Professional Documents

Culture Documents

How To Apply Suede-Tex - 3

Uploaded by

Zoran ŠušakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Apply Suede-Tex - 3

Uploaded by

Zoran ŠušakCopyright:

Available Formats

www.flockit.com DonJer Products Company 13142 Murphy oad !inne"a#o$ %& '1()) *)((+ 33','-3. *)1-+ 24.,)..

How To Apply Suede-Tex Instruction Sheet

Applying Flock It! Suede-Tex

The application of Suede-Tex is a simple process used in junior high school woodshops. Its simplicity is one of the beauties of the finish. Floc It! Suede-Tex finish allows you to create a professional looking suede-li e texture with no pre"ious experience. Important points to remember: # $o not s imp on the adhesi"e. # $o not s imp on the fibers. # %esist the temptation to touch the surface before the finish has dried. If you are concernedfind a junior high school student to help you!

Step 1 - PREPARE THE SURFACE

&lean the surface remo"ing excess dirt and grime. Seal crac s' sand rough surfaces so that they are relati"ely smooth. The surface does not ha"e to be perfectly smooth' but the finish will show bumps and crac s. If applying to plastic use a (paint primer( to assure the finish will adhere permanently. If the surface is porous, it is essential that it be sealed. The purpose of sealing is to pre"ent the absorption of the undercoat adhesi"e. If the adhesi"e is absorbed' the fibers will ha"e nothing to adhere to and the finish will ha"e thin spots. )"en surfaces that appear solid can be porous *e.g. +asonite, and will absorb the adhesi"e. Sealing may be done with lac-uer' shellac' sanding sealer' polyurethane' etc..anything that will pre"ent the surface from soa ing up the adhesi"e. If the surface is very porous *i.e.' soft woods' open grains' foams etc, be sure you ha"e sealed it sufficiently / it may re-uire more than one coating of sealant. If the sealer lea"es a "ery slic finish' rough it up slightly with sandpaper. +etal' glass' and plastics do not re-uire sealing' but may need a sanding to roughen up the surface. The sol"ents in the adhesi"e may affect certain plastics and foam. It may be necessary to put a protecti"e coat of a rubberbased primer *e.g.' latex paint, on these surfaces' and then it will be o ay to apply the Suede-Tex undercoat adhesi"e and continue with the coating process. 0ecause it is difficult to achie"e a permanent bond on plastics it is ad"isable to first use a paint primer on the surface. The Suede-Tex undercoat adhesi"e dries stiff' and therefore is not meant for flexible surfaces such as fabric' cushions' soft foam' etc.

Step 2 - APPLICATI ! PREPARATI !

If you want to get the most co"erage with the Suede-Tex fibers it will be necessary to set up a special spray area so that you can reclaim the excess fibers to reuse. To create a spraying area' line the inside of a cardboard box or a large trash can with a large plastic bag. Alternati"ely' using a large *refrigerator si1e, container create a booth that allows you to contain your fibers. If the object is too large for a booth line the floor with newspaper or plastic and ta e care not to contaminate the fibers.

C"e#ting # $p"#ying #"e# u$ing # c#"d%o#"d %ox #nd # l#"ge pl#$tic %#g&

1.

3.

# Fold o"er and tape open the flaps of a box. # &ut out the bottom corners a little

# 3ut a plastic bag in the box and tuc the mouth of the bag under the flaps. # 3o e the bottom of the bag through the corner holes in the box.

# 3ull the excess bag through the corners so it is tight within the box.

larger than needed to po e a finger through.

Fill the applicator of your choice *+ini Floc er' Air-Assisted Spray 4un' or &3 56 )lectrostatic Applicator, with Suede-Tex fiber and set aside. Filling T'e Applic#to"$ Mini Flocker

Slide the two cardboard tubes apart7 fill the unmar ed tube without the holes approx.289 full. This will allow space for the air to circulate the floc ing fibers within the +ini Floc er. 4ently slide the other tube *with the holes, o"er the one filled with floc fiber. Set aside for later use. Air-Assisted Spray Gun

%emo"e the cap from the canister. :sing a funnel with a large *2 ;(, spout' or a funnel made from a piece of waxed paper' pour the floc ing fibers into the canister. :se a pencil or stic to ensure the floc ing fibers continue to flow. Fill approximately ; full with Suede-Tex fibers. %eplace the spray gun handle7 ma e sure the top of the sprayer is in line with the large arrow on the label. It is helpful to ha"e a second' bac up canister already filled with floc fiber if your object is large.

C !" #lectrostatic Applicator

%emo"e the screened co"er and fill no more than < full with Suede-Tex floc ing fibers. &3 56 &hec that your transformer is plugged in and set at the correct "oltage. This will usually be at 56 =. 3ress the >on? button to ma e sure the floc ing fibers are flowing before beginning your coating job. 3reparation of the piece to be coated electrostatically is important. 0ecause a positi"e charge coming from the applicator is drawn to the object being coated it is necessary to create a ground at the object to maintain its negati"e field. If the piece is made from metal it is possible to ground directly to it. 0e careful to attach the ground lead in an area that will not be seen. If the object being coated is not conducti"e you can line the bac of it with aluminum foil and attach the ground lead to the foil. @arger objects *bigger than 2A( s-. in., re-uire either more than one ground lead or that the ground lead be mo"ed.

Step ( - APPL)I!* THE U!+ERC AT A+HESI,E

Floc It! Suede-Tex undercoat adhesi"e can be brushed, sprayed or rolled onto the area to be coated. If spraying' it may be necessary to thin the adhesi"e slightly with mineral spirits *no more than 2 tablespoon per pint, in order to spray it through your gun. The adhesi"e does tend to thic en when ept in a cool area under B6 degrees. If it appears too thic ' allow it to warm up before adding mineral spirits. Apply a generous coat of adhesi$e.that is' enough for the fibers to dig into when applied. This coat should appear li-uidy. The undercoat adhesi"e remains open to the fibers for 26 to 2C minutes.this is your %orking time. If you are wor ing on a larger object use a larger brush' apply the adhesi"e with a paint roller or spray it on. CAUTION: If you are wor ing on one continuous piece' &' (') %ork in sections as the lines between the sections will show. If you are wor ing on a project that has many small sections *compartments,' re-uiring a more detailed application' finish a few at a time. If you co"er the uncoated section*s, with a piece of cardboard and then mo"e the cardboard as needed you will not ha"e to wait for each compartment to dry before applying the fibers to the next area.

Step - - SPRA)

! THE SUE+E-TE. FI/ERS

To apply the fibers place the adhesi"e coated project in the lined cardboard box. :sing the applicator of your

choice' at a distance of E-26(' apply a $ery generous coating of floc fibers to the surface *holding the applicators as seen in the photos below,. Fnly so much will stic 7 the rest will fall off and can be reclaimed to be reused. Mini Flocker

Hold the outer tube *printed one, with one hand7 twist the inner tube *see photo abo"e, while pumping to spray the object you wish to coat. Geep the +ini Floc er E( to 26( from surface and as close to H6 degree to the object as possible. Iou may ha"e to prop up your object to create this angle as you will not be able to wor directly downward with the applicator. +a e sure there is a steady stream of floc fiber coming out of the applicator or you may be drying the adhesi"e. Air-Assisted Spray Gun

Set your compressor at 26 to 2C psi *it is o ay to go up to 96 psi' but the floc ing fibers will spray out of the canister more -uic ly re-uiring fre-uent refills,. Hold the gun on a slightly downward angle *see photo, and depress the trigger at the handle. Geep the AAS4 E( to 26( from surface and as close to H6 degrees to the object as possible. Iou may ha"e to prop up your object to create this angle as you will not be able to wor directly downward with the applicator. +a e sure there is a steady stream of floc fiber coming out of the applicator or you will be drying the adhesi"e. If the flocking fibers are not flowing check: 2. 9. D. A. the pressure to the gun the amount of floc fiber in the canister to ma e sure the handle is in line with the arrow on the canister if you are correctly holding the gun on a downward angle *see photo,

C.

if all fittings are tight.

C !" #lectrostatic Applicator

Hold the electrostatic applicator A( to C( from the surface being coated. Slide the switch forward and depress button until you see the red light go on. 4ently roc the applicator to assure the floc ing fibers continue to flow into the static field. Slowly mo"e the applicator around the piece. The floc ing fibers will be drawn at a H6 degree angle to the piece that is grounded creating a dense' e"en coating. Ta e care not to touch the applicator or the object being coated with your free hand or you can complete a current and recei"e a shoc . Hint: When coating boxes, after you have applied the adhesive, it is best to first spray the flocking fibers on the bottom and then spray the sides. If you tilt the box on its side you can aim at 9 degrees to the bottom first! then place the box flat and finish applying the flocking fibers to the sides. Hint: To ensure the floc ing fibers continue to hit the project on the same angle' hold the applicator at the same angle to the piece you are coating *as much as possible, and raise and lower the applicator. $o not tilt it when possible.

Step 0 - +R)I!*

Fnce you ha"e applied sufficient fibers set aside your project to dry for approximately *" to *+ hours before you remo"e excess fibers. If you need to reclaim some of the fibers before this drying process is completed you may turn the project upside down to allow the excess to fall off. &o not tap or shake the project at this time as this may dislodge fibers that are sitting in wet adhesi"e. It is possible to speed up the initial drying time with a heat lamp. It will now ta e approx. 5 hours depending on your en"ironment. )A,# CA-# )' ,## ).# .#A) /AM A) /#AS) *01 A2A3 F-'M ).# FI4#-S. &' (') 5S# A .#A) /AM 2I). A 4/'2#-. IM '-)A().Jhile the adhesi"e is dried at this point *26 to 2C hours, it will ta e 59 hours to 2 wee for it to cure completely. &are should be ta en in handling during this time.

Step 1 - CLEA! UP Cle#ning )ou" Applic#to"2

Mini Flocker

Separate tubes and empty the unused floc ing fibers into the original plastic bag. A gentle tap will remo"e any excess floc ing fibers. Air-Assisted Spray Gun :nscrew the canister and empty the unused floc ing fibers into the original plastic bag. A gentle tap will remo"e the rest of the floc ing fibers or you may blow them away with compressed air. C !" #lectrostatic Applicator %emo"e screen and empty the unused floc ing fibers into the original plastic bag. 0low excess floc ing fibers from plastic canister and screen. If there is a tiny amount of floc fiber left inside the applicator' it will blend into the next color used and not be noticed *with the exception of white,. Cle#ning )ou" P"o3ect2 To remo"e the excess floc ing fibers from your project after it has dried sha e the item o"er a lined cardboard box.remember these flocking fibers are still usable. Fr' using a dry' clean' soft brush' remo"e the excess floc ing fibers. &ompressed air may be used' but ta e care during the initial AE hours. =acuuming may be used after the project has cured completely.

You might also like

- Flock Dashboard 3Document4 pagesFlock Dashboard 3Zoran ŠušakNo ratings yet

- More Terrain For The Ogre KingdomsDocument13 pagesMore Terrain For The Ogre KingdomsAndy Kirkwood100% (2)

- Luggage Tag InstructionsDocument2 pagesLuggage Tag InstructionsBordados Industriales AndesNo ratings yet

- Good Stuff 6364 PDFDocument1 pageGood Stuff 6364 PDFbubbaclemNo ratings yet

- Epoxy InstructionsDocument1 pageEpoxy Instructionskarenth23No ratings yet

- 2-Part Plaster Mold-Making: Materials and EquipmentDocument4 pages2-Part Plaster Mold-Making: Materials and Equipmentweeble1000No ratings yet

- Marking TortoiseDocument3 pagesMarking TortoiseLuthfi YazidNo ratings yet

- Bo-Nash Fuse It Powder InstructionsDocument4 pagesBo-Nash Fuse It Powder InstructionsJSNo ratings yet

- FIXED PROSTHODONTICS IMPRESSION MATERIALSDocument34 pagesFIXED PROSTHODONTICS IMPRESSION MATERIALSAisha MutiaraNo ratings yet

- Canoe Plans Part 2Document20 pagesCanoe Plans Part 2cockybundooNo ratings yet

- Screen Printing Fabric LessonDocument2 pagesScreen Printing Fabric LessonarianamoonNo ratings yet

- Resin Infusion of A Carbon FibreDocument14 pagesResin Infusion of A Carbon FibreMAXIMODRAGON100% (1)

- Build a Dagorhir Sword in 40 StepsDocument9 pagesBuild a Dagorhir Sword in 40 StepsfriendjdfNo ratings yet

- Embroidery Garden Memo Pad CoverDocument3 pagesEmbroidery Garden Memo Pad CoverBordados Industriales AndesNo ratings yet

- Carbon Fibre Skinning Starter KitDocument8 pagesCarbon Fibre Skinning Starter KitcraigbonnymanNo ratings yet

- Hand LayupDocument1 pageHand Layupkumar4cimNo ratings yet

- Victoria Skimboards Repair GuideDocument4 pagesVictoria Skimboards Repair GuideOrfelino CatralinoNo ratings yet

- RodSmith Build-It! KitsDocument1 pageRodSmith Build-It! KitsCamil BwoyNo ratings yet

- Painted Silk Shapes Silk ShapesDocument2 pagesPainted Silk Shapes Silk Shapesapi-308354320No ratings yet

- Work Instruction For Spray CoatingDocument3 pagesWork Instruction For Spray CoatingKrunal Jani100% (3)

- F1D Construction: Last Revised 7/9/2015Document26 pagesF1D Construction: Last Revised 7/9/2015Josh TerrazasNo ratings yet

- Duct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsFrom EverandDuct Tape Engineer: The Book of Big, Bigger, and Epic Duct Tape ProjectsRating: 5 out of 5 stars5/5 (1)

- EPP Surface Preparation NetDocument5 pagesEPP Surface Preparation Netumunera2997No ratings yet

- Batik Art: The Ancient Wax Resist Dyeing TechniqueDocument28 pagesBatik Art: The Ancient Wax Resist Dyeing TechniqueAnkita SinhaNo ratings yet

- Fabrication of Model: General Rules For Pouring, Trimming and Handling CastsDocument47 pagesFabrication of Model: General Rules For Pouring, Trimming and Handling CastsRachel BenitezNo ratings yet

- 8-2C500 Woodworking Plans - Projects 1-200Document752 pages8-2C500 Woodworking Plans - Projects 1-200Angel ArchilaNo ratings yet

- Dirt Maker 14 ManualDocument16 pagesDirt Maker 14 Manualcompudog0% (1)

- 6000+ Woodworking Projects PagesDocument1,079 pages6000+ Woodworking Projects Pagesmnboks100% (6)

- FSEL Strain Gage For Concrete Rev 00Document7 pagesFSEL Strain Gage For Concrete Rev 00jbmune6683No ratings yet

- Group: Preparations of Microscope SlidesDocument16 pagesGroup: Preparations of Microscope SlidesNova Jane EdradNo ratings yet

- E L S K: Mergency Eak & Eal ItDocument12 pagesE L S K: Mergency Eak & Eal ItJason WallaceNo ratings yet

- Impression Techniques of FPDDocument20 pagesImpression Techniques of FPDBhavan Chand YemineniNo ratings yet

- T-Nuts in FoamDocument6 pagesT-Nuts in Foamscribd4uall100% (1)

- How To Build A Paracord FloggerDocument9 pagesHow To Build A Paracord FloggerReaperGod 245No ratings yet

- Making A Fiberglass Mold The PlugDocument3 pagesMaking A Fiberglass Mold The PlugrfffffNo ratings yet

- Fabric Facemask TutorialDocument14 pagesFabric Facemask TutorialDavid Ibanez91% (11)

- Application-0 1603076965Document9 pagesApplication-0 1603076965Ahmed AllamNo ratings yet

- Jewelry Box: Woodworks: Beginner Project 2009-2010Document7 pagesJewelry Box: Woodworks: Beginner Project 2009-2010Sal GNo ratings yet

- Strain Gauge InstallationDocument5 pagesStrain Gauge InstallationAnonymous UoHUagNo ratings yet

- Innovative AppliquéDocument7 pagesInnovative AppliquéAlina PopNo ratings yet

- Essential Clutch FinalDocument7 pagesEssential Clutch FinalLaura Nardi100% (1)

- Molding Your Own Carbon Fiber ComponentsDocument15 pagesMolding Your Own Carbon Fiber ComponentsandresboliviaNo ratings yet

- Kitplane Composite 4Document5 pagesKitplane Composite 4proxymo1No ratings yet

- Photoplate Lithography 2014Document4 pagesPhotoplate Lithography 2014Joana ParadinhaNo ratings yet

- Mould Making Kit (For Use With Carbon Fibre)Document7 pagesMould Making Kit (For Use With Carbon Fibre)eyewired2000100% (1)

- Langstroth Modification KitDocument8 pagesLangstroth Modification KitWolfgangNo ratings yet

- 8500 Woodworking ProjectsDocument752 pages8500 Woodworking Projectsclivehawnt100% (11)

- RH S Replica CapsDocument4 pagesRH S Replica CapsAdri Muhaimin AfifNo ratings yet

- The Ultimate Duct Tape Book: 25 Cool & Creative Projects to Get You on a Roll!From EverandThe Ultimate Duct Tape Book: 25 Cool & Creative Projects to Get You on a Roll!Rating: 3 out of 5 stars3/5 (2)

- Power: Hartge Engine Conversions For The E30 325iDocument1 pagePower: Hartge Engine Conversions For The E30 325iZoran ŠušakNo ratings yet

- Old School Maintenance Schedule v01.09Document17 pagesOld School Maintenance Schedule v01.09Cornea Vlad100% (1)

- Flyback Driver User Manual: General Description Main CharacteristicsDocument3 pagesFlyback Driver User Manual: General Description Main CharacteristicsZoran ŠušakNo ratings yet

- WD Caviar SE: Desktop Hard DrivesDocument2 pagesWD Caviar SE: Desktop Hard DrivesZoran ŠušakNo ratings yet

- LM78XX Series Voltage Regulators: FeaturesDocument11 pagesLM78XX Series Voltage Regulators: FeaturesHanZhangNo ratings yet

- Flyback Transformer EPC3014: Electronics IncDocument1 pageFlyback Transformer EPC3014: Electronics IncZoran ŠušakNo ratings yet

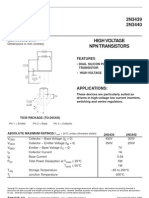

- 2N5655G, 2N5657G Plastic NPN Silicon High-Voltage Power TransistorsDocument5 pages2N5655G, 2N5657G Plastic NPN Silicon High-Voltage Power TransistorsZoran ŠušakNo ratings yet

- Applications:: FeaturesDocument2 pagesApplications:: FeaturescristiangodeanuNo ratings yet

- Chassis 449ZA: Nokia Display Products Oy P.O.Box 14 FIN - 24101 Salo, FinlandDocument66 pagesChassis 449ZA: Nokia Display Products Oy P.O.Box 14 FIN - 24101 Salo, FinlandZoran ŠušakNo ratings yet

- Nikša Lemo: Hrvatski Kinološki Savez // Croatian Kennel ClubDocument1 pageNikša Lemo: Hrvatski Kinološki Savez // Croatian Kennel ClubZoran ŠušakNo ratings yet

- ST 2310Document9 pagesST 2310Ariel MedinaNo ratings yet

- Assembly Manual: In-Circuit LOPT/FBT Tester K 7205Document6 pagesAssembly Manual: In-Circuit LOPT/FBT Tester K 7205majanaam100% (1)

- Slup 127Document20 pagesSlup 127bekonq12we3No ratings yet

- DCA Flock Colour Chart: 1.0mm - 3.3 Dtex Matt Polyamide NylonDocument1 pageDCA Flock Colour Chart: 1.0mm - 3.3 Dtex Matt Polyamide NylonZoran ŠušakNo ratings yet

- Powder CodesDocument1 pagePowder CodesZoran ŠušakNo ratings yet

- Service BC 2Document8 pagesService BC 2Zoran ŠušakNo ratings yet

- Expert Advice: Making The Connection With Your ClientsDocument16 pagesExpert Advice: Making The Connection With Your ClientsZoran ŠušakNo ratings yet

- Slentrol Treatment Plan: A Medically Appropriate Approach To Weight Management For Obese DogsDocument8 pagesSlentrol Treatment Plan: A Medically Appropriate Approach To Weight Management For Obese DogsZoran ŠušakNo ratings yet

- Sle Ntrol InfoDocument16 pagesSle Ntrol InfoZoran ŠušakNo ratings yet

- Expert Advice: Making The Connection With Your ClientsDocument16 pagesExpert Advice: Making The Connection With Your ClientsZoran ŠušakNo ratings yet

- Expert Advice: Making The Connection With Your ClientsDocument16 pagesExpert Advice: Making The Connection With Your ClientsZoran ŠušakNo ratings yet

- 6008a Summary Immo Systems Renault AllDocument20 pages6008a Summary Immo Systems Renault AllPedro Silveira Malheiro100% (4)

- Uzgoj PasaDocument185 pagesUzgoj PasaBojana Petkovic100% (3)

- GVC AclDocument6 pagesGVC AclZoran ŠušakNo ratings yet

- 7 Days To A Housetrained DogDocument104 pages7 Days To A Housetrained DogAlejandro LozanoNo ratings yet

- Use of Adhesive and Primers in Shoe ManufacturingDocument24 pagesUse of Adhesive and Primers in Shoe ManufacturingVijay ChandanNo ratings yet

- Architectural SpecificationsDocument10 pagesArchitectural SpecificationsJayteeNo ratings yet

- BoqDocument18 pagesBoqkunal humane0% (1)

- Internship Report Final (Amna Farooqui)Document68 pagesInternship Report Final (Amna Farooqui)Amna Farooqui100% (1)

- DS - Epilux - 4 - HB - Epoxy - Finish F-6BDocument2 pagesDS - Epilux - 4 - HB - Epoxy - Finish F-6Bparvez_ameenNo ratings yet

- 0810 Sigma Sprayplaster PDFDocument2 pages0810 Sigma Sprayplaster PDFEdwin HarrisNo ratings yet

- Type 1 BricksDocument20 pagesType 1 Bricksprachi410No ratings yet

- PTS Painting and Linings2019Document64 pagesPTS Painting and Linings2019MOHAMAD NIZAMUDIN100% (7)

- Corrosion Resistant Coatings for MetalsDocument24 pagesCorrosion Resistant Coatings for MetalsAlexander Franco CastrillonNo ratings yet

- Standard Primer Product Data PDFDocument2 pagesStandard Primer Product Data PDFgafarmerdan100% (1)

- R1BOQ - Structural - 13.03.2021Document24 pagesR1BOQ - Structural - 13.03.2021prasanth parthasarathyNo ratings yet

- V-1P0 SP802 r11 Application of Industrial Coating SystemDocument32 pagesV-1P0 SP802 r11 Application of Industrial Coating Systemanderson añezNo ratings yet

- Stonproof CT5 Product Data - en - USDocument2 pagesStonproof CT5 Product Data - en - USVentas ExpertisNo ratings yet

- BLD 205-Workshop Practice IIIDocument139 pagesBLD 205-Workshop Practice IIIVietHungCao83% (18)

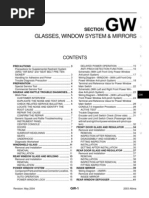

- 2003 Nissan Altima 2.5 Serivce Manual GWDocument62 pages2003 Nissan Altima 2.5 Serivce Manual GWAndy Dellinger100% (1)

- BOQ of Sylhet RCC 01.07.19 OldDocument98 pagesBOQ of Sylhet RCC 01.07.19 OldAtiq R Rafi100% (1)

- 7N180 Ant Cin BT enDocument4 pages7N180 Ant Cin BT enDercioNo ratings yet

- WaboCrete Membrane 1206Document4 pagesWaboCrete Membrane 1206MARCO ANTONIO AYALA MARTINEZNo ratings yet

- PDS - Sikaflex®-11 FC+Document4 pagesPDS - Sikaflex®-11 FC+Mahmoud MohamedNo ratings yet

- Thermaline 1248 PDSDocument3 pagesThermaline 1248 PDSGudang PagardewaNo ratings yet

- @airbus: Component Maintenance Manual With Illustrated Part ListDocument59 pages@airbus: Component Maintenance Manual With Illustrated Part ListAnh Tuan PhamNo ratings yet

- Solving Conformal Coating Problems in The Application ProcessDocument30 pagesSolving Conformal Coating Problems in The Application ProcessMael Azmi100% (1)

- Product Elastakote Oct18Document1 pageProduct Elastakote Oct18DWI RAHMASARI FATMAWATINo ratings yet

- PS6040 Painting Guide - October 2021 - ISSUUDocument32 pagesPS6040 Painting Guide - October 2021 - ISSUUDanny SantosoNo ratings yet

- Sikalastic®-590: Product Data SheetDocument5 pagesSikalastic®-590: Product Data SheetKhin Sandi KoNo ratings yet

- Interspec Paint SpecificationDocument17 pagesInterspec Paint Specificationcameo.exteriorlightsNo ratings yet

- PI2076 - Coatings - DAREX® PR 1154-18 Primer Lacquer - LA - TTavares - CLOSURE - 06.30.2017Document2 pagesPI2076 - Coatings - DAREX® PR 1154-18 Primer Lacquer - LA - TTavares - CLOSURE - 06.30.2017Anonymous SZfwy3HAFCNo ratings yet

- Mastertop Primer 9Document3 pagesMastertop Primer 9Doby YuniardiNo ratings yet

- Programme-Balance of ActivitiesDocument82 pagesProgramme-Balance of ActivitiesP Eng Suraj SinghNo ratings yet

- C - SPEC of Order 22.83 (EURU505293-505459) - 2022-11-15 PDFDocument7 pagesC - SPEC of Order 22.83 (EURU505293-505459) - 2022-11-15 PDFRod SantosNo ratings yet