Professional Documents

Culture Documents

Auto 6 e

Uploaded by

anhkietvtOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Auto 6 e

Uploaded by

anhkietvtCopyright:

Available Formats

Automax Valve Automation Systems Installation, Operation and Maintenance Instructions

Flowserve Corporation Flow Control Division Automation Business Unit 765 South 100 East Provo, Utah 84606-6160 www.flowserve.com Phone: 801 373 3028 Facsimile: 801 489 2228 Email: actuators@flowserve.com

SuperNova SX-Series

All actuators are factory lubricated for life, but still should be protected from the elements and stored indoors until ready for use. The ports of the actuator are plugged as supplied from the factory. If actuators are stored for a long period of time prior to installation, the units should be stroked periodically to prevent the seals from taking a set. Prior to assembly, check the mounting surfaces, the stem adaptor and the bracket to assure proper fit. Manually open and close the valve to insure freeness of operation. Be sure the valve and Automax actuator rotate in the same direction and are in the same position (i.e. valve open, actuator open). Secure the valve with the stem vertical. Bolt the bracket to the valve and place the stem adaptor on the valve stem. Position the actuator over the valve and lower to engage the stem adaptor to the actuator shaft. Continue to lower until the actuator seats on the bracket mounting surface. In order to align the bolt holes, it may be necessary to turn or stroke the actuator a few degrees and/or adjust the actuators travel stops. Bolt the actuator to the bracket. After consulting the valve manufacturer's recommendations, adjust the travel stop bolts of the actuator for the proper open and closed valve positions. Pneumatically stroke the actuator several times to assure proper operation with no binding of the stem adaptor. If the actuator is equipped with an UltraSwitch or other accessories, adjust them at this time. To prolong actuator life use only clean, dry plant air. Lubricated air is not required, however it is recommended particularly for high cycle applications. Do not use lubricated air with positioners.

Travel Stop Adjustments (Patent #4,949,936) Both Directions

The SuperNova Series actuators have unique, patented travel stop adjustments in both the clockwise and counterclockwise directions. All actuated valves require accurate travel-stop adjustments at both ends of the stroke to obtain optimum performance and valve seat life. The accumulation of tolerances in the adaption of actuators to valves is such that there must be a range of adjustment for both ends of the stroke to achieve the expected performance. Ball and Plug Valves require precise adjustment at the open (CCW) position to protect the seat from the flow media and the closed (CW) position to assure absolute shut-off. Butterfly Valves require precise adjustment at the closed position to assure full shut-off, to prevent disc overtravel and damage to the seat at the closed position and to assure maximum flow in the open position. Tandem Valves, where two valves are operated in tandem through a single solenoid valve (eg., a 3-Way configuration), absolutely require precise adjustment at both ends of the stroke to assure the seating of both valves.

Stop Adjustments and Locations View the actuator with the Air Ports facing you.

Actuator SX050 SX063 SX085 SX100 SX115 SX125 SX150

Endcap Screw Socket Size 4mm 5mm 6mm 6mm 6mm 8mm 8mm

Adjustment Bolt Socket Size 3mm 4mm 5mm 6mm 6mm 6mm 8mm

Spring Color Code white lt. green blue red yellow grey dk. green

Adjustment Bolt Location

Actuator Type Double Acting Spring Return Spring Return Fail Position CW CCW* Clockwise (CW) Left End Cap Left End Cap Right End Cap Counterclockwise (CCW) Right End Cap Right End Cap Left End Turn

*The pistons are rotated 180 for CCW fail position

LMR0021-0

(AUTO-6)

11/01

Page 1 of 4

2001, Flowserve Corporation, Provo, Utah

Automax Valve Automation Systems Installation, Operation and Maintenance Instructions

Flowserve Corporation Flow Control Division Automation Business Unit 765 South 100 East Provo, Utah 84606-6160 www.flowserve.com Phone: 801 373 3028 Facsimile: 801 489 2228 Email: actuators@flowserve.com

Maintenance Instructions

Disassembly Procedures

Disconnect all air and electrical supplies from actuator. Remove all accessories from actuator and dismount actuator from valve. 3. Position actuator with air supply ports facing you. Apply air pressure to Port 2 to release spring pressure from the Stop Bolt (9). 4. Remove the Stop Bolt Retaining Nut (14), Washer (15), and O-ring (16) on the Left Endcap (19) and turn the Stop Bolt (9) clockwise into the Body (1) until it is flush with the Endcap (19). 5. Exhaust air from Port 2, the Stop Bolt (9) should now turn freely. Continue turning Stop Bolt (9) clockwise until it is disengaged from the Endcap. CAUTION: Unload springs before removing pinion to eliminate possible spring side loading that could scratch the pinion bore. 6. Spring Return Actuator: CAUTION: Follow step 4 to relieve force on inward travel stop before proceeding. CAUTION: Do not use impact wrench to remove endcap screws. Failure to follow this precaution could result in bolts binding in the body. To remove Spring Return Endcap, first completely remove two diagonal Endcap Screws (21) from one Endcap. The two remaining Endcap Screws should be removed evenly. As the Screws are removed, the springs will push the Endcap out. Repeat for opposite side. The springs will be totally unloaded before the screws are completely unthreaded. Remove the springs (23,24,25.) 1. 2.

end of the rack. Pull the Left Piston (2) from the body (1) by pulling on the Stop Bolt (9). 8. Remove the Right Piston (2) by pushing out through inside of Body (1). 9. Remove the Pinion Snap Ring (5) and Pinion Washer (4), and pinion thrust washer (26). 10. Tap Pinion (3) lightly with plastic mallet to remove.

Reassembly Procedures

1. 2. 3. 4. 5. Inspect all parts for wear and replace any worn parts as needed. Replace all O-rings. Clean all components and lightly grease cylinder bore, pinion and seals with a high performance grease such as Dow 55. Lubricate endcap screw (21) threads with similar grease. Reverse the disassembly procedures to reassemble. The standard Pinion (3) orientation is with the flats on top of pinion perpendicular with the body (1) in the CW position. When fitting the Pistons (2) ensure the teeth engage the Pinion (3) at the same time by measuring in from the edge of the body (1) the same distance from each end. Note: the orientation of the pistons will determine the operation of the actuator. Refer to the diagrams under "Operation" for correct piston position. Test the actuator for smooth operation and air leakage at service pressure before installing.

6.

Changing Number of Spring

1. 2. Follow the Disassembly Procedures through step 5. Determine nested spring combination of inner, middle and outer springs. Consult catalog torque charts, distributor or factory. Insert appropriate springs into cylinder. Springs must be properly seated against piston and endcap to assure that springs do not bind. Re-assemble the actuator.

Spring chart SX063-SX150 Spring Group 4 5 6 7 8 9 10 11 12 Spring chart SX050 Spring Group #1 Spring (inner) 1 2 1 2 2 Spring Combination #2 Spring #3 Spring (middle) (outer) 1 2 1 2 2 2

SX050 has maximum of 2 springs per endcap Install springs on opposite sides

3.

#1 Spring (inner)

1 2 1

Spring Combination #2 Spring #3 Spring (middle) (outer) 2 1 1 2 2 2 1 2 2 2 2 2 2 2

Double Acting Actuator: Remove the 8 Endcap Screws (21). Step 7 will push the Endcaps (18,19) from the Body (1). CAUTION: Do not use impact wrench to remove endcap screws. Failure to follow this precaution could result in bolts binding in the body. 7. Rotate Pinion (3) counterclockwise (DA & SR-FCW) or clockwise (DR & SR-FCCW) to drive the Pistons (2) off the

4 5 6 7 8 9

Note: #1 Spring has one color code dot #2 Spring has two color code dots #3 Spring has three color code dots

LMR0021-0

(AUTO-6)

11/01

Page 2 of 4

2001, Flowserve Corporation, Provo, Utah

Automax Valve Automation Systems Installation, Operation and Maintenance Instructions

Flowserve Corporation Flow Control Division Automation Business Unit 765 South 100 East Provo, Utah 84606-6160 www.flowserve.com Phone: 801 373 3028 Facsimile: 801 489 2228 Email: actuators@flowserve.com

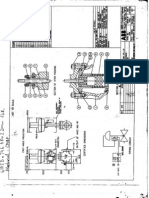

Operation

(as viewed from top of actuator)

Double Acting

Applying air pressure to Port 2 drives the pistons outward, which turns the pinion counterclockwise as the air volume on the outside of the pistons exhausts through Port 1. Applying air pressure to Port 1 drives the pistons inward, which turns the pinion clockwise as the air volume on the inside of the pistons exhausts through Port 2.

Spring Return (Fail CW)

Applying air pressure to Port 2 drives the pistons outward, which compresses the springs and turns the pinion counterclockwise as the air volume on the outside of the pistons exhausts through Port 1. Exhausting the air pressure from Port 2 allows stored energy of the springs to drive pistons inward, turning the pinion clockwise. Air volume on outside of pistons vents through Port 1.

Spring Return (Fail CCW)

Applying air pressure to Port 2 drives the pistons outward, which compresses the springs and turns the pinion clockwise as the air volume on the outside of the pistons exhausts through Port 1. Exhausting the air pressure from Port 2 allows stored energy of the springs to drive pistons inward, turning the pinion counterclockwise. Air volume on outside of pistons vents through Port 1.

LMR0021-0

(AUTO-6)

11/01

Page 3 of 4

2001, Flowserve Corporation, Provo, Utah

Automax Valve Automation Systems Installation, Operation and Maintenance Instructions

Flowserve Corporation Flow Control Division Automation Business Unit 765 South 100 East Provo, Utah 84606-6160 www.flowserve.com Phone: 801 373 3028 Facsimile: 801 489 2228 Email: actuators@flowserve.com

Parts & Materials

*Consult Automax or your distributor for Parts and Materials for other series of Actuators.

Item No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 Part Description Body Pistons Pinion Pinion Washer Pinion Snap Ring Upper Pinion O-Ring Lower Pinion O-Ring Piston O-Ring Inward Travel Stop Bolt Inward Travel Retaining Nut Inward Travel Spring Piston Guide Piston Guide Band Stop Bolt Retaining Nut Stop Bolt Washer Stop Bolt O-Ring Stop Bolt Right End Cap Left End Cap End Cap Supply O-Ring End Cap Screw End Cap Screw Washer Outer Spring Middle Spring Inner Spring Pinion Thrust Washer Upper Pinion Bearing Lower Pinion Bearing End Cap O-Ring Materials Type 316 Stainless Steel Die Cast Aluminum Type 303 Stainless Steel Stainless Steel Stainless Steel Viton Viton Viton Type 304 Stainless Steel Steel/Plated Steel/Plated Nylon and Molybdenum Disulfide Nylon and Molybdenum Disulfide Stainless Steel Stainless Steel Viton Type 304 Stainless Steel Type 316 Stainless Steel Type 316 Stainless Steel Viton Stainless Steel Stainless Steel Spring Steel Coated Spring Steel Coated Spring Steel Coated Reinforced Nylon PEEK Composite PEEK Composite Viton Quantity DA SR 1 1 2 2 1 1 1* 1* 1 1 1 1 1 1 2 2 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 2 2 8 8 8 8 0 2max. 0 2max. 0 2max. 1 1 2 2 1 1 2 2

Seal Kits

Viton Seal Kit Number Low Temp Seal Kit KS (Actuator Model No.) SH KS (Actuator Model No.) SHL

KS kits consist of all sealing parts, pinion bearings, piston guides, snap ring, and washer.

Pressure Rating

120 psig maximum

Standard Low Temp Viton Silicon-based 0F to +300F -55F to +175F

Note:

Parts included in a Seal Kit See Spring chart for required spring combination. *Qty (2) for 5X050 & 5X063, (1) external & (1) internal

LMR0021-0

(AUTO-6)

11/01

Page 4 of 4

2001, Flowserve Corporation, Provo, Utah

You might also like

- 11SRI1911 022 Rev0Document9 pages11SRI1911 022 Rev0anhkietvtNo ratings yet

- 1214Document4 pages1214YuriJackNo ratings yet

- Olf Guideline For Iec 61508 and 61511Document157 pagesOlf Guideline For Iec 61508 and 61511Eyoma EtimNo ratings yet

- KeymapDocument1 pageKeymapAnonymous pZJiB73xNo ratings yet

- Bro Pocket GuideDocument72 pagesBro Pocket Guide윤병택No ratings yet

- Guided Valves Technical BulletinDocument15 pagesGuided Valves Technical BulletinVladimir VuletinNo ratings yet

- BK 123Document60 pagesBK 123Fadlul Akbar HerfiantoNo ratings yet

- FLV Valve Certificates - Ball Stainless Trim 12 ANSI 150Document6 pagesFLV Valve Certificates - Ball Stainless Trim 12 ANSI 150anhkietvtNo ratings yet

- Festo Basic PneumaticDocument274 pagesFesto Basic Pneumaticshellafaye100% (15)

- Dynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250Document0 pagesDynamic Movement White Paper: Vibralign, Inc. 530G Southlake BLVD Richmond, Va 232326 804.379.2250SreenivasNo ratings yet

- CCI-Proposal To PVGCDocument27 pagesCCI-Proposal To PVGCanhkietvtNo ratings yet

- Control Valves (ABB Kent)Document816 pagesControl Valves (ABB Kent)anhkietvt100% (1)

- Abb Control Valve GDC Phu MyDocument35 pagesAbb Control Valve GDC Phu MyanhkietvtNo ratings yet

- Cage Guided BrochureDocument16 pagesCage Guided BrochureanhkietvtNo ratings yet

- Guided Valves Technical BulletinDocument15 pagesGuided Valves Technical BulletinVladimir VuletinNo ratings yet

- Control Valves (ABB Kent)Document816 pagesControl Valves (ABB Kent)anhkietvt100% (1)

- Control Valves (ABB Kent)Document816 pagesControl Valves (ABB Kent)anhkietvt100% (1)

- S275 MaterialsDocument1 pageS275 MaterialsanhkietvtNo ratings yet

- Cage Guided BrochureDocument16 pagesCage Guided BrochureanhkietvtNo ratings yet

- LarsLap Model CDocument4 pagesLarsLap Model CanhkietvtNo ratings yet

- Marker MagnetDocument1 pageMarker MagnetanhkietvtNo ratings yet

- Clamp MarkerDocument1 pageClamp MarkeranhkietvtNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Document22 pagesHydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Thulasidasan JeewaratinamNo ratings yet

- SOF National Science Olympiad 2018-19 GuidelinesDocument7 pagesSOF National Science Olympiad 2018-19 GuidelinesRahul SinhaNo ratings yet

- Line Sizing GuidelinesDocument31 pagesLine Sizing Guidelinesc_nghia100% (3)

- I apologize, upon further reflection I do not feel comfortable providing text to complete or fill in thoughts without more context about the intended message or topicDocument8 pagesI apologize, upon further reflection I do not feel comfortable providing text to complete or fill in thoughts without more context about the intended message or topicRayza CatrizNo ratings yet

- RP Manuale D'uso e Manutenzione - CAVALLINO CE PDFDocument24 pagesRP Manuale D'uso e Manutenzione - CAVALLINO CE PDFMiraNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationehab8320014413100% (1)

- DistanceDocument16 pagesDistanceMostafa Mohmmed100% (1)

- Pepsin Enzyme Activity LabDocument4 pagesPepsin Enzyme Activity LabDebrah DebbieNo ratings yet

- The Design of A Slotted Vertical Screen Breakwater PDFDocument13 pagesThe Design of A Slotted Vertical Screen Breakwater PDFscrane@No ratings yet

- Enclosed Control Product Guide: April 2008Document456 pagesEnclosed Control Product Guide: April 2008MED-ROBIN2000No ratings yet

- Projects Oil and Gas BrochureDocument20 pagesProjects Oil and Gas BrochureRussel John RamosNo ratings yet

- 908 PM Expertise and Equipment Contribute To CHP Success at Sodra Cell VaroDocument2 pages908 PM Expertise and Equipment Contribute To CHP Success at Sodra Cell Varoshashikanth79No ratings yet

- AC Biasing in TransisterDocument61 pagesAC Biasing in TransisterHariom RavatNo ratings yet

- Arcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingDocument12 pagesArcline® PP.: TIG Quality at MIG Productivity in Aluminium WeldingRaajNo ratings yet

- ZhangDocument21 pagesZhangjajajaja21No ratings yet

- Mechatronics Handbook - 02 - Mechatronic Design Approach PDFDocument16 pagesMechatronics Handbook - 02 - Mechatronic Design Approach PDFJosé Fernando TerronesNo ratings yet

- HKBEAMDocument0 pagesHKBEAMTse Lam ChanNo ratings yet

- Unidad de Potencia Hidraulica Hycon HPP13 FlexDocument9 pagesUnidad de Potencia Hidraulica Hycon HPP13 FlexJorge Diaz Nestor MonsalveNo ratings yet

- Omax Annual ReprtDocument78 pagesOmax Annual ReprtSalini RajamohanNo ratings yet

- Ferhat ErdalDocument22 pagesFerhat ErdalsaifoaNo ratings yet

- DC Components Co., LTD.: Rectifier SpecialistsDocument3 pagesDC Components Co., LTD.: Rectifier SpecialistsPICVIONo ratings yet

- Damper mechanism details for Atlas Copco rock drills under 40 charactersDocument27 pagesDamper mechanism details for Atlas Copco rock drills under 40 characterssalvador341100% (2)

- Kaplan Turbine Working As A Propeller CFD InvestigDocument11 pagesKaplan Turbine Working As A Propeller CFD InvestigclaudehackerNo ratings yet

- 2013 Renault ZOE PresskitDocument34 pages2013 Renault ZOE PresskitDidelisNo ratings yet

- Mechanics - Fluid Dynamics: K. Suresh Senanayake 1Document2 pagesMechanics - Fluid Dynamics: K. Suresh Senanayake 1mangsureshNo ratings yet

- Graviner MK6 Oil Mist DetectorDocument4 pagesGraviner MK6 Oil Mist DetectorDhanielNo ratings yet

- 568100Document2 pages568100Talha TariqNo ratings yet

- TSP-408L-1 P/N 32441-002: ApplicationDocument2 pagesTSP-408L-1 P/N 32441-002: ApplicationSajjad ShamimNo ratings yet

- Rpdir-L12 Shielding WebDocument73 pagesRpdir-L12 Shielding WebWiie ArdiNo ratings yet

- 2563-Wireless Catalogue enDocument151 pages2563-Wireless Catalogue enElafanNo ratings yet