Professional Documents

Culture Documents

Rigid Pavement Jointing Details For Intersections

Uploaded by

Suktara-Drubatara TaritOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rigid Pavement Jointing Details For Intersections

Uploaded by

Suktara-Drubatara TaritCopyright:

Available Formats

3.1.

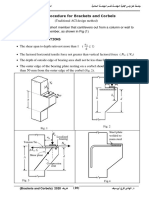

2 Rigid Pavement Jointing Details for Intersections The following basic principles must be observed in developing a correct jointing detail: 1. Never taper concrete down to less than 2 ft in width. 2. Depending upon the amount of transverse reinforcing steel, be careful of the number of lanes that are tied together. In JPCP, tying more than three 12-ft lanes toge ther may result in uncontrolled longitudinal cracking. 3. Always design the secondary (intersecting) route as independent in movement from the primary route. Thus, as the primary route expands and contracts, no unnecessary forces will be created in the secondary route. 4. Provide for expansion wherever payment is interrupted in its longitudinal dir ection. 5. Terminate joints at 90 to any intersecting joints, obstructions, or edges of p avement. 6. Where possible, lay out lane widths of the same dimension. This permits the c ontractor to pave all the lanes without changing the paving machine setup dimensio ns. 7. Unless unavoidable, all joints should be in a straight line. Curved joints ar e difficult to saw and generally require additional forming. 8. For plain (nonreinforced) concrete pavement, the slab length/slab width ratio should not exceed 2:1. Intersection details should always be included in construction plans. A proper jointing layout ensures that cracking occurs at locations where load transfer ex ists (contraction joints) and away from wheel paths (longitudinal joints). The jointi ng 3.1.3 Rigid Pavement Joint Sealing Joint sealing prohibits the infiltration of water into the pavement base and pre vents incompressibles from lodging within the joint cavity. The advantages of keeping water out from under a pavement are documented extensively in the AASHTO Pavement Design Guide and in various articles in this chapter. With an unsealed joint, co ntraction under cooler temperatures allows joint cavities to open up and become filled wit h sand, stone, and other incompressible material. When warmer temperatures try to expand the length of the pavement, the joints are unable to close, compressive s tresses develop, and spalling may result. The purpose of a sealant reservoir (Figs. 3.1, 3.2, and 3.6) is to prevent water and incompressibles from entering the joint cavity. The design criteria for the seal ant reservoir ensure that the sealant stays in place. The ability of the sealant to expand and contract with the movement of the joint is a function of the material properties of the sealant (defined by the manufacturer s specifications) and the expected movement o f the joint. Joint movement can be calculated using the following relationship: L CL(A T Z) (3.4)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Civil PSC Exam Preparation (Bangladesh)Document5 pagesCivil PSC Exam Preparation (Bangladesh)Suktara-Drubatara TaritNo ratings yet

- Computation of Seepage Pressure and Exit GradientDocument3 pagesComputation of Seepage Pressure and Exit GradientSuktara-Drubatara TaritNo ratings yet

- Transformer Circuit Analysis and Performance CalculationsDocument3 pagesTransformer Circuit Analysis and Performance CalculationsSuktara-Drubatara TaritNo ratings yet

- Title BlockDocument2 pagesTitle BlockSuktara-Drubatara TaritNo ratings yet

- Khoslas theory of flow netsDocument3 pagesKhoslas theory of flow netsSuktara-Drubatara Tarit0% (1)

- Hydrologic ElementDocument3 pagesHydrologic ElementSuktara-Drubatara TaritNo ratings yet

- Hydraulic Design for Sub-Surface Flow StabilityDocument3 pagesHydraulic Design for Sub-Surface Flow StabilitySuktara-Drubatara TaritNo ratings yet

- Chapter 1 Introduction To Machinery PrinciplesDocument3 pagesChapter 1 Introduction To Machinery PrinciplesSuktara-Drubatara TaritNo ratings yet

- Line WidthsDocument2 pagesLine WidthsSuktara-Drubatara TaritNo ratings yet

- Grain Size AnalysisDocument2 pagesGrain Size AnalysisSuktara-Drubatara TaritNo ratings yet

- Tacheometry: An Optical Method for Measuring DistanceDocument7 pagesTacheometry: An Optical Method for Measuring DistanceSuktara-Drubatara TaritNo ratings yet

- Excel PDFDocument9 pagesExcel PDFSuktara-Drubatara TaritNo ratings yet

- SW July2003 Benjamin FranklinDocument0 pagesSW July2003 Benjamin FranklinSuktara-Drubatara TaritNo ratings yet

- SM ArchimedesDocument0 pagesSM ArchimedesSuktara-Drubatara TaritNo ratings yet

- SM James Clerk MaxwellDocument0 pagesSM James Clerk MaxwellSuktara-Drubatara TaritNo ratings yet

- Galileo GalileiDocument0 pagesGalileo GalileiSuktara-Drubatara TaritNo ratings yet

- Isaac NewtonDocument0 pagesIsaac NewtonSuktara-Drubatara TaritNo ratings yet

- Balaram 26 28Document3 pagesBalaram 26 28Suktara-Drubatara TaritNo ratings yet

- Type of Thread PDFDocument13 pagesType of Thread PDFrefae0% (1)

- PLO4, CLO3, C4: Rubrics For AssessmentDocument2 pagesPLO4, CLO3, C4: Rubrics For Assessmentbook wormNo ratings yet

- Brackets and Corbels ACI 318 L # 1Document7 pagesBrackets and Corbels ACI 318 L # 1soran azizNo ratings yet

- Rodrigo GuardhouseDocument7 pagesRodrigo GuardhouseRodrigo MiñozaNo ratings yet

- GM 9984001Document3 pagesGM 9984001Felipe De la cruzNo ratings yet

- Product Features: Why Is Shrinkkomp Superior To Conventional Non-Shrinking Grout?Document3 pagesProduct Features: Why Is Shrinkkomp Superior To Conventional Non-Shrinking Grout?saiemNo ratings yet

- Weight and dimensions of water-filled steel and PVC pipesDocument11 pagesWeight and dimensions of water-filled steel and PVC pipesmoh. rusli bahtiarNo ratings yet

- GR GRF Cob AppletonDocument5 pagesGR GRF Cob AppletonwillyysNo ratings yet

- Corrosion Resistance of MiTek Metal ConnectorsDocument4 pagesCorrosion Resistance of MiTek Metal ConnectorsEduardo Depiné TarnowskiNo ratings yet

- Cseb-Compressed Stabilized Earth Blocks: Building The Future With Earth Using A "Greener Material"Document7 pagesCseb-Compressed Stabilized Earth Blocks: Building The Future With Earth Using A "Greener Material"Pradnya NaikNo ratings yet

- 33 05 23.16 Pipe JackingDocument3 pages33 05 23.16 Pipe JackingisaacalvareztejanoNo ratings yet

- Architectural Fasteners & Fittings - Stainless Steel - AnzorDocument18 pagesArchitectural Fasteners & Fittings - Stainless Steel - AnzorBhaiJan59No ratings yet

- Toplotna IzolacijaDocument12 pagesToplotna IzolacijaZdravko GrbićNo ratings yet

- Cube TestDocument7 pagesCube TestMani PathakNo ratings yet

- S235, S275, S355 Structural Steel Grades GuideDocument5 pagesS235, S275, S355 Structural Steel Grades GuideGopi KrishnanNo ratings yet

- 092116Document7 pages092116kupaloidNo ratings yet

- Bi-Component FibersDocument5 pagesBi-Component FibersMilon MirdhaNo ratings yet

- Building Technology (ALE Review 5)Document1 pageBuilding Technology (ALE Review 5)Jehan MohamadNo ratings yet

- Chapter 4Document6 pagesChapter 4Dika WijayaNo ratings yet

- Flexible SUS304 - SF6700Document1 pageFlexible SUS304 - SF6700hungNo ratings yet

- HS PDFDocument11 pagesHS PDFSawa Zayia MichaelNo ratings yet

- JZ LSR Catalog AllDocument27 pagesJZ LSR Catalog AllJZ HuangNo ratings yet

- Use of Plastic Waste in Road Construction: Shweta N. Rokdey P. L. Naktode M. R. NikharDocument3 pagesUse of Plastic Waste in Road Construction: Shweta N. Rokdey P. L. Naktode M. R. NikharIndra AgraNo ratings yet

- Astm A747 Standard Specification For Steel Castings, Stainless, Precipitation HardeningDocument4 pagesAstm A747 Standard Specification For Steel Castings, Stainless, Precipitation HardeningLuiz Henrique V Souza50% (2)

- OMV Pipe ClassDocument160 pagesOMV Pipe Classliviu_dovaNo ratings yet

- Hebel MC v09.11Document12 pagesHebel MC v09.11Majed NabeelNo ratings yet

- Astm B150-2003 PDFDocument6 pagesAstm B150-2003 PDFRashedul HasanNo ratings yet

- PRESENTATION - Belzona Cold BondingDocument37 pagesPRESENTATION - Belzona Cold BondingNathachai LeewathanakijNo ratings yet

- Pds - Floor Hardener NMDocument2 pagesPds - Floor Hardener NMkasivisanadhNo ratings yet

- W623Document2 pagesW623Jebi Se0% (1)