Professional Documents

Culture Documents

1,3 Butadiene Production

Uploaded by

asharab70Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1,3 Butadiene Production

Uploaded by

asharab70Copyright:

Available Formats

Page : 1 of 26

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Rev: 01

www.klmtechgroup.com

September 2011

KLM Technology Group Malaysia #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru USA PO Box 1814 Livingston Texas 77351

Author: Rev 01 Mochamad Adha Firdaus

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINE)

Karl Kolmetz

TABLE OF CONTENT INTRODUCTION Scope General Design Consideration DEFINITION NOMENCLATURE THEORY

Properties Manufacturing Extractive Distillation Advantages of Extractive Distillation Spesifications Stabilization, Storage, and Transportation Uses and Economic Importance

5 5 6 8 10 11

11 28 35 44 45 46 47

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 2 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

APPLICATION

Application Case : Problems in Extractive Distillation

50

50

REFEREENCE LIST OF TABLE

Table 1: Explosion limits of butadiene in air Table 2: Binary azeotropic mixtures of 1,3 butadiene Table 3: Solubility of butadiene in water at 101.3 kPa Table 4: Product Distirbution from steam cracking Table 5: Catalytic dehydrogenation of butanes Table 6: Feedstocks and steam cracking yields (in wt%) Table 7: Typical analysis of C4 fractions (in vol%) Table 8: Comparison of relative volatility Table 9: Comparison of Solvent swap Table 10 : Typical spesifications of butadiene Table 11 : Butadiene production, capacities, and consumption in 1998 Table 12 : Butadiene usage in 1998

60

12 12 12 30 33 33 34 35 40 45 47 48

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 3 of 63

Rev: 01 BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

September 2011

LIST OF FIGURE

Figure 1.(a): The s-cis form Figure 1.(b): The s-trans form Figure 2: 1,2 addition product Figure 3: 1,4 addition product Figure 4: The intermediate of addition product Figure 5: The addition of HI Figure 6: The addition of HCN Figure 7: 1,2-cyclic intermediate Figure 8: Chloroprene production Figure 9: Addition of SO2 Figure 10: 1,4-butadienol production Figure 11 : Trans-2-butene-d2 Figure 12: Oxidized products of butadiene Figure 13: Direct oxidation butadiene with air or oxygen Figure 14: The Diels-Alder reaction Figure 15: 1,4 Addition with sulfur dioxide to butadiene Figure 16.(a) : 1,6-octadiene Figure 16.(b) : 1,7-octadiene Figure 17: Dimerization in the presence of reducing agents Figure 18.(a) : COD 13 13 14 14 14 15 16 17 17 18 18 19 20 21 22 22 24 24 24 24

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 4 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Figure 18.(b) : CTT Figure 18.(c) : TTT Figure 19: Telomerization of butadiene with a carboxylic acid Figure 20: Process Figure 21: Telomerization butadiene with ammonia Figure 22: Telomerization of butadiene with carbon dioxide Figure 23: Tricarbonyl complex Figure 24: O-xylene reacts with butadiene Figure 25: Producing butadiene from acetylene Figure 26: The Houdry Catadiene Process Figure 27: Butadiene Extraction Overview Figure 28: Extractive Distillation between n-Butane and n-Butene Figure 29: Extractive distillation process with NMP Figure 30: Butadiene Extraction Plant Figure 31: Eco-Efficiency Analysis for NMP Solvent Figure 32: Classic Design of Extraction Distillation Section Figure 33: Divided Wall Design Figure 34: Classic Design of Degassing Section Figure 35: New Compressorless Degassing System Figure 36: Butadienes price in Western Europe, Figure 37: Causes of column malfunctions

24 24 25 26 26 27 27 28 29 31 36 36 37 39 40 42 42 43 44 49 52

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 5 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Figure 38: Typical Plant for Butadiene Extraction Figure 39: Evolutionof Structured Packing Figure 40: Liquid Hold Up Profile Figure 41: Popcorn Polymer Figure 42: Deck Opening Size Efficiency Figure 43: Stagnant Zones Figure 44: Baffle bar on the tray Figure 45: Elimination Stagnant zone

53 54 55 56 57 58 58 59

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 6 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

INTRODUCTION Scope This guideline provides the details of the processes for the production of 1,3 Butadiene and its derivatives. This guidelines discuses butadiene extraction or extractive distillation plants, which produce high purity 1,3-butadiene from raw C 4 (steam cracker) feeds. There are more than 100 such plants in the world. Process layouts considered are: (i) two extractive distillations, whereby in the first stage raffinate-1 is the distillate and in the second stage acetylenic components are removed, (ii) single extractive distillation with superfractionation, (iii) single extractive distillation with selective hydrogenation of acetylenic components. The benchmark also includes butane or butene dehydrogenation plants, which have a different feedstock. Extractive Distillation is an important tool for the separation of isomers and close boiling species. An extractive distillation solvent is added to the column increasing the relative volatility of the close boiling species allowing distillation to be utilized. Several applications of extractive distillation have been successfully commissioned

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 7 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

General Design Considerations 1,3 Butadiene is a conjungated diene with the formula C4H6. It is an important industrial chemical used as a monomer in the production of synthetic rubber. In the United States, Western Europe, and Japan, butadiene is produced as a byproduct of the steam cracking process used to produce ethylene and other olefins. When mixed with steam and briefly heated to very high temperatures (often over 900 C), aliphatic hydrocarbons give up hydrogen to produce a complex mixture of unsaturated hydrocarbons, including butadiene. The quantity of butadiene produced depends on the hydrocarbons used as feed. Light feeds, such as ethane, give primarily ethylene when cracked, but heavier feeds favor the formation of heavier olefins, butadiene, and aromatic hydrocarbons. Butadiene is typically isolated from the other four-carbon hydrcarbons produced in steam cracking by extractive distillation using a polar solvent such as acetonitrile, Nmethylpyrrolidone, furfural, or dimethylformamide, from which it is the stripped by distillation. Most butadiene is polymerized to produce synthetic rubber. While polybutadiene itself a very soft, almost liquid material, copolymers prepared from mixtures of butadiene with styrene and/or acrylonitrile, such as acrylonitrile butadiene styrene (ABS), acrylonitrile butadiene (NBR) and styrene-butadiene (SBR) are tough and/or elastic. SBR is the material most commonly used for the production of automobile tires. Smaller amounts of butadiene are used to make the nylon intermediate adiponitrile, by the addition of a molecule of hydrogen cyanide to each of the double bonds in a process called hydrocyanation. Other synthetic rubber materials such as chloroprene, and the solvent sulfolane are also manufactured from butadiene. Butadiene is used in the industrial production of 4-vinylcyclohexane via a Diels Alder dimerization reaction. Storage of butadiene as a compressed, liquified gas carries a specific and unusual hazard. Overtime, polymerization can begin, creating a crust of solidified material (popcorn polymer) inside the vapor space of cylinder. If the cylinder is then disturbed, the crust can contact the liquid and iniatiate an auto-catalytic polymerization. The heat released accelerates the recaction, possibly leading to cylinder rupture.

o

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 8 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Inhibitors are typically added to reduce this hazard, but butadiene cylinders should still be considered short-shelf life times. The hazard presented by popcorn polymer is also present in bulk commercial storage tanks. It is important to keep the oxygen concentration in the tanks and any process wash water low in order to reduce the rate of polymerization. As with other light hydrocarbons, butadiene leaks can be detected bu the formation of ice balls (from the evaporative freezing of water out of the atmosphere) even when the o temperature is well above 0 C.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 9 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

DEFINITIONS Bottoms The stream of liquid product collected from the reboiler at the bottom of a distillation tower. Bubble point The temperature at constant pressure (or the pressure at constant temperature) at which the first vapor bubble forms when a liquid is heated (or decompressed). Dew point The temperature at constant pressure (or the pressure at constant temperature) at which the first liquid droplet forms when a gas (vapor) is cooled (or compressed). Distillate The vapor from the top of a distillation column is usually condensed by a total or partial condenser. Part of the condensed fluid is recycled into the column (reflux) while the remaining fluid collected for further separation or as final product is known as distillate or overhead product Downcomer - a vertical channel that connects a tray with the next tray below which carries froth and creates residence time which helps the vapor disengage from the froth. Downcomer Area - is the area available for the transport of liquid from one tray to the next tray below. Endothermic - A process or reaction that absorbs heat, i.e. a process or reaction for which the change in enthalpy, H, is positive at constant pressure and temperature Entrainment liquid carried by vapor up to tray above and caused by high vapor flow rates Exothermic - A process or reaction that absorbs heat, i.e. a process or reaction for which the change in enthalpy, H, is negative at constant pressure and temperature Flooding brought about by excessive vapor flow, causing liquid to be entrained in the vapor up the column. Popcorn butadiene polymerizes to polybutadiene.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 10 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Reboiler Is a heat exchanger typically used to provide heat to the bottom of industrial distillation columns. They boil the liquid from the bottom of a distillation column to generate vapors which are returned to the column to drive the distillation separation. Reflux ratio The ratio of the reflux stream to the distillate. The operating reflux ratio could affect the number of theoretical stages and the duties of reboiler and condenser. Relative volatility Defined as the ratio of the concentration of one component in the vapor over the concentration of that component in the liquid divided by the ratio of the concentration of a second component in the vapor over the concentration of that second component in the liquid. For an ideal system, relative volatility is the ratio of vapor pressures i.e. = P2/P1 Steam cracking - High-temperature cracking of petroleum hydrocarbons in the presence of steam. Splitter - A name applied to fractionators, particularly those separating isomers

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 11 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

1,3 BUTADIENE 1,3 Butadiene is a conjungated diene with the formula C4H6. It is an important industrial chemical used as a monomer in the production of synthetic rubber. In the United States, Western Europe, and Japan, butadiene is produced as a byproduct of the steam cracking process used to produce ethylene and other olefins. When mixed with steam and briefly heated to very high temperatures (often over o 900 C), aliphatic hydrocarbons give up hydrogen to produce a complex mixture of unsaturated hydrocarbons, including butadiene. The quantity of butadiene produced depends on the hydrocarbons used as feed. Light feeds, such as ethane, give primarily ethylene when cracked, but heavier feeds favor the formation of heavier olefins, butadiene, and aromatic hydrocarbons. Butadiene is typically isolated from the other four-carbon hydrcarbons produced in steam cracking by extractive distillation using a polar solvent such as acetonitrile, Nmethylpyrrolidone, furfural, or dimethylformamide, from which it is the stripped by distillation. Most butadiene is polymerized to produce synthetic rubber. While polybutadiene itself a very soft, almost liquid material, copolymers prepared from mixtures of butadiene with styrene and/or acrylonitrile, such as acrylonitrile butadiene styrene (ABS), acrylonitrile butadiene (NBR) and styrene-butadiene (SBR) are tough and/or elastic. SBR is the material most commonly used for the production of automobile tires.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 12 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

THEORY Properties Butadiene is a colorless gas undernormal conditions. Some physical properties are summarized in the following : mp at 101.3 kPa bp at 101.3 kPa

Critical Temperature, Tc Critical Pressure, Pc

Critical molar volume Density o At 0 C o At 25 C o At 50 C Gas Density (air = 1) Viscosity of liquid o At 0 C o At 50 C Vapor Pressure o At -4.4 C o At 0 C o At 25 C o At 50 C o At 75 C o At 100 C Enthalphy of vaporization o At -4.4 C o At 25 C Enthalphy of formation Enthalphy of combustion Enthalphy of formation Enthalpy of melting

-108.9 C o -4.4 C 425 K 4.32 MPa 3 221 cm /mol 0.646 g/cm 3 0.616 g/cm 3 0.582 g/cm 1.87

3

0.25 mPa.s 0.20 mPa.s

101.3 kPa 120 kPa 273.6 kPa 537.9 kPa 986.7 kPa 1733 kPa 22.47 kJ/mol 20.86 kJ/mol 110.0 kJ/mol (gaseous, at 298 K, 101.3 kPa) 2541.5 kJ/mol (gaseous, at 298 K, 101.3 kPa) 199.0 J/mol.K (liquid, at 298 K, 101.3 kPa) 7.988 kJ/mol (at 164.2 K, 101.3 kPa)

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 13 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

o

The technical data important for reasons of safety are, above all, the flash point, 85 C, o the ignition temperature, 415 C, and the explosion limits when mixed with air and oxygen (Table 1). Unstabilized or insufficiently stabilized butadiene forms explosive peroxides with atmospheric oxygen. Table 2. lists azeotropic mixtures relevant to distillation of butadiene-containing hydrocarbons.

Table 1. Explosion limits of butadiene in air o At 101.3 kPa, 20 C 3 Limit Vol % g/cm Lower Limit 1.4 31 Upper Limit 16.3 365

At 490.4 kPa, 30 C 3 Vol % g/cm 1.4 150 ca. 22 ca. 2400

Table 2. Binary azeotropic mixtures of 1,3 butadiene o Mixture bp, C (at Composition 101.3 kPa) Butane/Butadiene Min. trans-2-Butene/1-butyne 25.5 wt % 1 butyne cis-2-Butene/vinylacetylene Min. Butadiene/2-butene -5.53 24.5 wt % 2-butene Methylamine/vinylacetylene -6.8 2.5 wt % vinylacetylene Ammonia/butadiene -37 45 wt% butadiene Ammonia/1-butene -37.5 55 wt% 1-butene Ammonia/isobutene -38.5 55 wt% isobutene Ammonia/n-butane -37.1 55 wt% n-butane Ammonia/isobutane -38.4 65 wt% isobutane Methylamine/butadiene -9.5 58.6 wt% butadiene Acetaldehyde/butadiene 5.0 94.8 wt% butadiene

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 14 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Butadiene is sparingly soluble in water, see Table 3, soluble in methanol and ethanol, and very soluble in higher-boiling polar solvents, e.g., methylpyrrolidone.

Table 3. Solubility of butadiene in water at 101.3 kPa, and solubility L of water in liquid butadiene

t, C 10 20 30 40

, m3/m3

0.29 0.23 0.19 0.16

L, g H2O/kg butadiene 0.53 0.66 0.82

1,3 Butadiene, the simplest conjungated diene, has been the subjected of intensive theoretical and experimental studies to understand its physical and chemical properties. The conjungation of double bonds makes it 15 kJ/mole (3.6 kcal/mol) more thermodynamically stable than a molecule with two isolated single bonds. Butadiene has two conjugated double bonds and therefore can take part in numerous reactions, which include 1,2- and 1,4-additions with itself (polymerization) and other reagents, linear dimerization and trimerization, and ring formation. The s-trans isomer, often called the trans form, is more stable than the s-cis form at room temperature. Although there is a 20 kJ/mole (4.8 kcal/mol) rotational barrier, rapid equilibrium allows reactions to take place with either the s-cis or the s-trans form (Figure 1)

. (a) (b)

Figure 1.(a) the s-cis form, (b) the s-trans form The double-bond length in 1,3-butadiene is 0.134 nm, and the single-bond, 0.148 nm. Since normal carbon-carbon single bonds are 0.154 nm, this indicates the extent of double-bond character in the middle single-bond. Upon complexing with metal carbonyl

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 15 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

moieties like Fe(CO)3, the two terminal bonds lengthen to 0.141 nm, and the middle bond shortens even more to 0.145 nm. Reactions Since the discovery of 1,3-butadiene in the 19th century, it has grown into extremely versatile and important industrial chemical. Its conjungated double bonds allow a large number of unique reactions at both the 1,2- and 1,4-positions. Many of these reactions produce large volumes of important industrial materials. Addition 1,3-Butadiene reacts readily via 1,2- and 1,4-free radical or electrophilic addition reactions to produce 1-butene or 2-butene substituted products, resperctively. The reactions shows in Figure 2 & Figure 3 The natures of these polymers depends greatly on the way in which they are prepared and on the catalyst system employed.

Figure 2. 1,2-addition product

Figure 3. 1,4-addition product

The intermediate in these reactions in the case of the addition of XY is consistent with the addition of Y to the 1-position to form an allylic intermediate to which X adds to produce either the 1,2 or 1,4-product as follows in Figure 4.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 16 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Figure 4. The intermediate of addition product.

The addition of HX, where X is halogen compounds, has been thoroughly investigated. Wether 1,2- or 1,4-product dominates depends on reaction conditions. For instance, although HCl adds to butadiene at low temperature to produce 75 80% of the 1,2 addition product, the thermodynamically more stable 1,4-isomer is favored at higher temperatures. On the other hand, HI has been shown to add to butadiene in the vapor phase by a pericyclic mechanism to produce the 1,4-product.

Figure 5. The addition of HI. Addition of water or alcohols directly to butadiene at 40 100 C produces the corresponding unsaturated alcohols of ethers. Acidic ion exchangers have been used to catalyze these reactions. The yields for these latter reactions are generally very low because of unfavorable thermodynamics. At 50 C addition of acidic acid to butadiene produces the expected butenyl acetate with 60 100% selectivity at butadiene conversions of 50%. The catalysts are ion-exchange resins modified with quaternary ammonium, quaternary phosphonium, and ammonium substituted ferrocenyl ions.

o o

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 17 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Addition of amines yields unsaturated alkyl amines. The reaction can be catalyzed by homogenous catalysts such as Rh[P(C6H5)3] 3Cl of heterogeneous catalyst such as MgO and other solid bases. The manufacture of hexamethylenediamine[2], a key comonomer in nylon-6,6 production proceeds by a two step HCN addition reaction to produce adiponitrile[3] (Figure 6), NCCH2CH2CH2CH2CN. The adiponitrile is then hydrogenated to produce the desired diamine. The other half of nylon-6,6, adipic acid, can also be produced from butadiene by means of either of two similar routes involving the addition of CO. Reaction between the diamine and adipic acid produces nylon-6,6.

Figure 6. The addition of HCN In the production of adiponitrile and hexamethylenediamine, hydrogen cynide reacts with butadiene in two steps, and the adiponitrile thus obtained is hydrogenated to give the 0 diamine. Typical catalysts are Ni phospoine and phospite complexes with Al/Zn o promotors. Typical reaction conditions are 90 150 C and ambient pressure in THF. The first CO route to make adipic acid is a BASF process employing CO and methanol in a two-step process producing dimethyl adipate which is then hydrolyzed to the acid. Cobalt carbonyl catalysts such as Co2(CO)8 are used. Palladium catalysts can be used to effect the same reactions at lower pressures.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 18 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

The other CO route for adipic acid manufacture involves 1,4 addition of CO and O 2 to butadiene to produce an intermediate, which is subsequently hydrogenated and hydrolyzed to adipic acid. This is called the oxycarbonylation process. Both the BASF and the oxycarbonylation processes have been intensively investigated. Halogenation of butadiene has also attracted a lot of interest. Both 1,2- and 1,4-isomers are formed. Since the trans-1,4-isomer was observed from the 1,4 addition product, + researchers postulate that the electrophilic X forms a 1,2-cyclic intermediate (Figure 7) and not a 1,4-cyclic intermediate that would form the cis-1,4-addition product.

Figure 7. 1,2-cyclic intermediate Fluorination with XeF2 or C6H5IF2 gives both the 1,2- and 1,4-difluoro products. This + reaction proceeds via initial electrophilic addition of F to the diene. Chloroprene, 2-chloro-1,3-butadiene (Figure 8), is produced commercially from butadiene o in a three-step process. Butadiene is first chlorinated at 300 C to 60:40 mixtures of the 1,2- and 1,4-dichlorobutene isomers. This mixture is isomerized to the 3,4-dichloro-1butene with the aid of a Cu-Cu2Cl2 catalysts followed by dehydrochlorination with base such as NaOH.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 19 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Figure 8. Chloroprene production.

Butadiene also undergoes a 1,4-addition reaction with SO2 to give sulfolene. This reaction followed by hydrogenation is commercially used to manufacture sulfolane (Figure 9).

Figure 9. Addition of SO2 Formaldehyde also reacts with butadiene via the Prins reaction to produce pentenediols or their derivatives. This reaction is catalyzed by a copper-containing catalyst in a

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 20 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

carboxylic acid solution or RuCl 3. The addition of hydrogen also proceeds via 1,2- and 1,4-addition. Several processes have been developed for the production of 1,4-butanediol from butadiene. In the three-step Mitsubishi process, butadiene catalytically reacts with acetic acid to give 1,4-diacetoxy-2-butene, which in turn is hydrogenated to 1,4-butanediol. A similar process was reported by BASF.

Figure 10. 1,4-butanediol production (Mitsubishi process)

The Toyo Soda process for the preparation of 1,4-butanediol involves the reaction of the butadience chlorine addition products 1,4-dichloro-2-butene and 1,2-dichloro-3-butene with sodium acetate or formate to give 1,4-diacetoxy-2-butene or 1,4-diromyl-2-butene, which are then hydrolyzed and hydrogenated to 1,4-butanediol.

Hydrogenation Reactions Butadiene can be hydrogenated to n-butanes and n-butane using a large number of heterogenous and homogenous catalysts. Palladium-containing membranes have also been used to allow the use of permeated hydrogen to effect hydrogenation. Many catalysts have been developed and used commercially to remove small quantities ( 3%) of butadiene from 1-butene streams.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 21 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Since 2-butene is more stable thermodynamically than 1-butene under mild conditions, catalysts that promote 1,2-addition and do not isomerize 1-butene are essential for getting high 1-butene selectivity. Many of the palladium catalysts require the use of CO to improve 1-butene selecitvity. Selectivities to various isomers are more difficult to predict when metal oxides are used as catalysts. ZnO prefentially produced 79% 1-butene and several percent of cis-2butene. CdO catalyst produced 55% 1-butene and 45% cis-2-butene. It was also reported that while interconversion between 1-butene and cis-2-butene was quite facile on CdO, cis-trans isomerization was slow. This was attributed to the presence of a -allyl anion intermediate. High cis-2-butene selectivities were obtained with molybdenum carbonyl encapsulated in zeolites. On the other hand, deuteration using ThO 2 catalyst produced predominantly the 1,4-addition product, trans-2-butene-d2 with no isotope scrambling.

Figure 11. Trans-2-butene-d2

Although supported Pd catalysts have been the most extensively studied for butadiene hydrogenation, a number of other catalysts have also been the object of research studies. Some examples are Pd film catalysts, molybdenum sulfide, metal catalysts containing Fe, 3Co, Ni, Ru, Rh, Os, Ir, Pt, Cu, MgO, HCo(CN) 5 on supports, and LaCoC3 Perovstrike. There are many others. Studies on the well-characterized Mo(II) monomer and Mo(II) dimer on silica carrier catalysts have shown wide variations not only in catalyst performance, but also of activation energies. Another method to hydrogenate butadiene occurs during an oxidation-reduction reaction in which n alcohol is oxidized and butadiene is reduced. Thus copper-chromia or copperzinc oxide catalyzes the transfer of hydrogen from 2-butanol or 2-propanol to butadiene at o 90 130 C.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 22 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

DEHYDROGENATION OF BUTANE: CHEMICAL REACTIONS: (a) Main reaction: C4H10 C4H6+ 2H2; H = +32.2 Kcal (b) Side reaction: C4H10 C4H8 + H2 A refinery gas of C4/C5 cut containing predominantly n-butane with some isopentane is mixed with recycle gas and preheated to reaction temperature prior to contact with a catalyst in a fixed bed, regenerative-heating system. A pair of reactors forms an adiabatic cycle with the heat of reaction required during the 5-15 minutes make period equal to that supplied by the combustion of carbon deposit on the catalyst during the regenerative period.

The temperature of reaction at the start of the make period is 650oC dropping to nearly 400oC at the end before switching to regeneration. The pressure is low, 120-150 mm absolute, to force the reaction to the right.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 22 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

The overhead is fractionated to yield crude butadiene at the top, which is purified by absorption using cuprous ammonium acetate (CAA), extractive distillation with furfural or azeotropic distillation with ammonia. The more common absorption process involves contact of the close-boiling butadiene-butene fraction with lean CAA solution, which dissolves butadiene. A desorption step at higher temperature is followed by distillation, compression, and liquefaction of butadiene to give 98-99% product purity. Ammonia is recovered in the distillation tower by water addition; it is then separated as substantially anhydrous NH3 by fractionation. MATERIAL BALANCE

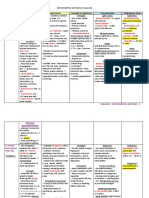

Stream No. C4H10 C4H8 C4H6 C3H8 C5H12 H2 CO2 O2 N2 Total

(mole fraction)

1 0.999985 0.0001318 0.0000161 1 172.4385

2 0.999913 0.00007689 0.00000939 1 295.5911

3 0.1887 0.8113 1 201.0086

4* 0.0137 0.175 0.8113 1 201.0086

5 0.2147 0.11906 0.18104 0.0000396 0.0000048 0.48580 1 573.52670

Flow rate

(kmol/min)

*Note: Streams 4(a) and 4(b) have same mole fraction as that of stream 4. Similarly mole fractions of streams 5,6 and 7 are same.

Stream No. C4H10 C4H8 C4H6 C3H8 C5H12 H2 Naphtha Total

(mole fraction)

7 0.2147 0.11906 0.18104 0.0000396 0.0000048 0.48580 1 573.52670

8 1 1 167.193

9 0.26650 0.14776 0.22386 4.92 x 10-9

0.000006009

0.0000602 0.3618 1 462.1048

10 0.0000978 0.99999 1 278.6193

11 0.41709 0.23125 0.35036

-

0.00000940 0.00127 1 573.52670

12 0.41910 0.23237 0.34828 1 293.846

13 0.7325 0.001966 0.2655 1 1.41226

Flow rate

(kmol/min)

*Note: Negligible amounts (mole fractions) are not taken into account.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 22 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

Stream No. C4H10 C4H8 C4H6 CAA NH3 H2O Total

(mole fraction)

14 0.81054 0.18946 1 181.266

15 0.194 0.2909 0.41744 0.09807 1 359.960

16 0.33330 0.49947 0.16750 1 205.02973

17 0.0529 0.94718 1 155.116

18 1

-

19 0.6653 0.000099 0.3346 1 102.6374

20 1 1

21 0.00372 0.62359 0.37269 1

1 102.39509

Flow rate

(kmol/min)

20.524

55.0727

*Note

Yield = 60% Conversion across the reactor = 35% In absorber, actual solvent rate be 1.2 times the minimum solvent rate. 1/2 kg of CAA be used per kg of crude butadiene. 0.2 kg of NH3be used per kg of Let 0.2 kg of H2O be used per kg of

C4H6, C4H8 mixture. C4H6, NH3 mixture (assumed).

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 22 of 63

BUTADIENE PROCESSING UNIT (ENGINEERING DESIGN GUIDELINES)

Rev: 01

September 2011

NOMENCLATURES atm ABS CR DM bp mp kJ K NBR Pa Pc ppm SBR SG Tc Tk t/a t/yr USITC US$ Vol % wt % Standard atmosphere, 101325 Pascal Acrylonitrile Butadiene Styrene Chloroprene Rubber Deutsche Mark, Official currency of Germany Boiling Point Melting Point Kilo Joule Quality characterization factor Nitrile Butadiene Rubber Pascal Critical Pressure Part per million Styrene Butadiene Rubber Spesific Gravity Critical Temperature Molal average boiling point, Kelvin Tons/Annual Tons/Year The United States Internation Trade Commission The United States Dollar, Official currency of US Percent volume Percent weight

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

You might also like

- Introduction to Petroleum Chemicals: Based on Lectures Given at the Manchester College of Science and TechnologyFrom EverandIntroduction to Petroleum Chemicals: Based on Lectures Given at the Manchester College of Science and TechnologyH. SteinerNo ratings yet

- 1,3 ButadieneDocument7 pages1,3 ButadieneAbdalmoedAlaiashyNo ratings yet

- 5 6251216941030047774Document41 pages5 6251216941030047774Salihah AbdullahNo ratings yet

- BASF Process Butadiene SeparationDocument6 pagesBASF Process Butadiene SeparationNatko47No ratings yet

- Fluid Catalytic Cracking: Science and TechnologyFrom EverandFluid Catalytic Cracking: Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Ethylene and Acetylene Plant PDFDocument405 pagesEthylene and Acetylene Plant PDFاحمد الدلالNo ratings yet

- ButadineDocument68 pagesButadineraihonaNo ratings yet

- Advanced Distillation Technologies: Design, Control and ApplicationsFrom EverandAdvanced Distillation Technologies: Design, Control and ApplicationsNo ratings yet

- تعديلات المشروعDocument114 pagesتعديلات المشروعSadam FirasNo ratings yet

- Manufacturing of AcetyleneDocument45 pagesManufacturing of Acetylenebecpavan100% (1)

- Polymer Next PDFDocument31 pagesPolymer Next PDFali100% (2)

- Acrylonitrile by The Ammoxidation of PropaneDocument10 pagesAcrylonitrile by The Ammoxidation of PropaneVincet Vega100% (1)

- UTM Propylene Production Plant Final ReportDocument119 pagesUTM Propylene Production Plant Final ReportGrey DaveNo ratings yet

- Maleic AnhydrideDocument6 pagesMaleic AnhydrideTechnologist ChemicalNo ratings yet

- Acido AceticoDocument13 pagesAcido Aceticoting_tatNo ratings yet

- Lecture 5 Acetic AcidDocument6 pagesLecture 5 Acetic AcidYan LaksanaNo ratings yet

- HYSYS - Multiple Reactions - Styrene Prepared by Robert P. Hesketh Spring 2005 Styrene Reactor SystemDocument9 pagesHYSYS - Multiple Reactions - Styrene Prepared by Robert P. Hesketh Spring 2005 Styrene Reactor SystemCarlos GonzalezNo ratings yet

- Project ReportDocument12 pagesProject ReportRabia SabirNo ratings yet

- Ethylene ProductionDocument14 pagesEthylene ProductionMaria Cecille Sarmiento Garcia100% (1)

- 2 - TDVS GopalkrishnaDocument61 pages2 - TDVS GopalkrishnaManav GaneshNo ratings yet

- C4 DerivativesDocument2 pagesC4 DerivativesdaabgchiNo ratings yet

- Project On Propylene OxideDocument38 pagesProject On Propylene Oxidemikelycan75% (4)

- Vinyl Chloride Monomer/Ethylene Dichloride (VCM/EDC)Document10 pagesVinyl Chloride Monomer/Ethylene Dichloride (VCM/EDC)PuLung Sambadha100% (1)

- Ethyl Benzene Plant DesignDocument45 pagesEthyl Benzene Plant DesignfaridzawiNo ratings yet

- PRODUCTIONOFMALEICANHYDRIDEFROMOXIDATIONOFn BUTANE PDFDocument456 pagesPRODUCTIONOFMALEICANHYDRIDEFROMOXIDATIONOFn BUTANE PDFRitik Chaudhary100% (2)

- Industrial Repor1Document33 pagesIndustrial Repor1Truly SelenatorNo ratings yet

- Production of Acrylonitrile by Ammoxidation of PropyleneDocument33 pagesProduction of Acrylonitrile by Ammoxidation of PropyleneJ José B VelasquezNo ratings yet

- Ethylene BalanceDocument29 pagesEthylene BalanceCraigUnderwood100% (2)

- Trambouze, P. - Petroleum Refining (Materials and Equipment)Document754 pagesTrambouze, P. - Petroleum Refining (Materials and Equipment)JosueGuayuscaSoriaGalvarro100% (1)

- Chapter 3Document14 pagesChapter 3Larry Jampong100% (1)

- Light Naphtha Isomerization Process ReviewDocument17 pagesLight Naphtha Isomerization Process Reviewagarwalashwin32100% (2)

- Aspen Acrylonitrile PDFDocument5 pagesAspen Acrylonitrile PDFPraveen KumarNo ratings yet

- Report Petrochemical Sec BenchmarkingDocument174 pagesReport Petrochemical Sec BenchmarkingSachin Chavan100% (2)

- Lecture2 (Petrochemical)Document12 pagesLecture2 (Petrochemical)ToniAndiwijaya100% (1)

- Glycol PlantDocument8 pagesGlycol PlantDian Risti PurwantiNo ratings yet

- Production of Vinyl Chloride From Ethylene Dichloride by Pyrolysis Aspen Model DocumentationDocument14 pagesProduction of Vinyl Chloride From Ethylene Dichloride by Pyrolysis Aspen Model DocumentationParaiba da Paraiba100% (2)

- Production of Mono Ethylene GlycolDocument170 pagesProduction of Mono Ethylene GlycolNoman Aslam100% (2)

- Oyekan, Soni - Catalytic Naphtha Reforming process-CRC Press - Taylor & Francis Group (2018) - CompressedDocument379 pagesOyekan, Soni - Catalytic Naphtha Reforming process-CRC Press - Taylor & Francis Group (2018) - CompressedBodhisatya Das100% (4)

- Methyl Methacrylate Plant CostDocument3 pagesMethyl Methacrylate Plant CostIntratec Solutions50% (2)

- 64788Document35 pages64788ghatak2100% (1)

- C4 Operations Optimization PDFDocument45 pagesC4 Operations Optimization PDFViệt HàNo ratings yet

- Project Ethyl Benzene .. 2019-20 .. Jay RSDocument100 pagesProject Ethyl Benzene .. 2019-20 .. Jay RSBhatu DevareNo ratings yet

- (Ted M. Knowlton, Chair) Proceedings of InternationalDocument832 pages(Ted M. Knowlton, Chair) Proceedings of InternationalAbshar ParamaNo ratings yet

- Vinyl Chloride MonomerDocument6 pagesVinyl Chloride MonomerRizqia Putri ZakkaNo ratings yet

- Vinyl Chloride ProductionDocument11 pagesVinyl Chloride ProductionHabib Maulana YasmintoNo ratings yet

- Benzene Production Using Hydrodealkylation RouteDocument3 pagesBenzene Production Using Hydrodealkylation RouteCluisantony Jayco DizeNo ratings yet

- Production of Styrene Via Dehydrogenation of EthylbenzeneDocument21 pagesProduction of Styrene Via Dehydrogenation of EthylbenzeneSeanne CruzNo ratings yet

- Qdoc - Tips - Sudhanshu Project Report of Production of ButadienDocument113 pagesQdoc - Tips - Sudhanshu Project Report of Production of ButadienJustin Marc Estipona100% (1)

- 265 Tons Per Day Production of Terephthalic Acid by Amoco ProcessDocument169 pages265 Tons Per Day Production of Terephthalic Acid by Amoco ProcessTania Noor100% (1)

- 350-Optimization of Vinyl Chloride Monomer (VCM) Production Using ASPEN PLUSDocument2 pages350-Optimization of Vinyl Chloride Monomer (VCM) Production Using ASPEN PLUSJesus AngaritaNo ratings yet

- LECTURE - 6: Ethylene Derivatives: Ethylene Oxide and Ethanol Amines 6.1 Ethylene OxideDocument7 pagesLECTURE - 6: Ethylene Derivatives: Ethylene Oxide and Ethanol Amines 6.1 Ethylene Oxideمحمود محمدNo ratings yet

- Cumene ProductionDocument26 pagesCumene ProductionAMOGH JHANWARNo ratings yet

- Cumene To PhenolDocument73 pagesCumene To Phenolvpsrpuch67% (3)

- Excellent Thesis DesignDocument117 pagesExcellent Thesis DesignHemanth Peddavenkatappa GariNo ratings yet

- Production of Mono Ethylene GlycolDocument170 pagesProduction of Mono Ethylene GlycolAbdullah ZndNo ratings yet

- التعديل النهائي محمد احمد علي عبدالله 22130011 PDFDocument115 pagesالتعديل النهائي محمد احمد علي عبدالله 22130011 PDFRojan Pradhan0% (1)

- Group Acetic Acid PresentationDocument24 pagesGroup Acetic Acid PresentationhaiderNo ratings yet

- SampleDocument1 pageSampleasharab70No ratings yet

- Directions: AntonymsDocument4 pagesDirections: Antonymsasharab70No ratings yet

- DistillationDocument124 pagesDistillationasharab70100% (1)

- Butadien Production Scribd File PDFDocument22 pagesButadien Production Scribd File PDFasharab70100% (2)

- LIST OF BSC PROJECTS (UET) PDFDocument13 pagesLIST OF BSC PROJECTS (UET) PDFasharab70No ratings yet

- Process Control Lab ManualDocument19 pagesProcess Control Lab ManualAnkit Singh100% (1)

- Particle TechnologyDocument40 pagesParticle Technologyasharab70No ratings yet

- KVPY Syllabus 2021 - (SA, SB and SX) For Class 11 & 12Document3 pagesKVPY Syllabus 2021 - (SA, SB and SX) For Class 11 & 12Tathya VaghasiaNo ratings yet

- MIT Biochemistry - 2012Document2 pagesMIT Biochemistry - 2012MichaelNo ratings yet

- XS Scuba O2cleaning ManualDocument15 pagesXS Scuba O2cleaning ManualreadyNAS104No ratings yet

- Chapt 5 MarshakDocument21 pagesChapt 5 Marshak周牮No ratings yet

- CCP Composites CookbookDocument482 pagesCCP Composites Cookbookjmorfit3100% (5)

- Bushing FailureDocument1 pageBushing FailureSatyam MadameNo ratings yet

- Noun UpdatedDocument4 pagesNoun UpdatedRengga SebastianNo ratings yet

- Produk LMTNOVDocument24 pagesProduk LMTNOVSeagate WaiNo ratings yet

- Members List of Duties: Worksheet No. 2 Acetone ObjectiveDocument6 pagesMembers List of Duties: Worksheet No. 2 Acetone Objectivenica velanoNo ratings yet

- Emulsion Properties and Phase EquilibriumDocument5 pagesEmulsion Properties and Phase EquilibriumUllNo ratings yet

- Classification of Elements Periodicity in Properties For Class XiDocument81 pagesClassification of Elements Periodicity in Properties For Class XiajayNo ratings yet

- Spray Nine Grez-Off Heavy-Duty Degreaser SDS 1 GallonDocument7 pagesSpray Nine Grez-Off Heavy-Duty Degreaser SDS 1 GallonAsadNo ratings yet

- Tutorial-8-Examples-Downstream Processing-3-Solutions PDFDocument10 pagesTutorial-8-Examples-Downstream Processing-3-Solutions PDFAlaa SabriNo ratings yet

- Additional Electronic Handouts: The Evolution of Stereochemical Models For C O AdditionDocument54 pagesAdditional Electronic Handouts: The Evolution of Stereochemical Models For C O Additionjames mellaleievNo ratings yet

- UV - Vis Spectroscopy: Mjla2015 - Spectrometric Methods 1Document15 pagesUV - Vis Spectroscopy: Mjla2015 - Spectrometric Methods 1Angeli Marie PadillaNo ratings yet

- पञ्जीकृत विषादीको सूचि तथा विषादी खपत तथ्याङ्क २०७९ - 1688707077Document149 pagesपञ्जीकृत विषादीको सूचि तथा विषादी खपत तथ्याङ्क २०७९ - 1688707077Biplov ShresthaNo ratings yet

- Loba List 2018-19Document249 pagesLoba List 2018-19Sandeep0% (1)

- Stitute: NCERT Solution For Class 10 Science Chapter 2 Acids, Bases and SaltsDocument8 pagesStitute: NCERT Solution For Class 10 Science Chapter 2 Acids, Bases and SaltsSuneethaNo ratings yet

- VDOT 2016 RB Specs PDFDocument1,091 pagesVDOT 2016 RB Specs PDFParamjit SinghNo ratings yet

- Handbook of Detergents, Part BDocument813 pagesHandbook of Detergents, Part BPeter67% (3)

- ReactionsDocument8 pagesReactionsdorutzuNo ratings yet

- BIS 154 - Mech Eng. 2 - Lecture 3.ppsxDocument32 pagesBIS 154 - Mech Eng. 2 - Lecture 3.ppsxMohamed NadaNo ratings yet

- AS/A2 - Chemistry: 2021-23 CurriculumDocument139 pagesAS/A2 - Chemistry: 2021-23 CurriculumenderothNo ratings yet

- Coco SugarDocument5 pagesCoco SugarJohn A. CenizaNo ratings yet

- Technical Data Sheet: Product: Product DescriptionDocument1 pageTechnical Data Sheet: Product: Product DescriptionSyed Israr HussainNo ratings yet

- DSCDocument8 pagesDSCthanhnguyenhhvnNo ratings yet

- Eldico Ed-1: The Electron DiffractometerDocument7 pagesEldico Ed-1: The Electron DiffractometerLucas RibeiroNo ratings yet

- 18 CheesDocument17 pages18 CheesAnonymousNo ratings yet

- Portion&Blueprint-class (Xi & Xii)Document13 pagesPortion&Blueprint-class (Xi & Xii)THANIGAINATHAN.G.D 10A3No ratings yet

- Lecture Notes (Theory and Practice of Sterilization)Document5 pagesLecture Notes (Theory and Practice of Sterilization)Zearo GamingNo ratings yet

- Ernst Haeckel's Art Forms in Nature: A Visual Masterpiece of the Natural WorldFrom EverandErnst Haeckel's Art Forms in Nature: A Visual Masterpiece of the Natural WorldNo ratings yet

- Creative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingFrom EverandCreative Abstract Watercolor: The beginner's guide to expressive and imaginative paintingRating: 3 out of 5 stars3/5 (1)

- Drawing and Sketching Portraits: How to Draw Realistic Faces for BeginnersFrom EverandDrawing and Sketching Portraits: How to Draw Realistic Faces for BeginnersRating: 5 out of 5 stars5/5 (5)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsFrom EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsRating: 4.5 out of 5 stars4.5/5 (2)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersFrom EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersRating: 3.5 out of 5 stars3.5/5 (3)

- Art Models KatarinaK034: Figure Drawing Pose ReferenceFrom EverandArt Models KatarinaK034: Figure Drawing Pose ReferenceRating: 3.5 out of 5 stars3.5/5 (3)

- Celtic Line Drawing - Simplified InstructionsFrom EverandCeltic Line Drawing - Simplified InstructionsRating: 5 out of 5 stars5/5 (4)

- Art Models Becca425: Figure Drawing Pose ReferenceFrom EverandArt Models Becca425: Figure Drawing Pose ReferenceRating: 3.5 out of 5 stars3.5/5 (3)

- Beginner's Guide To Procreate: Characters: How to create characters on an iPad ®From EverandBeginner's Guide To Procreate: Characters: How to create characters on an iPad ®3dtotal PublishingRating: 4 out of 5 stars4/5 (1)

- One Zentangle a Day: A 6-Week Course in Creative Drawing for Relaxation, Inspiration, and FunFrom EverandOne Zentangle a Day: A 6-Week Course in Creative Drawing for Relaxation, Inspiration, and FunRating: 4 out of 5 stars4/5 (25)

- Watercolor For The Soul: Simple painting projects for beginners, to calm, soothe and inspireFrom EverandWatercolor For The Soul: Simple painting projects for beginners, to calm, soothe and inspireRating: 5 out of 5 stars5/5 (6)

- The Perspective Drawing Guide: Simple Techniques for Mastering Every AngleFrom EverandThe Perspective Drawing Guide: Simple Techniques for Mastering Every AngleRating: 4 out of 5 stars4/5 (1)

- Art Models AnaRebecca009: Figure Drawing Pose ReferenceFrom EverandArt Models AnaRebecca009: Figure Drawing Pose ReferenceRating: 4 out of 5 stars4/5 (5)

- Draw Every Little Thing: Learn to Draw More Than 100 Everyday Items, From Food to FashionFrom EverandDraw Every Little Thing: Learn to Draw More Than 100 Everyday Items, From Food to FashionRating: 4.5 out of 5 stars4.5/5 (4)

- The Beginner's Guide to Watercolor: Master Essential Skills and Techniques through Guided Exercises and ProjectsFrom EverandThe Beginner's Guide to Watercolor: Master Essential Skills and Techniques through Guided Exercises and ProjectsNo ratings yet

- 15-Minute Watercolor Masterpieces: Create Frame-Worthy Art in Just a Few Simple StepsFrom Everand15-Minute Watercolor Masterpieces: Create Frame-Worthy Art in Just a Few Simple StepsRating: 4.5 out of 5 stars4.5/5 (7)

- Art Models Jenni001: Figure Drawing Pose ReferenceFrom EverandArt Models Jenni001: Figure Drawing Pose ReferenceRating: 5 out of 5 stars5/5 (1)

- Art Models Adrina032: Figure Drawing Pose ReferenceFrom EverandArt Models Adrina032: Figure Drawing Pose ReferenceRating: 5 out of 5 stars5/5 (2)

- Art Models Ginger040: Figure Drawing Pose ReferenceFrom EverandArt Models Ginger040: Figure Drawing Pose ReferenceRating: 4 out of 5 stars4/5 (5)

- Art Models SarahAnn031: Figure Drawing Pose ReferenceFrom EverandArt Models SarahAnn031: Figure Drawing Pose ReferenceRating: 3 out of 5 stars3/5 (4)

- Art Models 10: Photos for Figure Drawing, Painting, and SculptingFrom EverandArt Models 10: Photos for Figure Drawing, Painting, and SculptingRating: 2.5 out of 5 stars2.5/5 (6)