Professional Documents

Culture Documents

Earth Leakage Relays Elrm44v-1-A

Uploaded by

api-230026640Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Earth Leakage Relays Elrm44v-1-A

Uploaded by

api-230026640Copyright:

Available Formats

Type: ELRM44V ELRM44V-3/10/30

Earth Leakage Relay (Variable) - Type A

44mm (2.5 modules) wide DIN rail housing 3 models available (3A, 10A or 30A) Designed to monitor and detect true RMS earth fault currents in conjunction with a separate toroid LED bargraph provides constant indication of any leakage current Microprocessor controlled with internal monitoring (self-checking) Adjustable Sensitivity (In) and Time Delay (t) - 0 (instantaneous)* to 10 seconds Separate Test and Reset push buttons Connection facility for remote Test and Reset push buttons or N.O. contacts Toroid open circuit detection forces unit to trip (Red LED flashes during this condition) 2 Relay outputs - Standard Output (S.O.) and Positive Safety Output (P.S.O.) LED indication of Supply status and fault condition after unit has tripped

Dims: to DIN 43880 W. 44mm

Terminal Protection to IP20

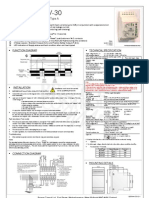

FUNCTION DIAGRAM

supply interrupted fault current

failure of connection to toroid

TECHNICAL SPECIFICATION

Supply voltage Un (5, 6, 7): (see connection diagram) 12 - 125V DC (85 - 110% of U) 24, 115/230, 400V AC (85 - 115% of Un) Please state Supply voltage when ordering. 50/60/400Hz (AC supplies) Over voltage cat. III 800V (24V AC supplies), 2.5kV (115V AC supplies) 4kV (230V, 400V AC supplies) 6VA (AC supplies) 5W (DC supplies) Up to 30A (15 - 400Hz) (through external toroid with 1000:1 ratio and connected to terminals 8 and 9)

Trip level (In) Reset level

All AC supplies are galvanically isolated between the supply and the toroid and remote test/reset connections.

Frequency range: Isolation: Rated impulse withstand voltage: (1.2 / 50S) IEC 60664 Power consumption (max.): Monitored leakage current:

Standard output Positive safety output

t

"Reset" button pressed "Test" button pressed

INSTALLATION

BEFORE INSTALLATION, ISOLATE THE SUPPLY.

Installation work must be carried out by qualified personnel.

Sensitivity In (see Accessories also) ELRM44V-3: 30, 50, 100, 200, 300, 500, 750mA, 1, 2, 3A (user selectable) ELRM44V-10: 30, 100, 300, 500, 750mA, 1, 3, 5, 7.5, 10A (user selectable) ELRM44V-30: 30, 100, 300, 500mA, 1, 3, 5, 10, 20, 30A (user selectable) Trip level limits: 80 - 90% of In Reset Value: 85% of tripped level Time delay t: 0*, 60, 150, 250, 500, 800mS, 1, 2.5, 5, 10 sec. (user selectable)

*Actual delay for 0 or Instantaneous is <25mS when fault current @ 5 x In.

Note: 1. For In setting of 30mA, the time delay is fixed to 0 (instantaneous) and is not adjustable (i.e. any other time delay cannot be selected when 30mA is set). 2. The unit is factory set to 30mA trip and instantaneous delay. Adjustment of these settings can be made if necessary to suit the requirements of the installation. A seal is supplied allowing the user to secure the clear window and hence prevent any unnecessary adjustment of the settings. Reset time: LED indication: Power supply present: Bargraph: Tripped: Memory: Ambient temp: Relative humidity: Output : Output rating: 2S (from supply interruption) Green Green x 3 (25, 50 and 75% of actual trip level) Red (see INSTALLATION to the left) storage of the leakage fault and reset with the Reset push button -20 to +55C (-5 to +40C in accordance with IEC 60755) +95% P.S.O. (10, 11) 6A (1500VA) 4A 6A (150W)

Connect the unit as shown in the diagram below (N.B. certain features may not be required and therefore do not need to be connected). Apply power, the green supply on LED will illuminate and the positive safety output relay will energise. The relay will de-energise if: a, the fault current level exceeds the set trip level (In) ** b, there is a failure of the connection between the relay and the toroid ** (Note the red tripped LED will flash during this condition) c, the supply to the unit is removed d, the relay fails internally ** causes the standard output relay to energise in response to the fault condition. Prior to a fault occurring, the LED bargraph will indicate the % of In being detected (the display is scaled between 25, 50, and 75% of the actual trip level). After all 3 LED's have illuminated and the unit trips due to an excessive fault current, the red tripped LED will illuminate. The unit will now remain in a latched condition.

Fault simulation (Test mode)

The unit can be placed into a fault condition by pressing the Test button on the front of the unit (or by pressing the remote Test button - if fitted). The output relays operate accordingly. Press the Reset button on the front of the unit (or remotely - if fitted) to reset the unit. The output relays revert back to their non-tripped state. The unit can also be reset by interrupting the power supply. To satisfy regulations, it is recommended that the device be tested periodically to ensure correct operation.

Troubleshooting Note:

1 x SPNO, 1 x SPDT relays S.O. (12, 13, 14) AC1 (250V) 8A (2000VA) AC15 (250V) 2.5A DC1 (25V) 8A (200W) Electrical life: 150,000 ops at rated load Dielectric voltage: 2kV AC (rms) IEC 60947-1 Rated impulse withstand voltage: 4kV (1.2 / 50S) IEC 60664

Remote Test / Reset (1, 2, 3) Requires N.O. contacts. (i.e. push buttons) Minimum trigger time: >80mS (Actual trigger time = 80mS + t setting for remote test) Housing: Weight: Mounting option: Terminal conductor size: Approvals: Grey flame retardant Lexan UL94 VO 190g (AC power supplies) 110g (DC power supplies) On to 35mm symmetric DIN rail to BS5584:1978 (EN50 002, DIN 46277-3) 2.5mm2 stranded, 4mm2 solid Conforms to: IEC60755, 60947, 62020, 61543.

If the unit fails to operate correctly check that all wiring and connections are good.

The operating function of this unit is classed as a Type A for which tripping is ensured for residual sinusoidal alternating currents and residual pulsating direct currents, whether applied suddenly or slowly rising. Additionally, this unit is protected against nuisance tripping . This unit will also satisfy the requirements for Type AC devices which only need to detect residual alternating currents. This unit should be installed in conjunction with the latest wiring regulations and practices (IEE, etc).

IEC 61000-4-2, -3, -4, -5 , -6, -12 and -16. CISPR 22. CE and Compliant. ( ) Numbers in brackets shown above refer to terminal numbers on the relay housing.

Options Accessories Toroids

Toroid Type: BZCT035 BZCT070 BZCT120 BZCT210 Internal diameter: 35mm 70mm 120mm 210mm In (min.) A 0.03 0.03 0.1 0.3

1. For other supply voltages, alternative trip levels or time delays, please consult the sales office.

CONNECTION DIAGRAM

reset

SETTINGS

A1 A2 (+ve) (-ve)

12-125V DC 24V AC 230V AC^ 400V AC 115VAC^

test

The Earth MUST NOT pass through the Toroid. For single phase applications, only the live and neutral need to be passed through the Toroid. *.Cabling: For distances >1m, use twisted pair cable between the unit and Toroid.

L1 L2 L3 N E

50m* max.

A3

MOUNTING DETAILS

1 2 3 4 5 6 7

44mm 30mm 49.5mm 63.5mm

9 10 11 12 13 14

Toroid

85mm

50m* max. E

positive safety output

standard output

ELRM44V-30 shown as example

Key: 1. 2. 3. 4. 5. 6. 7.

61mm 45mm

Both relays are shown in the de-energised state (i.e. where power is not present on the supply terminals). ^ Dual voltage only available as 115/230V AC. For 115V AC, connect across 6 and 7. For 230V AC (and other voltages), connect across 5 and 7.

Trip setting adjustment (In) in Amps Time delay adjustment (t) in Seconds Green Power On LED indication Green Leakage Current LED indication (% x In) Red Tripped LED indication RESET button TEST button

Broyce Control Ltd., Pool Street, Wolverhampton, West Midlands WV2 4HN. England Tel: +44 (0) 1902 773746 Fax: +44 (0) 1902 420639 Email: sales@broycecontrol.com Web: www.broycecontrol.com

The Information provided in this literature is believed to be accurate (subject to change without prior notice); however, use of such information shall be entirely at the users own risk.

ELRM44V-1-A

012421

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- AIR Modeller 75 2017-12-20 - 01Document68 pagesAIR Modeller 75 2017-12-20 - 01JoãoGilbertoAraújoPontes100% (4)

- 250T Frequency TransmitterDocument13 pages250T Frequency Transmitterreality88No ratings yet

- Template SOA (ISMS)Document51 pagesTemplate SOA (ISMS)sitiruzaimahNo ratings yet

- SLTRT Service Level Testing Reporting ToolDocument110 pagesSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- ELR: ABB Range of Front Panel Residual Current Relays: Protection Device According To IEC/EN 60947-2 Annex MDocument12 pagesELR: ABB Range of Front Panel Residual Current Relays: Protection Device According To IEC/EN 60947-2 Annex MNgọc Nguyễn Thanh100% (1)

- Fire Drencher System - Base-Engineer PDFDocument2 pagesFire Drencher System - Base-Engineer PDFpequenita34100% (1)

- Ultrasonic TestingDocument55 pagesUltrasonic Testingdhasdj100% (1)

- Crompton Protector 250Document33 pagesCrompton Protector 250jishyNo ratings yet

- IR470LYDocument3 pagesIR470LYHusejin MehmedovićNo ratings yet

- A Isometer IR475LYDocument3 pagesA Isometer IR475LYUrsula JohnsonNo ratings yet

- Earth Leakage Relays ELRM44V30-2-ADocument1 pageEarth Leakage Relays ELRM44V30-2-ABrian BurchNo ratings yet

- Earth Leakage Relays ELRM44V30-2-ADocument1 pageEarth Leakage Relays ELRM44V30-2-Akalesh005No ratings yet

- Earth Leakage Relays ELRV30-2-A RMS PDFDocument2 pagesEarth Leakage Relays ELRV30-2-A RMS PDFDEADMANNo ratings yet

- EARTH LEAKAGE RELAYS & CORE BALANCE CTsDocument2 pagesEARTH LEAKAGE RELAYS & CORE BALANCE CTsDEADMANNo ratings yet

- IRDH265Document4 pagesIRDH265pukyssNo ratings yet

- 1735A ManualDocument58 pages1735A ManualLilia MijangosNo ratings yet

- Control RelaysDocument21 pagesControl RelaysarifzakirNo ratings yet

- .J N I - .J N - P U1 0 S : 0Document15 pages.J N I - .J N - P U1 0 S : 0Montse TovarNo ratings yet

- Earth Leakage Relay P-373-ELRDocument2 pagesEarth Leakage Relay P-373-ELRIsmet KoracNo ratings yet

- Selectable AC Power and Reactive Power TransducerDocument4 pagesSelectable AC Power and Reactive Power TransducerRicardo NunesNo ratings yet

- TTi Model QPX1200 DC Power Supply Service ManualDocument49 pagesTTi Model QPX1200 DC Power Supply Service ManualT3brzNo ratings yet

- ANSI Code 87 Type RMC-131D Differential Current RelayDocument2 pagesANSI Code 87 Type RMC-131D Differential Current RelayshyamamolNo ratings yet

- ABB Substation Automation Trip Circuit Supervision Relay RXTCS Technical Data SheetDocument6 pagesABB Substation Automation Trip Circuit Supervision Relay RXTCS Technical Data SheetEr Anoop GuptaNo ratings yet

- A Isometer IR420 D6Document6 pagesA Isometer IR420 D6Ursula JohnsonNo ratings yet

- EL Series Service Manual (Including EL302Tv)Document49 pagesEL Series Service Manual (Including EL302Tv)dav_ob50% (2)

- Data Sheet: Overload Relays, RMP-111D ANSI Code 32Document7 pagesData Sheet: Overload Relays, RMP-111D ANSI Code 32LUATNo ratings yet

- Under voltage relay SUR353 monitors 3 phase AC systemsDocument2 pagesUnder voltage relay SUR353 monitors 3 phase AC systemsYasir AyubNo ratings yet

- RMC 131d Data Sheet 4921240104 UkDocument8 pagesRMC 131d Data Sheet 4921240104 UkAilton NevesNo ratings yet

- Eld E08405Document2 pagesEld E08405AndrewcaesarNo ratings yet

- Bender Rcm470lyDocument3 pagesBender Rcm470lyRobert Arias TabrajNo ratings yet

- Telemecanique PDFDocument60 pagesTelemecanique PDFMario PerezNo ratings yet

- Data Sheet Epn-110dn,-2Document5 pagesData Sheet Epn-110dn,-2roy fadliNo ratings yet

- Broyce Control - Control Relays PDFDocument21 pagesBroyce Control - Control Relays PDFrocket-vtNo ratings yet

- Ta 8050 PDocument9 pagesTa 8050 PJuan Alamada Reynoso100% (1)

- Adr 132 BDocument5 pagesAdr 132 Btandin tshewangNo ratings yet

- R1112N Series: Low Noise 150ma Ldo RegulatorDocument21 pagesR1112N Series: Low Noise 150ma Ldo RegulatorPankaj PatelNo ratings yet

- RMC-131D Data Sheet 4921240104 UK - 2014.06.25Document8 pagesRMC-131D Data Sheet 4921240104 UK - 2014.06.25Muhammad AhmadNo ratings yet

- Description: Eagle Quantum Premier Agent Release Module EQ2500ARMDocument2 pagesDescription: Eagle Quantum Premier Agent Release Module EQ2500ARMFernando Zambrano San Martín0% (1)

- Model Ut51-55: Operating ManualDocument20 pagesModel Ut51-55: Operating ManualAdv Faizan GorayaNo ratings yet

- Inst Ext GB Asm-01 UDocument2 pagesInst Ext GB Asm-01 UabdiNo ratings yet

- Em306a User ManualDocument2 pagesEm306a User ManualNguyễnĐìnhDầnNo ratings yet

- VMD421H Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsDocument6 pagesVMD421H Series: Digital Voltage, Frequency, Asymmetry, and Phase Loss Relay For Three-Phase AC SystemsjjcanoolivaresNo ratings yet

- Valleylab Force FX SpecsDocument17 pagesValleylab Force FX SpecsAnton LukinNo ratings yet

- Power Meter E51C2Document29 pagesPower Meter E51C2atereñoneNo ratings yet

- Iu.e5.116.0 XCSW240Document2 pagesIu.e5.116.0 XCSW240FolpoNo ratings yet

- LM 2678Document34 pagesLM 2678Kurnia SyaputraNo ratings yet

- 700W1000W User ManualDocument19 pages700W1000W User Manualvanhuong87No ratings yet

- 7sg118 Argus 8 Catalogue SheetDocument12 pages7sg118 Argus 8 Catalogue SheetCristi GrosuNo ratings yet

- TS Series Instruction Manual - Iss 8Document26 pagesTS Series Instruction Manual - Iss 8qazNo ratings yet

- TMP 35 GDocument16 pagesTMP 35 GWeslley FariaNo ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- DRC-24V30W1A Technical DatasheetDocument11 pagesDRC-24V30W1A Technical Datasheetzivko13No ratings yet

- ZEN-PA03024: Model Number StructureDocument8 pagesZEN-PA03024: Model Number Structuregustaf parlindunganNo ratings yet

- Service Manual Fastmig Pulse Power Sources: Released 30.12.2009 Updated 13.01.2010Document39 pagesService Manual Fastmig Pulse Power Sources: Released 30.12.2009 Updated 13.01.2010Solange Bacian San MartinNo ratings yet

- DC POWER SUPPLY SPECIFICATIONSDocument23 pagesDC POWER SUPPLY SPECIFICATIONSMe MeNo ratings yet

- RMC-131D Differential Current Relay Data SheetDocument8 pagesRMC-131D Differential Current Relay Data Sheetdavid loughlinNo ratings yet

- Description Power Range: Analog Servo DriveDocument7 pagesDescription Power Range: Analog Servo DriveElectromateNo ratings yet

- Data Sheet: Current Relays, RMC-111D, RMC-122D, RMC-132D ANSI Codes 50/51Document8 pagesData Sheet: Current Relays, RMC-111D, RMC-122D, RMC-132D ANSI Codes 50/51LUATNo ratings yet

- Delta PLC DVP SS ModelDocument4 pagesDelta PLC DVP SS ModelTarun SonwaneNo ratings yet

- IRDH375 Series: Digital Ground Fault Monitor / Ground Detector Ungrounded (Floating) AC/DC SystemsDocument6 pagesIRDH375 Series: Digital Ground Fault Monitor / Ground Detector Ungrounded (Floating) AC/DC SystemsZaw Thet OoNo ratings yet

- Earth Leakage Relays Bzct-3-ADocument1 pageEarth Leakage Relays Bzct-3-Aapi-230026640No ratings yet

- Three Phase Relays Mxprcs-2-ADocument1 pageThree Phase Relays Mxprcs-2-Aapi-230026640No ratings yet

- Quran Ki Nazar May ShirkDocument35 pagesQuran Ki Nazar May Shirkapi-230026640No ratings yet

- There Is Yet TimeDocument36 pagesThere Is Yet Timeapi-230026640No ratings yet

- Teach Youself Quran ReadingDocument112 pagesTeach Youself Quran Readingapi-230026640No ratings yet

- Basic Foundation of The DeenDocument16 pagesBasic Foundation of The Deenapi-230026640No ratings yet

- Concept of God in Islam Christianity As Per Bible QuranDocument5 pagesConcept of God in Islam Christianity As Per Bible Quranapi-230026640No ratings yet

- Universal CNC Turning Center Maxxturn 65 G2Document13 pagesUniversal CNC Turning Center Maxxturn 65 G2Vũ LêNo ratings yet

- EURAMET Cg-2 V 2.0 Calibration of Gauge Block ComparatorsDocument9 pagesEURAMET Cg-2 V 2.0 Calibration of Gauge Block ComparatorsRicarditoNo ratings yet

- Fontaine Quinta RuedaDocument2 pagesFontaine Quinta RuedaHamilton MirandaNo ratings yet

- LKPRDocument58 pagesLKPRcatchman86No ratings yet

- E380b PDFDocument12 pagesE380b PDFanaNo ratings yet

- Sant Gadge Baba Amravati University: Backlog From Session Winter-2019Document2 pagesSant Gadge Baba Amravati University: Backlog From Session Winter-2019Prashant pandeNo ratings yet

- EA 4b ArchiMate Views and Viewpoints PDFDocument41 pagesEA 4b ArchiMate Views and Viewpoints PDFanon_834023132No ratings yet

- Sennheiser MD 441Document2 pagesSennheiser MD 441ndujaNo ratings yet

- Company Profile 2021Document18 pagesCompany Profile 2021Hamza FaheemNo ratings yet

- BTSDocument75 pagesBTSgyanesh198450% (2)

- Cisco SD-WAN Policy Architecture - Dana Yanch PDFDocument1 pageCisco SD-WAN Policy Architecture - Dana Yanch PDFEmilio PazNo ratings yet

- GM300 SMDocument46 pagesGM300 SMSrboljub Milosavljevic100% (1)

- Elink For Windows: List of Pages in This Trip KitDocument130 pagesElink For Windows: List of Pages in This Trip KitAhmed GvNo ratings yet

- The Weka Guard and Protector - Weka MarineDocument2 pagesThe Weka Guard and Protector - Weka MarineJoko SusiloNo ratings yet

- Flyer M 10id 12 ENDocument2 pagesFlyer M 10id 12 ENTrevor SalazarNo ratings yet

- fEA CourseDocument3 pagesfEA CourseAnant KumbhojkarNo ratings yet

- You Yangs RP Visitor GuideDocument2 pagesYou Yangs RP Visitor GuideSomaNo ratings yet

- Premium Swab Rigs Since 1925Document8 pagesPremium Swab Rigs Since 1925fabricio3fabricio-1No ratings yet

- Pressure Regulators (DRV Valve) Suitable ForDocument4 pagesPressure Regulators (DRV Valve) Suitable ForNOUREDDINE BERCHAOUANo ratings yet

- Udayanandan, Notes On Tensors PDFDocument56 pagesUdayanandan, Notes On Tensors PDFhristos314No ratings yet

- High Voltage Grease Reduces Wear and ArcingDocument2 pagesHigh Voltage Grease Reduces Wear and ArcingtlnferreiraNo ratings yet

- Study of Buffer Overflows and Keyloggers in The Linux Operating SystemDocument8 pagesStudy of Buffer Overflows and Keyloggers in The Linux Operating Systemrobyrulz100% (1)

- Construction of Multistoried Boys Hostel by Kanwarjot SinghDocument22 pagesConstruction of Multistoried Boys Hostel by Kanwarjot SinghvipinNo ratings yet

- TSB 1106 - MFY Starter Solenoid - ChangeDocument1 pageTSB 1106 - MFY Starter Solenoid - ChangeChrisMNo ratings yet

- DseDocument20 pagesDsebrawijaya100% (1)