Professional Documents

Culture Documents

ECET-462: (Laboratory 6)

Uploaded by

Sengottu VelusamyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ECET-462: (Laboratory 6)

Uploaded by

Sengottu VelusamyCopyright:

Available Formats

ECET- 462

Application of Computers in Process Control

Purdue University, Calumet

Page 1 of 7

[LABORATORY 6]

Develop a Continuous Control Process of a Heating and Cooling System using ON-OFF controller having controllable Dead-band

Page 2 of 7

Develop a Heating and Cooling control system using ON-OFF controller having controllable Dead-band LAB 6

Objective: To demonstrate the use of ON/OFF controller using LabVIEW Software required: Lab View. Background: The purpose of on/off control is to keep a given physical variable, e.g. the ambient temperature, within certain limits or to change it according to a predetermined program. A control system serves to measure the value of the controlled variable, compare it with the desired value, and adjust the control unit, by which a possible deviation is reduced. Thermostats and pressure controls for on/off control are two-position regulators where the manipulated variable can only lead to two conditions: cut-in or cut-out. The temperature sequence for a room controlled by a thermostat is shown in figure.

The rise in the ambient temperature will not occur at the same time as the valve opens, as some time will pass before this happens, i.e. the dead time Tt. The dead time is defined as the time which will pass from when the valve opens until the bulb begins to register the temperature increase. At the measuring point the increase will follow an exponential function. The tangent to the starting point of the curve intersects the tangent to the final value of the curve at Tt + Ts. Ts is denoted the time constant and indicates the time it takes for the temperature to increase to 63% of the final value. In other words, the time constant is an expression of the rate at which the controlled variable changes as a result of a sudden change of the manipulated variable. Because of the great difference in temperature the curve of temperature will increase most rapidly at the beginning, to fade out gradually and approach the final value tangentially. When the temperature has increased

Page 3 of 7

to the point A the thermostat will cut-in and the cooling begins. However, it takes some time - 1 - before the ambient temperature begins to fall. During cooling the temperature drops to the point B where the thermostats cut out the refrigeration system. Because of the cold accumulated there will, however, be certain after cooling 2 - before the temperature increases again. The cooling is restarted at the point A, and a new cycle begins. td (= the section A to B) denotes the thermal differential of the thermostat, whereas tmax indicates the maximum temperature fluctuations. Procedure: During building the program, given in the other page you will need to do the followings: 1) Create a Case structure 2) Go to ModernRing and EnumText Ring (in front panel). Place it in front panel. Connect it to the Case structure. Right click on it and select propertiesEdit item and make it as follows:

3) You need to do Add case after after right clicking on top of the case structure. Now you shall have 0, 1 and 2 cases. 4) Go to ProgrammingArrayArray constant, Put Numeric into it to get 1D array inside the case structure; stretch it to make more blocks. 5) Follow step 4 and build two more to fit them inside other two cases 6) Create a simulation loop from Control designSimulationSimulation loop 7) Right click on the border and set the following parameters: Initial time-0 Final time-24 Rung kutta-4 Check Nan/Inf Step size 0.05

Page 4 of 7

8) For the look up table: Go to Control design and SimulationsimulationLook up table look up table 1D. Double click on it and make the following changes: Click on look up tableLUTX; from parameter source select terminal, do the same for LUT data also.

9) Go to control design and simulation simulation signal generationsimulation time to get the clock 10) Temperature reference is a step signal and can be found from the same location as above Double click on it and set Initial value to 55, final value to 65 and step time to 8

11) To get the thermostat go to Control design and simulationsimulationnonlinear systemrelay 12) Double click on relay Output value off=0 Output value on=1 Switch off point=-1 and Parameter source terminal Switch on point=1 and parameter source terminal

13) To get the furnace go to control and simulation simulation nonlinear systemsaturation. Set the upper limit to 400. 14) To get House go to Control design and Simulation SimulationContinuous Linear System 15) Double click on it and make A(x0)=0; B(u0)=0.1, the rest are unchanged. Click on initial state (xo), go to parameter source and select terminal 16) To connect the initial state to the house block you will need a Build array. 17) Bring collector from Control design and simulation simulation--.utilitiescollector 18) Make sure on the left side of the collector there is another Build array but this time it is stretched to make 4 input channels. 19) There is a expression node which can be found in mathematics numeric 20) Go to front panel to bring XY graph 21) Right click on the graph to change some of its properties: In appearance change the plot shown to 4

Page 5 of 7

In Plot change the names of the 4 plots as Heating, Room Temperature, outside temperature and reference temperature Make the following change in Heating plot:

Page 6 of 7

Page 7 of 7

Discussion: 1) Discuss what is going on in the labVIEW program. 2) Explain the plots obtained after running the program. Reference: This example was based on an example from the book Feedback Control of Dynamic Systems by Gene F. Franklin, J. David Powell and Abbas Emami-Naeini Prentice Hall, Fourth Edition, page 3.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Control Tutorials For MATLAB and Simulink - Introduction - PID Controller DesignDocument15 pagesControl Tutorials For MATLAB and Simulink - Introduction - PID Controller DesignSengottu VelusamyNo ratings yet

- Control Tutorials For MATLAB and Simulink - Introduction - PID Controller DesignDocument15 pagesControl Tutorials For MATLAB and Simulink - Introduction - PID Controller DesignSengottu VelusamyNo ratings yet

- Business Communication TodayDocument39 pagesBusiness Communication TodaymzNo ratings yet

- HPE SimpliVity RapidDR 3.5.0 User Guide-A00105770en - UsDocument65 pagesHPE SimpliVity RapidDR 3.5.0 User Guide-A00105770en - UsAldo Rafael Gomez GutierrezNo ratings yet

- Control Systems 2Document18 pagesControl Systems 2Sengottu VelusamyNo ratings yet

- Control SystemsDocument18 pagesControl SystemsSengottu VelusamyNo ratings yet

- ECET-462: (Laboratory 7)Document5 pagesECET-462: (Laboratory 7)Sengottu VelusamyNo ratings yet

- 12 Ecet462spclaboratoryDocument4 pages12 Ecet462spclaboratorySengottu VelusamyNo ratings yet

- Tancet 2012 Basic EnggDocument4 pagesTancet 2012 Basic EnggSengottu VelusamyNo ratings yet

- Rudrabhisheka-Stotram Telugu PDF File2009Document3 pagesRudrabhisheka-Stotram Telugu PDF File2009Sreenivas GNo ratings yet

- Alter Database Backup Controlfile To Trace - PM-DB PDFDocument3 pagesAlter Database Backup Controlfile To Trace - PM-DB PDFChander ShekharNo ratings yet

- Transistor Bias CircuitsDocument29 pagesTransistor Bias CircuitsbruhNo ratings yet

- Binomial HeapDocument16 pagesBinomial HeapNishant MishraNo ratings yet

- Search EngineDocument42 pagesSearch EngineiqraNo ratings yet

- DsPIC33F Family Reference Manual AllDocument4 pagesDsPIC33F Family Reference Manual AllVlad MizeffNo ratings yet

- R0310WL007224Document1 pageR0310WL007224princesenapati59No ratings yet

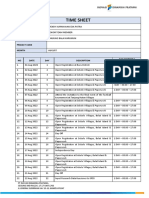

- Timesheet - August 2022 - An Wendy KurniawanDocument2 pagesTimesheet - August 2022 - An Wendy KurniawanWendy KurniawanNo ratings yet

- Course Description:: M21DE0108 Rdbms Lab L T P C Duration:14 Wks 0 0 2 2Document8 pagesCourse Description:: M21DE0108 Rdbms Lab L T P C Duration:14 Wks 0 0 2 2Gaurav NNo ratings yet

- Lab Exercise 2Document27 pagesLab Exercise 2Tharini SridharNo ratings yet

- Trending TechnologiesDocument4 pagesTrending TechnologiesNeeraj VarmaNo ratings yet

- ScopeDocument2 pagesScopeTirso Jr.100% (1)

- Assessment Response OdevilasDocument2 pagesAssessment Response OdevilasAdrian OdevilasNo ratings yet

- Quizizz: Sempoa: Quiz Started On: Thu 05, Nov 07:58 AM Total Attendance: 43 Average Score: 4820 Class Level # CorrectDocument28 pagesQuizizz: Sempoa: Quiz Started On: Thu 05, Nov 07:58 AM Total Attendance: 43 Average Score: 4820 Class Level # CorrectJuanito SammuelNo ratings yet

- Laboratory No. 3 - BAL-OTDocument4 pagesLaboratory No. 3 - BAL-OTChester Dave Bal-otNo ratings yet

- Excel TipsDocument4 pagesExcel TipsRohan sharmaNo ratings yet

- Manual HP Envy 17Document82 pagesManual HP Envy 17luisquitonNo ratings yet

- Citra Log - Txt.oldDocument7 pagesCitra Log - Txt.oldDiogo246No ratings yet

- Requirement Engineering Report ForDocument22 pagesRequirement Engineering Report ForIkramNo ratings yet

- Trust, Acceptance, and Use of Online Banking Services in The PhilippinesDocument15 pagesTrust, Acceptance, and Use of Online Banking Services in The Philippinesrafael oviedoNo ratings yet

- Parts Catalog: I R 1 0 2 3 / 1 0 2 2 / 1 0 1 9 / 1 0 1 8 SeriesDocument84 pagesParts Catalog: I R 1 0 2 3 / 1 0 2 2 / 1 0 1 9 / 1 0 1 8 SeriesmarecalinNo ratings yet

- Hana Exam DumpDocument17 pagesHana Exam DumpKumar WaibhavNo ratings yet

- Datasheet of iDS 7216HQHI M1 - E - V4.70.140 - 20220712Document4 pagesDatasheet of iDS 7216HQHI M1 - E - V4.70.140 - 20220712ikorangedane02No ratings yet

- BC FortinetVsJuniper July 2014v1Document2 pagesBC FortinetVsJuniper July 2014v1Speed DaemonNo ratings yet

- Resume Aidan Odonnell WebDocument1 pageResume Aidan Odonnell Webapi-540129961No ratings yet

- Programming With Python: ContentsDocument28 pagesProgramming With Python: ContentsBorderBRENo ratings yet

- ISO 27001 Foundation Exam SampleDocument30 pagesISO 27001 Foundation Exam SampleKaram AlMashhadi100% (1)

- Ehlers - FormulasDocument6 pagesEhlers - FormulasoaperuchenaNo ratings yet