Professional Documents

Culture Documents

478application of ESP and Fabric Filter in Power Plants in China

Uploaded by

amol1321Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

478application of ESP and Fabric Filter in Power Plants in China

Uploaded by

amol1321Copyright:

Available Formats

478

11th International Conference on Electrostatic Precipitation

Application of ESP and Fabric Filter in Power Plants in China

ZHAO Xiyong, YAO Yuping, DU Yujiang

(Zhejiang FEIDA Environment Science and Technology Co., Ltd. Wangyun Road 88, Zhuji, Zhejiang, 311800)

Abstract: Electrostatic precipitators have been used in power plants of China for decades. As the dust emission limit becomes stricter than before, fabric filters come into using in power plants. This paper presents two examples of electrostatic precipitator and fabric filter and analyze their technique economy. Keywords: Electrostatic precipitator, Fabric filter, Power plant Designed coal 47.62 3.88 6.09 0.84 0.83 56.51 22240 78 1500 1500 1500 50.72 35.8 2.59 2.83 0.5 1.24 0.6 0.6 0.73 0.14 4.25

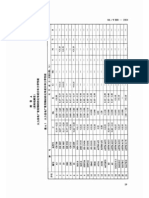

1 INTRODUCTION Electrostatic precipitator (ESP) and fabric filter (FF) are the two most widely used methods for industrial gas cleaning. The ESP application in power plants has been more than tens of years. The collecting mechanism of the ESP relies on that when the dust gas passes through the high voltage field of the precipitator, the particles will be charged and then move towards collecting plates under the electrical force. The advantage of ESP is of low resistance, usually 200 Pa-300 Pa, and a high cleaning efficiency, about 99.5%. But the particles resistivity has a great influence on the collecting efficiency. When the dust emission criterion is a bit stricter, especially lower than 50 mg/Nm3 (present criterion for coal-fired power plant), it is hard to maintain the new requirement. For FF ,people has little knowledge about it. This article presents a comparison between the two methods from the technical and economical aspects. 2 DESIGN CONDITIONS and EQUIPMENT CHOICE For ESP, properties of coals have great influence on the equipment performance and operating price, while FF hardly has these limitations. We use two illustrations to make technique economy analysis on the two methods. Two kinds coals are used. One is a normal kind and the other is a hard-collecting kind in allusion to the ESP. 2.1 Normal Kind Coal 2.1.1 Design Conditions Components of the coal and the corresponding fly ash are shown in Table 1. Table 1 Components of the coal and the corresponding fly ash Item Mt Mad Vdaf Aar Unit % % % % Designed coal 4.6 2.6 32.25 27.25

Item Car Har Elements Oar analysis Nar St.ar Car Lower heating value Qar.net.p Deform temperature DT ST Fluid temperature FT SiO2 Al2O3 Fe2O3 CaO MgO Fly ash components SO3 Na2O K2O TiO2 MnO2 Others Inlet flu gas temperature: 123

Unit % % % % % % kJ/kg HGI % % % % % % % % % % %

Inlet flu gas velocity: 1,900,000 m3/h Inlet dust concentration: 27 g/Nm3 Emission dust concentration: 50 mg/Nm3 2.1.2 Particle Removal Equipment Specification Based on the flu gas condition above, EP and FF are designed separately as follows. 2.1.2.1 Electrostatic Precipitation

Industrial analysis

Application of ESP and Fabric Filter in Power Plants in China Type: 2FAA635M-2120-150 Effective collecting area: 52500 m2 Specific collecting area: 99.5 m2/(m3/s) Equipment resistance: 250 Pa Equipment power consumption 2095 kW Suction fan (only considered Required power for overcoming Equipment resistance): 155 kW High voltage: 1700 kW Hoppers energy consuming: 240 kW Land area: 27 m45 m (front and rear heads not included) 2.1.2.2 Fabric Filter Type: 2LKPB179 Effective collecting area: 35800 m2 Filtration velocity: 1 m/min Equipment resistance: 1350 Pa Equipment power consumption: 1097 kW Suction fan (only consider resistance due to precipitator): 945 kW Air compressor: 72 kW Hopper heating, lighting and so on: 80 kW Land area: 28 m28 m (front and rear heads not included) 2.2 Hard-Collecting Kind Coal 2.2.1 Design Conditions Components of the coal and the corresponding fly ash are displayed in Table 2. Inlet flu gas temperature: 130 C Inlet flu gas velocity: 2,150,000 m3/h Inlet dust concentration: 30 g/Nm3 Emission dust concentration: 50 mg/Nm3 Table 2 Components of the Coal and the Corresponding Fly Ash Item Mad Car Vdaf Var Aar Car Har Oar Elements Nar analysis St.ar Mar Aar Lower heating value Qar.net.p Abrasion index DT Unit % % % % % % % % % % % % kJ/kg kcal/kg HGI Value 3.84 43.85 38 23.09 26 47.62 3.01 8.77 0.88 0.47 13.25 26 17981 4300 57 1.5 1250 Item ST FT SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O K2O TiO2 Others Unit % % % % % % % % % % 40.75 47.26 4.73 0.89 0.20 1.06 0.33 0.39 1.84 2.55 Value 1400

479

Ash component

2.2.2 Particle Removal Equipment Specification Based on the flu gas condition above, EP and FF are designed separately as follows. 2.2.2.1 Electrostatic Precipitation Type: 2FAA635M-2120-150 Effective collecting area: 97200 m2 Specific collecting area: 162.8 m2/(m3/s) Equipment resistance: 250 Pa Equipment power consumption: 3025 kW Suction fan (consider the required power for overcoming equip resistance): 175kW High voltage resource: 25580 kW Hoppers heating, lighting etc.: 292 kW Land area: 38 m53 m (front and rear heads not included) 2.2.2.2 Fabric Filter Type: 2LKPB179 Effective collecting area: 35800 m2 Filtration velocity: 1 m/min Equipment resistance: 1350 Pa Equip consumption 1097 kW Suction fan (power for overcoming equipment resistance): 945 kW Air compressor: 72 kW Hopper heating, lighting etc.: 80 kW Land area: 28 m28 m (front and rear heads not included) 3 A TECHNIQUE ECONOMY ANALYSIS ON TWO DEDUSTING APPARATUS Under the normal kind coal condition, an technologyeconomy comparison between two dedusting apparatus has been studied as shown in Table 3. When boilers used the very-hard-collecting kind of coal, a technique economy analysis on the two dedusting apparatus has been studied as shown in Table 4 Table 3 presents the normal kind coal, when the specific collecting area achieves 100 m2/(m3/s), the equipment costs of ESP and FF are almost equivalent but operating cost of FF is obvious lower than that of ESP. And for the hard collecting

Industrial analysis

480

11th International Conference on Electrostatic Precipitation

kind coal, cost of FF is much lower than that of ESP either in . aspect of equipment or operating. Table 3 A technique economy analysis on the two dedusting apparatus (normal coal) Item ESP FF General Two sets, two sections, five fields, 24 hoppers in Two sets 16 hoppers in total, 16 independent filter arrangement total chambers Dedusting Reluctantly assurance to obtain as low Dust emission concentration as low as 50 mg/Nm3 or efficiency concentration as 50 mg/Nm3 even lower Equipment 250 Pa 1350 Pa resistance Power 2080 kW 985 kW consumption Equipment About 16 million About 16 million investment Power consumption. If the running time is about Fees for changing fabric cloth. If the cloth life span is about 7500 h per year and the price is 3 yuan/kWh, the 4 years and annual spoilage is about 1%, the average cost whole year cost 209575003 =4,710,000 ; will be 1.2 million ; Cost for annual normal maintenance will be Eight years for a change, annual fees 140,000 ; Cost for annual 30,000 ; Considering annual running hours 7500h and electricity operating and If electrode plates and discharge wires are price 0.3 /kWh, the whole year cost: 98575000.3 maintenance renewed ever ten years, this cost will be 40,000 =2,220,000 ; every year; Cost for perishable articles, pulse valve etc.: 40,000 per Not considering extra fees for reconstruct the year. equipment due to yearly accumulated operation Total fees: 3,600,000 Total fees: 5,140,000 Equipment Cannot working online Can working even under 100% load overhaul Land area 27 m45 m 25 m28 m Table 4 A technique economy analysis on the two dedusting apparatus (special coal) ESP FF Two sets, two sections, five fields, 24 hoppers in Two sets, 16 hoppers in total, 16 independent filter total chamber Though enough collecting area, no assurance to Assurance as low dust emission concentration as 50 obtain as low concentration as 50 mg/Nm3 mg/Nm3 or even lower 250 Pa 3025 kW About 28million Including: Power consumption: According the annual running time 7500h the price 3 /kWh, the whole year cost: 302575003 =6,810,000 ; Annual normal maintenance cost: 30,000 ; Assuming renewing of electrode plates and discharge wires every ten years, accordingly 40,000 per year; Not considering extra fees for reconstructing the equipment due to yearly accumulated operation damage. Total fees: 7,540,000 Cannot online overhauling 1350 Pa 1097 kW About 18million Including: Fees for changing fabric cloth. Assuming the cloth life span about 4 years and annual damage about 1%, the average cost about 1.2million ; Fees for changing framework. Eight years for a change annual fees 140,000 ; Power consumption: Considering annual running hours 7500h and electricity price 0.3 /kWh, the whole year cost: 98575000.3 =2,220,000 ; Cost for perishable articles, pulse valve etc.: about 40,000 per year. Total fees: 3,600,000 Can online overhauling even under 100% load

Item General arrangement Dedusting efficiency Equipment resistance Power consumption Equipment investment

Cost for annual operating and maintenance

Equipment overhaul

Application of ESP and Fabric Filter in Power Plants in China Floor covered area 38 m53 m 28 m28 m

481

To compare more clearly about ESP and FF, Figs. 1 and 2 illustrate the performances of the two apparatus under condition of combusting different kinds of coals.

3

PP ESP

0 Equip Operation Cover area

Fig. 1 A compare for the Normal Coal

3

PP ESP

Equip

Operation

Cover area

Fig. 2 A Compare for the Special Coal As illustration above, the performance of ESP has a close relationship with the coal type. From the comparison we can see that under the recent market condition and if the specific collecting area of ESP on the verge of 100 m2/(m3/s), FF has become an exceedingly competitive method to clean dust gas. For most FF applied in coal-fired plants, PP (polyphenylene sulfide) has the highest performance of technique economy among all the recent applicable fiber with high temperature resistance. Therefore, PP has been widely used as a filter material in coal-fired plants at home and abroad. On one hand, the design of FF and the choice of filter material have a direct effect on the longevity of the apparatus, on the other hand, the operation condition, such as dust gas temperature, oxygen concentration, also has an important influence on the actual usage life. Though there are many cases that FF service life are over 4 years at home and abroad, using PP as filter material, there are not a small amount cases that the life are less than 4 years. It is not a long time for our country to apply FF in power plant, so the accumulated experience is limited and the fact that whether the PP filter material can use 4 years is to be checked up in actual activity. However, in present field cases, the service life over 3 years of PP filter material is not a problem. Take a FF built by Feida Environment Corporation in Bafang power plant, Zhuji for example. The boiler with 75 t/h circulating fluid bed, was collocated a FF in August, 2004. The filter chamber has not damaged so far and the equipment resistance is lower than 1000 Pa. The service time of the first batch of filter bag in Fengtan power plant in Mongolia was also over 3 years.

Even the service time is considered to be 3 years in the apparatus operation cost, according to table 3, the actual operation cost of FF will increase from 3.6 million per year to 4 million per year. While according to table 4, the fees will increase from 4.08 million per year to 4.55 million per year. In this case, FF operation cost is also far below ESP. If the space of power plants is restricted, FF is a better choice. And if we consider the space covered by front and rear head of apparatus, the ratio of floor area covered by the two apparatus is higher than the data shown by Figs .1 and 2. However, it needs to be added that the data of this article is a general estimator. For the same flu gas condition, different apparatus makers adapting respective designs have a substantial effect on the apparatus price and operation cost as well as steels price and filter bags cost. The criteria of the dust emission of power plant is 200 mg/Nm3 before 2004. So the dust emission can meet the criteria if the effective collecting area is about 60 m2/(m3/s) for most ESP. Under new situation, ESP are more economic than FF. However, when the dust emission criteria is becoming stricter, the equipments price and operation cost will increase dramatically for ESP, and besides, whether the processing effect can meets the requirement is also a problem. But for FF, the dust emission concentration is not a problem even the criteria is higher. With the development of filter industry and improvement of FFs dependability and reduction of the cost, it will become a substantially competitive method in modern dust cleaning of coal-fired plants. 4 CONCLUSIONS With improving criteria of environment protecting, the traditional dedusting method of ESP has been challenged by FF in the power plants in China. The stricter the criteria requires, the more difficult for ESP to maintain requirement but not for FF. In the aspect of easy-collecting coal, under present market price and the effective collecting area of EPS of 100m2/(m3/s), the apparatus cost of FF is equivalent to the EPS, but the former operation cost is far less than that of the latter. Whats more, FF has a higher collecting efficiency and a lower covering floor. Thus the FF exhibits a stronger competition. With the increase usage of FF in power plant, people begin to gain a deeper understanding about it, and its cost gradually reduce as the beginning of domestic production of filter material. This imposes a higher requirement for EPS and urges more EPS manufactures to make more effect to face the challenge. REFERENCES 1. Zaishi, Li, Static Precipitator, Metallurgy Engineering Press, 1993. 2. Fiber Precipitator Committee Of China Environmental Protection Association, Handbook of Fiber Precipitators filter and accessories, Northeast University Press, 2007.

482

11th International Conference on Electrostatic Precipitation

3. Hui Tao, Feng Tao, Air pollution Control and Fiber Precipitator and its filter, Proseminar Papers of National Fiber Precipitator and filter material, 2007, Fu Shun.

You might also like

- Static and Dynamic Balancing of Rigid RotorsDocument20 pagesStatic and Dynamic Balancing of Rigid RotorsTeng Soon Chye100% (1)

- Boiler Tube Thickness ProcedureDocument19 pagesBoiler Tube Thickness Procedureamol1321100% (3)

- Atomic Structure Worksheet: Name PeriodDocument4 pagesAtomic Structure Worksheet: Name Periodapi-496534295100% (1)

- Nursing Care of A Family With An InfantDocument26 pagesNursing Care of A Family With An InfantJc GarciaNo ratings yet

- Co-Generation in Textile Industries: Sandeep KumarDocument4 pagesCo-Generation in Textile Industries: Sandeep KumartheijesNo ratings yet

- Paper-4 SetA Key Final 8may2009Document10 pagesPaper-4 SetA Key Final 8may2009SHAMSIK2002No ratings yet

- The Potential of Solar Industrial Process Heat Applications: Soteris KalogirouDocument25 pagesThe Potential of Solar Industrial Process Heat Applications: Soteris Kalogiroueinhaw1985No ratings yet

- Case Study On Cement Kiln Energy SavingDocument3 pagesCase Study On Cement Kiln Energy Savingengr kazamNo ratings yet

- Chapter 5-Slides PDFDocument92 pagesChapter 5-Slides PDFMonaElabbassiNo ratings yet

- National Certification Examination 2008 FOR Energy AuditorsDocument10 pagesNational Certification Examination 2008 FOR Energy AuditorsMukesh KumarNo ratings yet

- Conversion Used: Name: Manish Paradkar Assignment No 1Document9 pagesConversion Used: Name: Manish Paradkar Assignment No 1Ankush JakhmolaNo ratings yet

- Economic Evaluation of The Industrial Solar Production of LimeDocument22 pagesEconomic Evaluation of The Industrial Solar Production of Limeoscop2009No ratings yet

- Pgweg: Recycling of Lead/Acid Batteries in A Small PlantDocument3 pagesPgweg: Recycling of Lead/Acid Batteries in A Small PlantCarolina SalcedoNo ratings yet

- Shaangu For Metalurgical Industry 2013Document49 pagesShaangu For Metalurgical Industry 2013zzgiadinhzzNo ratings yet

- OPTIMIZATION (Economic Balance) What, Why, Aims/objectives Essential Features Simple Model, Methods of Solving Application: Insulation EvaporationDocument93 pagesOPTIMIZATION (Economic Balance) What, Why, Aims/objectives Essential Features Simple Model, Methods of Solving Application: Insulation EvaporationRyle Arbon100% (1)

- Induction Motor 15kWDocument8 pagesInduction Motor 15kWAnnamali ThiayagarajanNo ratings yet

- 5 Mark Paper 3Document25 pages5 Mark Paper 3YogaAnandNo ratings yet

- Air Pollution Control Technology Fact SheetDocument5 pagesAir Pollution Control Technology Fact SheetSiddharth RajendranNo ratings yet

- Energy Management Tutorial SolutionsDocument9 pagesEnergy Management Tutorial SolutionsLucas LentzNo ratings yet

- Eco-Sheet 1.6 MVA Industrial Transformer Designs With Increasing EfficiencyDocument5 pagesEco-Sheet 1.6 MVA Industrial Transformer Designs With Increasing EfficiencySeyed IbrahimNo ratings yet

- Encon Basement VentilationDocument15 pagesEncon Basement VentilationLuis Alfonso González VergaraNo ratings yet

- Natural Gas Turbine POWPLA v2Document29 pagesNatural Gas Turbine POWPLA v2Bryan Ray TanNo ratings yet

- Wa0001.Document3 pagesWa0001.Bahadur NazirNo ratings yet

- Cement Industries in Satna Cost, Efficiency and Environment ImpactDocument19 pagesCement Industries in Satna Cost, Efficiency and Environment ImpactNeeraj Bhalerao100% (1)

- Cubic Unit Cooler: SKB Semi-Industrial RangeDocument8 pagesCubic Unit Cooler: SKB Semi-Industrial RangeMohammad AmerNo ratings yet

- ZKG Dic12 p46-54 PDFDocument7 pagesZKG Dic12 p46-54 PDFRICARDOALEXBORGES100% (1)

- Paper 4A SolutionDocument10 pagesPaper 4A SolutionSHAMSIK2002No ratings yet

- Cogenerationof Power Utilising Waste Heatin Cement ManufactureDocument12 pagesCogenerationof Power Utilising Waste Heatin Cement ManufactureRedouane RadwanNo ratings yet

- EnergyManagement Workbook Director StudentDocument10 pagesEnergyManagement Workbook Director StudentHMNoorHaqOpuNo ratings yet

- Don't Let The PinchDocument10 pagesDon't Let The PinchNguyễn Tiến DũngNo ratings yet

- Application of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaDocument24 pagesApplication of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaSJ ChuaNo ratings yet

- 1 s2.0 S0196890498000582 MainDocument10 pages1 s2.0 S0196890498000582 MainAnkit KumarNo ratings yet

- Progress of Emission Control System in EAF ShopsDocument8 pagesProgress of Emission Control System in EAF ShopsJoão CoelhoNo ratings yet

- Dry Condenser Cooling Systems For Thermal Power StationsDocument24 pagesDry Condenser Cooling Systems For Thermal Power StationsBabis PapadopoulosNo ratings yet

- Ketapang Coal Fired Power Plant Ash Handling Operation ManualDocument24 pagesKetapang Coal Fired Power Plant Ash Handling Operation ManualKulata IrminaNo ratings yet

- Realization of Exhaust Air Recovery and Waste Heat Recovery Systems For Energy Conservation and Sustainable DevelopmentDocument5 pagesRealization of Exhaust Air Recovery and Waste Heat Recovery Systems For Energy Conservation and Sustainable DevelopmentRahmatullah Jami'inNo ratings yet

- 3 Energy Audit MethodolgyDocument46 pages3 Energy Audit MethodolgyPavan ReddyNo ratings yet

- Thermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesDocument2 pagesThermal Analysis of Electrical Machines Limits and Heat Transfer PrinciplesAnonymous sAmJfcVNo ratings yet

- Particulate Removal From High-Temperature, PDFDocument59 pagesParticulate Removal From High-Temperature, PDFUmanath R PoojaryNo ratings yet

- Coal PulverizedDocument113 pagesCoal PulverizedSherwin Naldoza Dela Cruz100% (2)

- 12 National Certification Examination - October, 2011 FOR Energy Managers & Energy AuditorsDocument8 pages12 National Certification Examination - October, 2011 FOR Energy Managers & Energy AuditorssamirNo ratings yet

- Role of Energy Conservation in Spinning MillsDocument15 pagesRole of Energy Conservation in Spinning MillsMufaddal BagwalaNo ratings yet

- Industrial InsulationDocument9 pagesIndustrial Insulationahad_shiraziNo ratings yet

- Yuan 2015Document8 pagesYuan 2015AdiKurdiNo ratings yet

- LCC enDocument16 pagesLCC enAlfred LamNo ratings yet

- Section 9 Electricity GenerationDocument23 pagesSection 9 Electricity GenerationhaqjmiNo ratings yet

- Celdas Autoaspirantes OutotecDocument25 pagesCeldas Autoaspirantes OutotecfbaxterNo ratings yet

- Report - Solar Thermoelectric Refrigeration NewDocument16 pagesReport - Solar Thermoelectric Refrigeration NewsachinNo ratings yet

- A Combined Heat and Power System For Bui PDFDocument7 pagesA Combined Heat and Power System For Bui PDFzhiwaNo ratings yet

- Efficiency of Geothermal Power Plants - A Worldwide Review-AzDocument13 pagesEfficiency of Geothermal Power Plants - A Worldwide Review-Azbitconcepts9781No ratings yet

- 1 s2.0 S0304389400003526 Main PDFDocument24 pages1 s2.0 S0304389400003526 Main PDFAnonymous NxpnI6jCNo ratings yet

- Cualquier DocumentoDocument6 pagesCualquier DocumentoChristian Avendaño LedezmaNo ratings yet

- Toscotec - Pratical Applications For Energy Consumption ReductionDocument7 pagesToscotec - Pratical Applications For Energy Consumption ReductionKoushik MadapatiNo ratings yet

- Chapter 1 - Economics of Power GenerationDocument18 pagesChapter 1 - Economics of Power GenerationBF3nobel100% (1)

- Enen 619-03 Final Research ProjectDocument26 pagesEnen 619-03 Final Research ProjectSalman NoorNo ratings yet

- Control of Emissions From Power PlantsLarge Scale IndustriesDocument48 pagesControl of Emissions From Power PlantsLarge Scale IndustriesSonu Kumar100% (1)

- SSCWG7 Repan3 Convers Fact Solar CollectorsDocument3 pagesSSCWG7 Repan3 Convers Fact Solar CollectorsMeng SunNo ratings yet

- Dept.: Course: Code: Zagazig University Faculty of EngineeringDocument3 pagesDept.: Course: Code: Zagazig University Faculty of EngineeringAhmed FathiNo ratings yet

- VENCO Articles Ventilation in Multi Storey Car ParksDocument8 pagesVENCO Articles Ventilation in Multi Storey Car Parksallan kimutaiNo ratings yet

- Chapter 1Document7 pagesChapter 1Surbhi BaliNo ratings yet

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsFrom EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsNo ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Tender Details: Company Name: MSPGCL Unit Name: Project Khaperkheda (Kpkd-500X1)Document74 pagesTender Details: Company Name: MSPGCL Unit Name: Project Khaperkheda (Kpkd-500X1)amol1321No ratings yet

- IBR Amendmnet - 2015Document50 pagesIBR Amendmnet - 2015amol1321No ratings yet

- Table01 PDFDocument1 pageTable01 PDFamol1321No ratings yet

- Company BrochureDocument32 pagesCompany Brochureamol1321No ratings yet

- Filter Testing PDFDocument23 pagesFilter Testing PDFamol1321No ratings yet

- Technical Data Sheet - Steel Cord FR GradeDocument2 pagesTechnical Data Sheet - Steel Cord FR Gradeamol1321No ratings yet

- Hardness Testing Power Point TrainingDocument33 pagesHardness Testing Power Point Trainingamol1321No ratings yet

- Chemical Properties of Chinease MaterialDocument17 pagesChemical Properties of Chinease Materialamol1321No ratings yet

- BHEL ASh Handling Equp QA RequiremntDocument27 pagesBHEL ASh Handling Equp QA Requiremntamol1321100% (2)

- Seamless Tubes and Pipes For Power Plants OKDocument7 pagesSeamless Tubes and Pipes For Power Plants OKJason BrownNo ratings yet

- Ibr - April 2000Document320 pagesIbr - April 2000sujitsaha1No ratings yet

- Aluminum PropertiesDocument15 pagesAluminum PropertiesAmit PatelNo ratings yet

- Radiography in Modern IndustryDocument212 pagesRadiography in Modern IndustryMohammed Abdul Sayeed50% (2)

- 15 Ni Cu Mo NB 5Document14 pages15 Ni Cu Mo NB 5bejaouiabdelhamidNo ratings yet

- Food and ThoughtDocument77 pagesFood and ThoughtMrudula V.100% (18)

- Mo in Stainless Steels WeldsDocument12 pagesMo in Stainless Steels WeldsElias KapaNo ratings yet

- Api Ut 1Document6 pagesApi Ut 1Ricardo Andres Santamaria Torres100% (1)

- 15 Ni Cu Mo NB 5Document14 pages15 Ni Cu Mo NB 5bejaouiabdelhamidNo ratings yet

- RT Practical ExperianceDocument25 pagesRT Practical Experianceamol1321100% (2)

- Api Ut 2Document14 pagesApi Ut 2amol1321No ratings yet

- Viewing and Interpretation of RadiographsDocument30 pagesViewing and Interpretation of RadiographsNatrajiNo ratings yet

- Api Ut 2Document14 pagesApi Ut 2amol1321No ratings yet

- Is 3832Document7 pagesIs 3832amol1321No ratings yet

- Fluid Sealing Standards For NMEJ StandardsDocument9 pagesFluid Sealing Standards For NMEJ Standardsamol1321No ratings yet

- Is 3832Document7 pagesIs 3832amol1321No ratings yet

- Radiography Examination ProcedureDocument49 pagesRadiography Examination Procedureamol1321100% (2)

- Basic Calculations Piping System Design PDFDocument14 pagesBasic Calculations Piping System Design PDFjeff_shawNo ratings yet

- Music Therapy: Treatment For Grade 11 Stem Students Who Suffer Stress From Basic CalculusDocument12 pagesMusic Therapy: Treatment For Grade 11 Stem Students Who Suffer Stress From Basic CalculusArvinel L. VileganoNo ratings yet

- Biotecnologia de Células AnimaisDocument396 pagesBiotecnologia de Células AnimaisKayo Paiva100% (1)

- Solved Rail Chapter 1Document7 pagesSolved Rail Chapter 1spectrum_48No ratings yet

- HooksDocument7 pagesHooksapi-233765416No ratings yet

- Unit5 TestDocument3 pagesUnit5 TestAndrea MészárosnéNo ratings yet

- Eaton BECOPAD P Range TechnicalDataSheet enDocument4 pagesEaton BECOPAD P Range TechnicalDataSheet enEsteban Fernando Meza IbacetaNo ratings yet

- Normal Microflora of Human BodyDocument14 pagesNormal Microflora of Human BodySarah PavuNo ratings yet

- (Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFDocument441 pages(Clinical Sociology - Research and Practice) Howard M. Rebach, John G. Bruhn (Auth.), Howard M. Rebach, John G. Bruhn (Eds.) - Handbook of Clinical Sociology-Springer US (2001) PDFMuhammad AliNo ratings yet

- Knopp2017 Article OnceACheaterAlwaysACheaterSeriDocument11 pagesKnopp2017 Article OnceACheaterAlwaysACheaterSeriAnda F. CotoarăNo ratings yet

- Philosophy For Management and DisciplineDocument8 pagesPhilosophy For Management and Disciplineapi-300120362No ratings yet

- DiffusionDocument25 pagesDiffusionbonginkosi mathunjwa0% (1)

- NSF 型錄2Document2 pagesNSF 型錄2Nermeen ElmelegaeNo ratings yet

- High Resolution Computed Tomography of The Lungs - UpToDateDocument83 pagesHigh Resolution Computed Tomography of The Lungs - UpToDatejjjkkNo ratings yet

- Polymer LedDocument14 pagesPolymer LedNaveenNo ratings yet

- Paracetamol DegradationDocument9 pagesParacetamol DegradationTruyền Phạm MinhNo ratings yet

- Notes About BurnsDocument11 pagesNotes About BurnsMichelle Ann GacudNo ratings yet

- Compositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanDocument13 pagesCompositional Changes of Crude Oil SARA Fractions Due To Biodegradation and Adsorption Supported On Colloidal Support Such As Clay Susing IatroscanNatalia KovalovaNo ratings yet

- CRISIL Mutual Fund Ranking: For The Quarter Ended September 30, 2020Document48 pagesCRISIL Mutual Fund Ranking: For The Quarter Ended September 30, 2020MohitNo ratings yet

- Future Proofing Cities Toolkit by Craig Applegath 2012-03-01sm PDFDocument20 pagesFuture Proofing Cities Toolkit by Craig Applegath 2012-03-01sm PDFJorge Fernández BaluarteNo ratings yet

- Absenteeism in Public Sector: Presented byDocument25 pagesAbsenteeism in Public Sector: Presented byPravin Rathod50% (2)

- Tara FeminismDocument3 pagesTara FeminismDushyant Nimavat100% (1)

- Neurology and Special Senses: High-Yield SystemsDocument72 pagesNeurology and Special Senses: High-Yield SystemsMahmoud Abu MayalehNo ratings yet

- Urie BronfenbrennerDocument27 pagesUrie Bronfenbrennerapi-300862520100% (1)

- Heat Shrink CoatingDocument5 pagesHeat Shrink CoatingMekhmanNo ratings yet

- Kolano - Plastrowanie DynamiczneDocument9 pagesKolano - Plastrowanie DynamiczneRobert WadlewskiNo ratings yet

- Worksheet - Government Microeconomic IntervenDocument20 pagesWorksheet - Government Microeconomic IntervenNguyễn AnnaNo ratings yet

- LISD LetterDocument2 pagesLISD LetterAnonymous Pb39klJ100% (1)

- Ir33+ Range: ... Continuity, Innovation and DesignDocument4 pagesIr33+ Range: ... Continuity, Innovation and DesignbenNo ratings yet