Professional Documents

Culture Documents

Engineering Design Guideline - Measurement Rev02web

Uploaded by

lutfi awnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Design Guideline - Measurement Rev02web

Uploaded by

lutfi awnCopyright:

Available Formats

Page : 1 of 61

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Rev: 02

Rev 01 March 2007 Rev 02 May 2012

www.klmtechgroup.com

Co Author

KLM Technology Group #03-12 Block Aronia, Jalan Sri Perkasa 2 Taman Tampoi Utama 81200 Johor Bahru

Fluid Flow Measurement Selection and Sizing (ENGINEERING DESIGN GUIDELINE)

Rev 01 A L Ling Rev 02 K Kolmetz

Karl Kolmetz

KLM Technology Group is providing the introduction to this guideline for free on the internet. Please go to our website to order the complete document. www.klmtechgroup.com TABLE OF CONTENT

INTRODUCTION Scope Flow Measurement DEFINITIONS NOMENCLATURE THEORY Selection Criteria of Flowmeter Accuracy Flow Range and Rangeability Discharge Coefficient Reynolds Number Differential Pressure Flowmeter Orifice Plate I) Design and Construction 6 6 7 11 13 14 14 14 15 15 15 16 19 19

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 2 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

II) Flow Calculations of Orifice Plate a) Liquid flow b) Gas flow Venturi Tube I) Design and Construction II) Flow Calculations of Orifice Plate Pitot-Static Tube I) Design and Construction II) Flow Calculation of Pitot - Static Tube Nozzle I) Design and Construction II) Flow Calculations of Nozzle Variable Area Flowmeter Rotameter I) Design and construction II) Flow Calculation Equation (Spherical Ball as Float) Positive Displacement Flowmeter Design and Construction Turbine Flowmeter Electromagnetic Flowmeter Ultrasonic Flowmeter Doppler Transit-Time Flowmeters Coriolis Flowmeter General Flowmeters Selection Guide

21 22 24 25 25 26 27 27 28 29 29 30 32 32 32 33 34 35 37 39 40 40 42 43 45

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 3 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

APPLICATION Example Case 1: Orifice Sizing for Liquid Flow Example Case 2: Orifice Sizing for Gas Flow Example Case 3: Venturi Tube Sizing for Liquid Flow Example Case 4: Venturi Tube Sizing for Gas Flow REFERENCES LIST OF TABLE Table 1: Variance Orifice plate design and application Table 2: The performance and applications of common differential pressure flowmeters Table 3: Typical Flowmeter Applicable Services LIST OF FIGURE Figure 1: A Concentric Sharp Edged Orifice Plate Flowmeter Figure 2: A Venturi Tube Flowmeter Figure 3: A Nozzle Flowmeter Figure 4: A Cross Sectional of Rotameter Figure 5: Typical Rotameter Bob Geometries Figure 6: Types of pressure taps for orifices Figure 7: Pitot-static tube Figure 8: ISA 1932 nozzle and long radius nozzle 8 9 9 10 10 22 28 31 20 31 45 46 49 52 54 56

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 4 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

Figure 9: Rotameter Figure 10: Type of positive displacement flowmeters Figure 11: Simplify turbine flowmeter Figure 12: Selection Guide for displacement and Turbine meter Figure 13: Element of electromagnetic flow meter Figure 14: Typical Doppler flowmeter operating principle Figure 15: Transit-time ultrasonic flowmeter Figure 16: U-shaped Coriolis mass meter

34 36 37 38 39 41 42 43

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 5 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

INTRODUCTION Scope This design guideline assists engineers to understand the functions of several types of instruments which are used to measure fluid flow. The flow of fluids is commonly measured using flow meters. These flow meters may be classified into differential pressure flow meter, variable area flow meter, and positive displacement flow meters. Several considerations are needed to choose the proper flow meter to be utilized. The selection is based on the application and / or economical aspects. The differential pressure flow meters are operated based on Bernoulli equation, but their application is limited for viscous liquids. The variable area flow meter is simple to install and maintain, but its accuracy is determined by the accuracy of pressure, temperature, and flow control during initial calibration; making this device relatively sensitive to any pressure or temperature changes. A positive displacement flow meter is accurate and durable; but its usage is limited to clean and non-corrosive service. The other theories of each type of flow meter and their selection considerations are included in this design guideline. All the important parameters used in the guideline are explained in the definition section to help the reader understand the meanings of the parameters used. In the theory section, selection of the flow meters is included and the general theories for the sizing for each type of the flow meters are included as well. This will aid the engineer from the selection through sizing. In the application section, several case studied are shown and discussed in detail to apply the theory for the calculation. The case studied will aid the engineers to do the selection and sizing for the several flow meters base on their own system.

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 6 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

Flow Measurement The important of industrial flow measurement has grown in the past 50 years, not just because of the widespread use for accounting purposes, such as custody transfer of fluid from supplier to customers, but also because of its application in manufacturing processes. Example of the industrial involvement in flow measurement includes food and beverage, oil and gas industries, medical, petrochemical, power generation, and water distribution and etc. Flow measurement is the determination of the quantity of a fluid, either a liquid, or vapor, that passes through a pipe, duct or open channel. Flow may be expressed as a rate of volumetric flow (such as gallons per minute, cubic meters per minute, cubic feet per minute), mass rate of flow (such as kilograms per hour, pounds per hour), or in terms of a total volume or mass flow (integrated rate of flow for a given period of time). Fluid flow measurement can be divided into several types; each type requires specific considerations of such factors as accuracy requirements, cost considerations, and use of the flow information to obtain the required end results. Normally the flow meter is measure flow indirectly by measuring a related property such as a differential pressure across a flow restriction or a fluid velocity in a pipe. A number of different fundamental physical principles are used in flow measurement devices. There is various kind of the flowmeter available in market; they can be classifier types as i) Difference pressure flow meter a. Orifice plate, (Figure 1) b. Venturi tube (Figure 2), c. Pitot tube and d. Nozzle (Figure 3) Variable area flowmeter a. Rotameter (Figure 4), b. Movable vane meter, and c. Weir, flume

ii)

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 7 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

iii)

Positive displacement flowmeter a. Sliding-vane type PD meter, b. Tri-rotor type PD meter, c. Birotor PD meter, d. Piston type PD meter, e. Oval gear PD meter, f. Nutating disk type PD meter, g. Roots PD meter, h. The CVM meter ,and i. Diaphragm meter Turbine flowmeter Electromagnetic flowmeter Ultrasonic flowmeter a. Doppler b. Transit- Time Coriolis (Mass) flowmeter

iv) v) vi)

vii)

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 8 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

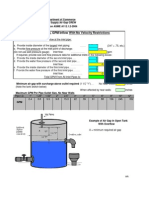

Orifice Plate

Pressure Tapping (pressure drop across flowmeter measured at these points)

P1

P2

Flow Direction

1

A1

2

A2

Figure 1: A Concentric Sharp Edged Orifice Plate Flowmeter

Flow Direction

Pressure Tapping

Figure 2: A Venturi Tube Flowmeter

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 9 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

Pressure Tapping (Pressure drop across flowmeter measured at these points) Nozzle

Flow Direction

Figure 3: A Nozzle Flowmeter When selecting the flow meter for the specific applications, certain studied have to be undertaken. Review the specific meters service record and reference to industry standards and users within an industry are important points to review in choosing the best meter for the given applications. Difference fluid properties (viscosity, type of fluid, velocity profiles, flow profiles, Reynolds number) are the important because of the differential flow measurements available in market. A lot of flowmeter techniques have been developed to a particular application, only few flow meters can be used for widespread application and no one single can use for all applications.

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 10 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

Flow Direction

Figure 4: A Cross Sectional of Rotameter

Guided Reading line

Figure 5: Typical Rotameter Bob Geometries

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 11 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

DEFINITION Beta Ratio- The ratio of the measuring device diameter to the meter run diameter (i.e., orifice bore divided by inlet pipe bore) or can be define as ratio of small to large diameter in orifices and nozzles. Capacity - Is the water handling capability of a pump commonly expressed as either gallon per minute (gal/min) or cubic meter per minute (m3/min). Coriolis Flowmeter - Direct mass measurement sets Coriolis flowmeters apart from other technologies. Mass measurement is not sensible to changes in pressure, temperature, viscosity and density. With the ability to measure liquids, slurries and gases, Coriolis flowmeters are universal meters. Diameter Ratio (Beta) - The diameter ratio (Beta) is defined as the calculated orifice plate bore diameter (d) divided by the calculate meter tube internal diameter (D). Differential Pressure- The drop in pressure across a head device at specified pressure taps locations. It is normally measured in inches or millimeters of water. Differential Pressure Flowmeter- A flowmeter in which the pressure drop across an annular restriction placed in the pipeline is used to measure fluid flow rate. The most common types use an orifice plate, Venturi tube, or nozzle as the primary device. Differential Pressure Transmitter- Secondary device that measures the differential pressure across the primary device and converts it into an electrical signal. Discharge Coefficients- The ratio of the true flow to the theoretical flow. It corrects the theoretical equation for the influence of velocity profile, tap location, and the assumption of no energy loss with a flow area between 0.023 to 0.56 percent of the geometric area of the inlet pipe. Electromagnetic Flowmeter -An electromagnetic flowmeter operate on Faraday's law of electromagnetic induction that states that a voltage will be induced when a conductor moves through a magnetic field. The liquid serves as the conductor and the magnetic field is created by energized coils outside the flow tube.

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 12 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

Manometer- A device that measures the height (head) of liquid in a tube at the point of measurement. Mass Meter- Meter that measures mass of a fluid based on a direct or indirect determination of the fluids weight rate of flow. Measurement- The act or process of determining the dimensions, capacity, or amount of something. Meter Factor (MF) - The meter factor (MF) is a number obtained by dividing the quantity of fluid measured by the primary mass flow system by the quantity indicated by the meter during calibration. For meters, it expresses the ratio of readout units to volume or mass units. Meter Static- Meters that measure by batch from a flowing stream by fill and empty procedures. Non-pulsating (see pulsation) - Variations in flow and/or pressure that are below the frequency response of the meter. Orifice Plate- A thin plate in which a circular concentric aperture (bore) has been machined. The orifice plate is described as a .thin plate and with sharp edge, because the thickness of the plate material is small compared with the internal diameter of the measuring aperture (bore) and because the upstream edge of the measuring aperture is sharp and square. Pipeline Quality- Fluids that meet the quality requirements of contaminant as specified in the exchange contract such as clean, non-corrosive, single phase, component limits, etc. Positive Displacement Flowmeter -The positive displacement flowmeter measures process fluid flow by precision-fitted rotors as flow measuring elements. Known and fixed volumes are displaced between the rotors. The rotation of the rotors is proportional to the volume of the fluid being displaced.

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 13 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

Pulsation- A rapid, periodic, alternate increase and decrease of pressure and/or flow. The effect on a meter depends on the frequency of the pulsation and the frequency response of the meter.

NOMENCLATURE A1 A2 C cd D g h1 h2 hL k P1 P2 Q1 q qm Re Y Sectional area of upstream pipe, ft2 Sectional area of meter bore, ft2 Correction constant of the design of Pitot-static tube (from vendor of flowmeter), dimensionless Discharge coefficient, dimensionless Internal diameter of pipe, in Acceleration of gravity, 32.2 ft/s2 Height of flow for upstream, ft Height of flow for downstream, ft Head loss due to friction in meter, ft Gas isentropic exponent, dimensionless Absolute pressure for upstream, psia Absolute pressure for downstream, psia Mass flow, gal/min Volumetric flow rate, ft3/s Mass flow rate, Ibm/s Reynolds number, a dimensionless number Expansibility factor, for compressible fluid (Liquid =1)

Greek letters Beta ratio, ratio of orifice bore diameter to pipe diameter Equivalent roughness of the pipe wall material, in Weight density of fluid, Ibm/ft3 Absolute (dynamic) viscosity, cp Velocity for upstream, ft/s Velocity for downstream, ft/s

1 2

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 14 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

THEORY Selection Criteria of Flowmeter To select a suitable flow meter for a particular application is not an easy task especially with the wide variety of flow meters in the market. It requires considerable evaluation of the total cost, fluid state, flowing condition, Reynolds number, density, range ability, mechanical installation constraints and accuracy requirements. The design engineer should decide the design condition for mass, volume (operating standard) or energy. The pressure and temperature of the fluid should be provided as well for the flow meter and transmitter to compensate for process variations in these variables. A specific gravity or density analyzer may also be needed to account for variability in stream composition. In considering the cost, it should consider the total cost involved. These include; equipment cost, total cost installation, maintained cost, and operating cost. Costs must be carefully evaluated, particularly as the meter size or the operating pressure changes. For instance, a small sized Venturi might be of comparable cost to an averaging pitot, but as the size increases the cost of the Venturi rapidly exceeds that of the averaging pitot for a given pipe size. Increasing design pressure has the same effect.

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 15 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

Accuracy A term used frequently in flow measurement is accuracy. Accuracy is more abused than correctly used. Unfortunately, it is a sales tool used commercially by both suppliers and users of metering equipment. The supplier with the best number wins the bid. Likewise, the user will sometimes require accuracies beyond the capabilities of any meter available. For decades, accuracy was the term most commonly used to describe a meters ability to measure flow. It was defined as the ratio of indicated measurement to true measurement. The antithesis of uncertainty and is an expression of the maximum possible limit of error at a defined confidence. Why accuracy is important for flow meter? The important point for custody transfers because it is related to money. Left said at a meter station measuring product worth $2 million a day, an inaccuracy of 0.2% represents $4,000 a day, or $1,460,000 a year an amount that justifies considerable investment to improve flow measurement. The same error for a station measuring $1,000 worth of product a day represents only $2 a day, and the law of diminishing returns limits investment justifiable to improve measurement accuracy. Flow Range and Range ability Flow range is the differential between the minimum and maximum flow rate over which a meter produces acceptable performance within the basic accurately specification of meter. Range ability is a flow meter's ability to cover a range of flow rates within specified accuracy limits. It is usually defined as the ratio of the maximum to minimum flow rates and is also known as meter turndown. This is important parameter when do selecting of the flow meter (specific range ability of respectively flow meter are discussed in the following section). For example, a meter with maximum flow (100%) of 100 gallons per minute and minimum flow of 10 gal/min (within a stated tolerance such as 0.5%) has a 10:1 range ability or turndown of 10. It will be accurate 0.5% from 10 to 100 gal/min.

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

KLM Technology Group

Practical Engineering Guidelines for Processing Plant Solutions

Page 16 of 61

Fluid Flow Measurement Selection and Sizing

( ENGINEERING DESIGN GUIDELINE)

Rev: 02

May 2012

Discharge Coefficient (C) The discharge coefficient corrects the theoretical flow rate equation for the influence of velocity profile (Reynolds number). Specific discharge coefficients for various flow meter geometries have been determined by actual tests run by many different organizations (e.g., API, ASME, and ISO). The discharge coefficient is a very important factor in defining the shape of the flow path. It is heavily influenced by factors such as: the size of the orifice bore, the size of the pipe, fluid velocity, fluid density, and fluid viscosity. Reynolds Number The Reynolds number (Re) is a useful tool in relating how a meter will react to a variation in fluids from gases to liquids. Since there would be an impossible amount of research required to test every meter on every fluid we wish to measure, it is desirable that a relationship of fluid factors be known. Re = Which, Re

50.6 Q1 D

Eq (1)

D Q1

= Reynolds number, a dimensionless number = weight density of fluid, Ibm/ft3 = internal diameter of pipe, in = Mass flow, gal/min = absolute (dynamic) viscosity, cp

These design guideline are believed to be as accurate as possible, but are very general and not for specific design cases. They were designed for engineers to do preliminary designs and process specification sheets. The final design must always be guaranteed for the service selected by the manufacturing vendor, but these guidelines will greatly reduce the amount of up front engineering hours that are required to develop the final design. The guidelines are a training tool for young engineers or a resource for engineers with experience. This document is entrusted to the recipient personally, but the copyright remains with us. It must not be copied, reproduced or in any way communicated or made accessible to third parties without our written consent.

You might also like

- Engineering Design Guideline-Hydrotreating Rev 02 WebDocument32 pagesEngineering Design Guideline-Hydrotreating Rev 02 WebPham TinNo ratings yet

- ENGINEERING DESIGN GUIDELINES Relief Valves Sizing and Selection Rev WebDocument31 pagesENGINEERING DESIGN GUIDELINES Relief Valves Sizing and Selection Rev Webjr_satish6965No ratings yet

- Fluid Flow Rev03webDocument19 pagesFluid Flow Rev03webaizatmaricanNo ratings yet

- Engineering Design Guidelines Refrigeration Systems Rev02webDocument24 pagesEngineering Design Guidelines Refrigeration Systems Rev02webkarlitox123No ratings yet

- Comp Selection GuideDocument32 pagesComp Selection GuideAnkit Gandhi0% (1)

- Engineering Design Guideline Control Valve Rev 8Document24 pagesEngineering Design Guideline Control Valve Rev 8Ashish SukhwalNo ratings yet

- ENGINEERING DESIGN GUIDELINES Instrumentation Sizing and Selection Rev Web PDFDocument23 pagesENGINEERING DESIGN GUIDELINES Instrumentation Sizing and Selection Rev Web PDFBkhari Haran0% (1)

- AIChE Equipment Testing Procedure - Trayed and Packed Columns: A Guide to Performance EvaluationFrom EverandAIChE Equipment Testing Procedure - Trayed and Packed Columns: A Guide to Performance EvaluationNo ratings yet

- FlareTot - Total Flare AnalysisDocument8 pagesFlareTot - Total Flare AnalysisArjun KapoorNo ratings yet

- Natural Gas Processing from Midstream to DownstreamFrom EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirNo ratings yet

- Guideline - Pump - System - Designers (Pump Fundamentals) PDFDocument16 pagesGuideline - Pump - System - Designers (Pump Fundamentals) PDFyyukin1100% (1)

- Advances in Solid–Liquid Flow in Pipes and Its ApplicationFrom EverandAdvances in Solid–Liquid Flow in Pipes and Its ApplicationIraj ZandiRating: 5 out of 5 stars5/5 (2)

- Chemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsFrom EverandChemical Process Design and Simulation: Aspen Plus and Aspen Hysys ApplicationsRating: 2 out of 5 stars2/5 (1)

- Ethylene c2 Splitter Tower Selection SizDocument27 pagesEthylene c2 Splitter Tower Selection Sizmsn1981No ratings yet

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28From EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28No ratings yet

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentFrom EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentNo ratings yet

- Scaling Chemical Processes: Practical Guides in Chemical EngineeringFrom EverandScaling Chemical Processes: Practical Guides in Chemical EngineeringNo ratings yet

- Safety in OverpressureDocument27 pagesSafety in OverpressurevrajakisoriDasiNo ratings yet

- Chemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningFrom EverandChemical and Process Plant Commissioning Handbook: A Practical Guide to Plant System and Equipment Installation and CommissioningNo ratings yet

- DWC Column SimulationDocument14 pagesDWC Column SimulationFatih FıratNo ratings yet

- P&IDDocument24 pagesP&IDSebastian Cardenas100% (1)

- Energy Optimization Using Pinch Analysis: Practical ConsiderationsDocument10 pagesEnergy Optimization Using Pinch Analysis: Practical ConsiderationsconfyNo ratings yet

- Treated Water Storage TankDocument31 pagesTreated Water Storage TankMurthy PalachollaNo ratings yet

- Valve Sizing Sample CalculationDocument6 pagesValve Sizing Sample Calculationanne_sibius100% (1)

- Engineering Design Guidelines - Distillation Column Selection N Sizing - Rev 03 WebDocument34 pagesEngineering Design Guidelines - Distillation Column Selection N Sizing - Rev 03 WebKeena Rahim50% (2)

- Aspentech Safety WebinarDocument34 pagesAspentech Safety WebinarabsahkahNo ratings yet

- How to Size Liquid Ring Vacuum PumpsDocument3 pagesHow to Size Liquid Ring Vacuum PumpsdayrogNo ratings yet

- Beginner's Errors to Avoid in Process DesignDocument10 pagesBeginner's Errors to Avoid in Process DesignAnonymous NwnJNONo ratings yet

- ENGINEERING - DESIGN - GUIDELINES - Control - Valve - Sizing - and - Selection by KLM PDFDocument28 pagesENGINEERING - DESIGN - GUIDELINES - Control - Valve - Sizing - and - Selection by KLM PDFSyed Waqas Haider50% (2)

- ChERD PaperDocument15 pagesChERD PaperSuleman AhmadNo ratings yet

- Process Plant Design - Training Course - Day 1 - 23 Dec 2017 PDFDocument77 pagesProcess Plant Design - Training Course - Day 1 - 23 Dec 2017 PDFNgàyMưaNo ratings yet

- Process Flow Diagram (PFD) - How To & ExamplesDocument43 pagesProcess Flow Diagram (PFD) - How To & ExamplesKu KemaNo ratings yet

- Insulation AuditDocument44 pagesInsulation AuditJustin ReyesNo ratings yet

- Fire Relief Rate Calculation-Part 2Document4 pagesFire Relief Rate Calculation-Part 2zubair195No ratings yet

- Automation Engineering Practice For Pressure Definitions: AEP-32e 13 January 2010Document25 pagesAutomation Engineering Practice For Pressure Definitions: AEP-32e 13 January 2010arraziy fauzanNo ratings yet

- Engineering Design Guidelines Distillation Column Rev4Document24 pagesEngineering Design Guidelines Distillation Column Rev4zackii90No ratings yet

- Basco IBC Catalog 2013Document16 pagesBasco IBC Catalog 2013Mario BarbarićNo ratings yet

- Flash Separator Design Conversion of Low PDFDocument19 pagesFlash Separator Design Conversion of Low PDFShoaib JadoonNo ratings yet

- Slides Plant Description (From PFD & P&IDs) E.HDocument47 pagesSlides Plant Description (From PFD & P&IDs) E.HRobert Waters100% (1)

- Process Engineering Course DetailsDocument5 pagesProcess Engineering Course DetailsAnonymous KpVxNXs0% (2)

- Instrument Process Datasheet (IPDS)Document3 pagesInstrument Process Datasheet (IPDS)Vraja KisoriNo ratings yet

- Process Isolation Guidelines - Refining, Hydrocarbons, Oil, and Gas - CheresourcesDocument5 pagesProcess Isolation Guidelines - Refining, Hydrocarbons, Oil, and Gas - Cheresourcesjayrolling dollazNo ratings yet

- On The Design of Thermal BreathingDocument6 pagesOn The Design of Thermal BreathingLizbeth Fiallos AvilaNo ratings yet

- Guidelines 40Document6 pagesGuidelines 40piolinwallsNo ratings yet

- Project Standards and Specifications Layout and Spacing Rev1.0Document17 pagesProject Standards and Specifications Layout and Spacing Rev1.0Mert EfeNo ratings yet

- Hot Water System Sizing CalculationDocument1 pageHot Water System Sizing CalculationPhyu Mar Thein KyawNo ratings yet

- CEeNews2 04Document6 pagesCEeNews2 04Antonio MezzopreteNo ratings yet

- ExchangersDocument64 pagesExchangersRathnakrajaNo ratings yet

- Tank PipingDocument29 pagesTank PipingDRJULIUSJORDAN100% (1)

- Piping Fluid Flow Material Selection and Line SizingDocument18 pagesPiping Fluid Flow Material Selection and Line SizingRamachandran RamNo ratings yet

- Engineering Design Guideline - Compressor Rev2Document19 pagesEngineering Design Guideline - Compressor Rev2Joe GoparNo ratings yet

- Engineering Design Guideline Pump Rev3Document14 pagesEngineering Design Guideline Pump Rev3prasathbalaNo ratings yet

- Engineering Design Guideline Pump Rev3Document14 pagesEngineering Design Guideline Pump Rev3yaser201xNo ratings yet

- Engineering Design Guideline Pump Rev3Document14 pagesEngineering Design Guideline Pump Rev3hclsvw67% (3)

- Heavy Oil Upgrading by The Separation and Gasification of AsphaltenesDocument11 pagesHeavy Oil Upgrading by The Separation and Gasification of Asphalteneslutfi awnNo ratings yet

- E10 Blending Study Final ReportDocument107 pagesE10 Blending Study Final Reportlutfi awnNo ratings yet

- Astm D 86Document8 pagesAstm D 86lutfi awnNo ratings yet

- Lubricating Oils: Test Methods Test MethodsDocument32 pagesLubricating Oils: Test Methods Test MethodsCorina StanculescuNo ratings yet

- Liquid and Gas Velocity Gas Compressibility and Renolds Number.Document30 pagesLiquid and Gas Velocity Gas Compressibility and Renolds Number.lutfi awnNo ratings yet

- 04 Jet Mixing Design ApplicationsDocument6 pages04 Jet Mixing Design Applicationslutfi awnNo ratings yet

- Air Compressor Curve ToolDocument14 pagesAir Compressor Curve Toollutfi awnNo ratings yet

- Liquid Pressure DropDocument8 pagesLiquid Pressure Droplutfi awnNo ratings yet

- Bitumen Upgrading Shell Canada LimitedDocument301 pagesBitumen Upgrading Shell Canada Limitedlutfi awnNo ratings yet

- Hydraulic Calculations MKIIDocument8 pagesHydraulic Calculations MKIIlutfi awnNo ratings yet

- VISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSDocument8 pagesVISCOSITY CLASSIFICATION GUIDE FOR INDUSTRIAL LUBRICANTSFrancisco TipanNo ratings yet

- Air Compressor Tools APODocument7 pagesAir Compressor Tools APOlutfi awnNo ratings yet

- 2011 Chaudhuri U R Fundamentals of Petroleum and PetrochDocument33 pages2011 Chaudhuri U R Fundamentals of Petroleum and Petrochlutfi awnNo ratings yet

- Mixer Tank Jet Pumps Gea - tcm11 34889Document4 pagesMixer Tank Jet Pumps Gea - tcm11 34889Venodaren VelusamyNo ratings yet

- H2S RiskDocument6 pagesH2S Risklutfi awnNo ratings yet

- Conversion of Milligrams Per Cubic Meter To PPMDocument2 pagesConversion of Milligrams Per Cubic Meter To PPMlutfi awnNo ratings yet

- Calculation ExampelDocument21 pagesCalculation Exampellutfi awnNo ratings yet

- Energy conversion factors and density ranges for petroleum productsDocument2 pagesEnergy conversion factors and density ranges for petroleum productslutfi awnNo ratings yet

- Water Demand Calculation 1Document2 pagesWater Demand Calculation 1lutfi awnNo ratings yet

- Molecular Sieve Dehydration OptimizationDocument24 pagesMolecular Sieve Dehydration Optimizationlutfi awn100% (1)

- Line sizing for gas flow from PCV to flare headerDocument2 pagesLine sizing for gas flow from PCV to flare headerlutfi awnNo ratings yet

- Fonds Bombes - Surface MouilleeDocument3 pagesFonds Bombes - Surface MouilleesegunoyesNo ratings yet

- Gas TurbDocument10 pagesGas Turblutfi awnNo ratings yet

- Valve Sizing Worksheet InstructionsDocument11 pagesValve Sizing Worksheet Instructionslutfi awnNo ratings yet

- Plumbing H 2 Osu Pair Gap CalculatorDocument9 pagesPlumbing H 2 Osu Pair Gap Calculatorlutfi awnNo ratings yet

- ZM KV Idag eDocument6 pagesZM KV Idag elutfi awnNo ratings yet

- PumpDocument31 pagesPumpkajale_shrikant2325No ratings yet

- Gas ReservesDocument8 pagesGas Reserveslutfi awnNo ratings yet

- GOR Vs GVFDocument8 pagesGOR Vs GVFlutfi awnNo ratings yet

- Centrifugalcompressorpower Si UnitsDocument4 pagesCentrifugalcompressorpower Si UnitsJoshi DhvanitNo ratings yet

- Chapter 3b Fugacity and Fugacity Coefficient For MixtureDocument26 pagesChapter 3b Fugacity and Fugacity Coefficient For MixtureSeptiana AyuningtiasNo ratings yet

- CAT 320/323GC Electrical DiagramDocument33 pagesCAT 320/323GC Electrical DiagramSammyNo ratings yet

- Me6302 - Manufacturing Technology - I: Iii Semester Mechanical EngineeringDocument69 pagesMe6302 - Manufacturing Technology - I: Iii Semester Mechanical EngineeringamdevaNo ratings yet

- Unfired Pressure VesselDocument30 pagesUnfired Pressure VesselSrinivasan RajenderanNo ratings yet

- Vibrational Analysis of Machine Foundation ACI 351.3R-04 (FEA Method)Document9 pagesVibrational Analysis of Machine Foundation ACI 351.3R-04 (FEA Method)Randy CernaNo ratings yet

- Service News: Installation of Stage 2 Long MK Ii Onzr4 Priority: Iv Gac: 48 Ecb Aif 1357/C1 Date: 17/07/2004Document30 pagesService News: Installation of Stage 2 Long MK Ii Onzr4 Priority: Iv Gac: 48 Ecb Aif 1357/C1 Date: 17/07/2004Muhammad HardiusNo ratings yet

- ASTM A153 Guide for Galvanized Hardware & FastenersDocument5 pagesASTM A153 Guide for Galvanized Hardware & FastenersMekhmanNo ratings yet

- General Knowledge: 1.1 Non-Destructive Testing (NDT) 1.1.1 Definition and Nature of NDTDocument28 pagesGeneral Knowledge: 1.1 Non-Destructive Testing (NDT) 1.1.1 Definition and Nature of NDTAsad KhanNo ratings yet

- Flushmate 501B Series Owners Service ManualDocument6 pagesFlushmate 501B Series Owners Service ManualiloNo ratings yet

- High-speed FANUC M-420iA industrial robotDocument2 pagesHigh-speed FANUC M-420iA industrial robotMarek GryskoNo ratings yet

- AS 1056.1-1991 Storage Water Heaters - General RequirementsDocument43 pagesAS 1056.1-1991 Storage Water Heaters - General RequirementsChetan ChopraNo ratings yet

- Getting A Good Fit: Selecting The Right Shaft and Housing ToleranceDocument2 pagesGetting A Good Fit: Selecting The Right Shaft and Housing Toleranceeng13No ratings yet

- Yfm35Fgx Yfm35Fax Yfm35Fgx Yfm35Fgx: (5UHL) (5UHM) (5UHN) (5UHP)Document0 pagesYfm35Fgx Yfm35Fax Yfm35Fgx Yfm35Fgx: (5UHL) (5UHM) (5UHN) (5UHP)Cristiano Marcelo Oliveira MelloNo ratings yet

- Metsec Engineering Forms the FutureDocument24 pagesMetsec Engineering Forms the Futureshashank adigaNo ratings yet

- Nook Jack CatalogDocument212 pagesNook Jack CatalogSakahi SharmaNo ratings yet

- Heat Flow Calculations Made Using The V C: Ventilation Test InstrumentsDocument6 pagesHeat Flow Calculations Made Using The V C: Ventilation Test Instrumentsretrospect1000No ratings yet

- CYTJ45-2 Specification - KAMACH 18UDocument8 pagesCYTJ45-2 Specification - KAMACH 18UJhonatan rincon martinezNo ratings yet

- Bagatelle Showroom Structural AnalysisDocument15 pagesBagatelle Showroom Structural AnalysisDhiraj BeechooNo ratings yet

- RVX Upgrade Ps 100 7 Ea4Document8 pagesRVX Upgrade Ps 100 7 Ea4Mark HydeNo ratings yet

- Test 1 BFC 43103 Semi I 20202021Document7 pagesTest 1 BFC 43103 Semi I 20202021Mohamad Ridhwan Bin ZahriNo ratings yet

- Compresor Atlas Copco GA30Document16 pagesCompresor Atlas Copco GA30Florin Maria Chirila100% (1)

- Check List-For LMI-on Bypassing Protn & Interlocks-OGN/OPS/SYST/005-021Document13 pagesCheck List-For LMI-on Bypassing Protn & Interlocks-OGN/OPS/SYST/005-021rudra singhNo ratings yet

- Kumera-848027c - Installation and Maintenance - en - 2015-08 PDFDocument40 pagesKumera-848027c - Installation and Maintenance - en - 2015-08 PDFgilbertogatoNo ratings yet

- PPM High-Strength Anchor Bolt Peikko Group 05-2015Document36 pagesPPM High-Strength Anchor Bolt Peikko Group 05-2015Jody Inggil PambudiNo ratings yet

- Gerstle1989 PDFDocument8 pagesGerstle1989 PDFJorge HenriqueNo ratings yet

- Elektrisk (Katalog - Ermax)Document267 pagesElektrisk (Katalog - Ermax)ionel1987No ratings yet

- Thermowave Competence Refrigeration enDocument21 pagesThermowave Competence Refrigeration enTechnill Serviços e RepresentaçõesNo ratings yet

- Printable Fastener Tools PDFDocument28 pagesPrintable Fastener Tools PDFAgustin PeraltaNo ratings yet

- Actuator dimensions and specificationsDocument1 pageActuator dimensions and specificationsDaniel Camargo PérezNo ratings yet

- Sachin Solanki CNC/IPC/13 Summary SupportDocument61 pagesSachin Solanki CNC/IPC/13 Summary Supportshivam modanwalNo ratings yet