Professional Documents

Culture Documents

HRD Hot Water Pump P001

Uploaded by

nguyenquoc1988Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HRD Hot Water Pump P001

Uploaded by

nguyenquoc1988Copyright:

Available Formats

DATASHEET FOR HRD HOT WATER PUMP

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56

Tag No: Service P & ID No.: Specification No.: No. of Units: Service Description: P-001 Fresh Water xxxxxxxx xxxxxxxx ONE (1) x 100% Hot Water Pump Client: Plant Location: Vendor: Manufacturer: Model No: Purchase Order No.: by Manufacturer Type: Serial No.: GENERAL Number Motor Driven Motor Item Number Motor Provided By Motor Mounted By ONE (1) P-001 Manufacturer Manufacturer Number Turbine Driven Turbine Item Number Turbine Provided By Turbine Mounted By Gearbox Item Number Gearbox Provided By Gearbox Mounted By

xxxxx

xxxxx TBA TBA TBA by Purchaser or Manufacturer

Notes: Indicates Information completed by PURCHASER Pump Size Model

OPERATING CONDITIONS Capacity (m3/h) Suction Pressure (kPag) Discharge Pressure (kPag) Differential Pressure (kPa)

Differential Head (m) @ Min. S.G.

PERFORMANCE Normal 6 0 2 2 20 Min. Performance Curve Number Speed (rpm) Measured at Capacity Rated Max. NPSH Req'd VTA Total Differential Head @ Rated Impeller Max. Differential Head @ Rated Impeller Minimum Continuous Flow Thermal (m3/h) Stable (m3/h) VTA Available Operating Region (m3/h) Best Efficiency Point for Rated Impeller (m3/h) VTA Max

Rated VTA

Max.

Normal VTA VTA

Min. VTA m m

Hydraulic Power (kW) At Designated Capacity Rated Max. Normal Operating Time (hr/yr) NPSH Available (m) TBA System Design Stand Alone Operation Parallel Operation Series Operation with Item Number Suction Pressure Min / Max VTA / VTA Service Continuous Intermittent (Starts/Day) TBA

Min.

VTA to

Suction Specific Speed Impeller Diameter (mm) Rated Pump Rated Power kPa Efficiency Max. Power @ Rated Impeller Rotation (viewed from coupling end) Max sound press. Level reqd @ 1m: Est. Max sound pressure @ 1m: Case Pressure Rating Max. Allowable Working Pressure @ Hydrostatic Test Pressure

Min bhp % kW CW 85 VTA CCW (dBA) (dBA) kPa C kPa

System Control Method ( BY OTHERS) Speed Flow Level Temperature Pressure Pipe Friction Resistance Only Others : Manual PUMPED FLUIDS Pumped Fluid Fresh Water Rated Pumping Temperature (C) At Designated Temp Specific Gravity

Vapor Pressure (kPaa)@ 90 oC

SITE CONDITIONS Normal Normal Min. Min. Location TBA Altitude TBA Ambient Temperature Min / Max Electrical Classification Non-hazardous m C

Max. Max.

20.7 Zone Gr

Rated

90 Temp Cls

GENERAL REMARKS

Viscosity (cP) @ 90 oC Specific Heat (kJ/kg.C) Initial Boiling Point Liquid Hazardous Others C @ Flammable (kPa abs)

Corrosion / Erosion caused by VTA % Solid Max. Particle Size

VTA

mm

A01 REV

28-Oct-13 DATE

ISSUED FOR IDC REVISION

NQ BY

NTP CHECK

APPV

PTSC Appv

xxxxx

TLJOC Appv

xxxxx Project No: Datasheet No: XXXXX XXXXX Page 1 of 6

DATASHEET FOR HRD HOT WATER PUMP

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60

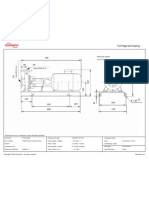

Tag No: Service P & ID No.: Specification No.: No. of Units: Service Description: Impeller Type Closed Semi-open Casing Mounting (VTA) Foot Vertical In-line Bearings Bearings Manufacturer Radial Bearing Type Thrust Bearing Type Bearing Isolators Shaft Stiffness Ratio (L3/D4) Lubrication Flood Pure Mist Shielded (Grease) Sealed (Grease) Remarks BASEPLATE Grouted Free Standing Centerline of Pump to Stilt Bottom Vertical Pump Case Support Bracket PIP Standard RESP002 (Data Sheet Attached) Manufacturer's Standard mm Grease Purge Mist Constant Level Oiler Required Housing Vent Required Magnetic Drain Plug in Housing Required Oil Cooler Required Seal Spray Guard Required Oil Viscosity ISO Grade Other Nozzle Connections Suction Discharge Aux. Case Connection Size Threaded Material Class Code Casing Impeller Cover Shaft Shaft Sleeve Baseplate Casing Gasket Impeller Gasket Casing Fasteners Bearing Housing Bearing Housing Adapter Bearing Housing End Seals Coupling Guard Mechanical Seal Gland Mechanical Seal Gland Fasteners Horsepower Rating Driver HP selected @ Max. S.G. kW 304 SS (VTA) 304 SS (VTA) 304 SS (VTA) 304 SS (VTA) 304 SS (VTA) Carbon Steel Test VTA VTA Size Rating 150#; ASME B16.5 150#; ASME B16.5 Drain Required mm Welded and Flanged MATERIALS Facing RF RF Pump Manufacturer's Standard Other: Shipment Domestic Total Weight Export VTA Number of Months of Storage PAINT AND SHIPMENT PREPARATION Baseplate Manufacturer's Standard Other: Export Boxing Required 12 months kg Days Notification Req'd 30 Witnessed Certificate Open Other Centerline Close-coupled P-001 Fresh Water xxxxxxxx xxxxxxxx ONE (1) x 100% Hot Water Pump MECHANICAL DATA Client: xxxxx Plant Location: xxxxx Vendor: TBA Manufacturer: TBA Model No: TBA Purchase Order No.: COUPLING BETWEEN PUMP AND DRIVER Manufacturer VTA Type Flexible Spacer Coupling Size VTA Model VTA Spacer Length VTA Coupling Guard Type Manufacturer's Standard Baseplate Mounted Nonspark Coupling Guard Required Remarks 1. Bronze non-sparking coupling guard preferred.

mm

Antifriction Antifriction

No. No.

Design Remarks

INSPECTION AND TESTING REQUIREMENTS Final Inspection Required Nonwitnessed

Hydrostatic Performance NPSH Vibration/ Sound Other (Complete Unit Test) Dismantle and Inspect after Test Casting Repair Procedure Approval Required Material Certification Required Casing Cover Impeller Other Wear Ring Inspection Required for Connection Welds Shaft

VTA VTA DRIVER Speed Max Visc rpm cP

Manufacturer's Standard Inspection Required for Castings Manufacturer's Standard Other

Visual Inspection Visual Inspection

MANUFACTURER DOCUMENTATION REQUIREMENTS For Vendor Data Requirements, refer Remarks

Type Insulation Temp Rise Volts / Phase / Hertz 400V/ 3phases/ 50 Hz Service Factor

xxxxx

xxxxx

Project No: Datasheet No:

XXXXX XXXXX

Rev. A01

Page 2 of 6

DATASHEET FOR HRD HOT WATER PUMP

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67

Tag No: Service P & ID No.: Specification No.: No. of Units: Service Description: Supplied By Mounted By Seal Classification Code Manufacturer Model Manufacturer Code Seal Type Cartridge Seal Design Seal Chamber Seal Chamber Size Sleeve Material Pumping Ring Required Throat Bushing Required Remarks Materials Single Pressurised Taper Bore Oversized Dual P-001 Fresh Water xxxxxxxx xxxxxxxx ONE (1) x 100% Hot Water Pump MECHANICAL SEAL (VTA) Pump Manufacturer Pump Manufacturer Purchaser Purchaser Client: Plant Location: Vendor: Manufacturer:

xxxxx

xxxxx TBA TBA

Model No: TBA Purchase Order No.: BARRIER / BUFFER FLUSH SYSTEM - N.A. Barrier Flush Plan Barrier Flush Liquid Temperature Min. / Max. Specific Gravity Specific Heat Vapor Pressure Component Dry gas Unpressurised Cylindrical Bore Standard kJ/kg C (kPa abs) @ C kPa kPa C Tubing Carbon Steel mm Unions Socket Welded Flanged Pipe / C

Pressure Required Min. / Max. MAWP of Secondary Seal System Temperature Required Min. / Max. Secondary Seal Flush Piping Material 316SS Other Piping / Tubing Size Piping Assembly Threaded Tube Type Fittings Remarks

Taps Required

SEAL GLAND Quench Flush Other Throttle Bushing Materials SEAL FLUSHING (VTA)

Drain

SEAL SYSTEM INSTRUMENTATION - N.A. Primary Seal Gauge Switches Flow Temperature Pressure Secondary Seal Flow Pressure Level Remarks

TBA Primary Flushing Plan No. External Flush Liquid Supply Temperature Min/Max Specific Gravity Specific Heat Vapor Pressure (kPa abs) @ Flow Rate Required Pressure Required Temperature Required Primary Seal Flush Piping Tubing Material Pipe 316SS Other Piping / Tubing Size Piping Assembly Threaded Tube Type Fittings Remarks Min/Max Min/Max Min/Max Other Carbon Steel mm Unions Socket Welded

/ kJ/kg C

C m /h kPa C

3

COOLING OR HEATING PIPING PLANS - N.A. Piping Plan No. Name of Fluid Inlet Temperature Outlet Temperature Rated Flow Supply Pressure Max. Allowable P

C C m3/h kPa kPa SS Tubing

Flanged Galvanised Pipe Sight Flow Indicator Outlet Shut-off Valve Remarks WEIGHTS

Motor Driven: Weight of Pump (kg) Weight of Baseplate (kg) Weight of Motor (kg) Weight of Gear (kg) Total Weight (kg) VTA VTA VTA VTA VTA NOTES

Turbine Driven: Weight of Baseplate (kg) Weight of Turbine (kg) Weight of Gear (kg) Total Weight (kg) Remarks: N.A. N.A. N.A. N.A.

xxxxx

xxxxx

Project No: Datasheet No:

XXXXX XXXXX

Rev. A01

Page 3 of 6

DATASHEET FOR HRD HOT WATER PUMP

1 2 3 4 5 6 7 8 9 10 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53

OPERATING PERFORMANE AT RATED 400 VOLTS STARTING PERFORMANE

Tag No. : Service: P & ID No. : Specification No. : No. of Units: Service Description:

Location: Altitude: Ambient air temp: Hazardous area classification:

PM-001 Fresh Water xxxxxxxx xxxxxxxx ONE (1) x 100% Hot Water Pump

ENVIRONMENTAL CONDITIONS Outdoor, Tropical Saliferous Corrosive Humidity: Min: 20.7 C TBA UNITS

kW RPM mm Kg % sec % pu A FL / FL / FL FL / FL / FL FL / FL / FL FL / FL / FL A pu pu RPM Yes / No Yes / No db mm2 mm2

Client: Plant Location: Vendor: Manufacturer: Model No: Purchase Order No. :

xxxxx xxxxx TBA TBA TBA

POWER SYSTEM

System Voltage: System Frequency:

400 50

10 V

99% Max: 34.2 C

Hz Solidly Earthed

Neutral Earthing:

PARTICULARS OF EQUIPMENT

MODEL / SERIAL NO. TYPE CODE AND STANDARD RATING NO OF POLES / SYNCHRONOUS SPEED NO OF PHASES SERVICE DUTY STARTING METHOD ROTATION TYPE OF CONNECTION DRIVE TYPE ENCLOSURE & PROTECTION COOLING MOUNTING TYPE OVERALL DIMENSION (H x W x L) WEIGHT FRAME & BRACKET FAN MATERIAL TERMINAL BOX LEAD TERMINALS LUBRICANT PAINTING INSULATION CLASS ROTOR CONDUCTOR VIBRATION OVERLOAD CAPACITY STARTING ACC. TIME: STARTING TORQUE (% OF FLT): STARTING POWER FACTOR: STARTING CURRENT: AMPERE EFFICIENCY POWER FACTOR SPEED

PURCHASER'S REQUIREMENTS

VTA

VENDOR'S RESPONE

3 Phases

Induction Motor IP 55 Minimum IC 411 -

FRAME: CS

BRACKET:

VTA

VTA

Class F VTA VTA

VTA VTA VTA VTA / 6 TIMES THE RATED CURRENT VTA VTA VTA VTA / / / / VTA VTA VTA VTA / / / / VTA VTA VTA VTA

/ / / /

/ / / /

ANTI-CONDENSATION HEATER RATING/POWER SUPPLY NO. OF GROUND POINTS NOISE LEVEL LIFTING HOOK INTERFACE CABLE TYPE CABLE SIZE NOTES: 123456TBC=To be confirmed, VTA=Vendor to advise

No (SEE NOTE 3) SEE NOTE 6 < 80 dB at 1m REQUIRED IF WEIGHTED > 10KG (HOLD) (HOLD)

All terminal boxes should be provided with metric size cable entries complete with certified sealing plugs Anti-Condensation Heater with supply voltage 230V AC 50Hz 1P shall be provided for electric motor rated 10kW and above. Motor hot thermal withstand time at 100% voltage shall be 2sec.(min.) more than the max. starting time subject to tolerance of the motor Motor shall be capable of giving rated output for 10minutes without injurious overheating at a terminal voltage of 80% for torque requirement One earthing stud on motor enclosure & one earthing terminal inside motor terminal box.

xxxxx

xxxxx

Project No.: Datasheet No.:

XXXXX XXXXX

Rev. A01

Page 4 of 6

DATASHEET FOR HRD HOT WATER PUMP

Tag No. : Service: P & ID No. : Calculation Ref. : P-001 Fresh Water xxxxxxxx Client: Plant Location: Vendor: Manufacturer: Model No: Purchase Order No. :

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71

xxxxx xxxxx TBA TBA TBA

NOISE DATASHEET

1. GENERAL This requisition cover the noise limits of the equipment, given below. For definitions, method of measuring etc. reference is made to EEMUA specification no. 140 : Noise procedure specification. 2. NOISE LIMITS TO BE MET BY THE EQUIPMENT The noise generated by the equipment shall not exceed the more stringent of the noise limits given in the table below, for any of the conditions of operation for which the equipment may normally be expected to be used. Lp is the maximum (A-weighted) sound pressure level, dB re 20 uPa at any location at 1m from the equipment surface. Lw is the maximum (A-weighted) sound power level, dB re 1 pW. If the equipment generates noise with tonal or impulsive components the limits shall be taken 5 dB(A) more stringent. 3. INFORMATION TO BE SUBMITTED WITH THE TENDER a) This noise data sheet shall be returned with the tender and with guaranteed noise data filled in. b) Supplier shall state which silencing measures were taken to meet the noise requirements. 4. LOW NOISE ELECTRIC MOTORS ARE REQUIRED.

a Equipment (Items / Locations) 63 Hot Water Pump 1) Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Lp Lw Noise levels guaranteed by supplier in dB(A) (upper tolerance + 0 dB) 125 250 500 1k 2k 4k 8k

Total

b Noise limit dB (A)

80 @ 1m

Remarks

Silencing measures

Purchaser shall indicate : - In column "b", the noise limit - In column "a" using the appropriate number, which of the following applies to the required noise levels : 1) without acoustic provisions 2) with acoustic provisions and / or special low noise design. 3) suppliers best estimate, not necessarily guaranteed.

xxxxx

xxxxx

Project No.: Datasheet No.:

XXXXX XXXXX

Rev. A01

Page 5 of 6

DATASHEET FOR HRD HOT WATER PUMP

Tag No.: Service: P & ID No. : Calculation Ref. : P-001 Fresh Water xxxxxxxx Client: Plant Location: Vendor: Manufacturer: Model: Purchase Order No. : No. of Units: Service Description:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62

xxxxx xxxxx TBA TBA TBA

One (1) x 100% Hot Water Pump

WEIGHT DATA SHEET

NOTES: 1. Equipment orientation on each skid or item shall be indicated 2. COG coordinates shall be clearly shown on the G.A. drawings.

Lmax X

C.O.G.

Wmax Y

OVERALL SIZES

DIMENSION Lmax (mm) DIMENSION Wmax (mm) DIMENSION Hmax (mm)

PLAN

Dimension

C.O.G. X Y

CENTER OF GRAVITY Dry Operating

Hydrotest

Hmax

Z

ELEVATION

Z Weight

PERMANENT ACCESS REQUIRED AROUND THE SKID / EQUIPMENT (SPACE ENVELOPE) Supplier shall indicate orientation by showing location of main connections or prime mover etc.

PLAN

xxxxx

xxxxx

Project No.: Datasheet No:

XXXXX XXXXX

Rev. A01

Page 6 of 6

You might also like

- CycloneDocument1 pageCycloneEDUARDO100% (1)

- Pressure Drop CalculatorDocument12 pagesPressure Drop CalculatorKevin PratyatamaNo ratings yet

- Calculation Sheet For Make - Up Water Tank: #Value!Document4 pagesCalculation Sheet For Make - Up Water Tank: #Value!thanh_79No ratings yet

- Pressure Loss - SwitchyardDocument1 pagePressure Loss - Switchyardkarthikraja21No ratings yet

- Pressure Drop Calc - STDDocument25 pagesPressure Drop Calc - STDhardik5818No ratings yet

- Heat Exchanger Ball Cleaning Package Data SheetDocument2 pagesHeat Exchanger Ball Cleaning Package Data SheetEDUARDONo ratings yet

- Heat Exchanger Specification SheetDocument1 pageHeat Exchanger Specification SheetGreisly MarrugoNo ratings yet

- Thermal 3TPH 12Kg FO Fired Boiler R0Document6 pagesThermal 3TPH 12Kg FO Fired Boiler R09913489806No ratings yet

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDocument2 pagesHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamNo ratings yet

- Burner specification document summaryDocument6 pagesBurner specification document summaryHafiz Muhammad AbubakarNo ratings yet

- Steam CondenserDocument2 pagesSteam CondenserAlphaEcc EngineeringTeamNo ratings yet

- CALCULATION OF PUMP HEAD AND POWER REQUIREDDocument2 pagesCALCULATION OF PUMP HEAD AND POWER REQUIREDlutfi awn100% (1)

- Optimizing Gas/Liquid Separator PerformanceDocument14 pagesOptimizing Gas/Liquid Separator PerformanceWendellReeceFrankNo ratings yet

- Gravity Line Calculations Flow AnalysisDocument7 pagesGravity Line Calculations Flow AnalysisAnshuman ChoudhuryNo ratings yet

- 2K Method Excess Head Loss in Pipe FittingsDocument8 pages2K Method Excess Head Loss in Pipe Fittingsjxd3261No ratings yet

- Air Exchanger TDDocument9 pagesAir Exchanger TDRajput PratiksinghNo ratings yet

- Control Valve Sizing - EnggcyclopediaDocument4 pagesControl Valve Sizing - EnggcyclopediaazitaggNo ratings yet

- Liquid Orifice SizingDocument4 pagesLiquid Orifice SizingrmaganNo ratings yet

- Calculation AgitatorDocument3 pagesCalculation AgitatorKrishnaAgarwalNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Gas Line Pressure LossesDocument4 pagesGas Line Pressure Lossesyash saragiyaNo ratings yet

- Flow and Pressure Drop in Valves and FittingsDocument5 pagesFlow and Pressure Drop in Valves and FittingsĐoàn TrangNo ratings yet

- 11005312-IBR Pipe CalculationDocument40 pages11005312-IBR Pipe CalculationTrishul Nath PallayNo ratings yet

- FLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Document3 pagesFLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Ekundayo JohnNo ratings yet

- Calculate Steam Pipe Sizing and CapacityDocument2 pagesCalculate Steam Pipe Sizing and CapacityjoeljdiazNo ratings yet

- Pump by BoseDocument26 pagesPump by BoseSonu SinghNo ratings yet

- Pressure Drop Caln - 1Document390 pagesPressure Drop Caln - 1Prashant SinghNo ratings yet

- Sewer Pumpstation Design Calculations For AlqiDocument7 pagesSewer Pumpstation Design Calculations For AlqiTahirJabbarNo ratings yet

- RNZ Integrated (M) SDN BHD: Calculation SheetDocument14 pagesRNZ Integrated (M) SDN BHD: Calculation SheetNhantran VanNo ratings yet

- Friction Loss in Pipe LineDocument3 pagesFriction Loss in Pipe LineAvinash VasudeoNo ratings yet

- Blending and AgitationDocument18 pagesBlending and AgitationSivanand SNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- Demister DatasheetDocument1 pageDemister Datasheetdeion29No ratings yet

- Unit conversion program for engineering processesDocument9 pagesUnit conversion program for engineering processesAnubhav KhandelwalNo ratings yet

- Air Compressor SizingDocument11 pagesAir Compressor Sizingalquin08No ratings yet

- Condenser & EvaporatorDocument21 pagesCondenser & EvaporatorfitratulqadriNo ratings yet

- Mesh & Vane Mist EliminatorsDocument16 pagesMesh & Vane Mist EliminatorsstressesNo ratings yet

- Heat Exchanger Input Correction FactorDocument11 pagesHeat Exchanger Input Correction FactorTrần Tuấn VũNo ratings yet

- No Item: I/D CR KR SF THKDocument30 pagesNo Item: I/D CR KR SF THKnil100% (1)

- Air Blowers Data SheetDocument9 pagesAir Blowers Data Sheetgharsallah mounaNo ratings yet

- Room ACis.1391.2.1992Document36 pagesRoom ACis.1391.2.1992Ajay MenonNo ratings yet

- Vapor Line Sizing-Mpp6Document10 pagesVapor Line Sizing-Mpp6Nitin KurupNo ratings yet

- Pressure Drop Calculation For Rect. DuctsDocument2 pagesPressure Drop Calculation For Rect. Ductsmahmutovicm3488No ratings yet

- Control Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4Document4 pagesControl Valve Sizing: Unit L m3/d 1800 1.03 Bar 8.2 Bar 7.2 Bar 1 °C 120 Bar in 3 in 4ghandri1986No ratings yet

- 1 Darcy Friction CalculatorDocument2 pages1 Darcy Friction CalculatorTheodoros AtheridisNo ratings yet

- Calculation of time needed to mix liquids with pitch blade impellersDocument10 pagesCalculation of time needed to mix liquids with pitch blade impellershadiNo ratings yet

- Orifice SizingDocument1 pageOrifice SizingMarco D'OnofrioNo ratings yet

- Pressure Drop AND HEADDocument2 pagesPressure Drop AND HEADHoney TiwariNo ratings yet

- D. Design Load D.1. Loading DataDocument14 pagesD. Design Load D.1. Loading DataEdNo ratings yet

- Desuperheater Flow CalculationDocument1 pageDesuperheater Flow CalculationMechanicalVee18No ratings yet

- Understanding NPSHDocument34 pagesUnderstanding NPSHeliyanto budiartoNo ratings yet

- Data Sheet: Hydraulic Power UnitDocument3 pagesData Sheet: Hydraulic Power UnitEDUARDONo ratings yet

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- DAT Centrifugal PumpDocument5 pagesDAT Centrifugal PumpEDUARDONo ratings yet

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Water Cooled Chiller Package Data SheetDocument9 pagesWater Cooled Chiller Package Data SheetMohan VarkeyNo ratings yet

- Pages From TBDP-A-M-SP-0008 - Rev 0 SPEC FOR CENTRIFUGAL PUMP PDFDocument12 pagesPages From TBDP-A-M-SP-0008 - Rev 0 SPEC FOR CENTRIFUGAL PUMP PDFSamuel JohnsonNo ratings yet

- WPI-KE-1104-SP141-QM5433 (Datasheet)Document4 pagesWPI-KE-1104-SP141-QM5433 (Datasheet)Jèfrì PìnémNo ratings yet

- MAXROY Series A, B & D DatasheetDocument4 pagesMAXROY Series A, B & D Datasheetnguyenquoc1988No ratings yet

- Diaphram Plunger Injection PumpDocument8 pagesDiaphram Plunger Injection PumpengrtahirNo ratings yet

- Diesel Sigma S 10w API CDSFDocument1 pageDiesel Sigma S 10w API CDSFnguyenquoc1988No ratings yet

- Vendor Data Review Responsibility Matrix (09jan12)Document9 pagesVendor Data Review Responsibility Matrix (09jan12)nguyenquoc1988No ratings yet

- Mechanical Packages - Project ComparisonDocument10 pagesMechanical Packages - Project Comparisonnguyenquoc1988No ratings yet

- Appendix 5 - TC - Process 1Document2 pagesAppendix 5 - TC - Process 1nguyenquoc1988No ratings yet

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988No ratings yet

- Piping System Safety ChecklistDocument1 pagePiping System Safety Checklistnguyenquoc1988No ratings yet

- STV SW Project Level Gauge DatasheetDocument4 pagesSTV SW Project Level Gauge Datasheetnguyenquoc1988No ratings yet

- SVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage TankDocument4 pagesSVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage Tanknguyenquoc1988100% (1)

- How To Use This Tool Bar: 1 To Place A Cloud, You First Have To Highlight The Cells or Regions To Be CloudDocument2 pagesHow To Use This Tool Bar: 1 To Place A Cloud, You First Have To Highlight The Cells or Regions To Be Cloudnguyenquoc1988No ratings yet

- g06 013 Heavy Maintenance Components List ADocument2 pagesg06 013 Heavy Maintenance Components List Anguyenquoc1988No ratings yet

- Flange Calculation Sheet..Document2 pagesFlange Calculation Sheet..nguyenquoc198850% (2)

- List of HVAC SpecificationsDocument46 pagesList of HVAC Specificationsnguyenquoc1988100% (1)

- Polyurethane Insulation Coating Specification for STV South West Project PipelinesDocument42 pagesPolyurethane Insulation Coating Specification for STV South West Project Pipelinesnguyenquoc1988100% (1)

- Quoc IQDocument1 pageQuoc IQnguyenquoc1988No ratings yet

- HST A TS M DS 0031 - Rev F01 Datasheet For MTG Housing LouversDocument1 pageHST A TS M DS 0031 - Rev F01 Datasheet For MTG Housing Louversnguyenquoc1988No ratings yet

- Centrifugal PumpDocument2 pagesCentrifugal Pumpnguyenquoc1988No ratings yet

- Quoc IQDocument1 pageQuoc IQnguyenquoc1988No ratings yet

- HST A TS M TR 0020 - Rev F01 TR For Microturbine Generator HousingDocument24 pagesHST A TS M TR 0020 - Rev F01 TR For Microturbine Generator Housingnguyenquoc1988No ratings yet

- HRD Hot Water Pump P001Document6 pagesHRD Hot Water Pump P001nguyenquoc1988No ratings yet

- PumpDocument1 pagePumpnguyenquoc1988No ratings yet

- PumpDocument10 pagesPumpnguyenquoc1988No ratings yet

- Seismic LoadDocument37 pagesSeismic Loadnguyenquoc1988No ratings yet

- Quoc IQDocument1 pageQuoc IQnguyenquoc1988No ratings yet

- Mechanical COG of EquipmentDocument1 pageMechanical COG of Equipmentnguyenquoc1988No ratings yet