Professional Documents

Culture Documents

12-385 Item 01 - Monitor

Uploaded by

leokareyxoxoersOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12-385 Item 01 - Monitor

Uploaded by

leokareyxoxoersCopyright:

Available Formats

DATA SHEETS Monitors

Project No.: Customer ref.: Shipowner: Shipyard: Hull no.: Type of vessel: Vessel name: Vessel Class Fi-Fi Class 12-385 PO Nr.:50110688 TBA COTEMAR SA DE CV 504 MT 6012 MK-2, Multirole & ROV-Support Vessle TBA DNV 2

Date: Prep. By: Sheet no.:

12.12.2012 BSI 1

PROJECT ITEM NO. 01

CONTENTS

Item No: 01 Qty 4 Type FFS 1800LB Description 1800 m3/h / 11,0 bar Sheet No 2

DATA SHEETS Monitors

ITEM NO.

General information Quantity Monitor series Operation Manufacturer Design Criteria Fluid Flange standard Pressure class Technical data Dual Flow function Nozzle type Deflector Capacity Full Throw length -Capacity Full Reaction force -Capacity Full Capacity Reduced Throw length -Capacity Reduced Reaction force -Capacity Reduced Inlet pressure Power supply operation Weight Protection class Elevation max Azimuth max Material Body and branch pipe Nozzle Other parts Surface Treatment Base Coating Documentation Certificate Throw curve Electrical wiring diagram Dimensional drawing Assembly drawing w/partslist Instruction manual Data sheet

Date: Prep. By: Sheet no.:

12.12.2012 BSI 2

01

FFS 1800LB

4 FFS 1800LB Electrical operation FFS Sea Water DN200 DiN PN16 PN 16 Yes Pelton Yes 1800 m3/h >150 m 24750 N NA m3/h NA m NA N 11 bar 440VAC/ 60 Hz/ 3 phase 180 kg IP 56 - 20 / +80 deg +/- 180 deg Ni-Al-Bronze Ni-Al-Bronze AISI 316L /GRP / POM(plastic) Primer RAL 3002 Red DNV FFS 429 12-385_ C1/C2/C3 FFS1800LB 112A-22 / FFS-255 FFS 203 FFS406

12-385

FFS 1800LB SINGLE / DUAL FLOW MONITOR

FFS 406 JUN 2011

Description

The FFS single/dual flow monitors offer a unique combination of high performance in relation to weight and dimensions. The units are extremely robust and require minimal maintenance. The monitor flow channels are designed using the latest technology in fluid engineering. In this way low pressure loss is achieved, and the throw characteristics are well within FI-FI 1 requirements. The monitors are manufactured and performance tested in Scandinavia in accordance with the highest quality standards. Material for main castings is nickel-aluminium-bronze with superb strength and corrosion resistance. Stainless steel (AISI 316L) and composites are used for smaller components. Ball bearings for elevation and horizontal movements are made from high grade stainless steel and permanently grease filled. They are sealed from both internal water pressure and atmosphere by O-rings. The monitor is protected by a lightweight GRP cover, which can easily be removed. The dual flow mechanism is operated by water pressure. The components are well protected against external damage as integrated parts of the castings. The vertical and horizontal movements are operated by electrical motors via gearboxes. All gears are completely sealed from the surroundings, thus eliminating accidental contact. Robust hand wheels made from composites and stainless steel provide manual back-up operation for the monitor movements.

Product subjected to technical changes without prior notice

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

FFS 1800LB SINGLE / DUAL FLOW MONITOR

FFS 406 JUN 2011

Dimensions

FF S

Technical data

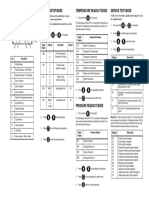

Weight Nominal capacity Reduced capacity Elevation sector Horizontal sector Horizontal/elevation operation Dual flow Spray deflector Limit switches Inlet pressure Static pressure testing Power supply Inlet flange Materials in internal wetted parts Monitor cover Seals Coating

1 bar = 0,1 Mpa = 14,5 psi 180 kg 1800 m/hour Yes -20 to +80 180 Electrical with manual override On/off or stepless electrical operation Remote electrical operation Easily adjustable Selected from performance curve Factory tested at 24 bar 380-440V/3 phase/50 or 60 Hz + 24V DC DN200/PN16 (DIN 2526 Form A) Stainless steel / bronze /composites Glass fibre reinforced polyester Moulded nitrile O-rings External red colour coating (RAL 3002)

Product subjected to technical changes without prior notice

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

FFS-429 Jan 2011

FI-FI MONITOR THROW CURVE

MODEL: SEA WATER FLOW: FFS1200 LB 1800 m3/h

MINIMUM HORIZONTAL RANGE AT WIND STILL CONDITIONS

170 160 150 140 130 Throw Length (m) 120 110 100 90 80 70 60 50 40 6 7 8 9 10 11 12 13 Pressure (bar)

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 08 / 06.07.2009 Page 1 of 14

Operation and Maintenance Instruction

FFS 3600 Monitors FFS 2400 and FFS 2400/600 Monitors FFS 1200 and FFS 1200/300 SB/LB/DB Monitors FFS 600 and FFS 600/150 Monitors FFS 300 Monitors

Version 08 07 06 05 04 03 02 01 00 Document no. : FFS -203 Description Additions to Installation procedure Reviced lifting instruction, ref. to datasheet Added FFS2400/3600 docking & lifting ins. Added FFS 300 Added FFS 1200DB, FFS 2400, FFS 3600 Additions to Installation procedure Added FFS 600 and FFS 600/150 Added section 8.3 Lifting Instruction First Release Document control Written Approved Date by RS OIB 2009-07-06 RS ES 2008-12-19 HMP RS 2008-11-04 HMP RS 2008-04-30 RS RS 2007-08-30 OIB RS 2007-02-20 RS OIB 2005-12-22 OIB TAa 2005-12-05 PHR TAa 2004-10-04

Contents

1 GENERAL DESCRIPTION 1.1 Safety precautions 1.2 Inspection 1.3 Installation 1.4 Adjustment of the operating sectors 1.4.1 Setting the elevation limit switches 1.4.2 Setting the rotation (horizontal) limit switches 1.5 Start up and Commissioning OPERATION 2.1 Electric remote control mode 2.1.1 System activation 2.1.2 System deactivation 2.2 Manual override mode 2.2.1 Activating manual override (with or without water supply to the monitor). 2.2.2 Deactivating manual override. 2.3 After use MAINTENANCE AND INSPECTION 3.1 Maintenance 3.2 Inspection TROUBLE SHOOTING AND FAULT FINDING SPARE PARTS NEEDED SERVICE TOOLS 6.1 LIFTING INSTRUCTION Sizes incl. FFS1200 series and smaller 6.2 LIFTING INSTRUCTION Sizes incl. FFS2400 series and larger FFS 2400 AND FFS 3600 SERIES BARREL DOCKING STATION 2 3 3 3 4 4 4 6 7 7 7 7 8 8 9 9 9 9 9 10 11 11 12 13 14

4 5 6

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 2 of 14

1 General description

This document is made to describe the operation and maintenance of the fire fighting monitors FFS 3600, FFS 2400, FFS 2400/600, FFS 1200, FFS1200/300 SB/LB/DB, FFS 600, FFS 600/150 and FFS 300, designed and manufactured by FFS AS. The FFS single/dual flow monitors offer a unique combination of high performance in relation to weight and dimensions. The units are robust and require minimal maintenance. Material for main castings is nickel-aluminium-bronze with superb strength and corrosion resistance. Stainless steel (AISI 316L) and composites are used for smaller components. Ball bearings for elevation and horizontal movements are made from high grade stainless steel and permanently grease filled. They are sealed from both internal water pressure and atmosphere by O-rings. The monitor is protected by a lightweight GRP cover, which can easily be removed. The dual flow mechanism is operated by water pressure. The components are well protected against external damage as integrated parts of the castings. The vertical and horizontal movements are operated by electrical motors via gearboxes. All gears are completely sealed from the surroundings, thus eliminating accidental contact. Robust hand wheels made from composites and stainless steel provide manual back-up operation for the monitor movements.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 3 of 14

Installation

1.1 Safety precautions The installation is uncomplicated, but must be performed by qualified personnel. The directives given in this manual must be followed closely. Make sure that all electric power is disconnected before any installation or maintenance work is started. Only use approved and certified lifting gear for performing lifting operation.

Warning! Do not direct the flow beam towards any persons Cut the power before repairs and maintenance Risk of squeezing when the monitor is moving

1.2 Inspection Inspect the monitor carefully for any signs of transport damage or other deviations which may have occurred during transport. Make sure that all equipment and parts are available. Check ID plate for correct part and serial no. 1.3 Installation The monitor is intended to be mounted on a vertical standpipe. Reducer shall be max. 1m from the monitor inlet pipe bend min. 1m from the monitor inlet. Check to see that the interface flange on the standpipe matches the inlet flange on monitor base. Place a standard gasket on the flange and make sure that the correct no. of bolts and nuts are available. Lift the monitor onto the standpipe by use of suitable lifting slings and a crane according to enclosed lifting instruction 8.5. Make sure that the gasket is in place between the two flanges before the bolts are inserted. If a shut-off valve is installed just before the monitor, the swing-out for the disc must not interfere with the monitor inlet flange. Valve is recommended installed min 0,5m before the monitor. Install the bracket for the electrical junction box as following: 1) Normally to be mounted on the opposite side of the general throw direction by use of two of the flange bolts. 2) The Junction box should also be positioned at the middle point of the horizontal operation sector, allowing the flexible cable to move freely in both directions. The flange bolts shall be tightened in cross-sequence up to the recommended torque according to bolt class. Minimum recommended bolt class 8.8.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 4 of 14

1.4 Adjustment of the operating sectors Caution! Read chapter 3 Operation before starting the monitor. Warning! Keep away from moving parts of the monitor to avoid injuries. 1.4.1 Setting the elevation limit switches Fig. 1, FFS 1200LB (limit switch setting), Remove the monitor protection cover. This is done by removing the four hand knobs Adjustable holding the cover. cam segments Two limit switches are located in the (2pcs). transparent circular box on the left side of the monitor. Remove the cover by turning it by hand counter clockwise. The top limit switches is restricting the movement upwards and the bottom one is Limit switches restricting the downward movement. (2pcs). Orient the outlet barrel of the monitor to the desired extreme lower position. Its recommended to use the manual override (see section 3.2) and avoiding operating the monitor beyond its mechanical limitations. Set the limit switch by lifting the bottom cam and turn it until the lower switch is activated and then release the cam. The spring will push the cam back on the splined shaft and lock it in correct position. Check afterwards with your hand that the cam is securely locked in position. When the outlet barrel located in its intended extreme position, control that the limits switch is operating normally by trying to activate the electrical motor beyond this point. If the setting is correct the monitor will only be possible to move from this extreme position towards the intended sector of operation. Set the limit switch in the upper extreme position operation by repeating the above described steps for the limit switch. The upper cam shall be pushed down and turned. Install the cover, and make sure that the sealing o-ring is in right position.

1.4.2 Setting the rotation (horizontal) limit switches Two limit switches are located in the transparent circular box/cover at the top of the monitor (see Fig. 2). Remove the top of the box by turning it counter clockwise. The top limit switches is restricting the movement towards left and the bottom one is restricting the movement towards right.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 5 of 14

Orient the outlet barrel of the monitor to the desired extreme left direction (clockwise or counter clockwise). Its recommended using the manual override (see section 3.2) and avoiding operating the monitor beyond its mechanical limitations. Set the limit switch by lifting the bottom cam and turn it until the lower switch is activated and then release the cam. The spring will push the cam back on the splined shaft and lock it in correct position. Check afterwards with your hand that the cam is securely locked in position. When the outlet barrel located in its intended extreme position, control that the limits switch is operating normally by trying to activate the electrical motor beyond this point. If the setting is correct the monitor will only be possible to move from this extreme position towards the intended sector of operation. Set the limit switch in the right extreme position operation by repeating the above described steps for the limit switch. The upper cam shall be pushed down and turned.

Fig. 2, FFS 1200SB (limit switch box location)

Horizontal limit switches under protective cover

Elevation limit switches under protective cover

Lock the cam segment in this position. When the outlet pipe is located in its intended extreme position, control that the limits switch is operating normally by trying to activate the electrical motor beyond this point. If the setting is correct the monitor will only be possible to move from this extreme position towards the intended sector of operation. Set the limit switch in the other extreme sector of operation by repeating the above described steps for the limit switch. Install the cover, and make sure that the sealing o-ring is in right position.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 6 of 14

1.5

Start up and Commissioning

Caution! Read chapter 3 Operation before starting the monitor. Warning! Keep away from moving parts of the monitor to avoid injuries. 1. Remove protection cover. This is done by removing the four hand knobs holding the cover. 2. Check that all bolts and screws that have been adjusted or relocated are firmly fixed. Follow the instructions given in this chapter. 3. Check the equipment against material specification and order confirmation to ensure that voltage rating etc. is corresponding to the available power connection. Check also the water capacity and pressure rating. 4. Check that the settings of operating sectors are corresponding to the safe areas of operation. Study instructions in chapter 2. 5. Run the system according to instructions given in chapter 3. 6. After adjustment, a new functional test without water is recommended, before monitor is tested with water. 7. If foam concentrate have been used, flush the monitor with water afterwards. 8. Be aware of any obstacles, as radars, antennas, mast funnel and lights which may get damaged if hit by the water beam.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 7 of 14

OPERATION

2.1 Electric remote control mode The electric remote control mode is the normal way to operate the monitor. This can be done from a local or remote control panel. For details see separate documentation for the controls system. Note ! Installation instructions and setting of operating sectors must be followed and completed prior to running the monitor in remote control mode. Warning Keep away from moving parts of the monitor to avoid injuries.

2.1.1 System activation 1. Activate the water supply to the monitor starting the pump. 2. Fill up the piping system up to the monitor slowly and carefully in order to prevent any water hammering in the system. 3. Activate the control system for the monitor if it is not already activated. 4. Orient the outlet barrel of the monitor in such a direction that the water jet can not cause injuries or damages. Be aware that the power of the jet is extremely dangerous. 5. Orientation of the jet can now easily and accurately be manoeuvred from the control panel. Usually by means of ajoystick. 6. The monitor is also equipped with a deflector allowing for a wider spray beam pattern, this is normally activated from the control panel. 7. (Option Dual Flow) The unit can also be delivered with a Dual Flow, allowing for a lower flow setting at typical foam fire fighting applications. This function will normally be activated from the control panel 8. (Option Dual Barrel) The unit can also be delivered with a Dual Barrel, allowing for a lower flow setting trough a separate barrel. This barrel has an aspirating function for foam fire fighting applications. This function will normally be activated from the control panel. 2.1.2 System deactivation 1. Shut the water supply off. 2. Orient the monitor in the desired park position 3. If risk for sub zero whether condition, the nozzle shall be directed downwards below horizontal level in order to drain the nozzle. 4. Deactivate the monitor control system 5. Report any observed deviations from normal operation or wear.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 8 of 14

2.2 Manual override mode The manual override mode is a good and safe way to operate the monitor during installation and adjustment of limit switches. Also during maintenance and service, the manual override is useful. The manual override mode serves a back up possibility of the monitor in case of a power supply failure of the control circuits. 2.2.1 Activating manual override (with or without water supply to the monitor). 1. Make sure that the power supply to the monitor control circuits are shut off. 2. Release the crank handles located inside the hand wheel; these are spring loaded and must be folded out. 1. The monitor is now ready to be operated manually. To alter the orientations of the monitor turn the hand wheel accordingly.

Fig. 3, FFS 1200LB (rear view),

Hand wheel for manual operation of monitor. movement.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 9 of 14

2.2.2 Deactivating manual override. 1. To again prepare the monitor for electric remote control the crank handles must be folded into the hand wheel in their standby fold in position. Note! Never operate the monitor remotely with the cranking handles pointing out on the monitor. 2. Connect the power supply to the control circuits of the monitor. 3. Orient the monitor into a desired parking position. 4. Activate the monitor control system if that is included in the local procedures. 2.3 After use Make sure the monitor is ready to be used on short notice, and that all functions are in good working order. Make sure that any observed deviations is reported and corrected.

3 MAINTENANCE AND INSPECTION

3.1 Maintenance The monitor does not require any regular maintenance. It is however recommended that the monitor should be operated electrically or manually on a regular basis. At least once a month is recommended, to see that the monitor is in good working order. This can be done with or without water supply. 3.2 Inspection Detail Inspection of the monitor is recommended to be carried out monthly. Visually inspect the monitor for any occurred damages, improper or unauthorised adjustments etc. Inspect for and repair any paint damage. The oil level of the gearboxes is not necessary to check since permanent lubrication is provided. The only check point necessary is to look for oil leakage, which is unusual. Electric motors and other moving parts are intended for marine application and will not require any special attention. Inspect and check that all bolts on the fire monitor are securely tightened.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 10 of 14

4 TROUBLE SHOOTING AND FAULT FINDING

This monitor is made to meet the highest requirements for reliability. If the operations and maintenance instructions are followed properly, malfunction or deviating performance shall not be expected. If any trouble is encountered, the guide can be of use. Observation Monitor does not move during remote control operation. 1. 2. 3. 4. 5. Check power supply to control circuits Check if motor protection is tripped. Make sure the monitor is not positioned in any extreme position (limit switches activated). Check functionality of electrical control system. Run the monitor in manual operation mode to exclude possibility of mechanical failure.

If none-of the above suggested investigations lead to any conclusion, contact FFS for advice.

Observation Monitor does operate, but outside the pre-set operation sector during remote control operation. Warning. Stop operating the monitor immediately since permanent mechanical damage may occur! 1. This problem may occur if service or repair has been performed and the phase on the terminals on the 3 phase electrical system has been changed. In this case, the directions of rotation for the electrical motor may have changed; up become down and/or left becomes right. 2. Check if the limit switches are correctly set or if they are damaged.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 11 of 14

5 SPARE PARTS

Spare parts and spare part lists are available from FFS upon request.

6 Needed Service Tools

Traditional spanners and Allen keys Loctite 577 Torque wrench and suitable Allen bits Different screwdrivers Lifting crane and suitable lifting slings Consult sectional drawing for correct use of assembly paste, thread locking agent and other important notes.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 12 of 14

6.1 LIFTING INSTRUCTION Sizes incl. FFS1200 series and smaller Only use approved and certified lifting gear for performing lifting operation. Available equipment: 2 soft slings + lifting device suitable for weights according to product datasheet. When lifting the monitor either from the crate or onto the monitor pedestal in the vessel, never attach a sling to the monitor barrel. This could cause damage to the unit. A lifting instruction is also permanently attached to the monitor barrel.

Use soft slings around the monitor body as shown below. This way of lifting is the same for both long barrel and short barrel monitors. If necessary, the hand wheel for barrel elevation can be rotated to adjust the monitor centre of gravity during lifting.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 13 of 14

6.2 LIFTING INSTRUCTION Sizes incl. FFS2400 series and larger Only use approved and certified lifting gear for performing lifting operation.When lifting the monitor either from the crate or onto the monitor pedestal in the vessel, never attach a sling to the monitor barrel. This could cause damage to the unit. Available equipment: 2 soft slings + lifting device suitable for weights according to product datasheet. If necessary, the hand wheel for barrel elevation can be rotated to adjust the monitor centre of gravity during lifting.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

Doc.no.: FFS-203 Written by: RS Rev. 07 / 19.12.2008 Page 14 of 14

7 FFS 2400 and FFS 3600 series Barrel Docking Station

The FFS water monitors of type FFS 2400 and FFS 3600 are supplied with a support bracket. The bracket is to be mounted as a Barrel Docking Station and will unload the gravity forces generated by the heavy monitor barrel. This bracket is to be mounted outside the monitor working area and the monitor must be manually operated into the Barrel Docking Station when it is not in operation. The Barrel Docking Station is not an absolute requirement, but it is recommended by FFS to dock the monitor when not in operation to ensure a long life time of the monitor. The limit switches are set relevant to the opportunities of each individual application. Therefore, the FFS prescribed procedure is to use the elevation and rotation(if needed) hand-crank to manually fit the barrel to the Docking Station.

The support bracket is delivered with 4 mounting holes. This is to be mounted to the vessel structure for example on a supported rod to the deck or in combination with the vessels railing.

Fire Fighting Systems AS Box 369 N-1502 MOSS NORWAY

Tel: +47 69 24 49 90 Fax: +47 69 24 49 95 e-mail: ffs@fifisystems.com www.fifisystems.com

You might also like

- Damen ASD Tug 2810 Hybrid (Product Sheet) BernardusDocument2 pagesDamen ASD Tug 2810 Hybrid (Product Sheet) Bernardusерпарапр шрглрплплNo ratings yet

- Manual 3553-54 PDFDocument116 pagesManual 3553-54 PDFLuiz Claudio Martins FreireNo ratings yet

- Building customer yard winch dataDocument38 pagesBuilding customer yard winch datazzz zzz100% (1)

- External Fire Fighting Pumps For Ships - Allied Centrifugal Pumps PDFDocument28 pagesExternal Fire Fighting Pumps For Ships - Allied Centrifugal Pumps PDFSheik Abdullah BakrudeenNo ratings yet

- Gunclean Toftejorg 270FT Mark I, IM-TE102766-3-En10Document57 pagesGunclean Toftejorg 270FT Mark I, IM-TE102766-3-En10petrakou aglaia100% (1)

- Cedervall CHON 265 ManualDocument23 pagesCedervall CHON 265 Manualaugustorezende25100% (1)

- Catalogue Card Catalogue Card Catalogue Card Catalogue Card: HydrosterDocument10 pagesCatalogue Card Catalogue Card Catalogue Card Catalogue Card: HydrosterTasmiaH.ShoilyNo ratings yet

- Install Rolls-Royce Thruster ManualDocument3 pagesInstall Rolls-Royce Thruster ManualMaricel Hincu0% (1)

- OMD 2005 RWO Manual en 5Document20 pagesOMD 2005 RWO Manual en 5Val ShaNo ratings yet

- ACO Marine Data Sheet Clarimar MF v3 2014 (00000002)Document2 pagesACO Marine Data Sheet Clarimar MF v3 2014 (00000002)HAYDEENo ratings yet

- PDS - GulfSea Hydraulic HVI Plus 68Document2 pagesPDS - GulfSea Hydraulic HVI Plus 68Obydur Rahman100% (1)

- Viking: Product ManualDocument26 pagesViking: Product ManualCristian RobiconNo ratings yet

- Data Steering GearDocument32 pagesData Steering GearBaris AkgülNo ratings yet

- KG2Document3 pagesKG2anon_697917996No ratings yet

- Lindenberg-Anlagen GMBH: Stromerzeugungs-Und Pumpenanlagen SchaltanlagenDocument10 pagesLindenberg-Anlagen GMBH: Stromerzeugungs-Und Pumpenanlagen SchaltanlagenБогдан Кендзер100% (1)

- KHI Marine Propulsion CatalogueDocument24 pagesKHI Marine Propulsion CataloguefabianoossolaNo ratings yet

- Product Sheet Damen ASD Tug 2813 StockDocument2 pagesProduct Sheet Damen ASD Tug 2813 StockSCT-TMNo ratings yet

- UL - General Fact Sheet - November 2005Document2 pagesUL - General Fact Sheet - November 2005RICROD71No ratings yet

- SC 360apr-Th-M 04 28-40Document13 pagesSC 360apr-Th-M 04 28-40Ivaylo IvanovNo ratings yet

- Ffianra: Existing ModificationDocument128 pagesFfianra: Existing ModificationGary ChanNo ratings yet

- 31 AHUsDocument46 pages31 AHUsZen LohNo ratings yet

- Luciano Federico L Brochure PDFDocument4 pagesLuciano Federico L Brochure PDFbft23No ratings yet

- 45m Ferry Equipment List Rev 1Document3 pages45m Ferry Equipment List Rev 1bdthanhvkct100% (1)

- SKL Main Bearing ProcedureDocument11 pagesSKL Main Bearing ProcedureVaibhav SinghalNo ratings yet

- Pilot CardJuayanh 2Document2 pagesPilot CardJuayanh 2sarora_usNo ratings yet

- Reintjes - Operating ManualDocument70 pagesReintjes - Operating Manualmoshe levingerNo ratings yet

- Cat Marine Engine ProgramDocument4 pagesCat Marine Engine ProgramRobert BeddingfieldNo ratings yet

- Pneumatic Valves - Viking Lite Series - Catalogue PDE2658TCUKDocument24 pagesPneumatic Valves - Viking Lite Series - Catalogue PDE2658TCUKDinda MaharaniNo ratings yet

- Ship Survey Status: Tirumala GasDocument27 pagesShip Survey Status: Tirumala GasHoa LuuNo ratings yet

- 01 - System Description - Twin Stern RollerDocument16 pages01 - System Description - Twin Stern Rollermiguel100% (1)

- MAN ProspektDocument35 pagesMAN ProspektОлег АгопянNo ratings yet

- Bow Thruster Installation InstructionsDocument9 pagesBow Thruster Installation InstructionsRovert AlonzoNo ratings yet

- Ut 733-3 G6 R0Document10 pagesUt 733-3 G6 R0sumbermisuriaNo ratings yet

- OSV Book 12-2012 PDFDocument113 pagesOSV Book 12-2012 PDFStanislav LitvinenkoNo ratings yet

- Technische Dokumentation Technical Documentation: Fallreepanlage Accommodation Ladder SystemDocument23 pagesTechnische Dokumentation Technical Documentation: Fallreepanlage Accommodation Ladder SystemGogaNo ratings yet

- BUKH DV36 Diesel Engine Workshop ManualDocument196 pagesBUKH DV36 Diesel Engine Workshop Manualasaturday85No ratings yet

- Bergen KVGB 12 Diesel Engine Spare PartsDocument12 pagesBergen KVGB 12 Diesel Engine Spare PartsMatheusNo ratings yet

- Favelle Favco Cranes: Operating, Maintenance and Parts ManualDocument5 pagesFavelle Favco Cranes: Operating, Maintenance and Parts ManualNimmakayala Manikanta100% (1)

- Icon DP Sys - User ManualDocument338 pagesIcon DP Sys - User ManualRicardo Torres ZamudioNo ratings yet

- Zanussi Hod TypeDocument126 pagesZanussi Hod Typesohorye santoshNo ratings yet

- M020 Code Book For Spare Parts, Diesel United - SULZER Diesel Engine RTA72Document227 pagesM020 Code Book For Spare Parts, Diesel United - SULZER Diesel Engine RTA72Matija Segarić100% (1)

- Quint DC Ups 24dc 20Document9 pagesQuint DC Ups 24dc 20danielliram993No ratings yet

- Engine Data: Dead Slow Astern Slow Astern Half Astern Full AsternDocument1 pageEngine Data: Dead Slow Astern Slow Astern Half Astern Full AsternAlex Belgrave100% (1)

- Alpha: Propeller Maintenance Concept Type VBSDocument6 pagesAlpha: Propeller Maintenance Concept Type VBSEdgar Real ViúlaNo ratings yet

- TomCat Owners ManualDocument78 pagesTomCat Owners Manualapi-3745677100% (1)

- E-09 Window WiperDocument17 pagesE-09 Window Wiperkaunghtet san1212No ratings yet

- 7H17-28 Clearances and Wear LimitsDocument3 pages7H17-28 Clearances and Wear LimitsDimitris KNo ratings yet

- Aqua Metro VZF 15 50 MeterDocument40 pagesAqua Metro VZF 15 50 MeterIrfan AshrafNo ratings yet

- Filharmony Shipmanagement, Inc QuotationDocument3 pagesFilharmony Shipmanagement, Inc QuotationJoel Albert FantoneNo ratings yet

- Compound Geaquello E950Document2 pagesCompound Geaquello E950antonNo ratings yet

- Preloading Plan FO GuayaquilDocument1 pagePreloading Plan FO GuayaquilGanesh AnandNo ratings yet

- DSS-2 Two-Channel Digital Speed Switch: Application NoteDocument12 pagesDSS-2 Two-Channel Digital Speed Switch: Application Noterodruren01100% (1)

- Emc 0200000001Document68 pagesEmc 0200000001Gurmi100No ratings yet

- I 11.VSN Vertical Centrifugal Pump CatalougeSILI PUMPDocument9 pagesI 11.VSN Vertical Centrifugal Pump CatalougeSILI PUMPfauzi bebe100% (1)

- Nacos Platinum ASPDocument21 pagesNacos Platinum ASPSpalatelu Iuliana100% (1)

- S90me-C9 2Document367 pagesS90me-C9 2Htet Myat SoeNo ratings yet

- Trafag Pressure Transmitters Catalogue 2015Document154 pagesTrafag Pressure Transmitters Catalogue 2015FazleMasoodNo ratings yet

- Ship Resistance Estimation and Engine SelectionDocument20 pagesShip Resistance Estimation and Engine SelectionSean GyarinoNo ratings yet

- Ras-10ukv-E SVM-020007Document79 pagesRas-10ukv-E SVM-020007Para Club MilazzoNo ratings yet

- Tug70 - DichatoDocument1 pageTug70 - DichatoleokareyxoxoersNo ratings yet

- Pontoon Deck Plans H2-2 - APPRDocument1 pagePontoon Deck Plans H2-2 - APPRleokareyxoxoersNo ratings yet

- Orion - General ArrangementDocument1 pageOrion - General ArrangementleokareyxoxoersNo ratings yet

- Coastal Voyager: Shoalbuster 3209Document2 pagesCoastal Voyager: Shoalbuster 3209leokareyxoxoersNo ratings yet

- Coastal Voyager: Shoalbuster 3209Document2 pagesCoastal Voyager: Shoalbuster 3209leokareyxoxoersNo ratings yet

- ABS Part3 Steel Vessel 2011Document225 pagesABS Part3 Steel Vessel 2011Mohd Firdaus AlmusannaNo ratings yet

- Design of A Mooring System For An Offshore Structure: A Case Study of 5000 Tonnes Offshore Work Barge (WB)Document11 pagesDesign of A Mooring System For An Offshore Structure: A Case Study of 5000 Tonnes Offshore Work Barge (WB)leokareyxoxoersNo ratings yet

- Coastal Voyager: Shoalbuster 3209Document2 pagesCoastal Voyager: Shoalbuster 3209leokareyxoxoersNo ratings yet

- Link ManualDocument26 pagesLink ManualleokareyxoxoersNo ratings yet

- Advanced Part 2012Document356 pagesAdvanced Part 2012leokareyxoxoers100% (2)

- Heli PuertoDocument2 pagesHeli PuertoleokareyxoxoersNo ratings yet

- Part 1 Chapter Ships General RegulationsDocument19 pagesPart 1 Chapter Ships General RegulationsleokareyxoxoersNo ratings yet

- Acero Hi TenDocument24 pagesAcero Hi TenleokareyxoxoersNo ratings yet

- Part 0 Chapter 1 Ships User Information Amendments and IndexesDocument60 pagesPart 0 Chapter 1 Ships User Information Amendments and IndexesleokareyxoxoersNo ratings yet

- Padaeye CalculationDocument3 pagesPadaeye CalculationleokareyxoxoersNo ratings yet

- Hitachi SCX 1200-2 PDFDocument0 pagesHitachi SCX 1200-2 PDFleokareyxoxoersNo ratings yet

- King Post Wall Design-1Document10 pagesKing Post Wall Design-1Ibrahim MeharoofNo ratings yet

- Q1 TLE Shielded Metal Arc Welding (SMAW) NC I Module 1Document64 pagesQ1 TLE Shielded Metal Arc Welding (SMAW) NC I Module 1Pladie Salomon100% (5)

- CH 22 - Electric Charges and ForcesDocument12 pagesCH 22 - Electric Charges and ForcesounsydNo ratings yet

- Electrolytic Capacitor ExplanationDocument2 pagesElectrolytic Capacitor Explanationempeeno1No ratings yet

- Chapters 1, 2 & 6Document95 pagesChapters 1, 2 & 6Mwizukanji NakambaNo ratings yet

- IntelligAIRE II Diagnostic Procedures Using Drivers Display ModuleDocument2 pagesIntelligAIRE II Diagnostic Procedures Using Drivers Display ModuleNino PamindoNo ratings yet

- Basic Ideas in ChemistryDocument16 pagesBasic Ideas in ChemistryLucianaAcostaNo ratings yet

- Im-7 Unit CoolerDocument108 pagesIm-7 Unit CoolerstefanNo ratings yet

- Lexus Is 250 2007Document1 pageLexus Is 250 2007Rosa SozaNo ratings yet

- Operating Manual 64913Document256 pagesOperating Manual 64913Rafa MuñozNo ratings yet

- Energetics and Kinetics of Protein FoldingDocument28 pagesEnergetics and Kinetics of Protein FoldingSasikala RajendranNo ratings yet

- 13e Chap 08Document144 pages13e Chap 08kaiNo ratings yet

- P-N JunctionDocument14 pagesP-N JunctionsahilNo ratings yet

- ASM720P: Programming Switches Mode Control Engine StartingDocument4 pagesASM720P: Programming Switches Mode Control Engine Startingdargom salamanNo ratings yet

- CFD Cuenot Book20016 PDFDocument113 pagesCFD Cuenot Book20016 PDFalexey mikhaylovNo ratings yet

- Matrix Structural Analysis and Dynamics Theory and Computation PAZDocument505 pagesMatrix Structural Analysis and Dynamics Theory and Computation PAZJorge VarelaNo ratings yet

- Rail-Steel Deformed and Plain Bars For Concrete ReinforcementDocument4 pagesRail-Steel Deformed and Plain Bars For Concrete ReinforcementmjgutierrezperaltaNo ratings yet

- Daily Check of DC Coil and AC YokeDocument2 pagesDaily Check of DC Coil and AC YokeJohn DolanNo ratings yet

- Directional Solenoid and Pneumatic ValvesDocument176 pagesDirectional Solenoid and Pneumatic ValvesKelvin Viza SoraideNo ratings yet

- Checklist For Installation of Pressurization UnitDocument1 pageChecklist For Installation of Pressurization Unitvictor100% (3)

- Octavia Manual Running Gear Part4Document136 pagesOctavia Manual Running Gear Part4Mihai IordacheNo ratings yet

- MODES OF OSCILLATIONDocument3 pagesMODES OF OSCILLATIONpaul catalinNo ratings yet

- 1 Which Intermolecular Force Is The Weakest?Document4 pages1 Which Intermolecular Force Is The Weakest?Loh Jun Xian100% (1)

- DT PaperDocument5 pagesDT PaperR Krishnakumar MA. ME.No ratings yet

- Ferrites and Accesories - E 25-13-7 (EF25) PDFDocument10 pagesFerrites and Accesories - E 25-13-7 (EF25) PDFcarlosD2884No ratings yet

- Cooling Load Temperature Difference Calculation MethodDocument3 pagesCooling Load Temperature Difference Calculation Methodvickers50% (2)

- Internship Report 28 PDF FreeDocument45 pagesInternship Report 28 PDF FreeMuhammad Talha ShahidNo ratings yet

- EE 4003 – PRE BOARD EXAM (MODEL PAPERDocument2 pagesEE 4003 – PRE BOARD EXAM (MODEL PAPERMulayam Singh ChoudharyNo ratings yet

- PDP-4270XD Pdp-427xa Pdp-4270xaDocument206 pagesPDP-4270XD Pdp-427xa Pdp-4270xaTech ReyNo ratings yet

- Goldscope SD 515Document4 pagesGoldscope SD 515finianurNo ratings yet