Professional Documents

Culture Documents

HVAC System

Uploaded by

omeshchemOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HVAC System

Uploaded by

omeshchemCopyright:

Available Formats

The main purpose of commercial HVAC (heating, ventilating, and air conditioning) systems is to provide the people working

inside buildings with "conditioned" air so that they will have a comfortable and safe work environment. "Conditioned" air means that air is clean and odor-free, and the temperature, humidity, and movement of the air are within certain comfort ranges. Many factors affect the way people respond to their work environment. Air quality is one of these factors. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) has established standards which outline air quality for indoor comfort conditions that are acceptable to 80% or more of a commercial building's occupants. Generally, these indoor comfort conditions, sometimes called the "comfort zone," are between 68 degrees F and 75 degrees F for winter and 73 degrees F to 79 degrees F during the summer. Both these temperature ranges are for room air at approximately 50% relative humidity and moving at velocity of 30 feet per minute or slower.

Heat and Temperature

Heat is energy in the form of molecules in motion. As a material becomes warmer, its molecular motion and energy level (temperature) increases, and vice versa. Temperature describes the level of heat (energy) with reference to no heat. Heat is a positive value relative to no heat. Therefore, warm, hot, cool and cold are comparative terms used to describe higher or lower temperature levels. The Fahrenheit scale is the standard system of temperature measurement used in the United States. The U.S. is one of the few countries in the world that still uses this system. Most countries use the metric temperature measurement system-the Celsius scale. However, the Fahrenheit and Celsius scales are currently used interchangeably in the U.S. to describe equipment and fundamentals in the heating, ventilating and air conditioning industry.

Heat Transfer

Heat naturally flows from a higher energy level to a lower energy level. In other words, heat travels from a warmer material to a cooler material. The unit of measurement used to describe the quantity of heat contained in a material is a British thermal unit (Btu). When there is a temperature difference between two materials, heat transfer will occur. In fact, temperature difference is the driving force behind heat transfer,

i. e., the greater the temperature difference, the greater the heat transfer. The rate of heat transfer can be described by adding the dimension of time, for example, British thermal units per hour (Btu/hr or Btuh).

Types of Heat Transfer

The three types of heat transfer are conduction, radiation, and convection. Your hand touching a cold wall is an example of heat transfer by conduction. A portable electric heater that glows red-hot is an example of heat transfer by radiation. Heat transfer by convection is when some material that is readily movable such as air, water, steam, and refrigerant moves heat from one location to another. For example, when air is heated, it rises; this is heat transfer by "natural" convection. "Forced" convection is when a fan or pump is used to convey heat in fluids such as air and water. Compare the words "convection" (the action of conveying) and "convey" (to take or carry from one place to another).

HVAC System Components

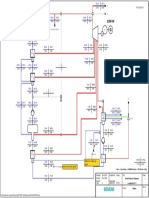

The basic components in a common central HVAC system as illustrated in Figure 1 are: 1. Fan(s) to circulate the supply air (SA) and return air (RA). 2. Supply air ductwork in which the air flows from the supply fan to the conditioned space. 3. Air devices such as supply air outlets and return air inlets. 4. Return air path or ductwork in which the air flows back from the conditioned space to the mixed air chamber (plenum). 5. Outside air (OA) device such as an opening, louver or duct to allow for the entrance of outside air into the mixed air chamber. 6. Mixed air chamber to receive the return air and mix it with outside air. 7. Filter section(s) to remove dirt and dust particles from the mixed air. 8. Heat exchanger(s) such as hot water coil(s), steam coil(s), refrigerant evaporator(s), or chilled water coil(s) to add heat to or remove heat from the circulated air. 9. Auxiliary heating devices such as natural gas furnace(s) or electric heating element(s).

10. Compressor(s) to compress the refrigerant vapor and pump the refrigerant around the system. 11. Condenser(s) to remove heat from the refrigerant vapor and condense it to a liquid. 12. Fan(s) to circulate outside air across air-cooled condenser(s) 13. Pump(s) to circulate water through water-cooled condenser(s); condenser water pump (CWP); and condenser water supply (CWS) and return (CWR). 14. Pump(s) to circulate hot water from the boiler(s) through the hot water coil(s) and back or to circulate chilled water from the chiller(s) through the chilled water coil(s) and back to the chiller(s). 15. For central systems, water or steam boiler(s) as a central heating source. 16. For central systems, water chiller(s) as a central cooling source. 17. For central systems, cooling tower(s) with water-cooled condenser(s). 18. Controls to start, stop, or regulate the flow of air, water, steam, refrigerant and electricity.

HVAC System Example

Airflow: The volume of air required to heat, cool and provide good indoor air quality is calculated based on the heating, cooling and ventilation loads. The air volumes are in units of cubic feet per minute (cfm). Constant volume fans (supply and return) circulate the conditioned air. For the example system (Figure 1), the total volume of air supplied to the conditioned space is 6,000 cfm. Of this 6,000 cfm circulated through the conditioned space and back to the air handling unit (AHU), 1,000 cfm is exhausted in the return air plenum through the exhaust air (EA) damper. The remaining 5,000 cfm goes into the mixed air chamber. At the same time, 1,000 cfm is exhausted another 1,000 cfm is brought in through the outside air (OA) dampers in the mixed air plenum. This 1,000 cfm of outside air mixes with the remaining 5,000 cfm of return air. The 6,000 cfm of mixed air then travels through the filters into the coil sections.

Heating: The heating load requirement is based on design indoor and outdoor winter conditions. The design conditioned space heating load is 227,000 Btu/hr. This is the amount of heat lost (mainly by conduction) through the walls, windows, doors, roofs, etc., in the winter. An additional amount of heat is required to heat the outside ventilation air based on design conditions. To maintain the temperature and humidity in the comfort zone for the conditioned space, the heating cycle is this: The supply air leaves the heating coil carrying 227,000 Btuh of heat. The air goes through the supply air fan (SAF), down the insulated supply duct, past the manual volume dampers (MVD) which have been set for the correct amount of air for each diffuser, and into the conditioned space. The supply air gives up all of its 227,000 Btuh of heat to the conditioned space to replace the 227,000 Btuh that is leaving the space through the walls, roof, etc. As the air gives up its heat it makes its way through the room and into the return air (RA) inlets, then into the return air duct and back to the air handling unit. This AHU is located on the roof and is therefore designated as a "roof top unit" (RTU). The return air goes through the return air fan (RAF), through the return air automatic temperature- controlled (ATC) dampers into the mixed air chamber and mixes with the outside air (OA). The mixed air flows through the filters, through the cooling coil (which is off), and into the heating coil. The mixed air travels through the heating coil where it picks up heat via conduction through the hot water tubes in the coil. In addition to the tubes, the heating coil also has fins attached to the tubes to facilitate the heat transfer. The supply air leaves the heating coil carrying its 227,000 Btuh of heat and the air cycle repeats. The water, after giving up heat to the air, leaves the coil and goes back to the oil-fired boiler through the hot water return (HWR) pipe and into the boiler where it picks up the same amount of heat that it has just given up in the coil. The water leaves the boiler, flows through the hot water pump (HWP) and is pumped through the hot water supply (HWS) or heating hot water supply (HHWS) piping into the heating coil to give up its heat into the mixed air and the water cycle repeats. Ventilating: In the human respiratory process, oxygen is inhaled and carbon dioxide, a contaminant, is exhaled. In commercial buildings, carbon dioxide and other contaminants such as cigarette smoke must be continuously removed or uncomfortable or unhealthy conditions will result. "Ventilation" is the process of supplying outside air to buildings in the proper amount to offset the contaminants and odors produced by people and equipment. In many situations, local building codes stipulate the amount of ventilation required for commercial buildings and work environments to maintain good indoor air quality (IAQ). This

requirement is usually 20 cubic feet per minute of outside air for each occupant. The example HVAC system supplies air to a suite in an office complex designed for 50 people. Therefore, the outside air requirement is 1,000 cfm. Air Conditioning (Cooling): For this system, the total heat given off by the people, lights and equipment in the conditioned space plus the heat entering the space through the outside walls, windows, doors, roof, etc., and the heat contained in the outside ventilation air will be approximately 195,000 Btu/hr. A ton of refrigeration is equivalent to 12,000 Btu/hr of heat. Therefore, this HVAC system requires a chiller that can provide 16.25 tons of cooling. To maintain the proper temperature and humidity in the conditioned space, the cooling cycle is described as: The supply air (which is approximately 20 degrees (F cooler than the air in the conditioned space) leaves the cooling coil and goes through heating coil (which is off), through the supply air fan, down the duct and into the conditioned space. The cool supply air picks up heat in the conditioned space. The warmed air makes its way into the return air inlets, then into the return air duct and back to the air handling unit. The return air goes through the return air fan into the mixed air chamber and mixes with the outside air. The mixed air goes through the filters and into the cooling coil. The mixed air flows through the cooling coil where it gives up its heat into the chilled water tubes in the coil. This coil also has fins attached to the tubes to facilitate heat transfer. The cooled supply air leaves the cooling coil and the air cycle repeats. The water, after picking up heat from the mixed air, leaves the cooling coil and goes through the chilled water return (CHWR) pipe to the water chiller's evaporator. The "warmed" water flows into the chiller's evaporator (sometimes called the water cooler) where it gives up the heat (from the mixed air) into the refrigeration system. The newly "chilled" water leaves the evaporator, goes through the chilled water pump (CHWP) and is pumped through the chilled water supply (CHWS) piping into the cooling coil to pick up heat from the mixed air and the water cycle repeats. The evaporator is a heat exchanger that allows heat from the CHWR to flow by conduction into the refrigerant tubes. The liquid refrigerant in the tubes "boils off" to a vapor removing heat from the water and conveying the heat to the compressor and then to the condenser. The heat from the condenser is conveyed to the cooling tower by the condenser water. Finally, outside air is drawn across the cooling tower, removing the heat from the water through the process of evaporation.

An HVAC system is simply a group of components working together to move heat to where it is wanted (the conditioned space) or to remove heat from where it is not wanted (the conditioned space) and put it where it is unobjectionable (the outside air).

Figure 1. HVAC system components.

You might also like

- Abs-Stripper 13septDocument2 pagesAbs-Stripper 13septomeshchemNo ratings yet

- 2 X 22MW 2 HP 105535Document1 page2 X 22MW 2 HP 105535omeshchemNo ratings yet

- 2 X 22MW 2 HP 105535Document1 page2 X 22MW 2 HP 105535omeshchemNo ratings yet

- Natural Gas DehydrationDocument34 pagesNatural Gas DehydrationJefMusNo ratings yet

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- 4616 PDFDocument9 pages4616 PDFBob SmithNo ratings yet

- 01 - Fluid FlowDocument76 pages01 - Fluid FlowMubarak AhmadNo ratings yet

- P9 Natural Gas - Removal of HydratesDocument34 pagesP9 Natural Gas - Removal of HydratesomeshchemNo ratings yet

- Analysis of Condenser Shell Side Pressure Drop Based On The Mechanical Energy LossDocument8 pagesAnalysis of Condenser Shell Side Pressure Drop Based On The Mechanical Energy LossomeshchemNo ratings yet

- Glycol Dehydration Unit English LetterDocument4 pagesGlycol Dehydration Unit English LetterRaulCamachoNo ratings yet

- HVAC System Design: Mark Hydeman, P.E., FASHRAE Taylor Engineering, LLCDocument42 pagesHVAC System Design: Mark Hydeman, P.E., FASHRAE Taylor Engineering, LLCsardarmkhanNo ratings yet

- Pipe Sizing Charts Tables.12890822Document29 pagesPipe Sizing Charts Tables.12890822forevertay2000No ratings yet

- 2980245C HVAC Handbook 2013 WebDocument35 pages2980245C HVAC Handbook 2013 WebomeshchemNo ratings yet

- Heat 4e Chap11 LectureDocument32 pagesHeat 4e Chap11 Lecturepradeepgautam1010198No ratings yet

- Heat Transfer InnovatorsDocument9 pagesHeat Transfer InnovatorsomeshchemNo ratings yet

- Crosby Pressure Relief Valve HandbookDocument93 pagesCrosby Pressure Relief Valve HandbookGlen AshwellNo ratings yet

- Heat Exchanger CalculationsDocument12 pagesHeat Exchanger CalculationsMichael J. BaneNo ratings yet

- Heat Exchanger CalculationsDocument12 pagesHeat Exchanger CalculationsMichael J. BaneNo ratings yet

- Pipe/connection Type Speed Possible Speed ValuesDocument1 pagePipe/connection Type Speed Possible Speed ValuesomeshchemNo ratings yet

- 2980245C HVAC Handbook 2013 WebDocument35 pages2980245C HVAC Handbook 2013 WebomeshchemNo ratings yet

- HVAC SystemDocument6 pagesHVAC SystemomeshchemNo ratings yet

- Sizing Shell and Tube Heat ExchangerDocument17 pagesSizing Shell and Tube Heat ExchangerCallum Biggs100% (3)

- ATM Tank DatasheetDocument1 pageATM Tank DatasheetomeshchemNo ratings yet

- Gas-Liquid Separator DesignDocument54 pagesGas-Liquid Separator DesignEng Kim Wei100% (6)

- Hydrostatic Test Pressure PipingDocument2 pagesHydrostatic Test Pressure PipingnitinchautreNo ratings yet

- Pump TrainingDocument15 pagesPump TrainingdalayeliNo ratings yet

- HSJFKKHFKKJDSGKSFMC Nbbbbzcgumkbwmscn, MLJFC S 544 SDocument1 pageHSJFKKHFKKJDSGKSFMC Nbbbbzcgumkbwmscn, MLJFC S 544 SomeshchemNo ratings yet

- E2 Knockout Drum PDFDocument2 pagesE2 Knockout Drum PDFKyaw Kyaw AungNo ratings yet

- Api 54Document2 pagesApi 54almandhari33100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Example Bills of QuantitesDocument66 pagesExample Bills of Quantiteshakim2020No ratings yet

- Plate Heat Exchanger CalculationDocument2 pagesPlate Heat Exchanger CalculationTint Tiger100% (2)

- Density Compensation For Steam Drum Level MeasurementDocument4 pagesDensity Compensation For Steam Drum Level MeasurementsaravananbscelecNo ratings yet

- Jean Bernard Parr Poems 2017Document128 pagesJean Bernard Parr Poems 2017thors_6026No ratings yet

- English Test 1Document5 pagesEnglish Test 1Nguyen LauraNo ratings yet

- Climate Change and Environmental Laws in IndiaDocument4 pagesClimate Change and Environmental Laws in IndiaVishesh AnandNo ratings yet

- Learn Comparative and Superlative AdjectivesDocument5 pagesLearn Comparative and Superlative AdjectivesShawn WilsonNo ratings yet

- Sponsored by TheDocument874 pagesSponsored by TheArmando HeilmannNo ratings yet

- CV Evghenii CamenscicDocument2 pagesCV Evghenii CamenscicAlex LebedevNo ratings yet

- Performance Analysis of SOKOWATCHDocument45 pagesPerformance Analysis of SOKOWATCHGowtham Sivakumar100% (2)

- CIV300Document10 pagesCIV300Numal JayawardenaNo ratings yet

- Study of The Abrasion Resistance in The Upholstery of Automobile SeatsDocument7 pagesStudy of The Abrasion Resistance in The Upholstery of Automobile SeatsAnonymous H5wo5gNo ratings yet

- Cehia EnglezaDocument6 pagesCehia EnglezaAndrei Cristian StoicaNo ratings yet

- Assessment of Man's Thermal Comfort - Fanger 1973Document12 pagesAssessment of Man's Thermal Comfort - Fanger 1973haniskamis82No ratings yet

- Cyclone AltheaDocument8 pagesCyclone AltheaKostas VlahosNo ratings yet

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- The Day It Rained FishDocument11 pagesThe Day It Rained FishjedydyNo ratings yet

- Zytel 80G33HS1L BK104Document3 pagesZytel 80G33HS1L BK104nimonhNo ratings yet

- Wa0013.Document5 pagesWa0013.Eyad SaqrNo ratings yet

- Proceedings 6th WorkhshopDocument176 pagesProceedings 6th WorkhshopMGiS100% (1)

- Depeche Mode Song Lyrics Collection 81-13Document564 pagesDepeche Mode Song Lyrics Collection 81-13jb_bueno_1No ratings yet

- Pica Cotto Floor Tiles ManualDocument91 pagesPica Cotto Floor Tiles ManualTalha FaruqueNo ratings yet

- Bus travel time prediction using machine learningDocument12 pagesBus travel time prediction using machine learningcristian_masterNo ratings yet

- English For Business Longman U 6-7 PDFDocument8 pagesEnglish For Business Longman U 6-7 PDFVirginia Gómez RojasNo ratings yet

- Scaling Up Integrated Coastal Management: Case Studies in Sustainable DevelopmentDocument68 pagesScaling Up Integrated Coastal Management: Case Studies in Sustainable DevelopmentPEMSEA (Partnerships in Environmental Management for the Seas of East Asia)No ratings yet

- Ozone Layer & Greenhouse EffectDocument29 pagesOzone Layer & Greenhouse EffectIlyas A HuqqaniNo ratings yet

- Short Story The Ugly Duckling (Dayu Ina 04)Document7 pagesShort Story The Ugly Duckling (Dayu Ina 04)DAYU INA100% (1)

- Petrotac EP Premium Open Gear LubricantDocument2 pagesPetrotac EP Premium Open Gear LubricantRafael Patricio OrellanaNo ratings yet

- The Scarlet Letter by Nathaniel HawthorneDocument125 pagesThe Scarlet Letter by Nathaniel HawthorneDiana CavasdanNo ratings yet

- Math Ia SampleDocument14 pagesMath Ia SampleJKNo ratings yet