Professional Documents

Culture Documents

Risktec Drilling Soc 0.3

Uploaded by

mashanghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risktec Drilling Soc 0.3

Uploaded by

mashanghCopyright:

Available Formats

Issue: 0.

3 Date: 12th July 2010

Statement of Capability

Drilling Risk Management Services

Risktec Solutions Inc. Ms Kris Smith President Risktec Solutions Inc 1110 NASA Parkway, Suite 203 Houston, TX 77058 United States of America Tel: +1 281 333 5080 Fax: +1 281 333 5089 e-mail: kris.smith@risktec.com Risktec Solutions Ltd. Mr Steve Lewis Director Risktec Solutions Limited Wilderspool Park Greenalls Avenue Warrington WA4 6HL United Kingdom Tel: +44 (0) 1925 611 203 Fax: +44 (0) 1925 611 647 e-mail: steve.lewis@risktec.co.uk

www.risktec.com

Drilling Risk Management Statement of Capability

1 1.1

OVERVIEW OF RISKTEC This Statement of Capability

This document summarises Risktecs capability to provide risk management services to the drilling industry.

1.2

Introduction

Risktec Solutions is an established, independent and specialist risk management consulting and training company, and is wholly owned by its employees. We assist clients in major hazard industries and commercial and public sectors to manage health, safety, security, environmental (HSSE) and business risk. Risktec has its principal office in Warrington in the UK, with other offices in key locations in the UK, Middle East and North America. Our activities are supported by a comprehensive network of local representatives in other regions around the world. Our intention is to be close to our clients. Risktec employs over 100 professional consultants with experience across a wide range of skill areas and industries.

Aberdeen, Ashford, Edinburgh, Glasgow, London, Warrington

Calgary Houston

Yuzhno-Sakhalinsk

Kuala Lumpur

Risktec office Representative office Agency office Dubai, Muscat

1.3

Our Clients

We are privileged to have many of the worlds best companies as clients in many sectors, including oil, gas and chemical, nuclear and defence, transport, commercial and government sectors. We have delivered over 1300 projects to over 450 clients in over 40 countries. We continuously seek new clients each year over 40% of our clients are new. We build longterm sustainable relationships with all our clients over 80% of our revenue is from existing clients. 100% of our clients in our annual independent survey would recommend Risktec.

1.4

Our Independence

Our independence is achieved through our selected range of services, our legal structure and our company values. As a wholly employee-owned company, our services are delivered by our shareholders who have a vested interest in maintaining long-term client relationships. We have no shareholders with competing corporate goals to satisfy, enabling us to offer truly impartial advice.

Risktec Solutions

Page 2 of 16

Drilling Risk Management Statement of Capability

1.5

Our Services

Risktec is recognised as a leading provider of professional consulting and training services in assessing and managing HSSE and business risks. Our experience ranges from delivering small self-contained work packages to managing complex, multi-disciplinary projects with a large number of stakeholders. Our approach is based on a unique blend of creative engineering, scientific and management skills, proven methodologies, up-to-date analytical tools and data, and a practical outlook.

RISK ENGINEERING

Hazard Identification Fire, Explosion & Toxic Gas Hazard Analysis Qualitative/ Deterministic Risk Assessment Bow-tie Hazard Management Human Factors Quantitative/ Probabilistic Risk Assessment Systems Design & Assurance Availability, Reliability & Maintainability Technical Integrity Independent Verification

RISK MANAGEMENT

HSSE/ Safety Cases Environmental Management HSSE Management Systems Competency Management Cultural & Behavioural Improvement Business Risk Assessment Business Continuity Management Project Risk Management Security Risk Management Knowledge Management

SPECIALIST SERVICES

Independent Review Auditing Business Performance Improvement Environmental Impact Assessment Fire Protection Health Risk Assessment Incident Investigation Natural Hazards Risk Assessment Organisational Change Radiological Protection Research and Technology Structural Integrity and Analysis

Products BowTieXP, SkillsXP, KM tools

We use industry standard risk and HSSE software to add value to our consulting services. We also develop customised tools to help solve unique problems not readily tackled by standard methods, including working closely with Microsoft certified partners.

RISK ENGINEERING

Event & Failure Databases, e.g. HSE-HCR, OREDA, NPRD HAZOP Manager, PHA Works, PHA Pro Reliability Workbench, FaultTree+, Risk Spectrum, Logan PHAST, FRED, CIRRUS CFAST, ALOFT, FDS, SCOPE US EPA dispersion models FLACS, CEBAM, AUTOREAGAS Experimental scale models Bespoke Event, Effects, SIL & Risk Models Shell SHEPHERD, PHASTRISK, RiskPlot, RiskCurves SURFER, @RISK, Crystal Ball BowTieXP, THESIS

MANAGEMENT SYSTEM

MS Maturity Model BowTieXP, THESIS SkillsXP KnowledgeXP

AuditKM FlowKM CaptureKM RiskKM

SPECIALIST SERVICES

Fire Protection

HAAS KY PIPE F&G Mapping Autocad

Human Factors

Bespoke HF Models HEART, THERP

Tripod-Delta Cultural Survey Tools Hearts & Minds Project Risk Tools

Incident Investigation & Analysis

Tripod-Beta Track Black BowTieXP

Evacuation Modelling

EXODUS

Natural Hazards Risk Assessment

Walkdown Tools Vulnerability Data

Structural Integrity and Analysis

Finite-Element Codes

Risktec Solutions

Page 3 of 16

Drilling Risk Management Statement of Capability

Risktec also offers a structured programme of risk management training modules in Risk and Safety Management. Modules qualify for continuous education units and can be delivered with assessment if required. Overall, our approach makes effective use of a clients training budget through structured training that meets business needs.

Training & Education in Risk & Safety Management

Core Modules

Introduction to Practical Risk Mgmt Hazard Identification Hazard Assessment Risk Reduction & ALARP

Health, Safety & Environment (HSE) Mgmt Systems

Key features of programme: Each module usually involves 2 days of classroom teaching Modules can be tailored to clients facilities and operations Programme can be delivered at clients premises and timing is flexible Learning delivered by practising risk consultants, with emphasis on hands-on practice Modules qualify for continuous education units

Oil & Gas, Chemical & Transport

Identification and Assessment

HAZOP Study Bowtie Analysis Safety Integrity Levels (SIL)

Availability, Reliability and Maintainability (ARM)

Nuclear & Marine

Nuclear Foundation Modules

Nuclear Reactor Basics Nuclear Reactor Safety Principles Principles of Regulatory Systems Implementing a Regulatory Regime Radiological Protection Radioactive Waste Management Design Substantiation

Management Systems and Implementation

Safety/HSE Cases Accident Investigation & Analysis Emergency Response Planning Workplace Safety

RiskRisk-Based Decision Making

Risk Control Systems & Performance QRA for Oil & Gas & Process Industries Oil & Gas & Process Industry Risk Studies PSA in Nuclear Industries Rail Safety Analysis Business Continuity Management

International Marine Safety & Security Courses

Company Security Officer Ship Security Officer Port Facility Security Officer Maritime Security Officer

Physical Effects Modelling Human Factors in Design & Operations Oil and Gas Lifecycle Hazards & Risks Nuclear Lifecycle Hazards & Risks Rail Industry Hazards & Risks Security Risk Management

Fault Tree & Event Tree Analysis Process Hazard Analysis

Assurance and Improvement

Performance Monitoring, Auditing & Mgmt Review

Specialist Software

BowTieXP Software Investigator 3 Software

Competency Mgmt, Culture & Behaviour

Research Methods

Project Risk Management

1.6

Our Solutions Approach

We are committed to providing clients with complete and pragmatic solutions, built on a sound understanding of their business. We focus on clarifying the underlying problems at the heart of any issue, before proposing a solution. We present our recommendations in a clear and straightforward way. Throughout a project we work with our clients to ensure ownership of the solution. We believe this philosophy leads to mutually trusting relationships with our clients.

1.7

Our People

Risktec consultants are highly qualified and experienced and come from a wide range of backgrounds, including engineering and science disciplines, information technology, operations and management. They are high calibre and motivated professionals with a clear focus on meeting client expectations. Experienced management team members and senior consultants assure technical expertise across our services, and have established reputations with major blue chip clients. The key values underpinning the culture at Risktec are empowerment, teamwork, solutions and integrity. Our consultants are fully empowered to deliver all aspects of projects and our employee ownership model promotes stability in our workforce.

Risktec Solutions

Page 4 of 16

Drilling Risk Management Statement of Capability

Examples of our values in practise are shown below:

Through Teamwork we will: Work collaboratively to win work and meet deadlines. Demonstrate respect for colleagues and clients. Be flexible in meeting changing situations and demonstrate cooperative behaviour. Share information and communicate in a timely, open and honest manner. Be helpful and supportive of colleagues. We will work with Integrity by: Taking personal responsibility to work hard and deliver personal and Company commitments. Being open and honest in all business activities. Communicating in a clear, concise and timely manner. Always seeking to provide value for money. Avoiding criticism of competitors and clients. Highlighting potential conflict of interest situations.

Differentiation

Motivated personnel Client Satisfaction

Integrity

Teamwork Our behaviour is what matters!

Empowerment

We will work towards Solutions by: Providing clear advice to clients and colleagues. Proactively identifying opportunities to reduce cost and time. Maximising the use of existing information. Being open minded, helpful and constructive. Acting decisively to meet client and Risktec objectives.

We are Empowered to: Take initiative whilst keeping relevant personnel informed. Take responsibility for your own actions and consider their impact on others. Seek opportunities to develop others through involvement and delegation. Provide support to other personnel, recognising that delegation is not an abdication of responsibility. Contribute constructively.

1.8

Quality Assurance

All work undertaken by Risktec is carried out in accordance with Risktecs QA System, which is certified to BS EN ISO 9001:2008.

1.9

Customer Feedback

Risktec has commissioned annual independent Customer Satisfaction Surveys to find out exactly what our clients think of us. The aim of these surveys, carried out in line with our ISO 9001:2008 certification, is to help us build a better understanding of our clients views of our strengths and weaknesses. The feedback has been consistently very positive. Risktec is committed to developing sustainable and long-term business relationships and the continuous improvement of all aspects of our service is a key part of this commitment.

Risktec Solutions

Solutions

Page 5 of 16

Drilling Risk Management Statement of Capability

DRILLING RISK MANAGEMENT SERVICES

Risktec has extensive experience in the drilling and well services sector. Our risk reduction and management services to this sector include:

Safety cases Drilling unit safety cases and full suites of integrated safety studies to meet regulatory requirements or company and industry (IADC) best practice guidelines. Safety, reliability and operability studies Studies and workshops for drilling equipment and activities, such as FMEAs, HAZOPs, HAZIDs, bow-ties, dropped objects, blowout and SIMOPs risk studies, and QRAs to reduce risks. Safety-critical system performance and verification Identifying safety-critical systems and elements, developing performance standards, assurance and verification schemes, to prevent and mitigate major accidents. Safety management systems Integrated health, safety, security and environmental management systems to international standards, including monitoring operational discipline and effectiveness. Competency management Competency requirements, role and task analysis, competency assessment and management systems, to improve operational effectiveness and comply with regulatory demands. Safety culture improvement Safety culture assessment, cultural change support, behavioural safety coaching, worksite risk assessment, incident investigation and training, to help develop just safety cultures. Independent review Safety case thorough reviews, technical assessments and audits, to provide a fresh look at key issues and identify opportunities for improving equipment, operations and practices. Training and education Accredited training and education to post-graduate level in risk and safety management topics, to help develop competent risk and safety professionals in industry.

Our experience encompasses a wide range of mobile offshore drilling units, as well as fixedplatform drilling rigs and land drilling rigs.

Risktec Solutions

Page 6 of 16

Drilling Risk Management Statement of Capability

3 3.1

DRILLING PROJECT EXPERIENCE

Range of Experience In the oil and gas exploration and production industry Risktec has a substantial track record of working with leading international and national oil companies, and drilling and well services companies. This has given us experience of a wide range of mobile offshore drilling units, including semi-submersibles, drill-ships, jack-ups and swamp barges, as well as fixed-platform drilling rigs and land drilling rigs. We have worked on all aspects of the facility life-cycle, from concept design, through detailed design, to construction, drilling and well service operations and SIMOPs. We have worked on all stages of drilling and well services operations, from well design, through exploration and development drilling, to well testing, completions, workover and wirelining activities. We also have considerable experience of a broad range of working environments, from harsh offshore to mild onshore environments, and from shallow water to deepwater wells.

3.2

Example Projects

Drilling safety cases

Introduction HSE Management System Rig Description Risk Management Emergency Response Performance Monitoring

Intro to Risktec Solutions Ltd

BP Sakhalin GSF KCA Deutag Noble Drilling Pride Saipem Shell Transocean

We specialise in practical, IADC compliant, safety cases which are understood and used by the workforce

Risktec Solutions

Page 7 of 16

Drilling Risk Management Statement of Capability

Bowtie hazard management

Threats

Well Control Incident-Kick During drilling, Tripping, etc.

Control Barriers

Well design, drilling program & procedures designed to minimize potential for a kick to occur

T.1.2.1 T.1.2.3 T.1.2.2 T.2.1.6

Recovery Barriers

Primary well control procedure maintain hydrostatic head

T.2.1.1

Consequences

Emergency response fire fighting Design of accommodation (A60) provides temporary refuge

T.1.1.11

Threat

Riser Failure Impact, Disconnect, Rig Offset

Trained, competent Drill Crew & Mud Loggers continually monitor downhole conditions, recognize & respond appropriately to any impending kick

T.2.1.1 T.2.1.3 T.4.1.1 T.4.2.2 T.4.2.1 T.4.2.3

Secondary well control procedures close in BOP

T.1.2.2 T.2.1.2 T.3.1.1

T.2.1.1 T.2.1.6

Well kill procedures wait & weight or circulate out kick as appropriate

T.1.2.2 T.3.1.3

T.2.1.1

Shear/blind rams (2 sets) can be operated to close off well

T.2.1.6 T.3.1.2

T.2.1.2 T.2.4.1

T.2.1.4

T.2.1.6

T.3.1.1

T.2.1.3 T.2.1.5 T.2.4.1 T.2.4.2

T.1.2.3

T.2.1.6

T.2.4.3

Hazard

Hydrocarbons in Formation H-01.02

Alert personnel by rig General Alarm and PA announcements

T.3.5.3 T.4.3.6

Isolate/control potential sources of ignition

T.3.3.4 T.4.1.8 T.4.1.10

Medivac/evacuation

Fatalities/Injuries Due to Fire/Explosion Effects

T.3.4.1 T.4.3.9

T.4.1.9

T.3.1.2

T.4.3.5 T.4.3.12

T.1.1.3 T.3.5.6 T.4.3.3

T.2.3.6 T.4.2.2 T.4.3.4

T.4.3.6

T.3.3.7

T.1.1.4 T.4.1.23

T.4.3.2 T.4.3.4 T.4.3.6

T.3.5.5 T.4.3.1

T.4.3.3 T.4.3.5

Consequence

Un-ignited Release or Spill to Sea

Design basis of riser to withstand environment

T.1.2.4

BOP operates casing shear & one blind shear automatically on loss of signals & power

T.2.4.3

T.2.1.1 T.2.1.6 T.3.1.2

Alert personnel by rig General Alarm and PA announcements

T.3.5.3 T.4.3.6

Emergency response pollution control

Threat

Dropped Object Impact to Riser or Controls

T.3.1.4

T.2.2.1

Lifting equipment design spec, SWL, maintenance & inspection

T.2.5.1 T.2.5.4 T.3.2.3

T.3.1.6

Pre-lift planning, risk assessment

Threat

Drill Into Producing Well

Lifting by trained & competent personnel in accordance with documented procedures

T.2.1.10

Loc: DD1 Event: Release of Hydrocarbons After BOP Installed

T.4.3.3 T.2.3.7

T.4.3.11

Consequence

T.2.5.3 T.3.1.7 T.3.3.4

T.3.1.5

T.2.5.1

T.2.5.2

T.2.5.2

T.4.2.5

T.2.2.2

T.4.2.2

Event

Secondary well control procedures close in BOP

T.2.1.1 T.2.1.6

Threat

Location of existing well bores relative to well being drilled known & audited prior to spud

T.1.2.1

Well design & drilling program take account of existing well bores

T.1.2.2 T.1.2.3

Drilling with real time positioning & forward ellipse of uncertainty

T.2.1.1 T.3.4.2 T.2.4.4

Control Barrier Effectiveness

Rating Is it used/is it in place? Does it work/is it effective? Always control has more than a 99% chance of working when required Generally control has a 99% - 75% chance of working when required Bowtie code Very Good Always Good Unknown Poor Frequently

Escalation Factors

T.4.1.23

T.4.1.23

Safety Critical Task Supporting Barrier Directly Safety Critical Task Supporting Escalation Factor

Unknown/cannot Unknown/cannot be guaranteed - control has a be guaranteed 75% - 50% chance of working when required Occasionally Possible control has a 50% - 25% chance of working when required Currently ineffective control has less than a 25% chance of working when required

Very Poor Rarely

Risktec is a world leader in the application of the bowtie method a unique, easily understood tool for identifying gaps, demonstrating risk control and communicating with people

Intro to Risktec Solutions Ltd

BHP Billiton GSF Japan Drilling Co KCA Deutag Noble Drilling OMV Pride Prosafe Saipem Shell Transocean

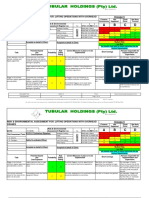

Safety-critical systems performance

Agip KCO Cameron Nabors Drilling

HSE-critical element Performance Standard Maintenance and Inspection Requirements

Pride Sakhalin Energy Shell Technip

Assess Integrity against requirements

Maintenance Mgmt System

Risktec personnel developed IADC North Sea verification scheme guidelines in 1996

Intro to Risktec Solutions Ltd

Technical Integrity Verification Plan

Risktec Solutions

Page 8 of 16

Drilling Risk Management Statement of Capability

Safety management system

Policy & Strategic Objectives Organisation, Resources & Competence Risk Evaluation & Management Leadership & Commitment Planning, Standards & Procedures Implementation & Monitoring Audit Management Review Continuous Improvement Corrective Actions

BHP Billiton Dockwise Ensco Pride

We specialise in practical systems that ensure risks are known and processes, procedures and resources are in place for managing them

Intro to Risktec Solutions Ltd

Independent review

Legislative Changes Findings from Audits and Exercises Organisational and Personnel Changes

ADCO BHP Billiton Blade Energy Bunduq OMV Shell

Industry Best Practices

New Industry Knowledge

Company Standards Change

Incident History

Procedural Changes Modifications to Facility or Operations (past & planned)

Ageing Issues

Intro to Risktec Solutions Ltd

We involve people and recommend improvements to equipment, operations and practices

Risktec Solutions

Page 9 of 16

Drilling Risk Management Statement of Capability

3.3

Representative Project Experience

Description and Location Year

REGION Client AMERICAS: BHP Billiton

Blade Energy Ensco, USA Global Santa Fe

Hazard Management Study and HSE Case communication and operational tools for Nabors Rig 657 jack-up, offshore Trinidad Well test hazard management study Audit protocols for hazard management audits of drilling contractors Corporate fatal risk protocol hazard bowtie Enterprise wide drilling risk management bowties Drilling HSE Case protocol Production of bowties and critical task tables for Paul Romano Drilling Rig Drilling HAZID Safe System of Work and PTW Training HSE Case for DD1 fifth-generation deepwater semi-submersible DD1 HSE Case update for completions activities HSE critical task booklets for bow-tie / HSE training of DD1 workforce FMECA for Shah Deniz Platform Wellhead, Azerbaijan HAZID of Shallow Water Testing of Subsea Production System Xmas Trees Dropped Object Survey for Jack Bates semi-submersible Dropped Object Survey for Nelson platform Workover HAZID for Dunlin Alpha Development and delivery of incident investigation and analysis training courses Combined Operations Notification Buzzard and Galaxy III Rig Audit Drilling risk analysis for Meteor well, North Sea Drilling Operations HSE Support Corporate Risk Bowties Rig Audit

2003 2003 2004 2004 2004 2004 2007 2008 2003 2004 2006 2006 2007 2006 2003 2003 2008 2007 - 09 2007 2007 2007 2009 2009 2006

EUROPE: BP Exploration Cameron Core Technical for Shell Expro Fairfield Energy Maersk Oil Ltd. Nexen, UK OMV, Austria OMV, UK

PETROM Romania (member of OMV Group) Pride North Sea UK

Prosafe Offshore Limited Shell UK / Shell EP Europe

Offshore Drilling Rig Operations HSE Audit Pride North Sea (semi-sub) Safety Case and Verification Scheme Pride Rotterdam (jack-up) Safety Case update, performance standards, fire & explosion assessment, blast overpressure modelling, and QRA Supplier quality management audit Hazard bowtie development Combined Operation HAZID and Interface HAZIDs for K17 and Cutter QC together with Combined Operations Safety Case for Cutter QC Gas lift risk assessment, Pierce FMEA for Riser handling system

2007 2002 2002 2002 2005 2005 2009 2006

Technip Offshore UK Ltd (TOUL) MIDDLE EAST & NORTH AFRICA: ADCO Hazard Register for onshore drilling facilities Blade Energy HSE support to Underbalanced Drilling project, onshore Yemen Partners for Total Yemen Blade Energy HSE support to Coiled Tubing UBD project, onshore UAE Partners for Margham Dubai Establishment Risktec Solutions

2002 2005

2006

Page 10 of 16

Drilling Risk Management Statement of Capability

REGION Client Blade Energy Partners for Total Algeria Bunduq Oil Company Dragon Oil, Turkmenistan Dubai Petroleum Petroleum Development Oman (PDO)

Description and Location HSE support to Underbalanced Drilling project, onshore Algeria

Year 2006

Hazard & effects register for drilling and well services Development and Delivery of Risk Management Training Course in Dubai and Turkmenistan Provision of technical resources for Well Control Incident investigation Rig move risk assessment HSE Support for the Harweel Adaptive Drilling Process (ADP) Managed Pressure Drilling program HSE Support for the Tight Gas Exploration Adaptive Drilling Process (ADP) Managed Pressure Drilling program - Jaleel SE Facilitation of HAZID and HAZOP workshops for Fahud Underbalanced Workover Pilot Project Independent Review of PDO H2S Respiratory Protection Equipment and Emergency Response philosophy Msileh A Blowout study Rabab SE Exploration Well Blowout Study Safety Audit (Compliance Review) for Saudi Aramco Drilling and Workover Department, Southern Area Drilling Operations Risk assessors training course for Drilling and Workover Department Managers risk assessment and management training course for Drilling and Workover Department Development of HSE Case for Underbalanced Drilling operations in PDO

2006 2006 2007 2008 2006

2007 2007 2008 2008 2008 2006 2010 2010 2004

Saudi Aramco

Shell International E&P AFRICA (see above for North Africa): BP Angola Well Testing HAZOPs for Blocks 18 and 31 Global Santa Fe HSE Case for High Island 5 jack-up drilling unit (GSF) for Shell Gabon Global Santa Fe HSE Case for High Island 7 jack-up drilling unit (GSF) for Pecten Cameroon KCA Deutag (Libya) Support for T-202 HSE case Transocean for SPDC HSE Cases and HSE-MS Bridging Document for Trident VI & VIII (jack-ups) EA Project Nigeria Transocean for HSE Case update for Transocean 709 SNEPCO Bonga Project FORMER SOVIET UNION: Agip KCO Comparative and concept HAZIDs of layout options for Island D Experimental Programme SIMOPS risk assessment Layout review and coarse HAZOP of D Island FEED Safety case for D island top hole drilling (Saipem) HSEMS bridging document for D island top hole drilling Fire and explosion study for D island reservoir drilling, including well spacing issues Interface HAZID for D island Gassy soils HAZID Safety case for D island reservoir drilling Minimum facilities wellhead platform and cantilever barge rig QRA D-Island Design HSE Case D-Island Hook up HSE Execution plan and supporting HAZIDs Risktec Solutions

2007 2006

2007

2007 2002 2001

2003 2003 2003 2005 2005 2005 2006 2006 2006 2007 2007 2007 Page 11 of 16

Drilling Risk Management Statement of Capability

REGION Client BP Exploration Azerbaijan BP Exploration (Elvary Neftegaz)

Description and Location SDX-4 Extended Well Test - HAZOP Industrial Safety Declaration for Sedco 600 (semi-sub) for offshore Sakhalin Well-specific risk assessment for Sedco 600 (semi-sub) for offshore Sakhalin Industrial Safety Declaration for Transocean Legend (semi-sub) for offshore Sakhalin Well-specific risk assessment for Transocean Legend (semi-sub) for offshore Sakhalin HSE Case update for T47 land rig (offshore island) HAZOP studies for D Island drilling and utility systems Fire and explosion assessment for well releases and mud systems HSE Case, Environmental Management Plan, HAZID, HAZOPs and HSE Studies for Rig 319 land rig (offshore island) Layout Hazard Review and Utilities HAZOP for Rig 321 land rig (offshore island) D Island rig removal HAZID and bowtie study Drilling dropped objects HAZID

Year 2006 2004 2004 2005 2005 2001 2005 2005 2002 2003 2008 2003

Deutag Drilling for Agip KCO National Oilwell for Agip KCO Pride International for Agip KCO

Saipem for Agip KCO Sakhalin Energy Investment Co. (SEIC)

Transocean for Agip KCO ASIA & AUSTRALASIA (*Risktec Malaysia): Japan Drilling HAZID study and hazard management guidelines for experimental wells Company Transocean Safety Case for Transocean D534 drill ship Transocean* Operational and Procedural HAZOP of Jack Bates Lifting and Racking Drill Floor Operations Nabors Drilling FMEA for drilling tube lifting equipment International Noble Drilling HSE Case for Noble Dave Beard HSE Case Review and Update for Noble Jim Thompson HSE Case Rollout Presentations for Noble Danny Adkins HSE Case Review and Update for Noble Danny Adkins

Shallow gas review for Lunskoye Platform Water injection well risk review QRA for shallow gas drilling Well perforation hazard management decision review Marine oil spill QRA PA-A Platform Gas Lift QRA HSE Case update and HSE Studies for T20 jack-up

2004 2004 2005 2005 2005 2007 2001

2003 2006 2005 2005 2008 2009 2009 2010

Risktec Solutions

Page 12 of 16

Drilling Risk Management Statement of Capability

KEY PERSONNEL

Profiles of a selection of Risktec key personnel are provided below. available on request. Detailed CVs are

Name Bonsall, David

Position Project Director

Qualifications B.Sc. in Mechanical Engineering MSc in Turbine Technology Member of the Institution of Mechanical Engineers

Experience Following 20 years in line and project management roles in the defence industry, David has over 19 years of experience in HSE risk management in the offshore and onshore oil & gas industry. His expertise encompasses the development and implementation of corporate and operational HSE management systems, HSE cases for high-hazard facilities and technical risk studies for particularly problematic issues. David has managed major UK and international projects with clients such as Sakhalin Energy, Shell Pearl GTL, Qatargas, OMV, BP, SNEPCO, BOC, Centrica, Brunei Shell, Maersk, Transocean, Ensco, KCA Deutag, Petroleum Development Oman and a number of companies in other energy sectors. Gareth Book has over 15 years experience in the development and delivery of HSE and risk management consulting projects in the oil and gas, petrochemical, chemical, mining and utilities industries. His expertise covers hazard identification (HAZOP and HAZID), HSE management systems for oil and gas facilities (upstream and downstream), including HSEIA/COMAH Reports, HSE Cases, formal HSE studies and QRAs, practical use of risk bow-tie methodology for control of HSE and business risks, HSE management support to projects and development and delivery of HSE risk management training workshops. Mr Book has extensive experience of managing major international HSE risk management projects for oil operators such as ADCO, ExxonMobil, PDO, Saudi Aramco, Shell and Total, as well as drilling and well service providers such as GSF, Weatherford and Blade Energy. Peter offers 39 years experience. For the first 22 years of his career Peter designed and implemented a wide range of control and monitoring systems based mostly on programmable technology, including a substantial number of systems with stringent performance and/or integrity requirements. Peter has also undertaken a number of power electrical engineering activities (LV, MV, HV and Power Electronics) as a supplementary discipline, drawing on his core electrical engineering education. In the last 17 years Peter has provided engineering services in a consultancy role, specialising in high-integrity control and electrical systems, concept design and engineering support (including review and requirements specification), integrity substantiation and assessment (including support for risk assessment and safety cases) together with performance assessment and recommendations for improvement in respect of reliability, availability, integrity and/or other performance objectives.

Book, Gareth

Project Director

BSC (Hons) Geology MSc Applied Geology Member of the American Society of Safety Engineers Member of the Institute of Environmental Management and Assessment

Clinton, Peter

Principal Consultant

FEANI Group 1 (Eur Ing) CEng, MIET, MIEEE BSc(Eng) (Hons) Electrical Engineering (Control Engineering Specialisation)

Cromarty, Michael

Senior Consultant

BA (Hons) Business Studies MSc Marketing NEBOSH General Certificate

Michael has over 9 years of experience in developing both quality and safety management systems for oil and gas service and operating companies. In addition he has implemented various safety systems on offshore installations, such as permit to work, risk assessment systems, etc. Previously working for a drilling contractor, Michael was responsible for providing HSE advice and support to installation personnel, and has offshore safety advisor experience. Other areas of experience include performing audits and incident investigations, developing emergency response plans, and HSE reporting.

Risktec Solutions

Page 13 of 16

Drilling Risk Management Statement of Capability

Name Flanagan, Ronan

Position Principal Engineer

Qualifications BEng (Hons) Chemical Engineering, MSc Reliability Engineering and Safety Management, Associate Member of the Institution of Chemical Engineers

Experience Ronan has over 17 years experience in the oil, gas, transportation and process industries. His experience includes technical safety for the design of offshore installations, provision of safety support to offshore drilling and production operations, support for regulatory submissions, reliability modelling, FMECA, maintenance planning, SIL assessments, bowtie and LOPA assessments, hazard identification, consequence assessment, QRA, physical effects modelling, development of offshore safety cases, input to COMAH cases and ALARP demonstration. Mr. Fortner is a degreed mechanical engineer with more than 12 years of professional safety and engineering experience. Mr. Fortners experiences include project management, hazard analysis, process safety management, security risk assessment, facility and equipment field surveys, training, mechanical certification, workshop facilitation and 3rd party verification and design review for both onshore and offshore facilities. He has conducted offshore safety case studies, as well as explosion risk assessments, Process Hazards Analyses (PHAs), Layer of Protection Analyses (LOPAs), dispersion analyses and facility siting studies for a variety of facilities. With his unique background, Sam has conducted 3rd party certification reviews, ship and pot security assessments, EER, ETERA, dropped object, vessel collision, SIMOPS, FMEA, and MOC studies on Pre-FEED and FEED, design stage, and existing projects. Onshore facilities include chemical, pharmaceutical, and petrochemical sites. Offshore facilities include ships, FPSOs, TLPs, semi-submersibles, and fixed platforms.

Fortner, Sam

Senior Consultant

B.S. Mechanical Engineering & B.S. Marine Engineering California Maritime Academy, Vallejo, CA U.S. Merchant Marine 3rd Assistant Engineer Steam and Motor Vessels, U.S. Coast Guard License, any horsepower

Harding, Andrew

Principal Consultant

BSc (Hons) Degree in Chemical Engineering MSc Biochemical Engineering Member of the Institute of Fire Engineers Associate Member of the Institution of Chemical Engineers

Andy has over 20 years experience in his field and is responsible for managing the Warrington Risk Management Team. He has extensive experience of projects within the oil, gas and chemical industries including: project risk management, fire and explosion risk assessment and protection, QRA, physical effects modelling, occupied building risk assessment, development of HSE Cases, HAZOP chair and peer review and recommendation for development and of safety management systems.

Hurst, Sheryl

Principal Consultant

BSc (Hons) Physics Associate of the Institute of Risk Management

Sheryl has 20 years experience of risk assessment and safety case development on projects in high-hazard industries including drilling rigs, offshore production facilities, onshore gas and process plant, refineries and infrastructure systems. Her work has also included development and delivery of technical training courses, HAZID workshops, physical effects modelling, QRA, cost-benefit analysis, ALARP demonstrations, and management system policies, processes and procedures. With over 25 years of experience in management system and risk assessment applications, Steve acts as project director or lead facilitator for large and complex risk consulting projects. He has managed a wide range of international projects ranging from strategic risk profiling studies, through risk quantification, to full risk reduction programmes and management system development. Sector experience includes oil & gas drilling and production, as well as other high-hazard industries. Emphasis has been on providing assurance to senior managers that risks to people, assets, reputation and the environment are being properly managed and opportunities for business improvement are recognised.

Lewis, Steve

Project Director

B.Sc. in Physics (First Class) Fellow of the Institute of Risk Management

Risktec Solutions

Page 14 of 16

Drilling Risk Management Statement of Capability

Name Lidstone, Andy

Position Principal Consultant

Qualifications BSc (Hons) in Physics Member of the Institute of Physics Chartered Physicist

Experience Andy has over 20 years experience in the field of safety and risk assessment and has worked in a number of industries, including oil and gas, mining, nuclear and defence, transport, manufacturing and chemical sectors. Over the past 15 years, Andys work has been predominately in the oil and gas industries, managing projects for facilities including drilling rigs, refineries, mines, gas plants, and logistics operations. His expertise includes techniques such as bowties, fault and event tree analysis, failure modes and effects analysis, consequence modelling, QRA, hazard identification, preparation and roll out of HSE cases and qualitative and quantitative risk assessments. Andy frequently provides training in these topics together with incident investigation training. Mr. Moore has over thirty years of experience in life safety management programs, fire & gas detection and suppression systems design & engineering, emergency program planning & management, automation system design & installation, system preventative maintenance, quality control and assurance system management and customer support. Mr. Moore is considered by many to be an expert in the design and development of fire & gas detection systems for oil & gas exploration / production facilities in extreme cold environments. His many years on an industry research & development team provided Greg with the knowledge necessary to design the most reliable of systems without impacting the budget. Mr. Moore is well versed in the use and understanding of the NFPA, Uniform & International Building Codes, Fire & Mechanical Codes and various other Federal Codes from OSHA Standards to DOD Standards. Mr. Moore has 20 years of Honorable service (active & reserve) in the U.S. Navy. His diverse background in Life Safety lends itself to a philosophy of keeping it simple and practical that appeals to Federal and State regulators and business managers.

Moore, Greg

Principal Consultant

National Institute for Certification in Engineering Technologies (NICET) multiple certifications NFPA Fire Inspector I State of Alaska-Fire System Permit, Level 1C (Engineer) State of Texas-Fire Alarm Planning Superintendant License (Engineer)

Myint, Sein (Lawrence)

Senior Consultant

PhD from UMIST, UK Registered Fire Protection Engineer (FPPE) Registered Chartered Mechanical Engineer (UK) Alaska Fire System Permit IIC-DO and IIIC30

Mr. Myint has over 20 years in fire protection engineering. He is an expert in fine water mist systems. He has designed and consulted on fire suppression and gas detection systems for a number of clients, including oil and gas, government, and the private sector. He was a Senior Lecturer at University Sains Malaysia after obtaining his PhD from University of Manchester Institute of Science & Technology (UMIST) in the UK. Mr. Myint developed corporate guidance documents and procedures for fire and gas suppression and detection systems for a large oil company. He has performed numerous fire code reviews for systems in oil and gas industries, as well as the government and private sectors. Mr. Myint has been involved in every aspect of fire protection engineering, including, research and development, design, installation, testing, maintenance and inspection. He is intimately familiar with NFPA, Uniform & International Building Codes, fire & mechanical codes and various other federal, company and country codes and standards.

Risktec Solutions

Page 15 of 16

Drilling Risk Management Statement of Capability

Name Smith, Duncan

Position Principal Consultant

Qualifications B.Sc. (Hons.) Physics

Experience Mr. Smith has 20 years of process safety and risk assessment experience. He has conducted offshore safety case studies including fire and explosion analyses, smoke and gas ingress, emergency system survivability, escape, evacuation and rescue analyses and dropped object studies for clients worldwide. He has conducted fire, toxic release, and explosion risk assessments, Process Hazards Analyses (PHAs), Layer of Protection Analyses (LOPAs), dispersion analyses and facility siting studies for a variety of facilities, including: offshore installations, refineries, petrochemical plants, and LNG import facilities. Mr. Smith has led and conducted offshore and onshore Quantitative Risk Analyses (QRAs) for BP, ConocoPhillips, CITGO, MODEC and others. He was the safety representative on the detailed design of the ExxonMobil Kizomba FPSO and worked with BP Exploration Production Technology Group to develop corporate standards and provide general support to exploration and production projects.

Smith, Kris

Principal Consultant

B.S. (Hons) Mechanical Engineering

Ms Smith has over 20 years of experience in the fields of safety, process safety, risk assessment, risk management, emergency response and training. Prior to joining Risktec, she was Safety & Security Manager at a large petrochemical site in Texas and was responsible for compliance with OSHA, EPA and DOT. She has conducted offshore safety case studies, as well as explosion risk assessments, Process Hazards Analyses (PHAs), Layer of Protection Analyses (LOPAs), dispersion analyses and facility siting studies for a variety of facilities, including: offshore installations, refineries and petrochemical plants. Ms Smith has led and conducted an offshore Quantitative Risk Analysis (QRAs) for Shell. She has led bowtie analyses and conducted multiple training classes involving the following topics: safety, process safety and risk management. Additionally, she has developed and implemented programs for behavior-based safety. Ms. Smiths diverse experience in safety, process safety and engineering offers a unique background for providing practical solutions to clients varied needs.

Taylor, Mark

Principal Consultant

BSc(Hons) in Chemical Engineering MBA Member of the Institution of Chemical Engineers Chartered Engineer

Mark Taylor has over 20 years experience in the oil, gas and process industries, with a background in managing complex R&D and engineering projects at British Gas. Mark has extensive experience in managing and delivering risk and process safety projects including HAZOP, HAZID, UK safety cases and international HSE cases, HSE planning, hazard management strategy, performance standards and training. His facility experience includes offshore and onshore production installations, drilling rigs and pipelines, as well as logistics operations.

Risktec Solutions

Page 16 of 16

You might also like

- Human Factors in Incident Investigation and AnalysisDocument150 pagesHuman Factors in Incident Investigation and AnalysismashanghNo ratings yet

- Evacuation DrillDocument6 pagesEvacuation DrillJohn RajeshNo ratings yet

- SLB Project Management Essentials 0 IntroductionDocument25 pagesSLB Project Management Essentials 0 IntroductionmashanghNo ratings yet

- Design ControlDocument16 pagesDesign ControlYusufNo ratings yet

- 9.5 NJM PAUT Corrosion MapDocument1 page9.5 NJM PAUT Corrosion MapTHIRU.SNo ratings yet

- Rig Specific Emergency Response Plan Rev1Document33 pagesRig Specific Emergency Response Plan Rev1bilou100% (1)

- Rig Safety PresentationDocument20 pagesRig Safety PresentationMohamed MostafaNo ratings yet

- ABS Drops Guide E-Sept17Document85 pagesABS Drops Guide E-Sept17Max BeeksNo ratings yet

- Drilling Rig Checklist Rev1Document29 pagesDrilling Rig Checklist Rev1Omaira Sánchez OrtizNo ratings yet

- RA For Assessment For Lifting OperationsDocument19 pagesRA For Assessment For Lifting OperationsMohamedSaidNo ratings yet

- Quality Docs DEP 17 0803Document7 pagesQuality Docs DEP 17 0803Edwin MPNo ratings yet

- PPI Rig Audit CheckDocument5 pagesPPI Rig Audit CheckAHMED BAKRNo ratings yet

- Field CSI ChecklistDocument14 pagesField CSI Checklistfazlullah fazilNo ratings yet

- Datalog Wellsite Procedures Manual 1999Document34 pagesDatalog Wellsite Procedures Manual 1999Muhammad HamdyNo ratings yet

- TCF 1 - Daily Safety Report 21-Aprl-2021Document4 pagesTCF 1 - Daily Safety Report 21-Aprl-2021Muhammad TariqNo ratings yet

- Management Leading and Collaborating in A Competitive World 13th Edition Bateman Solutions ManualDocument25 pagesManagement Leading and Collaborating in A Competitive World 13th Edition Bateman Solutions ManualMichaelPruittewnr100% (57)

- Drill Pipe I.RDocument6 pagesDrill Pipe I.REdwin MPNo ratings yet

- BA Interview Questions 1579753175Document16 pagesBA Interview Questions 1579753175jain_binitmitsNo ratings yet

- Hazards of Nitrogen AsphyxiationDocument10 pagesHazards of Nitrogen AsphyxiationRaja Senthil NathanNo ratings yet

- Land Rigs Equipment List Template - OZDocument50 pagesLand Rigs Equipment List Template - OZAbdel Azim MohamedNo ratings yet

- SPE 81130 A Look at Batch Drilling in Trinidad and TobagoDocument4 pagesSPE 81130 A Look at Batch Drilling in Trinidad and TobagoDiego LopezNo ratings yet

- Risk-Based OversightDocument17 pagesRisk-Based OversightRob De La EspriellaNo ratings yet

- Training Requirements - Rig Inspection ChecklistDocument4 pagesTraining Requirements - Rig Inspection ChecklistNeyaz MD ArFinNo ratings yet

- Drilling Fluid Waste Management in Drilling For Oil and Gas WellsDocument7 pagesDrilling Fluid Waste Management in Drilling For Oil and Gas WellsGasimovskyNo ratings yet

- Unity Health Safety ManualDocument19 pagesUnity Health Safety ManualKakaraparti SatishNo ratings yet

- Ford Case StudyDocument4 pagesFord Case StudyMANINDRA MOHAN SHUKLANo ratings yet

- StrongholdBarricade ProductsheetDocument1 pageStrongholdBarricade Productsheeteddy hariyadieNo ratings yet

- SAEP-390 - Radiation Protection Assessment (RPA)Document15 pagesSAEP-390 - Radiation Protection Assessment (RPA)EdAlmNo ratings yet

- Sms Gap Analysis Implementation Planning ToolDocument13 pagesSms Gap Analysis Implementation Planning ToolsmallhausenNo ratings yet

- Shift Handover HF KilDocument119 pagesShift Handover HF KilmashanghNo ratings yet

- Hazard Identification ProgramDocument2 pagesHazard Identification ProgramBeeNo ratings yet

- Rig Grip Safety MatsDocument4 pagesRig Grip Safety Matsromerov240% (1)

- OIl Rig Safety ChecklistDocument10 pagesOIl Rig Safety ChecklistTom TaoNo ratings yet

- Tennin HAZOPDocument4 pagesTennin HAZOPMohamed SamirNo ratings yet

- 3 School Based Management - Dod.processDocument36 pages3 School Based Management - Dod.processJemazel IgnacioNo ratings yet

- 024 - Competence Requirements For Drilling and Well Service PersonnelDocument16 pages024 - Competence Requirements For Drilling and Well Service PersonnelmashanghNo ratings yet

- 000-ZA-E-009000 - 00-Project Quality PlanDocument43 pages000-ZA-E-009000 - 00-Project Quality Plansalah abddayem44% (9)

- Risktec Drilling Soc 0.3Document16 pagesRisktec Drilling Soc 0.3mashanghNo ratings yet

- Hydrogen Sulfide ProtocolDocument32 pagesHydrogen Sulfide Protocolmashangh100% (1)

- 135 - Guidelines For Classification of Well Control Incidents and Well Integrity Incidents - Rev. 2Document21 pages135 - Guidelines For Classification of Well Control Incidents and Well Integrity Incidents - Rev. 2Sean CurnowNo ratings yet

- Form 5 5 Form Risk Assesment Contigency Planning - Designb EngineeringDocument10 pagesForm 5 5 Form Risk Assesment Contigency Planning - Designb EngineeringDeby PristantoNo ratings yet

- Monthly Hse Rig InspectionDocument7 pagesMonthly Hse Rig InspectionHidacio Da LimiaNo ratings yet

- 1126HSE-2001 EngDocument52 pages1126HSE-2001 EngMohamed HadjkacemNo ratings yet

- A Study of Customer Satisfaction Towards Honda Two Wheeler Vehicles With Reference To Kanase Honda, SataraDocument58 pagesA Study of Customer Satisfaction Towards Honda Two Wheeler Vehicles With Reference To Kanase Honda, Satararenuka rokadeNo ratings yet

- Slip and Cut Drilling Line. Number: 010 Date: December 5, 2002Document3 pagesSlip and Cut Drilling Line. Number: 010 Date: December 5, 2002Emre CengizNo ratings yet

- Apprisk Assessment HAZOPDocument1 pageApprisk Assessment HAZOPHakim YahiaouiNo ratings yet

- 2014-219 - Stabbing Board InspectionDocument3 pages2014-219 - Stabbing Board Inspectionchriswood1No ratings yet

- REGDOC2 1 2 Safety Culture Final EngDocument31 pagesREGDOC2 1 2 Safety Culture Final Engnagatopein6No ratings yet

- Viking H Se ManualDocument168 pagesViking H Se ManualAF Dowell MirinNo ratings yet

- Top Drive Systems Dropped Objects Prevention White PaperDocument4 pagesTop Drive Systems Dropped Objects Prevention White PaperneusadNo ratings yet

- DS-1 4th Ed - Volume 3 - Addendum 6 (09DEC2016) PDFDocument15 pagesDS-1 4th Ed - Volume 3 - Addendum 6 (09DEC2016) PDFisrael11288No ratings yet

- Safety PDFDocument368 pagesSafety PDFrmhona10No ratings yet

- 500 Ton 24 in Service ManualDocument23 pages500 Ton 24 in Service ManualImed HammoudaNo ratings yet

- Final Environmental Impact Assessment Report: Prepared ForDocument129 pagesFinal Environmental Impact Assessment Report: Prepared ForfosterbalaNo ratings yet

- Article 16 Magnetic Flux Leakage (MFL) ExaminationDocument4 pagesArticle 16 Magnetic Flux Leakage (MFL) ExaminationAnonymous ihanyMJNo ratings yet

- Company ProfileDocument16 pagesCompany ProfileDendukuri varmaNo ratings yet

- IDC SOP # XX Laying Down Drill Pipe From DerrickDocument4 pagesIDC SOP # XX Laying Down Drill Pipe From DerrickkareemNo ratings yet

- HIRADC Form (Approved 19-4-19)Document2 pagesHIRADC Form (Approved 19-4-19)MohdHuzairiRusliNo ratings yet

- Rig - LOUISIANA - JSA-IN-HAL-DF-402 CLEANING OF MIXING TANK 2018.10.28Document7 pagesRig - LOUISIANA - JSA-IN-HAL-DF-402 CLEANING OF MIXING TANK 2018.10.28Aziz AndriyantoNo ratings yet

- Norsok G 001Document70 pagesNorsok G 001Grant HosieNo ratings yet

- SIMOPS-Drilling Rigs CostsDocument4 pagesSIMOPS-Drilling Rigs CostsMarkyNo ratings yet

- Carbon Number Vs Hydrocarbon Stream NamesDocument1 pageCarbon Number Vs Hydrocarbon Stream NamesJames RodriguezNo ratings yet

- Risk AssesmentDocument2 pagesRisk Assesmentsabu1995No ratings yet

- Oil Blowout Contingency Planning and CountermeasuresDocument6 pagesOil Blowout Contingency Planning and Countermeasuresdaburto2No ratings yet

- WSHC - Landscape and Horticulture Guidelines - 16 Jan 2012Document69 pagesWSHC - Landscape and Horticulture Guidelines - 16 Jan 2012lwin_oo2435No ratings yet

- BSD-GL-HAL-HMS-100 - (Terms & Definitions)Document42 pagesBSD-GL-HAL-HMS-100 - (Terms & Definitions)Eduard GadzhievNo ratings yet

- Completion - Cementing and Perforating PDFDocument9 pagesCompletion - Cementing and Perforating PDFengineer1976No ratings yet

- Safety Lines 75Document7 pagesSafety Lines 75Ben FriskneyNo ratings yet

- Risktec Drilling Soc 0.3 PDFDocument16 pagesRisktec Drilling Soc 0.3 PDF1sNo ratings yet

- Praetorian Company OverviewDocument5 pagesPraetorian Company OverviewPeter SandersNo ratings yet

- Driick Man Hand Book: Getting Tied Off!Document2 pagesDriick Man Hand Book: Getting Tied Off!mashanghNo ratings yet

- Maintenance Bulletin 1062-BDocument13 pagesMaintenance Bulletin 1062-BmashanghNo ratings yet

- App Safety AwardsDocument1 pageApp Safety AwardsmashanghNo ratings yet

- QMS11403-1 20160705 Joining-Instruction BOSIET EDocument5 pagesQMS11403-1 20160705 Joining-Instruction BOSIET EmashanghNo ratings yet

- 3IOSH Mentor Scheme Reward Sept 2016Document1 page3IOSH Mentor Scheme Reward Sept 2016mashanghNo ratings yet

- Nor Scot BrochureDocument218 pagesNor Scot BrochureHaridevNo ratings yet

- Lowering The Bill With Trelleborg Floatover SolutionsDocument2 pagesLowering The Bill With Trelleborg Floatover SolutionsmashanghNo ratings yet

- Corrsoin Coupon Retriveal Incident Shell Action Alert May 2012Document1 pageCorrsoin Coupon Retriveal Incident Shell Action Alert May 2012mashanghNo ratings yet

- Human Factors in Incident Investigation and AnalysDocument151 pagesHuman Factors in Incident Investigation and AnalysmashanghNo ratings yet

- The Talent Factor in PurchasingDocument0 pagesThe Talent Factor in PurchasingaltezaserenisimaNo ratings yet

- BudgetingDocument3 pagesBudgetingSwati RathourNo ratings yet

- SWOT Analysis For Sri LankaDocument12 pagesSWOT Analysis For Sri LankaVinthuja Murukes100% (2)

- The Ultimate Guide To IBM Certified Administrator - Spectrum Scale V5.1 SolutionsDocument2 pagesThe Ultimate Guide To IBM Certified Administrator - Spectrum Scale V5.1 SolutionsStefanNo ratings yet

- Data WarehousingDocument15 pagesData WarehousingKunal26_MohapatraNo ratings yet

- Selling AIESEC To Your TargetsDocument7 pagesSelling AIESEC To Your TargetspijoowiseNo ratings yet

- The Application of GRAI Approach To The ServicesDocument39 pagesThe Application of GRAI Approach To The ServicesnajibgiNo ratings yet

- Domino's Case SolutionDocument2 pagesDomino's Case SolutionPrachi Rajan100% (1)

- Education CatalogDocument76 pagesEducation Catalogvenkat7tallyNo ratings yet

- Rubrics EvaluationDocument4 pagesRubrics EvaluationMuhammad Aiman Md NorNo ratings yet

- Pres 1117Document31 pagesPres 1117Hareen ReddyNo ratings yet

- CH - 12 Building and Managing A Winning TeamDocument22 pagesCH - 12 Building and Managing A Winning TeamNorman Ocana JrNo ratings yet

- Guide To Building and Executing An MSP Business ModelDocument16 pagesGuide To Building and Executing An MSP Business ModelMohammad Mostakim- Al-RashidNo ratings yet

- VSM - 2 PDFDocument43 pagesVSM - 2 PDFNicolas Pesquer AvellanasNo ratings yet

- Kotler MM 14e 08 Ippt GEDocument25 pagesKotler MM 14e 08 Ippt GEKartina MuhamadNo ratings yet

- Nairobi Case StudyDocument67 pagesNairobi Case StudyAdil HayatNo ratings yet

- Ansi MSE - 2000 - GATECH PDFDocument16 pagesAnsi MSE - 2000 - GATECH PDFjosecarlos6246No ratings yet

- Waterway IndustriesDocument2 pagesWaterway IndustriesEinstein BunNo ratings yet

- Lecture 2 - TQM BlocksDocument23 pagesLecture 2 - TQM BlockshgfyyNo ratings yet

- SEGI Business & AccountingDocument54 pagesSEGI Business & Accountingchee pin wongNo ratings yet

- PharmAnal 4Document35 pagesPharmAnal 4Aaron Jhulian SimbitNo ratings yet

- Orange and White Modern Creative Marketing Plan PresentationDocument12 pagesOrange and White Modern Creative Marketing Plan Presentationfakisik582No ratings yet

- Leadership Style in Banking Sector (Original)Document16 pagesLeadership Style in Banking Sector (Original)Akshay PariharNo ratings yet