitworth Tapered Pipe Thread DIN EN 10226-1, DIN EN 10226-2 Formerly Known As DIN 2999 BSPT (British Standard Tapered Pipe)LucianNechiforNo ratings yet

- Drilling MachineDocument27 pagesDrilling MachineDeepakNo ratings yet

- ThreadsDocument11 pagesThreadsBuddha PrakashNo ratings yet

- TABLE 4 Nut Proof Load Values, KN: OTE OTEDocument1 pageTABLE 4 Nut Proof Load Values, KN: OTE OTEanishNo ratings yet

- Sopa de LetrasDocument1 pageSopa de LetrasJohana Andrea Sepulveda SabogalNo ratings yet

- Setup Sheet Report: Generic Haas 4 - Axis VMCDocument5 pagesSetup Sheet Report: Generic Haas 4 - Axis VMCGandi SaputraNo ratings yet

- Thread Data ChartsDocument2 pagesThread Data Chartsguru_axiomNo ratings yet

- List of Standards - Fastening Elements - Part12Document1 pageList of Standards - Fastening Elements - Part12strijelavremenaNo ratings yet

- John Deere 6081Document2 pagesJohn Deere 608191101 CANo ratings yet

- Input To NC-3658.3 Flange Evaluation MethodDocument7 pagesInput To NC-3658.3 Flange Evaluation MethodVishal KandNo ratings yet

- Manufacturing Processes Open Ended Lab ReportDocument15 pagesManufacturing Processes Open Ended Lab ReportDawood KhanNo ratings yet

- Presentasi Teknologi Mekanik Minggu 10 (Bor)Document19 pagesPresentasi Teknologi Mekanik Minggu 10 (Bor)ibnuNo ratings yet

- ASME B1.1 thread dimensions and specificationsDocument1 pageASME B1.1 thread dimensions and specificationshughobNo ratings yet

- Instruction Manual AND Parts List: MODEL: MH-916JA/1016JADocument10 pagesInstruction Manual AND Parts List: MODEL: MH-916JA/1016JABrinkNo ratings yet

- 3 03 2Document1 page3 03 2wanpudinNo ratings yet

- All Cad Files Group 1Document20 pagesAll Cad Files Group 1api-598255067No ratings yet

- ISO Metric Screw Thread PDFDocument6 pagesISO Metric Screw Thread PDFthamskiotNo ratings yet

- MAZAK M32 ParametersDocument67 pagesMAZAK M32 ParametersJesus Abraham Contreras Hernandez100% (4)

- Mill-Thread Toolholders With Internal Coolant BoreDocument4 pagesMill-Thread Toolholders With Internal Coolant BoreÁdám RáczNo ratings yet

- Pipe Thread NPT and BSPT Fittings Compatibility PDFDocument5 pagesPipe Thread NPT and BSPT Fittings Compatibility PDFrefaeNo ratings yet

- Desain Sumur PantauDocument1 pageDesain Sumur PantauGlobal Container IndonesiaNo ratings yet

- Calibration &thread Ring Gauge Plan.2012-13Document16 pagesCalibration &thread Ring Gauge Plan.2012-13Er Avinash KumarNo ratings yet

- 09-Hardox Tool Recommendations For Hardox Wear PlateDocument4 pages09-Hardox Tool Recommendations For Hardox Wear PlateAnonymous c8uPXQW7No ratings yet

- Panel Assy-Wired CG, Overhead Main SectionDocument7 pagesPanel Assy-Wired CG, Overhead Main Sectionsarvesh_ame2011No ratings yet