Professional Documents

Culture Documents

VA Refrigeration Working Principle

Uploaded by

Ahmed SalmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VA Refrigeration Working Principle

Uploaded by

Ahmed SalmanCopyright:

Available Formats

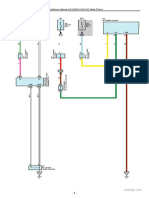

Working Principle of VA System

Working Principle of VA Refrigeration Absorption Refrigeration

Dr. M. Zahurul Haq

Professor Department of Mechanical Engineering Bangladesh University of Engineering & Technology (BUET) Dhaka-1000, Bangladesh zahurul@me.buet.ac.bd http://teacher.buet.ac.bd/zahurul/

ME 415: Refrigeration & Building Mechanical Systems

e518 c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration ME 415 (2011) 1 / 18 c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration ME 415 (2011) 2 / 18

Working Principle of VA System

Working Principle of VA System

e519

e520

c Dr. M. Zahurul Haq (BUET)

Absorption Refrigeration

ME 415 (2011)

3 / 18

c Dr. M. Zahurul Haq (BUET)

Absorption Refrigeration

ME 415 (2011)

4 / 18

Working Principle of VA System

Working Principle of VA System

e521

e522

c Dr. M. Zahurul Haq (BUET)

Absorption Refrigeration

ME 415 (2011)

5 / 18

c Dr. M. Zahurul Haq (BUET)

Absorption Refrigeration

ME 415 (2011)

6 / 18

Working Principle of VA System

Working Principle of VA System

VA & VC Comparison

Basic VA System

e523

e524 c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration ME 415 (2011) 7 / 18 c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration ME 415 (2011) 8 / 18

Analysis of VA System

Analysis of VA System

Example

Example

In an absorption system using LiBr, TG = 100o C, TE = 10o C, Ta = 30o C, Tc = 40o C. Estimate the values of COP for the following conditions:

1 2 3

ideal/Carnot cycle a real cycle if pump delivers 0.6 kg/s solution if a heat exchanger is inserted after the pump and water enters the generator at 52o C. if condensing temperature is reduced to 34o C, is there any chance of crystallization?

e525 4

COP |max =

TE TG

TG To To TE

TG COP , TE COP , To COP

c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration Analysis of VA System Example ME 415 (2011) 9 / 18 c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration Analysis of VA System Example ME 415 (2011) 10 / 18

1. Carnot cycle: Let, To = (Ta + Tc )/2 = 35o C TR TG To 10+273 10035 COP = T To TR = 100+273 3510 = 1.97 G Real Cycles using LiBr: Two pressures exist in the system:

1 2

High pressure (generator & condenser): TC = 40o C PH = 7.38 kPa Low pressure (absorber & evaporator): TE = 10o C PL = 1.23 kPa

e526

Without heat exchanger, (1) & (2) and (3) & (4) are the same.

c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration ME 415 (2011) 11 / 18

e527 c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration ME 415 (2011) 12 / 18

Analysis of VA System

Example

Analysis of VA System

Example

x1 = 0.50 & x3 = 0.667 2. Without heat exchanger: LiBr balance: m1 x1 = m3 x3 = m3 =

0.5 0.667 0.6

= 0.452 kg/s

m1 = m3 + m5 = m5 = 0.6 m3 = 0.148 kg/s qg = m3 h3 + m5 h5 m2 h2 = 473.3 kW qe = m7 h7 m6 h6 = 348.2 kW COP =

qe qg

= 348.2/476.6 = 0.735

3. 50% Solution leaves heat exchanger at 52o C h2 (x = 0.50 & 52o ) = 120 kJ/kg

e528

Using LiBr solution Chart: h1 = 168 kJ/kg & h3 = 52 kJ/kg Using Steam Table: h5 = 2676.0 kJ/kg, saturated vapour at 100o C h6 = 167.0 kJ/kg, saturated liquid at 40o C h7 = 2520.0 kJ/kg, saturated vapour at 10o C

c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration Analysis of VA System Example ME 415 (2011) 13 / 18

qg = m3 h3 + m5 h5 m2 h2 = 444.5 kW COP =

qe qg

= 348.2/444.5 = 0.783

Note that, maximum possible COP is only 1.97, with heat exchanger COP improves from 0.736 to 0.783.

c Dr. M. Zahurul Haq (BUET)

Absorption Refrigeration Analysis of VA System

ME 415 (2011)

14 / 18

4. Tcond is reduced to 34o C: if Tcond = 34o C PHP = Psat = 5.32 kPa. x3 = 0.69 m3 = 0.435 & m5 = 0.165 kg/s h1 = 168, h2 = 120 & h3 (x = 0.69 & 100o ) = 57 kJ/kg Energy balance in heat exchanger: m1 (h2 h1 ) = m3 (h3 h4 ) h4 = 120 kJ/kg From chart, x = 0.69 & h4 = 120) crystallized state. Crystallization is most likely to occur where the solution from the generator leaves the heat exchanger. An operating condition conducive to crystallization is low condensing pressure/temperature. Modern systems maintains higher condensing pressure even when low-temperature condensing water is available to avoid crystallization.

Aqua-ammonia Absorption System

e529

Rectier & analyser are used to minimize the presence of water vapour going to condenser and evaporator.

c Dr. M. Zahurul Haq (BUET) Absorption Refrigeration ME 415 (2011) 16 / 18

c Dr. M. Zahurul Haq (BUET)

Absorption Refrigeration

ME 415 (2011)

15 / 18

Analysis of VA System

Analysis of VA System

Aqua-ammonia vs. LiBr System

Problems with Vapour Absorption System

two systems have comparable COPs. aqua-ammonia system can provide temperatures below 0o C, but commercial LiBr systems are limited to temperatures higher than 3o C. auqa-ammonia system requires extra components such as rectier & analyser. aqua-ammonia system operates at pressures higher than atmospheric, LiBr systems operate at very low pressures. LiBr is very corrosive, hence require special inhibitors.

high initial cost shorter life (15 yrs for VA systems, 25 yrs for VC systems.) requires more space requires more condenser water ( 4.4 gpm/ton for VA systems, 3.0 gpm/ton for VC systems), high capacity cooling tower and water treatment plant. requires chimney. require proper maintenance and longer downtime for overhauling.

c Dr. M. Zahurul Haq (BUET)

Absorption Refrigeration

ME 415 (2011)

17 / 18

c Dr. M. Zahurul Haq (BUET)

Absorption Refrigeration

ME 415 (2011)

18 / 18

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Log ChillerDocument4 pagesLog ChillerJoe JordisonNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Trane Air Conditioning Clinic - Refrigeration System ComponentsDocument67 pagesA Trane Air Conditioning Clinic - Refrigeration System Componentscperez10000100% (4)

- REPORT - Water DesalinationDocument35 pagesREPORT - Water DesalinationAhmed SalmanNo ratings yet

- Rcomendacoes DissertacaoDocument28 pagesRcomendacoes DissertacaoNivaldo MonteiroNo ratings yet

- A Review of Absorption RefrigerationDocument30 pagesA Review of Absorption RefrigerationSoni Rodríguez Castellanos100% (1)

- Balancing of Reciprocating SystemsDocument20 pagesBalancing of Reciprocating SystemsAhmed SalmanNo ratings yet

- Report Refrigeration SystemsDocument22 pagesReport Refrigeration SystemsAhmed SalmanNo ratings yet

- Heat Exchanger LectureDocument22 pagesHeat Exchanger LectureAhmed SalmanNo ratings yet

- A745Document6 pagesA745smitashivaleNo ratings yet

- Life Management and Extension StudiesDocument6 pagesLife Management and Extension StudiesAhmed SalmanNo ratings yet

- Refrigeration: Vapor Compression Refrigeration SystemsDocument8 pagesRefrigeration: Vapor Compression Refrigeration SystemsRita FaridaNo ratings yet

- Preliminary: Samsung Electronics Co., LTDDocument57 pagesPreliminary: Samsung Electronics Co., LTDManuel Figueroa PradoNo ratings yet

- Valvulas DanfossDocument41 pagesValvulas DanfossJhoaoNo ratings yet

- Ferroli RGA EuroventDocument1 pageFerroli RGA EuroventKenan TaletovicNo ratings yet

- Datasheet ET7 16 F1 4040 TA RT W6Document3 pagesDatasheet ET7 16 F1 4040 TA RT W6Sermed IngenierosNo ratings yet

- Air Conditioner (Manual A/C) (M15A-FKS) (TMC Made 5 Door)Document12 pagesAir Conditioner (Manual A/C) (M15A-FKS) (TMC Made 5 Door)Shimmer CrossbonesNo ratings yet

- Carga Automatica VRV IVDocument3 pagesCarga Automatica VRV IVDiegoAlejandroNo ratings yet

- Copeland Discus CompressorsDocument1 pageCopeland Discus CompressorsElmer100% (1)

- ME183 Lectures 1LE Problem Solving Pages 21-30Document10 pagesME183 Lectures 1LE Problem Solving Pages 21-30Paul RodgersNo ratings yet

- Refrigerant Recovery Unit: Features & BenefitsDocument2 pagesRefrigerant Recovery Unit: Features & BenefitsSatrio Ongis NadeNo ratings yet

- Fan Coil Unit Daikin (FXDQ M) (07 24 MBH) CeilMountSlim SupAirFront RetAirBackDocument2 pagesFan Coil Unit Daikin (FXDQ M) (07 24 MBH) CeilMountSlim SupAirFront RetAirBackdheerajdorlikarNo ratings yet

- Meneses, Keziah F.: Cop T T T T T T Where: T T T Cop COP 1.4696 1.47Document19 pagesMeneses, Keziah F.: Cop T T T T T T Where: T T T Cop COP 1.4696 1.47Eriane GarciaNo ratings yet

- Log data water cooled chillerDocument1 pageLog data water cooled chillerMadan TiwariNo ratings yet

- Refrigerator and Air-Conditioner Condensers: Condenser CondenserDocument2 pagesRefrigerator and Air-Conditioner Condensers: Condenser CondenserKifayat UllahNo ratings yet

- Water Loop Heat Pump Technical Specifications and Product GuideDocument14 pagesWater Loop Heat Pump Technical Specifications and Product GuideOarga CalinNo ratings yet

- Vision Home - G+9-DSO-R-22 - Date-22-Mar-2015Document6 pagesVision Home - G+9-DSO-R-22 - Date-22-Mar-2015amir shahNo ratings yet

- Nawras CHILLER SUMMARY SHEETDocument2 pagesNawras CHILLER SUMMARY SHEETAhmed BahgatNo ratings yet

- DuPont™ Suva® 407A (R-407A)Document2 pagesDuPont™ Suva® 407A (R-407A)JorgeCantanteNo ratings yet

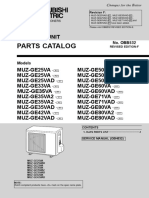

- Parts Catalog: Outdoor UnitDocument8 pagesParts Catalog: Outdoor UnitMirali HeydariNo ratings yet

- Air CondenserDocument40 pagesAir CondenserAlvaro DiazNo ratings yet

- Condensor AKMDocument14 pagesCondensor AKMSharmin SumiNo ratings yet

- Aircon LabDocument3 pagesAircon LabAbenliciousNo ratings yet

- Introduction To RefrigerationDocument79 pagesIntroduction To RefrigerationN S SenanayakeNo ratings yet

- Vertiv FWU ManualDocument40 pagesVertiv FWU Manualsantoshj423No ratings yet

- Reference Chart For Bullet "Restricto" Capillary Tubing For All Refrigerants in Low, Medium and High ApplicationsDocument2 pagesReference Chart For Bullet "Restricto" Capillary Tubing For All Refrigerants in Low, Medium and High ApplicationsGeorge UribeNo ratings yet

- Service: Compressors Suitable For Service and RepairDocument8 pagesService: Compressors Suitable For Service and RepairSasha RadosavljevicNo ratings yet

- Automotive Air Conditioning and Heating System PDFDocument19 pagesAutomotive Air Conditioning and Heating System PDFCarl AriffNo ratings yet

- Mitsubishi Electric Heat Pump Parts Outdoor MUZ-GE PDFDocument10 pagesMitsubishi Electric Heat Pump Parts Outdoor MUZ-GE PDFTony SavageNo ratings yet