Professional Documents

Culture Documents

Accuracy Inspection Equipment CNC

Uploaded by

jimmy_bikerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Accuracy Inspection Equipment CNC

Uploaded by

jimmy_bikerCopyright:

Available Formats

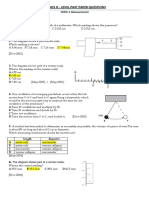

4-1

Lecture 4

Accuracy Inspection & Equipment

4-2

The Benefits of Accuracy Inspection

Increase machine accuracy and

repeatability.

Lower maintenance and production costs.

Reduce scrap, rework and parts inspection

costs.

Reduce catastrophic breakdowns and

increase equipment life.

Precision machining and greater

productivity means increased profits.

4-3

Machine Tool Performance

Machine tool performance is directly linked

to the parametric errors within a machine.

Parametric testing isolates and identifies

each of the error sources.

4-4

Basic Tests

Each linear motion in a machine contains 7

parametric errors:

1. Axial linear positioning

2. Axial straightness horizontal direction

3. Axial straightness vertical direction

4. Roll error

5. Pitch error

6. Yaw error

7. Axial squareness

4-5

Basic Tests

From axial linear positioning we obtain

repeatability, average and maximum

reversal error.

From axial straightness we obtain

translational lost motion.

From roll, pitch and yaw we obtain angular

lost motion.

4-6

Additional Tests

Performing additional tests helps to further isolate

and identify performance problems such as:

1. Periodic error testing of the positioning and feedback

device

2. Servo performance

3. Contouring performance using the Telescopic Ball Bar

4. Laser diagonal performance

5. Rotary positioning accuracy, periodic error, repeatability

and reversal errors

6. Off axis/Trunion positioning accuracy, periodic error,

repeatability and reversal errors

7. Tool change repeatability

8. Pallet change repeatability

4-7

Machine Tools Inspection

Equipment

Measurement Standards

Inspection Equipment

Laser Interferometer System

Double Ball Bar (DBB)

Grid Encoder ()

Comparator System

4-8

Measurement Standards

ANSI/ASME B5.54-92 (USA)

Methods for Performance Evaluation of Computer

Numerically Controlled Machining Centers

ISO 230-2:2006

Test code for machine tools - Part 2: Determination of

accuracy and repeatability of positioning of numerically

controlled axes

ISO 230-6:2002

Test code for machine tools - Part 6: Determination of

positioning accuracy on body and face diagonals

(Diagonal displacement tests)

4-9

ANSI/ASME B5.54

ANSI/ASME B5.54 defines common terms,

machine types, machining ranges (workzone),

position resolution, and operating modes. It also

addresses machine environmental requirements

and responses. This standard provides tests for

evaluating machine accuracy performance as a

machine tool, the machine as a measuring

machine with probes in the spindle, machine

cutting performance and, optionally, the

machining of test parts for the assessment of

point-to-point machining capability and

contouring capability.

4-10

ISO-230-2

The International Organization for Standardization (ISO)

clearly defines the requirements for fully documenting set-

up instructions for machine tool calibration in ISO-230-2.

These must include:

1. Location of all (non moving) machine tool axis positions

2. Location of the laser material temperature sensor

3. Location of the air temperature sensor.

4. The effective expansion coefficient used

5. Starting and ending temperatures of both the machine and its

surrounding environment

6. Location of the pitch line in the machine including:

Distance from the spindle face to the pitch line

Distance from the spindle centerline to the pitch line

Distance form the work holding surface to the pitch line.

4-11

ISO 230-6

This part of ISO 230 specifies diagonal

displacement tests which allow the

estimation of the volumetric performance of

a machine tool. Complete testing of the

volumetric performance of a machine tool is

a difficult and time-consuming process.

Diagonal displacement tests reduce the time

and cost associated with testing the

volumetric performance.

4-12

ISO 230-6

A diagonal displacement test is not in itself a

diagnostic test, although conclusions of a

diagnostic nature may sometimes be possible from

the results. In particular, when face diagonal tests

are included, a direct measurement of the axes

squareness is possible. Diagonal displacement tests

on body diagonals may be supplemented by tests

in the face diagonals, by tests parallel to the

machine axes in accordance with ISO 230-2, or by

the evaluation of the contouring performance in

the three coordinate planes as defined in ISO 230-

4.

4-13

Laser Interferometer System

Agilent Laser Calibration System

Renishaw Inspection Equipment

Optodyne MCV-500C Complete Machine

Calibration System

API 5/6D Laser Measurement System ()

4-14

Agilent Laser Calibration System

4-15

Renishaw Inspection Equipment

Laser Calibration System

4-16

Optodyne MCV-500C Complete

Machine Calibration System

http://www.optodyne-sh.com

4-17

API 5/6D Laser Measurement

System

http://www.apisensor.com/PR_XDLaser031805.html

4-18

API 5/6D Laser

4-19

X X X X X X X X X 6D

X X X X X X X X 5D

X X X X 3D

X X 1D

Roll Flatness Rotary Table Parallelism Pitch,Yaw Squareness Straightness Diagonal Linear XD Series

API 5/6D Laser

4-20

Laser Calibration

Machine Tool Laser Calibration (Pitch Error

Compensation) and Backlash Compensation is a

simple and straightforward process only a few

things need to be taken into consideration.

1. Machine Tool Geometry is within tolerance i.e.,

machine is level, gibs are tight, axes are square to each

other, etc.

2. Backlash of the axes is minimum.

3. Control has the compensation program option

installed.

4. Machine Control Parameters have been set up

correctly.

4-21

Linear Calibration

1D: Accuracy, Repeatability, Straighness,

Backlash, Flatness

2D: Squareness, Pitch, Roll, Yaw

Along Axis:

4-22

Angular Accuracy (Pitch & Yaw)

2D

4-23

Parallelism & Flatness

Roll is cross rail leveling. (Parallelism)

Pitch is top surface leveling. (Flatness)

These two must be adjusted correctly for

precision machining.

Yaw is positive edge straightness. In most

cases this is not adjustable.

4-24

Linear Calibration - 3D

Renishaw

3D: Laser Diagonal Test:

4-25

Linear Calibration - 3D

Diagonal Interpolation

4-26

Rotational Calibration

Spindle Dynamic Analyzer

Thermal Spindle Analyzer

http://www.apisensor.com/spindle.html

API Spindle Analysis System

4-27

Double Ball Bar (DBB)

History

Hardware

Heidenhain DDB

http://www.auto-

met.com/heidenhain/machine_tool/default.htm

Renishaw QC10 System

Polargauge DBB System (HP)

Optodyne LB-500 Laser/Ballbar

API Telescopic Ballbar System ()

DBB measurement steps

Plots Presentation

4-28

DBB - History

Double Ball Bar (DBB) method is one of so called rapid

tests for measure the motion error of a milling machine, a

machining center or another machine tools which are

driven by NC and have circular interpolation motion.

The measuring equipment records the points on a circular

curve, enlarges the extension or contraction of the bar and

then shows them in polar coordinates, it is called the

motion error trace.

Then the trace is analysed and the volumetric accuracy is

evaluated. Very valuable work concerning the phenomena

in DBB measurements was studied in the laboratory of

Kakino at late 80's. The most of later studies and work are

based on this research.

4-29

DBB - Hardware

External calibrator

Internal reference

mark

Calibration:

250 samples/s 100,000 samples/s Max. capture frequency:

RS232 IK121 ISA card Data capture:

1 micron 1 micron System accuracy:

1mm 5mm Measurement range:

100, 150, 300mm

250, 400, 450, 550,

600mm

150, 200, 250,

300mm

Ball bar lengths

(calibrated):

(non-calibrated lengths):

Renishaw Heidenhain

4-30

DBB 110

Heidenhains DDB

The DBB Double Ball Bar: a telescoping double ball bar

linear encoder for performing circular interpolation

tests with large radii to inspect primarily the machine

tool geometry.

4-31

Heidenhains DDB

4-32

Renishaw QC10 DBB System

Double Ball Bar (DBB)

Ball-bar photo courtesy Renishaw.

4-33

Renishaw Measurement Installation

4-34

Polargauge DBB System

http://www.cullam.com.tw/chinese/products/polargauge/index_c_polar.html

(CullamTechnologies Co., Ltd.)

4-35

Polargauge DBB

System

4-36

Optodyne LB-500 Laser/Ballbar

4-37

Optodyne LB-500 Laser/Ballbar

Optodyne's LB-500 Laser/Ballbar (Patent

Pending) is an add-on package to

Optodyne's MCV-500, Linear-Machine

Calibration System.

The combined system can be used to calibrate

CNC machine tools, CMM's (Coordinate

Measuring Machines), and other precision

measuring machines and stages and perform

circular test for servo-tuning and dynamic

testing.

4-38

Optodyne LB-500 Laser/Ballbar

4-39

Comparison of Laser/Ballbar and

Telescoping Ballbar

4-40

API Telescopic DBB System

4-41

DBB Measurement Steps

1. Start the measurement session with adjusting the DBB

device on the calibrator.

2. Calibrate the DBB device by clicking the calibrate button.

3. Run the machine tool to the zero position and center the

socket to it's place.

4. Run the machine tool to the measurement position.

5. Start the measurement by clicking the data capturing

button.

6. The machine tool starts the CW measurement circle.

7. Change the measurement direction.

8. The machine tool starts the CCW measurement circle.

9. Save the measurement.

10. Close the measurement window.

11. Analyse the measurement data.

4-42

Plots Presentation

4-43

4-44

Analysis Plots of Measurement Result

4-45

Analysis Plots of Measurement Result

4-46

Result

Report

4-47

Ballbar Analysis (Renishaw QC10)

4-48

Explanation of Result Plots for

Errors Using DBB System

4-49

Axis reversal spikes

When an axis is being

driven in one direction

and then has to reverse

and move in the opposite

direction, instead of

reversing smoothly it may

pause momentarily at the

turnaround point. This

appears as short spikes

that appear on either axis

reversal point. This could

mean servo response time

is poor and excessive

friction in axis.

http://www.machinetoolhelp.com/Preventativemaintenance/Ballbaranalysis.html

4-50

Scale Mismatch

Scale mismatch is shown as

an oval plot, extended

along one axis. One of the

machine axes is either over

traveling or under

traveling relative to the

other. One axis could be

feeding too far or the other

is not feeding far enough,

possibly due to overheating

or a faulty ballscrew. Servo

loop gains may need

adjustment.

4-51

Backlash

Backlash- If positive backlash

it could be ballscrew end float,

worn drive nut, or guide way

play. If negative backlash the

machine parameter might be

overcompensated. If unequal

backlash then there could be a

wind up in the ballscrew

where it becomes stiff on one

end of the travel. It also

typically occurs on a vertical

axis and can also be caused by

any counterbalance

mechanisms or weight.

4-52

Stick-slip

Stick-slip results when friction

causes one axis to stick when

it is fed at a very low rate. Left

unchecked, this error could

prevent the machine from

producing an acceptable

surface finish.

Guideways or bearings could

be bad or damaged. Improper

lubrication or power can be

supplied to overcome friction.

4-53

Squareness error

Squareness error is shown in

an oval ballbar plot It occurs

when normally orthogonal

axes are no longer moving at

90 relative to one another.

This may be due to a bent axis

or some other misalignment.

This squareness error oval tilts

at 45 with respect to the two

axes, and remains in the same

position regardless of the

direction of travel of the

ballbar (CW or CCW).

4-54

Servo Mismatch

Servo mismatch is shown as

an oval plot tilted by 45that

does not stay in place - It

shifts back and forth by

90depending on the

direction of travel.

This indicates mismatched

servo gains in the CNC,

causing the axis with the

higher gain to lead the other,

and makes a precise circular

interpolation impossible.

4-55

Cyclic Error, Master/slave change

over error & Lateral Play

Cyclic error is shown as a plot with waviness that varies in

amplitude and reaches a maximum amplitude at axis

reversal. This error is caused by a flaw in the axis

leadscrew or leadscrew mounting. If only in one half of

plot on a vertical axis it may have to do with a

counterbalance type problem.

Master/slave change over error often results on CNC s that

can only interpolate one axis at a time. Varying the speed

of the master axis while the slave axis follows generates

arcs This changeover error produces a plot with 45steps,

and may make precision machining of circular features

impossible.

4-56

Lateral Play

Lateral Play is caused by looseness in the gibs or

guide ways causing a fish tail effect. When

machining interpolated holes you will tend to get

an oval shaped hole.

4-57

Offset change/Plot discontinuity/Plot

rotation/Radius change/Tri-lobe/spiral

These plots all tend to be setup

errors with the ballbar

equipment. The tool cup is

either damaged, dirty, or

walking out of the cup while

running the test. It could be an

error in the ballbar program

you are running. It could also

be the joints in the ballbar rods,

cup or balls that are loose. It

could also be that the

computer is slow and not

capturing quick enough.

4-58

Straightness

Straightness or Scaling

error Lack of

straightness in machine

guideways. They may be

bent, misaligned, worn

or poor machine

foundation. Scaling error

may be caused by scales

encoder or drive.

4-59

Vibration

Vibration can be invoked

by the machine itself, drive

train, servo loop, damaged

guideways or surrounding

environment.

4-60

Rotary Calibrator

Heidenhain KGM Grid Encoder

http://www.auto-

met.com/heidenhain/machine_tool/default.htm

Renishaw RX10 Rotary Calibrator

API Rotary Table Calibrator

4-61

KGM 181

Heidenhain KGM Grid Encoder

The KGM Grid Encoder for performing circular

interpolation tests with small radii and curved path tests,

to inspect primarily the dynamic performance of a control

4-62

Renishaw RX10 Rotary Calibrator

4-63

API Rotary Table Calibrator

http://www.apisensor.com/rotary.html

4-64

Comparator

Early machine tool calibration techniques

used a comparator and mechanical artifacts,

such as a mechanical square, to measure

static accuracy. But even under optimum

conditions, the comparator has low

resolution.

And since any mechanical method is

dependent on the operator for accuracy,

human skill is still an issue.

This is why the use of mechanical squares

and comparators is limited today.

4-65

VM 182

Heidenhain VM 182 Comparator

System

The VM 182 Comparator System for measuring the

positioning accuracy, repeatability, and guideway error of

linear axes on manual and CNC-controlled machines

http://www.auto-met.com/heidenhain/machine_tool/vm.htm

4-66

Heidenhain VM 182 Comparator

System

The VM 182 Comparator System from HEIDENHAIN

serves for acceptance testing, inspection and calibration of

machine tools and measuring equipment with traverse

ranges up to 1520 mm in longitudinal direction and 1

mm in lateral direction.

Machine tool builders and distributors can determine the

linear and nonlinear error curves as well as the reversal

error of machine axes according to ISO 230-2. At the same

time, it also measures guideway error perpendicular to the

direction of axis traverse. The resulting error values can

then be used in the subsequent electronics (display unit or

control) for electronic error compensation. TNC

contouring controls from HEIDENHAIN can download

the error compensation values directly.

4-67

Specification VM 182 Comparator

1 m, 0.1 m, 0.01 m Recommended

measuring steps

ACCOMfor AT-compatible PCs Evaluation software

(option)

IK 220 counter card for PCs Evaluation electronics

(option)

1 m in longitudinal direction

1.5 m in transverse direction

Accuracy grade

At beginning of measuring length Reference mark

420 mm, 520 mm, 1020 mm, 1220 mm, 1520 mm 1 mm Measuring lengths ML

Measuring range in

transverse direction

a

therm

=10 ppm/K Coefficient of thermal

expansion

4 m in longitudinal and transverse directions Signal period

Two-coordinate DIADUR phase grating on steel Measuring standard

4-68

Six Steps to Improved Machine

Capability (1/4)

1. Determine the accuracy you need -

tolerance on the drawing / blueprint

determine the machine accuracy required.

2. Establish baseline: current performance -

run an automated ball bar check. In this

simple 10 minute procedure, your machine

moves in a programmed circular path. The

ball bar detects the machines deviations

from this path, representing errors in

contouring.

4-69

Six Steps to Improved Machine

Capability (2/4)

3. Identify and rank error sources - ball bar analysis

software is available that will isolate and rank 18

machine parameters in terms of their impact on

your machines ability to servo and position

accurately (error sources include squareness,

cyclic error, stick-slip, reversal spikes, scale

mismatch, machine vibration, servo mismatch and

backlash). You also get an indication of dynamic

positioning accuracy from overall "circularity" or

"circular deviation" values in accordance with

international standards. Use this information to

prioritize maintenance and to determine the best

corrective action: compensation or repair.

4-70

Six Steps to Improved Machine

Capability (3/4)

4. Eliminate or calibrate errors - use a laser

calibration system to eliminate systematic

positioning errors. For example, if the ball

bar identifies scale mismatch, just laser the

axis that needs to be linear error corrected.

Running a laser system on your machines

will make them repeatable and accurate.

4-71

Six Steps to Improved Machine

Capability (4/4)

5. Establish new baseline - once geometric error

sources have been eliminated or minimised, re-test

with the ball bar to set the new baseline for your

machine.

6. Regular health checks - run regular checks (at

least once a month) to detect any deviation from

the baseline. By plotting the critical machine

performance parameters on a control chart (see

example on right) you have a "medical" record for

your machine, and you can schedule maintenance

before deteriorating machine performance results

in scrapped parts. If a crash should occur, run the

ball bar to see if your machine is still fit to

continue production.

You might also like

- Kant Twist Clamp PlansDocument2 pagesKant Twist Clamp Plansjimmy_biker100% (5)

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Manual Guide +Document648 pagesManual Guide +Aloisio Gonzaga0% (1)

- Astm D2122-2004 3Document5 pagesAstm D2122-2004 3Tanvir HasanNo ratings yet

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- Fanuc Ot CNC Program Manual Gcodetraining 588Document104 pagesFanuc Ot CNC Program Manual Gcodetraining 588hiepkhachbk2010824350% (2)

- Form 4 Chapter 1 PhysicsDocument19 pagesForm 4 Chapter 1 PhysicsAngie Kong Su MeiNo ratings yet

- Activity 1. Basic MicrosDocument11 pagesActivity 1. Basic MicrosRoan Eam Tan100% (1)

- Part Programming Manual PDFDocument80 pagesPart Programming Manual PDFTejas KumarNo ratings yet

- General CatalogueDocument60 pagesGeneral CatalogueLuthfi100% (1)

- Accuracy of Machine ToolsDocument55 pagesAccuracy of Machine Toolsandrewscline100% (2)

- Mastercam 2017 Lathe CY Axis Toolpaths Tutorial SAMPLEDocument32 pagesMastercam 2017 Lathe CY Axis Toolpaths Tutorial SAMPLEsekhon8751150% (1)

- Programming MillDocument81 pagesProgramming MillEddy ZalieNo ratings yet

- English - Lathe NGC - Operator's Manual - 2018Document456 pagesEnglish - Lathe NGC - Operator's Manual - 2018Francisco Salas GalvánNo ratings yet

- Machine Tools: Nri Institute of TechnologyDocument57 pagesMachine Tools: Nri Institute of TechnologySavant100% (2)

- Haas Lathe Programming ManualDocument143 pagesHaas Lathe Programming Manualdoshi78No ratings yet

- Development of A Postprocessor For A Multi-Axis CNC Milling CenteDocument58 pagesDevelopment of A Postprocessor For A Multi-Axis CNC Milling CenteAnonymous PJP78mSxNo ratings yet

- Machine Tool DesignDocument2 pagesMachine Tool DesignBhavesh Pipaliya50% (2)

- Turm Mate ManualDocument292 pagesTurm Mate Manualanniyan009No ratings yet

- GSK980TD Turning Machine CNC System User Manual (English Version)Document408 pagesGSK980TD Turning Machine CNC System User Manual (English Version)Yadai CastilloNo ratings yet

- CNC Milling Instruction ManualDocument92 pagesCNC Milling Instruction ManualPraveen Raj100% (1)

- CNC Class Notes PDFDocument28 pagesCNC Class Notes PDFMaximiliano GarciaNo ratings yet

- Tool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesDocument7 pagesTool Path Optimization of Contouring Operation and Machining Strategies For Turbo Machinery BladesseventhsensegroupNo ratings yet

- Programacion en EnglishDocument174 pagesProgramacion en EnglishGustavo BecerrilNo ratings yet

- Tool Engineering Jig and Fixture BookDocument261 pagesTool Engineering Jig and Fixture Bookaashishyogesh95100% (3)

- Haas TM ManualDocument66 pagesHaas TM ManualSilvia_282008roNo ratings yet

- Work HoldingDocument337 pagesWork HoldingMuhammad FadhilNo ratings yet

- Unit-II-Capstan & Turret LatheDocument101 pagesUnit-II-Capstan & Turret LatheRavichandran GNo ratings yet

- My CNC TurningDocument7 pagesMy CNC Turningde_stanszaNo ratings yet

- Touch Probe Cycles: Product InformationDocument6 pagesTouch Probe Cycles: Product Informationsonnv_hcmuteNo ratings yet

- Metal CuttingDocument39 pagesMetal Cuttingavinashn12No ratings yet

- CNC Machine Tools and Control SystemsDocument39 pagesCNC Machine Tools and Control Systemsp_a_jeevaNo ratings yet

- Axes Design Basics-Apr2018Document76 pagesAxes Design Basics-Apr2018Srinivas MurthyNo ratings yet

- 1 ToleranceDocument8 pages1 ToleranceRaymond LO OtucopiNo ratings yet

- 26 Broaching - Principles, Systems and ApplicationsDocument16 pages26 Broaching - Principles, Systems and ApplicationsPRASAD326100% (2)

- 118 - Puma 240Document24 pages118 - Puma 240TombongNo ratings yet

- Chapter 6 High Speed MachiningDocument31 pagesChapter 6 High Speed Machiningmuhamadsaidi100% (5)

- What Is Milling MachineDocument6 pagesWhat Is Milling MachineGlenn VergaraNo ratings yet

- Cutting Speeds & RPM CalculationsDocument7 pagesCutting Speeds & RPM Calculationsyanuar_adhiNo ratings yet

- Prepared by Deepak A Vishwakarma .: Roll No L081040008 T Y B Tech ProductionDocument30 pagesPrepared by Deepak A Vishwakarma .: Roll No L081040008 T Y B Tech ProductionDIPAK VINAYAK SHIRBHATE100% (2)

- Mastercam Mill-Turn Tutorial: June 2017Document198 pagesMastercam Mill-Turn Tutorial: June 2017Joy G MosesNo ratings yet

- Deep Hole Drlling On Maching Centres BOTEKDocument2 pagesDeep Hole Drlling On Maching Centres BOTEKmapalptsNo ratings yet

- Quick Knurling CatalogueDocument28 pagesQuick Knurling CatalogueMilos Lazovic100% (1)

- CNC LecturaDocument157 pagesCNC LecturaPablo PillajoNo ratings yet

- M800 M80 E80 C80 Programming Manual Machining Center SystemDocument1,072 pagesM800 M80 E80 C80 Programming Manual Machining Center SystemJosimarNo ratings yet

- CNC TRGDocument248 pagesCNC TRGJuan100% (1)

- Vericut HelpDocument832 pagesVericut HelpdenissondermannNo ratings yet

- PBT mt11060 GDocument250 pagesPBT mt11060 Gandreeaoana45No ratings yet

- Feed Rate CalculationsDocument4 pagesFeed Rate CalculationsJesus Said Mercado VegaNo ratings yet

- Advances in Machine Tool Design and Research 1969: Proceedings of the 10th International M.T.D.R. Conference, University of Manchester Institute of Science and Technology, September 1969From EverandAdvances in Machine Tool Design and Research 1969: Proceedings of the 10th International M.T.D.R. Conference, University of Manchester Institute of Science and Technology, September 1969S. A. TobiasNo ratings yet

- Production Engineering - Jig And Tool DesignFrom EverandProduction Engineering - Jig And Tool DesignRating: 3.5 out of 5 stars3.5/5 (3)

- Manual Fag, Alineacion LaserDocument17 pagesManual Fag, Alineacion Laserjimmy_bikerNo ratings yet

- 2 BokDocument1 page2 Bokjimmy_bikerNo ratings yet

- M05 MicroKom Hi-FlexDocument16 pagesM05 MicroKom Hi-Flexjimmy_bikerNo ratings yet

- Linear Way Vertical Machining Center: MM SeriesDocument16 pagesLinear Way Vertical Machining Center: MM Seriesjimmy_biker100% (1)

- 2001 2Document21 pages2001 2jimmy_bikerNo ratings yet

- A Tool For Faster and Easier Maintenance Works: ELSA SupercombinataDocument4 pagesA Tool For Faster and Easier Maintenance Works: ELSA Supercombinatajimmy_biker100% (3)

- 2-3 Height GageDocument16 pages2-3 Height GageBalram JiNo ratings yet

- Standard Calibration For Steel Ruler and Flexible ScaleDocument5 pagesStandard Calibration For Steel Ruler and Flexible ScaleJohn Rafael Atienza100% (1)

- Calculation of Measurement Uncertainty For Tensile Strength and Flexural Strength of ThermoplasticDocument11 pagesCalculation of Measurement Uncertainty For Tensile Strength and Flexural Strength of ThermoplasticHassam BashirNo ratings yet

- Cedrick JoshuaDocument7 pagesCedrick JoshuaRommel TayactacNo ratings yet

- Metrology ReportDocument11 pagesMetrology ReportRahimin RashidNo ratings yet

- Precision MeasurementDocument39 pagesPrecision MeasurementNishanth Shannmugam100% (1)

- 1.4 Understanding Measurements Using Measuring Intruments 1.metre Rule 2.stopwatch 3.thermometer 4.measuring Cylinder 5.protractor 6.measuring TapeDocument26 pages1.4 Understanding Measurements Using Measuring Intruments 1.metre Rule 2.stopwatch 3.thermometer 4.measuring Cylinder 5.protractor 6.measuring TapeE-one Saw-dNo ratings yet

- 2016 Machine Shop Manual PDFDocument95 pages2016 Machine Shop Manual PDFShravan Shetty100% (1)

- RCBS 2013 Catalog and Parts ListDocument37 pagesRCBS 2013 Catalog and Parts ListRendabNo ratings yet

- Part - I (EVS) : Sample Test Paper STD 5 MovingDocument6 pagesPart - I (EVS) : Sample Test Paper STD 5 MovingChiragNo ratings yet

- Ratchet Thimble MicrometerDocument4 pagesRatchet Thimble MicrometerHamdan Rusli HabibiNo ratings yet

- Three-Point Internal Micrometer: Article GroupsDocument1 pageThree-Point Internal Micrometer: Article GroupsIqbalNo ratings yet

- Eng RomanusDocument9 pagesEng RomanusEmmanuelNo ratings yet

- Physics 1 PDFDocument103 pagesPhysics 1 PDFPhodo MontanaNo ratings yet

- P20658 - Proto Torque WrenchesDocument2 pagesP20658 - Proto Torque Wrenchesdionisio emilio reyes jimenezNo ratings yet

- TOOLSDocument23 pagesTOOLSDito Dtx100% (1)

- Lees DispenserDocument2 pagesLees Dispenserp317No ratings yet

- TCI Catalogo de CalibradoresDocument68 pagesTCI Catalogo de CalibradoresWVPNo ratings yet

- Physics Manual XIDocument23 pagesPhysics Manual XIAnonymous ExAwm00UPNo ratings yet

- 10 pt3 Soalan Bi PDFDocument28 pages10 pt3 Soalan Bi PDFMelor DihatiNo ratings yet

- Product Manual For Prestressed Concrete Pipes (Including Specials) According To Is 784: 2019Document10 pagesProduct Manual For Prestressed Concrete Pipes (Including Specials) According To Is 784: 2019Ranaware NandkishorNo ratings yet

- o Level Worksheets PHYSICS PDFDocument337 pageso Level Worksheets PHYSICS PDFMr. roxNo ratings yet

- The Micrometer: V. Ryan © 2004 - 2009Document6 pagesThe Micrometer: V. Ryan © 2004 - 2009shrishtiNo ratings yet

- Gauge BlockDocument32 pagesGauge Blocksava88100% (1)

- Vernier Calliper and Micrometer Screw GaugeDocument5 pagesVernier Calliper and Micrometer Screw GaugeHillaryNo ratings yet

- BS Iso 12817-2013Document28 pagesBS Iso 12817-2013Ігор БадюкевичNo ratings yet

- 13 MathForManufacturing v143 Dec2013 ICCBDocument130 pages13 MathForManufacturing v143 Dec2013 ICCBJosephi_abbasNo ratings yet