Professional Documents

Culture Documents

Albert SGT Screw Jack

Uploaded by

Dado Maja Arsenin0 ratings0% found this document useful (0 votes)

96 views0 pagesA range of 11 sizes, coupled with a modul ar approach to nut and installation arrangements satisfy customer design requirements. The range has a logical progression of load capability between 5 and 1000 kN. Higher loads are possible and spindles upto10mlongcanbe provided.

Original Description:

Original Title

Albert Sgt Screw Jack

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA range of 11 sizes, coupled with a modul ar approach to nut and installation arrangements satisfy customer design requirements. The range has a logical progression of load capability between 5 and 1000 kN. Higher loads are possible and spindles upto10mlongcanbe provided.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

96 views0 pagesAlbert SGT Screw Jack

Uploaded by

Dado Maja ArseninA range of 11 sizes, coupled with a modul ar approach to nut and installation arrangements satisfy customer design requirements. The range has a logical progression of load capability between 5 and 1000 kN. Higher loads are possible and spindles upto10mlongcanbe provided.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 0

SGT screw jack

2013.01 INKOMA - GROUP

ALBERT INKOMA A- I - M

I

N

K

O

M

A

-

G

R

O

U

P

ALBERT- SGT- screw j acks ar e

el ect romechani cal t ransmi ssi on

components suitable for a wide

spectrum of industrial machinery. A

range of 11 sizes, coupled with a

modul ar approach to nut and

installation arrangements, satisfy

customer designrequirements.

The range has a logical progression of

load capability between 5 and 1000 kN.

Higher loads are possible and spindles

upto10mlongcanbe provided. Normal

stroke speeds up to 0.05m/s: For higher

speedspleaseenquire.

Logically designed combinations of

standard components, with good

i nterchangeabi l i ty, make si mpl e

installation possible whilst permitting

operation in any chosen position and

at t i t ude wi t h mi ni mum space

requirement.

ALBERT-SGT-screw jacks can be

provided with electrical, hydraulic,

pneumatic and manual inputs. Precise

relative motion is provided for screw

jacks used in combination but with

unequal loads. Rest positions are

maintained by the self locking

trapezoidal spindle or by the use of a

brake motor.

The wide range of available accessories

ensures the closest possible match to

customer requirements.

2013.01 INKOMA - GROUP

ALBERT INKOMA A- I - M

SGT screw jack

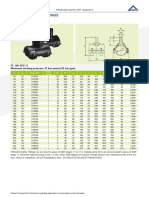

Running nut design

Version LO Version LU

Basic design

Ratio: N: normal, L: slow

Lubrication: grease

Accessories: see accessories for SGT screw jacks

Special sizes and executions are possible, please enquire.

S

p

i

n

d

l

e

Order code d

[mm]

F

max.

[kN]

N / L

[mm]

N / L

i

S

t

a

t

i

c

1

)

l

i

f

t

i

n

g

f

o

r

c

e

L

i

f

t

p

e

r

r

e

v

o

l

u

t

i

o

n

R

a

t

i

o

T

r

a

p

e

z

o

i

d

a

l

s

p

i

n

d

l

e

-

G

O

,

G

U

T

r

a

p

e

z

o

i

d

a

l

s

p

i

n

d

l

e

-

L

O

,

L

U

1)

The values for max. load apply only for initial jack selection. The actual

permitted liftingforce depends onthe versionof the jack and the operating

conditions.

SGT 5

SGT 20

SGT 50

SGT 200

SGT 350

SGT 750

SGT 30

SGT 150

SGT 300

SGT 500

SGT 1000

5

20

30

50

150

200

300

350

500

750

1000

0,6 / 0,25

1 / 0,25

1 / 0,25

1,17 / 0,29

1,5 / 0,5

1,5 / 0,5

1,5 / 0,5

1,5 / 0,5

1,5 / 0,5

1,5 / 0,5

1,67 / 0,56

Tr 20x6

Tr 26x6

Tr 30x6

Tr 40x7

Tr 60x12

Tr 65x12

Tr 90x16

Tr 100x16

Tr 120x16

Tr 140x16

Tr 160x20

10 / 24

6 / 24

6 / 24

6 / 24

8 / 24

8 / 24

10,66 / 32

10,66 / 32

10,66 / 32

10,66 / 32

12 / 36

SGT 5

SGT 20

SGT 50

SGT 200

SGT 350

SGT 750

SGT 30

SGT 150

SGT 300

SGT 500

SGT 1000

5

20

30

50

150

200

300

350

500

750

1000

0,6 / 0,25

1 / 0,25

1 / 0,25

1,17 / 0,29

1,5 / 0,5

1,5 / 0,5

1,5 / 0,5

1,5 / 0,5

1,5 / 0,5

1,5 / 0,5

1,67 / 0,56

Tr 20x6

Tr 26x6

Tr 30x6

Tr 40x7

Tr 60x12

Tr 65x12

Tr 90x16

Tr 100x16

Tr 120x16

Tr 140x16

Tr 160x20

10 / 24

6 / 24

6 / 24

6 / 24

8 / 24

8 / 24

10,66 / 32

10,66 / 32

10,66 / 32

10,66 / 32

12 / 36

G configuration has two : GO (

design, spindle above) and GU (basic design, spindle below). In

both cases the spindle moves to transmit the linear lifting motion.

The spindle is axially guided through the screw jack gear

housing. Any tendency of the spindle to rotate must be resisted.

(basic design) versions basic

L configuration (running nut) has two versions: LO ( ,

spindle above) and LU (running nut, spindle below). The axial

movement of the nut transmits the linear lifting motion due to

spindle rotation. In this configuration the spindle is axially fixed in

the gear housing.

running nut

Version GO Version GU

Maschinenfabrik ALBERT GmbH

Technologiepark 2

A - 4851 Gampern - Austria

phone: +43/(0)7682-39080-10

fax: +43/(0)7682-39080-99

e-mail: office@albert.at

internet: www.ALBERT.at

ALBERT

Request our complete catalogue or visit us on the Internet. You can obtain a free download of our brochure or the product drawing of the

selecteditem usingtheCADENASfacility.

You might also like

- Plates and ShellsDocument106 pagesPlates and ShellsMadhu Kiran KolatiNo ratings yet

- AGMA 915 1 A02 Gears Inspect PDFDocument46 pagesAGMA 915 1 A02 Gears Inspect PDFLuis TestaNo ratings yet

- Gear Cutting FormulaeDocument30 pagesGear Cutting Formulaeqoolshabi80% (5)

- Simp ValvesguideDocument27 pagesSimp ValvesguidevenkateshNo ratings yet

- FL Sim HDocument0 pagesFL Sim HDado Maja ArseninNo ratings yet

- G FortranDocument276 pagesG Fortranjavanbarg1893No ratings yet

- Gear Coupling 2014Document4 pagesGear Coupling 2014Dado Maja ArseninNo ratings yet

- Simp ValvesguideDocument27 pagesSimp ValvesguidevenkateshNo ratings yet

- Albert SpindlesDocument0 pagesAlbert SpindlesDado Maja ArseninNo ratings yet

- Albert JacksDocument0 pagesAlbert JacksDado Maja ArseninNo ratings yet

- Scilab 02Document0 pagesScilab 02Dado Maja ArseninNo ratings yet

- Albert JacksDocument0 pagesAlbert JacksDado Maja ArseninNo ratings yet

- Advanced ProgrammingDocument729 pagesAdvanced ProgrammingVladimir AnicicNo ratings yet

- Introduction To Discrete Probabilities With ScilabDocument39 pagesIntroduction To Discrete Probabilities With ScilabMargo HinesNo ratings yet

- Albert Accessories For SGT Screw JacksDocument0 pagesAlbert Accessories For SGT Screw JacksDado Maja ArseninNo ratings yet

- NCT90T Operator ProgrammerDocument143 pagesNCT90T Operator ProgrammerDado Maja ArseninNo ratings yet

- Advanced ProgrammingDocument729 pagesAdvanced ProgrammingVladimir AnicicNo ratings yet

- Advanced ProgrammingDocument729 pagesAdvanced ProgrammingVladimir AnicicNo ratings yet

- Volume Milling Wf4Document17 pagesVolume Milling Wf4Dado Maja ArseninNo ratings yet

- 04 Manual G Code Programming-1Document79 pages04 Manual G Code Programming-1Dado Maja ArseninNo ratings yet

- Abell - Differential Equations With MathematicaDocument641 pagesAbell - Differential Equations With MathematicaPablo100% (2)

- Heat Treatment SteelDocument48 pagesHeat Treatment Steeljiotoco33No ratings yet

- Heat Treatment of SteelsDocument18 pagesHeat Treatment of SteelsRajeev SaiNo ratings yet

- Heidenhain TNC 151 BQ Conversational ProgrammingDocument371 pagesHeidenhain TNC 151 BQ Conversational ProgrammingFranGiga100% (1)

- 04 Manual G Code Programming-1Document79 pages04 Manual G Code Programming-1Dado Maja ArseninNo ratings yet

- Jis and Fixture NotesDocument60 pagesJis and Fixture NotesMohammed KhatibNo ratings yet

- Tut OrialDocument152 pagesTut OrialAngel MntsNo ratings yet

- Advanced ProgrammingDocument729 pagesAdvanced ProgrammingVladimir AnicicNo ratings yet

- Short ProgrammingDocument101 pagesShort ProgrammingpadmarajanNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- F9540n Datasheet PDFDocument1 pageF9540n Datasheet PDFDanielNo ratings yet

- Fire Dampers Guide PL-12, PL-13, PL-14Document4 pagesFire Dampers Guide PL-12, PL-13, PL-14Muhidin KozicaNo ratings yet

- Opto-Isolated I/O Board: VCC Is 5 VDC, +V Is 5 VDC (VCC and +V Are Isolated For Each Other)Document2 pagesOpto-Isolated I/O Board: VCC Is 5 VDC, +V Is 5 VDC (VCC and +V Are Isolated For Each Other)Miklós GordosNo ratings yet

- TDK CD70 B2GA101KYGS Datasheet PDFDocument2 pagesTDK CD70 B2GA101KYGS Datasheet PDFSebastian ChaileNo ratings yet

- Cablemaster CM-8 - Rotater Application GuideDocument6 pagesCablemaster CM-8 - Rotater Application GuideGlendinning Products, LLC.No ratings yet

- 1SCA022798R0730 Ot600u03 Switch DisconnectorDocument3 pages1SCA022798R0730 Ot600u03 Switch Disconnectorsdk00No ratings yet

- The Mercedes-Benz C-ClassDocument61 pagesThe Mercedes-Benz C-ClassASIK1144No ratings yet

- Castle 6-10k User ManualDocument41 pagesCastle 6-10k User ManualNguyen VansuNo ratings yet

- LMC555 CMOS Timer: General Description FeaturesDocument8 pagesLMC555 CMOS Timer: General Description FeaturesDaryl ScottNo ratings yet

- US AutoSeal II 100 (EN) 2009 12Document54 pagesUS AutoSeal II 100 (EN) 2009 12tafhim rashidNo ratings yet

- Terasaki Short Form FINAL WEBDocument16 pagesTerasaki Short Form FINAL WEBgovind1965No ratings yet

- PriceDocument2 pagesPriceNik FirmannNo ratings yet

- Asl FD 260 - 380 (W)Document11 pagesAsl FD 260 - 380 (W)Comercial BrascomNo ratings yet

- Timberrite Controller Parts Manual: Series HarvesterDocument38 pagesTimberrite Controller Parts Manual: Series Harvestermauricio1barrientos1100% (1)

- 2n1487 PDFDocument3 pages2n1487 PDFneko1212121515123001No ratings yet

- Brief Introduction: ADVANCE Brand. We Are The OE Supplier of Some FamousDocument21 pagesBrief Introduction: ADVANCE Brand. We Are The OE Supplier of Some FamousАлександр ФедоровNo ratings yet

- Low VoltageDocument20 pagesLow VoltageFarhan ShahNo ratings yet

- 40XMH'11 40XW'11: (67TL) (67TK)Document50 pages40XMH'11 40XW'11: (67TL) (67TK)Carlos NetoNo ratings yet

- Rock dowel installation requirementsDocument4 pagesRock dowel installation requirementsMohamed SafrasNo ratings yet

- Spigot Saddles: Frialen Safety FittingsDocument2 pagesSpigot Saddles: Frialen Safety FittingsAlbertoNo ratings yet

- 8086/8088 Microprocessor Bus Timing AnalysisDocument6 pages8086/8088 Microprocessor Bus Timing AnalysisHassan Al BaityNo ratings yet

- Card Reading Accessories: Tps900 Eft PosDocument2 pagesCard Reading Accessories: Tps900 Eft PosEris Osman RifkiNo ratings yet

- Spare Parts List for Electric Stacker PS 16NDocument81 pagesSpare Parts List for Electric Stacker PS 16NMuhammad KhalidNo ratings yet

- Hyundai 35DS-7 technical manual parts listDocument489 pagesHyundai 35DS-7 technical manual parts listMichał LicznerskiNo ratings yet

- 29 Fs 2Document33 pages29 Fs 2Tiyo donald cobainNo ratings yet

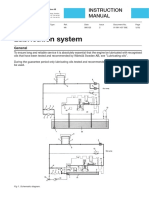

- Wärtsilä lubrication system manualDocument10 pagesWärtsilä lubrication system manualLIVIANo ratings yet

- Brosur SMA STP 8-10 - 3AV-40 - HDPDocument2 pagesBrosur SMA STP 8-10 - 3AV-40 - HDPadi brwNo ratings yet

- X11SNI&ODocument23 pagesX11SNI&Oprihartono_diasNo ratings yet

- ANSI Device Numbers 14-12-2015Document2 pagesANSI Device Numbers 14-12-2015mohammed KhaledNo ratings yet

- AIL Dahej Operation Manual For 18 Inch Dia. 15 Plates Zero Hold Up Sparkler Filter SystemDocument4 pagesAIL Dahej Operation Manual For 18 Inch Dia. 15 Plates Zero Hold Up Sparkler Filter SystemRishabh VermaNo ratings yet