Professional Documents

Culture Documents

Structure

Uploaded by

cblerCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structure

Uploaded by

cblerCopyright:

Available Formats

STRUCTURE magazine

15

design issues for

structural engineers

STRUCTURAL

DESIGN

Sompandh Wanant, P.E.,

M. ASCE, is Building/

Structural Section supervisor

in the Division of Building

Plan Review, Department of

Permitting, Inspections and

Enforcement, Prince Georges

County, Maryland. He may be

reached at swanant@co.pg.md.us.

By Sompandh Wanant, P.E.,

M. ASCE

A Practical Design for Thin

Composite Steel-Concrete

Floor Systems

I

n recent years, it has become more desir-

able, and in many cases necessary, for

architects and engineers to design build-

ings and structural frames with beams and

girders of limited depth. Shallower structural

depth allows building foor-to-foor height to

be lowered and the amount of materials used

such as exterior cladding, interior walls, parti-

tions, and stairs to be reduced. In high-rise

building construction, it allows extra foors to

be added within the proposed building height.

On expansion projects, a shallower structural

depth helps facilitate the need to match the

existing foor elevations.

Practical Design

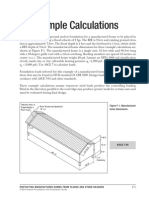

Tis system has been developed for use in build-

ing foor construction, specifcally for typical

rectangular or square column bay areas of around

1,000 square feet. One of the most economi-

cal and widely used foor framing systems is

the third-point loading of two in-fll beams on

girders which span between columns (Figure

1). Conventional composite steel-concrete foor

framing consists of rather deep steel beams and

girders which provide the most cost-efective

design in terms of tonnage of structural steel

used. In this article, American Institute of Steel

Construction (AISC)-standard structural steel

shapes will be used for both composite beams

and girders, and will be made as shallow as prac-

tically possible. It should be noted that moderate

column bay sizes are used in the design examples;

however, larger column bays in the range of 30

feet 45 feet can be designed economically.

Although this system is intended for building

foor construction, the concept may be applied

to any other composite beams/girders requiring

a shallower depth.

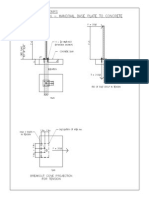

The Beam

Te conventional composite beam, consisting

of normal or light weight concrete, composite

steel deck and a steel beam, is made shallower

by replacing the steel beam section with a shal-

lower (heavier) one. Te concrete thickness over

the steel deck is between

2 inches to 4 inches,

and the standard 1, 2

or 3-inch deep steel deck

may be used as required.

Since the total depth of

the composite girder is

the depth of the system,

the total design depth of

the composite steel beam should be made as deep

as possible but not greater than the total depth of

the composite girder (Figure 2). It should be noted

that, if desired, square or rectangular steel tubes

(HSS sections) may be used in lieu of wide fange

shapes and a cover plate at the bottom of the steel

section may be added.

The Girder

Te composite steel-concrete section consists

of an inverted structural tee (WT), a steel

plate and a standard steel-concrete compos-

ite slab (Figure 3, page 16 ). For the system

to be practical, fexible and efcient, the

Figure 1: Framing plan.

Figure 2: Typical beam section.

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

rig

h

t

STRUCTURE magazine February 2014

16

standard structural tee (WT) and a thick

and narrow fange plate are selected. Te

thick and narrow fange plate provides not

only needed strength and minimizes creep

and long-term defection, but also leaves

adequate space required for feld attachment

of the steel deck to the steel girder built-up

section. Te steel girder built-up section

and the steel-concrete composite slab form a

very strong T-section fexural member. One

major advantage of this composite section

is that feld welding of the shear connectors

to the steel girder top fange is not required

since the top fange is embedded in the

concrete slab with the top of the fange at

or near the top of the concrete slab.

Te strength and stifness of the composite

girder can be calculated by transforming the

concrete portion into steel using Modular

Ratio, n = E

s

/E

c

; E

c

= w

c

3/2

(33) (f '

c

)

1/2

. Te

imaginary homogeneous transformed section

is analyzed for its physical properties by the

elastic methods of analysis.

As in any T-beam section, substantial

fexural horizontal shear exists at the inter-

section of the web and the fange. Tis

horizontal shear can be determined using

the familiar equation, v = VQ/I. For thin

concrete slabs above the top of the steel

deck, reinforcement is usually required to

increase the shear capacity. Shear-friction

provisions given in American Concrete

Institute (ACI) 318 Section 11.7 and its

commentary are referred to for the design of

concrete slab shear reinforcement. Figure 4

shows the concrete slab critical shear planes/

surfaces. Slippage at the interface of the

concrete and WT web can also occur; steel

stud shear connectors are used to prevent

slippage at the web. Te number of shear

studs required can be determined by cal-

culating the diference between the shear

capacity, found using ACI 318 Equation

(11-25): V

n

= A

vf

f

y

, and the total design

shear at the web. For other critical shear

planes ACI 318 (Commentary Section

R11.7.3) Equation: V

n

= 0.8 A

vf

f

y

+ A

c

K

1

is employed to obtain the amount of shear

reinforcement. Please refer to ACI 318 for

more design information.

With the existence of the steel deck, one

may want to consider its strength, along with

concrete, to help resist the horizontal shear.

Additional shear resistance of the steel deck

(limited to the attachment to the support

or the side lap capacity) is beyond the scope

of this article. In the design examples, the

concrete below the top of the steel deck, the

steel deck and the steel plate supporting the

deck are neglected from calculations; together

they constitute a few percentage points of the

total stifness.

Design Criteria for

the Steel-Only Asymmetric

Built-Up Section

To ensure proper and uniform design of the

composite girder section and to set the lower

strength limit of the steel-only built-up sec-

tion, the built-up section must have adequate

strength to support the total slab dead load

and its supporting steel frames.

Serviceability Requirements

AISC Specifcation for Structural Steel

Buildings (ANSI/AISC 360-05) section L5

requires that Te efect of vibration on the

comfort of the occupants and the function

of the structure shall be considered. As

in any foor system design, the vibration

characteristics of the foor system (i.e. the

natural frequencies, the amplitude/accelera-

tion due to the certain appropriate dynamic

loading) must be evaluated and satisfed.

Refer to AISC Steel Design Guide #11,

Floor Vibrations Due to Human Activity,

for design information and procedure.

Figure 4: Critical shear planes.

Figure 3: Typical girder section.

continued on page 18

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

rig

h

t

STRUCTURE magazine February 2014

18

STRUCTURE magazine

Connections and Choice of

Steel Girder Fabrications

Te system uses standard AISC beam-to-

girder and girder-to-column connections,

so the detailed connections are not shown.

In the examples, the author used the actual

girder span in the design calculations, i.e.

the column line dimension minus two times

the distance between the column center line

and the shear plate bolt holes. For a heavy

girder-to-column connection where the depth

of the girder web is limited, a beam seat may

be required at the bottom of the girder; i.e.

a standard AISC seated beam connection

may be used.

Since it is necessary to provide web open-

ings or drilled holes for the reinforcing bars,

and the WT section is cut from a large W

section, it may be easier and more cost

efective to fabricate the required WT, with

the notches for web openings, in a similar

manner to fabricating the castellated beam. If

this method is chosen, the actual total depth

of the WT should be used in the calcula-

tions. Alternately, one may prefer to simply

make the drilled holes. It should be noted

that if asymmetric shape rolled sections are

available domestically the fabrication cost

will be reduced.

Advantages over Other

Thin Floor Systems

At least a couple of thin/shallow foor systems,

such as the Girder-Slab and Slimfor systems,

are available for use in North America and

Europe. Both systems can be used in several

types of buildings, but are best suited for

certain applications. Te advantages of the

proposed thin foor system over these systems

are for general applications only:

Te proposed thin foor system is much

lighter than both the Girder-Slab and

the Slimfor systems.

Te composite beam of the proposed

thin foor system can span much longer

than 30 feet, whereas the Slimfor slab

has the span limit of less than 30 feet.

Due to lighter slab weight, both the

beam and the girder can span longer

distances resulting in larger open

foor spaces.

Te space between beams and girders

may be utilized as rectangular or square

recessed ceiling space, or as additional

utility space.

Te system is based on the conventional

composite foor system, therefore it

has all the benefts of composite foor

Design Examples

Example 1

Design a typical interior composite girder for an ofce foor space. Te depth of the girder

shall be as shallow as practically possible; provide shoring as required. W12 columns may

be used.

Given:

Floor framing as shown in Figure 1 with column line dimensions of 28 ft 28 ft

Beam span = 28 ft, Beam spacing = 28/3 = 9.33 ft

Girder span = 28.0 2(0.50 + 0.25) = 26.50 ft (Girder frames to W12 column fange)

Concrete: 3.25 in, 110 pcf light weight concrete, f '

c

= 4,000 psi

Composite steel deck: 19 gage, 1.50-inch deep; Structural steel: F

y

= 50 ksi

Live load = 50 psf; Partition load = 15 psf; Mechanical, electrical and misc. = 5 psf

Solution:

Dead load: Concrete and steel deck = 40 psf; Total dead load = (40 + 15 + 5) = 60 psf

Assumed beam weight = 40 plf

Live load: Live load reduction, L = L

0

(0.25 + 15 / (K

LL

A

T

)

1/2

) (IBC Section 1607.9.1)

Live load, L = 50 (0.25 + 15 / (2 9.333 28)

1/2

) = 50 (0.906) = 45.3 psf

Assumed girder weight = 75 plf

Loads on girder:

Dead load, P

DL

= (60 9.333 + 40) 28 = 16,800 lbs

Live Load, P

LL

= 45.3 9.333 28 = 11,838 lbs

Moment: M

DL

= 16.800 (8.58) + (0.075) (26.5)

2

/8 = 150.7 kip-ft

M

LL

= 11.838 (8.58) = 101.7 kip-ft

M

TL

= 150.7 + 101.7 = 252.4 kip-ft

Reaction: R

DL

= 16.80 + (0.075) (26.50 / 2) = 17.79 kips

R

LL

= 11.84 kips

R

TL

= 17.79 + 11.84 = 29.63 kips

Section modulus: F

b

= M/S, S

reqd

= 252.4 12/33.0 = 91.8 in

3

Moment of inertia and control of defection, (E = 29,000 ksi):

max

= Pa (3L

2

4a

2

)/24 EI (Two equal point loads)

max

= 5wL

4

/ 384EI (Uniform load)

DL

= 648.8 / I + 28.7 / I = 677.5 / I

LL

= 457.2 / I

TL

= 1134.7 / I

From the above design parameters, required girder section properties: S

reqd

= 91.8 in

3

, I

reqd

= 856.4 in

4

(Use defection limits,

LL

= L / 360 or

TL

= L / 240).

Design of composite girder:

Refer to Figure 4, use 1 inch of concrete cover over the fange plate, try WT 10.5 55.5

with 1 in 4 in fange plate, total girder depth = 12.755 in, efective fange width, b

ef

=

26.50 12 / 4 = 79.50 in; using the elastic methods of analysis for transformed section,

one can fnd: S

tr

= 125.2 in

3

and I

tr

= 960.8 in

4

(OK). Using Equation v = VQ / I, to fnd

shear stresses at critical locations (Figure 4), and ACI 318 Section 11.7 one can fnd: Slab

shear reinforcement: #4 @ 8 inches; and shear studs: in diameter @ 15 inch. See detailed

calculations below:

Horizontal shear at girder center line and center of the slab (fange)

v = VQ / I

Q = (21.53) (12.755 1.625 7.674) = 74.41 in

3

v = 29.63 74.41 / 960.8 = 2.295 kip/in

Shear stress varies linearly from maximum at girder center line to zero at the end of the

fange, from Figure 4, at distance 5 inches from center line girder where the slab thickness

is 3.25 inches, the shear stress

v

1

= (2.295 / 2) (1 / 3.25) (79.50 / 2 5.000) / (79.50 / 2) = 0.309 ksi

Using Load Factor, LF = (1.2 67 + 1.6 45.3) / (67 + 45.3) = 1.36

v

1u

= 1.36 309 = 420 psi

v

1n

= 420 / 0.75 = 560 psi (Reduction Factor, = 0.75)

V

1n

= 560 A

c

(A

c

is area of concrete section resisting the shear)

< 800 A

c

OK (ACI 318 11.7.5, Vn not greater than 0.2 f'

c

A

c

nor 800 A

c

)

continued on next page

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

rig

h

t

February 2014 STRUCTURE magazine February 2014

19

construction, including foundations,

seismic load resisting systems; other

benefts are foor framing fexibility and

lower overall costs.

Use of Computer Programs

and Laboratory Testing

As shown in the examples, the calculation

for strength and stifness is straightforward,

but for everyday design tasks, a computer

program will enhance and facilitate the

design process. Te structural design of the

composite girder presented herein should

be laboratory tested to confrm the theo-

retical and design analysis results and to

make further design developments should

one wish to do so.

Conclusions

Te above design examples show that a

practical thin foor system can be designed

and constructed. In both examples, approxi-

mately 7 to 9 inches in total girder depth

can be saved for most commonly used beam

and girder spans. Te system utilizes all

the elements of conventional composite

steel-concrete construction, i.e. normal or

light weight concrete, a composite steel

deck, welded shear studs, standard struc-

tural steel shapes and typical steel-to-steel

connections. Tough the system generally

requires shoring of the beams and girders

due to their shallow sections, a signifcant

amount of feld welding of shear studs to

the girder is not required. Unlike other thin

foor systems, this system maintains the

use of a thin composite steel-concrete deck

and standard structural steel shapes; there-

fore, the system will be as cost efective and

fexible for application as the conventional

composite foor construction.

From ACI Commentary Section R11.7.3

V

n

= 0.8 A

vf

f

y

+ A

c

K

1

560 (3.25 12) = 0.8 A

vf

(60,000) + (3.25 12) (200)

A

vf

= 0.29 in

2

By inspection, reinforcement at this location governs the design; use #4 @ 8", As = 0.30 in

2

.

Shear studs required to prevent slippage at WT web:

Design shear, v = 2.295 / 2 kip/in

Total V

n

= (2.295 / 2) (12) (1.36 / 0.75) = 24.97 kips

Capacity of shear-friction reinforcement, V

n

= A

vf

f

y

= 0.30 (60) (0.525) = 9.45 kips (ACI

318 11.7.4.3, = 0.70 0.75 = 0.525)

Shear capacity required by shear studs = 24.97 9.45 = 15.52 kips (Ultimate capacity)

Allowable shear capacity required = 15.52 0.75 / 1.36 = 8.56 kips

For -inch diameter shear stud, allowable shear = 13.30 0.83 = 11.04 kips, shear studs

spacing = 12 11.04 / 8.56 = 15.47 in. Use -inch diameter shear studs @ 15 inches.

Example 2

Design a typical interior composite girder for an ofce foor with the column bay spacing

of 30 ft 30 ft, and design live load of 80 psf throughout for the fexibility of future cor-

ridor arrangements.

Given:

Floor framing as shown in Figure 1 with column line dimensions of 30 ft 30 ft

Beam span = 30 ft, Beam spacing = 10 ft

Girder span = 30.0 2(0.50 + 0.25) = 28.50 ft (Girder frames to W12 column fange)

Concrete: 3.50 in, 145 pcf normal weight concrete, f '

c

= 4,000 psi

Composite steel deck: 20 gage, 2-inch deep; Structural steel: F

y

= 50 ksi

Live load = 80 psf; Partition load = 15 psf; Mechanical, electrical and misc. = 5 psf

Solution:

Select 1.50-inch concrete cover over the fange plate (for fre protection), try WT 12 73

with 1 in 4.50 in fange plate, total girder depth = 14.87 in. Following the same design

procedure as in Example 1, one can fnd: Composite Girder, I

tr

= 1849.6 in

4

(I

reqd

= 1555.0

in

4

), S

tr

= 193.6 in

3

(S

reqd

= 151.4 in

3

). Slab shear reinforcement: (2)#4 @ 12 inch (Spacing

~ 3 times slab thickness, OK). Shear studs: in diameter @ 14 inches.

Note on Total Building Cost

From Example 2, the steel girder weight is 88.3 plf (15.3 plf for fange plate plus 73 plf

for WT). As the estimated beam size is W 8 35 (not shown in the example), we calculate

the amount of steel to be 6.44 psf of the foor area. By determining the amount of steel

required for a conventional composite girder and beam design (W 18 60 for girder and

W 14 26 for beam), we get 4.60 psf. Since the size of the steel columns and lateral bracing

members varies greatly, from less than 1 psf to more than 1.5 psf, due to many parameters,

lets assume that the combined weight of columns and bracing members is approximately

1.25 psf. From the above information, we fgure the weight increase of the steel frames to

be (6.44 + 1.25) / (4.60 + 1.25) = 1.315, or a 31.5 % increase. According to many pub-

lications, including AISCs, the cost of raw material is only about one third of the total

cost of the structural steel frames, the rest being the cost of fabrication and erection; and,

the cost of the steel frames is about 10 % to 12 % of the total building cost. Terefore, we

can conclude that the increase in total building cost is approximately (31.5 / 3) 0.11 %

= 1.16 %. Since the increase in total building cost due to steel weight is very small, it is

believed that, in most cases, the saving in cost on the exterior wall (a major cost) and all

other interior constructions can adequately ofset the additional cost of steel.

Acknowledgments

Te author would like to thank Eric A.

Jackson, an engineer at the Department of

Environmental Resources, Prince Georges

County, Maryland for the CADD drawing

of the fgures.

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

rig

h

t

STRUCTURE magazine February 2014

20

References

1) ACI (2005), Building Code Requirements and Commentary for Reinforced Concrete (ACI

318-05), American Concrete Institute, Farmington Hill, MI.

2) AISC (1989), Manual of Steel Construction, Allowable Stress Design, 9

th

ed., American

Institute of Steel Construction, Chicago, IL.

3) AISC (2005), Specifcation for Structural Steel Buildings (ANSI/AISC 360-05),

American Institute of Steel Construction, Chicago, IL.

4) Bresler, B., Lin, T. Y. and Scalzi, J. B. (1968), Design of Steel Structures, 2

nd

ed., John

Wiley & Son, New York, NY.

5) Brockenbrough, R. L. and Johnston, B. G. (1974), USS Steel Design Manual, United

States Steel Corporation, Pittsburgh, PA.

6) Cost of Structural Steelwork (2013), Retrieved February 22, 2013, from

www.steelconstruction.info/Cost_of_structural_steelwork

7) Den Hartog, J. P. (1949), Strength of Materials, McGraw-Hill Book Company Inc.,

New York, NY.

8) Girder-Slab Design Guide v1.5 (2012), Retrieved February 23, 2013, from

www.girder-slab.com/system.asp

9) ICC (2006), International Building Code, International Code Council, Washington, D.C.

10) Murray, T.M., Allen, D.E., Ungar, E.E. (2003), Floor Vibrations Due to Human Activity,

Steel Design Guide # 11, American Institute of Steel Construction, Chicago, IL.

11) Shallow Floor Solutions in Steel (2010), Retrieved August 23, 2013, from

www.tatasteelconstruction.com/fle_source/StaticFiles/Construction/Library/Signs/

SN43_032010_shallow_foors.pdf

12) Understanding the Supply Chain (2013), Retrieved February 22, 2013, from

www.aisc.org/content.aspx?id=3812

S

T

R

U

C

T

U

R

E

m

a

g

a

z

i

n

e

C

o

p

y

rig

h

t

You might also like

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Timber ColumnDocument8 pagesTimber ColumnAlam Mohammad Parvez SaifiNo ratings yet

- Design of Steel BeamDocument19 pagesDesign of Steel BeamAnonymous tBhJoH5wgMNo ratings yet

- Masonry Design ExamplesDocument13 pagesMasonry Design ExamplesRoger FonsecaNo ratings yet

- Building Girt CalcDocument2 pagesBuilding Girt Calcwudongxiao3953No ratings yet

- Design Steel Column Base Plate AnchorsDocument30 pagesDesign Steel Column Base Plate AnchorsAdinda dwiNo ratings yet

- Unistrut CatalogDocument12 pagesUnistrut CatalogElia Nugraha AdiNo ratings yet

- Tutorial Ram ConectionDocument17 pagesTutorial Ram ConectionFOXMEXNo ratings yet

- Parametric Study of Double Layer Steel Dome With Reference To Span To Height RatioDocument9 pagesParametric Study of Double Layer Steel Dome With Reference To Span To Height RatioIjsrnet EditorialNo ratings yet

- Ram ConnectionDocument15 pagesRam ConnectiondpkNo ratings yet

- TIA 222G wind load parametersDocument29 pagesTIA 222G wind load parametersboypardede3552No ratings yet

- Wind Loading of Industrial, Mining and Petrochemical StructuresDocument16 pagesWind Loading of Industrial, Mining and Petrochemical StructuresapirakqNo ratings yet

- Composite Floor Deck Design PDFDocument4 pagesComposite Floor Deck Design PDFsaipodinNo ratings yet

- Connection DesignDocument33 pagesConnection Designjesus curielNo ratings yet

- Checklist For Concrete Shear Wall (ACI 318-14)Document5 pagesChecklist For Concrete Shear Wall (ACI 318-14)renzo1221No ratings yet

- Chapter 7 Snow LoadsDocument14 pagesChapter 7 Snow LoadsGhaedan HameedNo ratings yet

- Minimum Thickness of Solid Slab According To ACIDocument1 pageMinimum Thickness of Solid Slab According To ACImuhanned100% (1)

- Design of Column Base Plates and Steel Anchorage to ConcreteDocument31 pagesDesign of Column Base Plates and Steel Anchorage to Concretemonther_alsalkhadiNo ratings yet

- Weld Analysis For DummiesDocument6 pagesWeld Analysis For DummiesJosh SmithNo ratings yet

- Steel Connection Guide 211 EnuDocument64 pagesSteel Connection Guide 211 EnuAnonymous TRthlKkWWNo ratings yet

- 1002 Aisc d1w Shape Tension MemberDocument6 pages1002 Aisc d1w Shape Tension MemberFWICIPNo ratings yet

- تصميم الكمرات بطريقة ultimate PDFDocument42 pagesتصميم الكمرات بطريقة ultimate PDFqaisalkurdyNo ratings yet

- Effect of Backstay on RC BuildingDocument5 pagesEffect of Backstay on RC Buildingdharashah28No ratings yet

- Rectangular Spread Footing DesignDocument42 pagesRectangular Spread Footing DesignJedidiah MelakuNo ratings yet

- Ibc 2003 - Poles Footings DesignDocument4 pagesIbc 2003 - Poles Footings DesignAhmed ALiNo ratings yet

- Beam DesignDocument33 pagesBeam DesignstructuresNo ratings yet

- RAM Conncetion Standalone Manual PDFDocument34 pagesRAM Conncetion Standalone Manual PDFThanit ThanadirekNo ratings yet

- Staad Foundation - Heat ExchangerDocument13 pagesStaad Foundation - Heat ExchangerKritashna KjNo ratings yet

- Steel Plate Shear Wall DesignDocument5 pagesSteel Plate Shear Wall DesignbuddychichiNo ratings yet

- Anchor BoltDocument7 pagesAnchor BoltChris OngNo ratings yet

- The Behavior of Cold Formed Steel Structure Connections PDFDocument11 pagesThe Behavior of Cold Formed Steel Structure Connections PDFg1n2No ratings yet

- Drop Panel CalculationDocument2 pagesDrop Panel Calculationsandiok86No ratings yet

- Fabrication Tolerances for Cold-Formed and Built-Up Structural MembersDocument4 pagesFabrication Tolerances for Cold-Formed and Built-Up Structural MembersSyed Tauseef ShahNo ratings yet

- Wind Example Claculations FEMA ExcerptDocument20 pagesWind Example Claculations FEMA ExcerptEverson BoyDayz PetersNo ratings yet

- Broadway Hilti - Handrail BaseDocument4 pagesBroadway Hilti - Handrail Basexpertsteel100% (1)

- Design of an optimized baseplate connection according to EurocodesDocument6 pagesDesign of an optimized baseplate connection according to EurocodesAHSANNo ratings yet

- Anchorage To Concrete Per ACI 318-08 Appendix D and IBC 2006Document47 pagesAnchorage To Concrete Per ACI 318-08 Appendix D and IBC 2006Alexandru OlaruNo ratings yet

- Portal Frame Practice ProblemsDocument10 pagesPortal Frame Practice ProblemsBoyzz ChinNo ratings yet

- SAP2000 Introductory TutorialDocument62 pagesSAP2000 Introductory Tutorialanon_443224320100% (1)

- RAM Concrete Shear Wall Design Verification ExampleDocument21 pagesRAM Concrete Shear Wall Design Verification ExamplePushpakaran Pillai100% (1)

- A Design Guide For Bracing Cold-Formed Steel StructuresDocument10 pagesA Design Guide For Bracing Cold-Formed Steel StructuresSaravanan SilambanNo ratings yet

- Design of TrussDocument29 pagesDesign of Trussfrancis100% (1)

- Advanced Steel Composite BeamsDocument68 pagesAdvanced Steel Composite BeamsMert SarıNo ratings yet

- Designing anchor reinforcement for seismic shear loadsDocument38 pagesDesigning anchor reinforcement for seismic shear loadsSarah Perez100% (1)

- Software Verification: AISC-360-05 Example 001Document8 pagesSoftware Verification: AISC-360-05 Example 001Zakir KhanNo ratings yet

- Column SpliceDocument2 pagesColumn SpliceMdShahbazAhmedNo ratings yet

- Partial Fixity in Etabs - Waseem RanaDocument5 pagesPartial Fixity in Etabs - Waseem RanaAtiq R RafiNo ratings yet

- CSA A23.3-14 Reinforced Column DesignDocument4 pagesCSA A23.3-14 Reinforced Column Designyudhi putraNo ratings yet

- Portal Connection Details 181Document8 pagesPortal Connection Details 181Hoa Da100% (1)

- Wind Engineering 1983 3A: Proceedings of the Sixth international Conference on Wind Engineering, Gold Coast, Australia, March 21-25, And Auckland, New Zealand, April 6-7 1983; held under the auspices of the International Association for Wind EngineeringFrom EverandWind Engineering 1983 3A: Proceedings of the Sixth international Conference on Wind Engineering, Gold Coast, Australia, March 21-25, And Auckland, New Zealand, April 6-7 1983; held under the auspices of the International Association for Wind EngineeringJ.D. HolmesRating: 3 out of 5 stars3/5 (1)

- Wind Engineering 1983 3B: Proceedings of the Sixth international Conference on Wind Engineering, Gold Coast, Australia, March 21-25, And Auckland, New Zealand, April 6-7 1983; held under the auspices of the International Association for Wind EngineeringFrom EverandWind Engineering 1983 3B: Proceedings of the Sixth international Conference on Wind Engineering, Gold Coast, Australia, March 21-25, And Auckland, New Zealand, April 6-7 1983; held under the auspices of the International Association for Wind EngineeringJ.D. HolmesNo ratings yet

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNo ratings yet

- Foundation Design Using Common SenseDocument1 pageFoundation Design Using Common SenseZaheer AhmedNo ratings yet

- Proton Therapy VaultDocument1 pageProton Therapy VaultZaheer AhmedNo ratings yet

- QAof Structural Engineering Design Part-1Document2 pagesQAof Structural Engineering Design Part-1Zaheer AhmedNo ratings yet

- Calculation of Portal Frame DeflectionDocument3 pagesCalculation of Portal Frame DeflectionKonstantinos KalemisNo ratings yet

- C CS BuildingPeriods Jacobs June081 PDFDocument4 pagesC CS BuildingPeriods Jacobs June081 PDFsabareesan09No ratings yet

- D QualityAssurCorner Schwinger Nov09Document2 pagesD QualityAssurCorner Schwinger Nov09Jason VargasNo ratings yet

- Validating The Rsults of STR'L Engg SoftwareDocument2 pagesValidating The Rsults of STR'L Engg SoftwareZaheer AhmedNo ratings yet

- Performance Based Design With Application To Seismic HazardDocument3 pagesPerformance Based Design With Application To Seismic HazardZaheer AhmedNo ratings yet

- Viscous Dampers Come of AgeDocument4 pagesViscous Dampers Come of AgeZaheer Ahmed100% (1)

- SA - Are We Relying Too Much On ComputersDocument4 pagesSA - Are We Relying Too Much On ComputersZaheer AhmedNo ratings yet

- Tips For Designing Constructible Concrete Structures - Part1Document2 pagesTips For Designing Constructible Concrete Structures - Part1Zaheer AhmedNo ratings yet

- C CI Comp Action Grouting by GeraciDocument4 pagesC CI Comp Action Grouting by GeraciusfmanguNo ratings yet

- Avoiding STR'L Failures During Constn Part-2Document4 pagesAvoiding STR'L Failures During Constn Part-2Zaheer AhmedNo ratings yet

- 8 Spruce Street - Beekman TowerDocument1 page8 Spruce Street - Beekman TowerZaheer AhmedNo ratings yet

- Current Trends in Economical Reinforced Concrete Construction Part-1Document3 pagesCurrent Trends in Economical Reinforced Concrete Construction Part-1Zaheer AhmedNo ratings yet

- Antiquted STR'L Systems Series Part-3Document2 pagesAntiquted STR'L Systems Series Part-3Zaheer AhmedNo ratings yet

- Building Facade Inspection - Part1Document2 pagesBuilding Facade Inspection - Part1Zaheer AhmedNo ratings yet

- Becoming A Resullts-Oriented Structural Engineer - Part2Document3 pagesBecoming A Resullts-Oriented Structural Engineer - Part2Zaheer AhmedNo ratings yet

- Accommodation To Reinforced Concrete High-Rise Building Deformations & MovementsDocument3 pagesAccommodation To Reinforced Concrete High-Rise Building Deformations & MovementsZaheer AhmedNo ratings yet

- Becoming A Resullts-Oriented Structural Engineer - Part1Document2 pagesBecoming A Resullts-Oriented Structural Engineer - Part1Zaheer AhmedNo ratings yet

- Avoiding STR'L Failures During Constn Part-1Document4 pagesAvoiding STR'L Failures During Constn Part-1Zaheer AhmedNo ratings yet

- Becoming A Resullts-Oriented Structural Engineer - Part2Document3 pagesBecoming A Resullts-Oriented Structural Engineer - Part2Zaheer AhmedNo ratings yet

- Antiquted STR'L Systems Series Part-1Document2 pagesAntiquted STR'L Systems Series Part-1Zaheer AhmedNo ratings yet

- C GuestCol SeismicDesign SEAOC Sept08Document3 pagesC GuestCol SeismicDesign SEAOC Sept08trabajosicNo ratings yet

- Punching Shear SlabsDocument3 pagesPunching Shear Slabsshak543No ratings yet

- Antiquted STR'L Systems Series Part-1Document3 pagesAntiquted STR'L Systems Series Part-1Zaheer AhmedNo ratings yet

- Across-Wind Response of High-Rise BuildingsDocument3 pagesAcross-Wind Response of High-Rise BuildingsZaheer AhmedNo ratings yet

- Antiquted STR'L Systems Series Part-1Document3 pagesAntiquted STR'L Systems Series Part-1Zaheer AhmedNo ratings yet

- Antiquted STR'L Systems Series Part-1Document2 pagesAntiquted STR'L Systems Series Part-1Zaheer AhmedNo ratings yet

- Building Facade Inspection - Part1Document2 pagesBuilding Facade Inspection - Part1Zaheer AhmedNo ratings yet