Professional Documents

Culture Documents

PDF BeltConveyorsCalculationsCEMA5 Eng

Uploaded by

Maikol Gonzalo Vega BlancoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PDF BeltConveyorsCalculationsCEMA5 Eng

Uploaded by

Maikol Gonzalo Vega BlancoCopyright:

Available Formats

www.kmg.agh.edu.

pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Department of Mining, Dressing and Transport Machines AGH

Belt Conveyors for Bulk Materials

Calculations by CEMA 5

th

Edition

Piotr Kulinowski, Ph. D. Eng.

Piotr Kasza, Ph. D. Eng.

- piotr.kulinowski@agh.edu.pl

( 12617 30 92

B-2 ground-floor room 6

consultations: Mondays 11.00 - 12.00

Conveyors

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Nomenclature of components of a typical belt conveyor

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

TYPICAL BELT CONVEYOR TRAVEL PATHS

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Design Considerations

Characteristics and Conveyability of Bulk Materials

Capacities, Belt Widths, and Speeds

Belt Conveyor Idlers

Belt Tension, Power, and Drive Engineering

Belt Selection

Pulleys and Shafts

Vertical Curves

Steep Angle Conveying

Belt Takeups, Cleaners, and Accessories

Conveyor Loading and Discharge

Conveyor Motor Drives and Controls

Operation, Maintenance, and Safety

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Characteristics and Conveyability of Bulk Materials

The angle of repose of a material is the acute angle

which the surface of a normal, freely formed pile makes

to the horizontal.

The angle of surcharge of a material is the angle to the

horizontal which the surface of the material assumes

while the material is at rest on a moving conveyor

belt.This angle usually is 5 degrees to 15 degrees less

than the angle of repose, though in some materials it may

be as much as 20 degrees less.

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Flowabilityangle of surchargeangle of repose

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Characteristics of BuIk Solid Materials - CEMA

Material Characteristics Code

Size

Very fine100 mesh and under

Fine1/8 inch and under

GranularUnder 1/2 inch

Lumpycontaining lumps over 1/2 inch

Irregularstringy, interlocking, mats together

A

B

C

D

E

Flowability

Angle of Repose

Very free flowingangle of repose less than 19

Free-flowingangle of repose 20 to 29

Average flowingangle of repose 30 to 39

Sluggishangle of repose 40 and over

1

2

3

4

Abrasiveness

Nonabrasive

Abrasive

Very abrasive

Very sharpcuts or gouges belt covers

5

6

7

8

Miscellaneous Characteristics

(Sometimes more than one of

these characteristics may

apply)

Very dusty

Aerates and develops fluid characteristics

Contains explosive dust

Contaminable, affecting use or saleability

Degradable, affecting use or saleability

Gives off harmful fumes or dust

Highly corrosive

Mildly corrosive

Hygroscopic

Interlocks or mats

Oils or chemical presentmay affect rubber products

Packs under pressure

Very light and fluffymay be wind-swept

Elevated temperature

L

M

N

P

0

R

S

T

U

V

W

X

V

Z

Example: A very fine material that is free-

flowing, abrasive, and contains explosive dust

would be designated:

Class A26N.

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Material characteristics and weight per cubic foot - CEMA

Material

Average

weight

(lbs/cu ft)

Angle of

repose

(degrees)

Recommended

maximum inclination

(degrees)

Code

Ashes, fly 40-45 42 20-25 A37

Cement, Portland 72-99 30-44 20-23 A36M

Coal, anthracite, river, or culm, inch and under 60 35 18 B35TY

Coal, lignite 40-45 38 22 D36T

Copper ore 120-150 30-44 20 *D37

Dolomite, lumpy 80-100 30-44 22 D36

Gravel, dry, sharp 90-100 30-44 15-17 D37

Lignite, air-dried 45-55 30-44 *D35

Rock, soft, excavated with shovel 100-110 30-44 22 D36

Salt, common dry, fine 70-80 25 11 D26TUW

Sandstone, broken 85-90 30-44 D37

Wood chips 10-30 45 27 E45WY

Coal, anthracite, river, or culm,1/8 inch and under 60 35 18 B35TY

Coal, anthracite, sized 55-60 27 16 C26

Coal, bituminous, mined 50 mesh and under 50-54 45 24 B45T

Coal, bituminous, mined and sized 45-55 35 16 D35T

Coal, bituminous, mined, run of mine 45-55 38 18 D35T

*Coal, bituminous, mined, slack,1/2 inch and under 43-50 40 22 C35T

Coal, bituminous, stripping, not cleaned 50-60 D36T

Coal, lignite 40-45 38 22 D36T

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Belt Widths

The belt widths are as

follows: 18, 24, 30, 36,

42, 48, 54, 60, 72, 84,

and 96 inches.

The width of the

narrower belts may be

governed by the size of

lumps to be handled.

Belts must be wide

enough so that any

combination of prevailing

lumps and finer material

does not load the lumps

too close to the edge of

the conveyor belt.

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Recommended

maximum belt

speeds

1 m/s = 196,85 ft/min

1 ft = 0.3048 m

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Example: Belt Conveyor Parameters

Coal, anthracite, sized

Capacity: 1000 tph

Length: 1000 m 3300 feet

Lift: 115 feet

Belt speed: 600 fpm

Belt width: 42 inches

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Area of load cross section

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Belt Conveyor Capacity Table

1. Determine the surcharge angle of the material.

The surcharge angle, on the average, will be 5 degrees to 15 degrees less than the angle of repose.

(ex. 27 - 12 = 15)

2. Determine the density of the material in pounds per cubic foot

(lb/ft

3

).

3. Choose the idler shape.

4. Select a suitable conveyor belt speed.

5. Convert the desired tonnage per hour (tph) to be conveyed to the

equivalent in cubic feet per hour (ft

3

/hr).

(ex. 1000 tph x 2000 / 60 = 33333 ft

3

/hr)

6. Convert the desired capacity in cubic feet per hour to the

equivalent capacity at a belt speed of 100 fpm.

(ex. Capacity (eqiuv) = 33333 x (100 / 600 fpm) = 5555 ft

3

/hr

7. Find the appropriate belt width

8. Selected belt speed may require revision

Coal, anthracite, sized 27

Coal, anthracite, sized 55-60

1 lb = 0.4536 kg

1 ft

3

= 0.0283 m

3

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Belt Conveyor Capacity Table

1 lb = 0.4536 kg

1 ft

3

= 0.028 m

3

1 ft

2

= 0.093 m

2

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Idler Spacing

Factors to consider when selecting idler spacing are belt weight, material weight, idler load rating, belt

sag, idler life, belt rating, belt tension, and radius in vertical curves

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Example: Belt Conveyor Parameters

Belt speed: 600 fpm

Belt width: 42 inches

Trough Angle: 35

5555 [ft

3

/hr] / 7524 [ft

3

/hr] = 74%

Idler spacing: 4.5 feet

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

The Selection of Idlers

Idler life is determined by a combination of many factors, such as seals, bearings, shell thickness,

belt speed, lump size/material density, maintenance, environment, temperature, and the proper

CEMA series of idler to handle the maximum calculated idler load.

CEMA B load rating based on minimum L

10

of 30,000 hours at 500 rpm

CEMA C load rating based on minimum L

10

of 30,000 hours at 500 rpm

CEMA D load rating based on minimum L

10

of 60,000 hours at 500 rpm

CEMA E load rating based on minimum L

10

of 60,000 hours at 500 rpm

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Step No. 1 Troughing Idler Series Selection

Calculated Idler Load (lbs) = CIL = ((WB + (WM x K1)) x SI) + IML

Where:

WB = Belt weight (lbs/ft) use actual or estimate from Table 5-5

WM = Material weight (lbs/ft) = (Q x 2000) / (60 x Vee)

Q = Quantity of material conveyed (tons per hour)

Vee = Design belt speed (fpm)

SI = Spacing of idlers (ft)

Kl = Lump adjustment factor (see Table 5-6)

IML = Idler misalignment load (lbs) due to idler height deviation and

belt tension = (D x T) / (6 x SI)

Where:

D = Misalignment (in.)

T = Belt tension (lbs)

SI = Idler spacing (ft)

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Step No. 1 Troughing Idler Series Selection

WB = Belt weight (lbs/ft)

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Step No. 1 Troughing Idler Series Selection

Kl = Lump adjustment factor

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Idler Series Selection

Calculated Idler Load (lbs) = CIL = ((11+ (55 x 1.0)) x 4.5) + 0 = 297 lbs

Where:

WB = 11 lbs/ft

WM = (1000 x 2000) / (60 x 600 ) = 55 lbs/ft

Q = 1000 tons per hour

Vee = 600 fpm

SI = 4.5 ft

Kl = 1.0

IML = 0

Calculated Return Idler Load (lbs) = CILR = (11 x 10) + 0 = 110 lbs

SI = 10.0 ft

1 lbf = 4.45 N

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Load ratings for CEMA idlers, lbs

Notes:

1. Troughing idler load ratings (Tables 5.75.10) are for three equal length rolls.

2. Load ratings also apply for impact rolls.

3. Troughing idler load ratings are based on a load distribution of 70% on center roll and 15%

on each end roll for all trough angles.

4. Unequal length rolls or picking idlers are not covered by this standard.

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

K2 = Effect of load on predicted bearing L10 life

= 297 / 363 = 0.82 K2 = 2.0

Bearing L10 = (30,000 x 2.0) = 60,000 hours

L

10

(CORRECTED) = L

10

(RATING) x K2 x K3A x K3B (IF APPLICABLE)

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

K3A = Effect of belt speed on predicted bearing L10 life

= 600 x 12 / (4 x 3.14) = 573 rpm K3A = 0.9

K3B = Effect of roll diameter on predicted bearing L10 life

Bearing L10 = (60,000 x 0.9 x 1.0 ) = 54,000 hours

4 inches K3B = 1.0

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

K4 = Environmental, maintenance, and other special conditions

K4A = Effect of maintenance on

potential idler life.

K4B = Effect of environmental

conditions on potential idler life.

K4C = Effect of operating

temperature on potential idler life.

FAIR K4A = 0.5

Dusty, Wet K4B = 0.6

9/5*26C+32 = 79 F K4C = 1.0

1 deg F = 0.5556 C

C = 5/9 (F-32)

F = 9/5 * C + 32

Bearing L10 = (54,000 x 0.5 x 0.6 x 1.0 ) = 16,200 hours

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

CEMA C Idlers

= 297 / 791 = 0.4 K2 = 10.0

Bearing L10 = (30,000 x 10.0 x 0.9 x 0.5 x 0.6) = 81,000 hours

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Average weight (lbs) of idler

rotating partssteel rolls.

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Basic Power Requirements

The horsepower, hp, required at the drive of a belt conveyor, is

derived from the pounds of the effective tension, T

e

, required at the

drive pulley to propel or restrain the loaded conveyor at the design

velocity of the belt V, in fpm:

T

e

is the final summarization of the belt tensions produced by forces

such as:

1.The gravitational load to lift or lower the material being

transported.

2.The frictional resistance of the conveyor components, drive, and

all accessories while operating at design capacity.

3.The frictional resistance of the material as it is being conveyed.

4.The force required to accelerate the material continuously as it is

fed onto the conveyor by a chute or a feeder.

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Effective tension,T

e

T

e

= LK

t

(K

x

+ K

y

W

b

+ 0.015W

b

) + W

m

(LK

y

H) + T

p

+ T

am

+ T

ac

Where:

L = length of conveyor, ft

K

t

= ambient temperature correction factor

K

x

= factor used to calculate the frictional resistance of the idlers and the sliding resistance between

the belt and idler rolls, lbs per ft

K

y

= carrying run factor used to calculate the combination of the resistance of the belt and the

resistance of the load to flexure as the belt and load move over the idlers. For return run use

constant 0.015.

W

b

= weight of belt in pounds per foot of belt length.

W

m

= weight of material, lbs per foot of belt length

H = vertical distance that material is lifted or lowered, ft

T

p

= tension resulting from resistance of belt to flexure around pulleys and the resistance of pulleys

to rotation on their bearings, total for all pulleys, lbs

T

am

= tension resulting from the force to accelerate the material continuously as it is fed onto the

belts, lbs

T

ac

= total of the tensions from conveyor accessories, lbs

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

K

t

Ambient Temperature Correction Factor

79 F K

t

= 1.0

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

K

x

Idler Friction Factor, lbs/ft

The frictional resistance of idler rolls to rotation and sliding resistance

between the belt and the idler rolls.

Values of K

x

can be calculated from the equation:

W

b

= 11 lbs/ft

W

m

= (1000 x 2000) / (60 x 600 ) = 55 lbs/ft

S

i

= 4.5 ft

CEMA B4

Kx =0,00068(11+55)+2.3/4.5 = 0.0449 + 0.51 = 0.555 lbs/ft

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

K

y

Factor for Calculating the Force of Belt and Load

Flexure over the Idlers

Resistance of the belt to flexure as it moves over idlers

Resistance of the load to flexure as it rides the belt over the idlers

Table 6-2 gives values of K

y

for carrying idlers as they vary with differences in the

weight/ ft of the conveyor belt, W

b

; load, W

m

; idler spacing, S

i

; and the percent of

slope or angle that the conveyor makes with the horizontal.

W

b

+ W

m

= 66 lbs/ft

S

i

= 4.5 ft

Lenght: 3300 feet

Height: 115 feet

Slope: 2 degrees

K

y

= 0.020

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Corrected factor K

y

K

y

= 0.0214

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

K

y

vs. Belt Tension

After estimating the average belt tension and selecting an idler spacing, refer to Table 6-4

to obtain values for A and B for use in the following equation:

W

b

+ W

m

= 66 lbs/ft

S

i

= 4.5 ft

K

y

= 0.04036

K

y

= 0.01261

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

T

p

= total of the belt tensions required to rotate each of

the pulleys on the conveyor

2 x 200 = 400 lbs

3 x 150 = 450 lbs

T

p

=950 lbs

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Pulleys

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

T

am

force to accelerate the material continuously as it

is fed onto the belt

Where:

Q = Capacity of loading point, tph

g = 32.2 ft/sec

2

V = design belt speed, fpm

V

0

= initial velocity of material as it is fed onto

belt, fpm

T

am

= 2.8755 x 10

4

x Q x (V V

0

)

= 2.8755 x 10

4

x 1000 x (600 0) = 172.53 lbs

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

T

ac

resistance generated by conveyor accessories

Conveyor accessories such as trippers, stackers, plows, belt cleaning equipment, and skirtboards

usually add to the effective tension, T

e

T

tr

from trippers and stackers

T

pl

from frictional resistance of plows

T

bc

from belt-cleaning devices

T

sb

from skirtboard friction

T

sb

= L

b

(C

s

h

s

2

+ 6)

L

b

= skirtboard length, ft one skirtboard,

=10 ft

h

s

= depth of the material touching

the skirtboard, in =10 in

T

tr

=0 lbs

T

pl

=0 lbs

T

bc

=0 lbs

T

sb

=113.8 lbs

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Resistance Calculations

T

e

equals the total of the following:

lbs

T

x

, idler friction = L x K

x

x K

t

= 3300 x 0.555 x 1.0 = 1831.5

+ Tyc , belt flexure, carrying idlers = L x K

y

x W

b

x K

t

= 3300 x 0.0214 x 11 x 1.0 = 776.8

+ T

yr

, belt flexure, return idlers = L x 0.015 x W

b

x K

t

= 3300 x 0.015 x 11 x 1.0 = 544.5

Subtotal (A) LK

t

(K

x

+K

y

W

b

+0.015W

b

) 3152.8 lbs

+ T

ym

, material flexure = L x K

y

x W

m

= 3300 x 0.0214 x 55.0 = 3884.1

+ T

m

, lift or lower = H x W

m

= 115 x 55 = 6325

Subtotal (B) W

m

(LK

y

H) 10209.1 lbs

T

p

, pulley resistance 950

T

am

, accelerated material 172.5

T

ac

, accessories (T

tr

+ T

pl

+ T

bc

+ T

sb

) 113.8

Subtotal (C) 1236,3 lbs

Te = Subtotals (A), (B), and (C) 14598,2 lbs

CEMA Horsepower Formula hp = T

e

x V / 30,000

265,4 hp

If drive efficiency = .94, horsepower at motor shaft = 265.4/.94 = 282.3 hp.

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Wrap Factor, C

w

T

e

= T

1

- T

2

= effective belt tension, lbs

T

1

= tight-side tension at pulley, lbs

T

2

= slack-side tension at pulley, lbs

e = base of naperian logarithms = 2.718

f = coefficient of friction between pulley surface and belt surface (0.25 rubber surfaced belt driving bare

steel or cast iron pulley; 0.35 rubber surfaced belt driving rubber lagged pulley surface). Values

apply to normal running calculations

= wrap of belt around the pulley, radians (one degree = 0.0174 radians)

C

w

= wrap factor

C

w

=0.08

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Tension Relationships and Belt Sag Between Idlers

where :

W = weight, (W

b

+ W

m

), lbs/ft of belt and material

S

i

= idler spacing, ft

T = tension in belt, lbs

T

0

= 1856.2 lbs

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Maximum and Minimum Belt Tensions

Slack Side Tension, T

2

T

2

= T

e

C

w

or

T

2

= T

0

T

b

T

yr

Use the larger value of T

2

Tension, T

b

. The weight of the carrying and/or return run belt for a sloped conveyor

is carried on the pulley at the top of the slope. This must be considered in calculating

the T

2

tension, as indicated above.

T

b

= H x W

b

where:

W

b

= weight of belt, lbs/ft

H = net change in elevation, ft

Return Belt Friction Tension, T

yr

. The return belt friction is the belt tension

resulting from the empty belt moving over the return run idlers:

T

yr

= 0.015 x L x W

b

x K

t

where:

L = length, ft, of conveyor to center of terminal pulleys

K

t

= temperature correction factor

T

t

= T

0

or T

t

= T

2

T

b

+ T

yr

T

t

= T

min

T

1

= T

2

+ T

e

= T

max

T

2

= 1167.8 lbs

T

2

=1856.2 +1256 544.5 =2567.7 lbs

T

b

=115 x 11 =1265 lbs

T

yr

=544.5 lbs

T

min

= 1856.2 lbs

T

max

= 17165.9 lbs

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Belt Selection

Belt stress = T1 / Belt width = 17166/42 = 409 lbs per inch of width(PIW)

Item Units Description System

PIW LB/In-Width Max. Oper. Strength USA

EP N/mm or Kn/m Breaking Strength Metric

ST N/mm or Kn/m Breaking Strength Metric

Convert from PIW to EP:

(409 PIW x 10 SF)

5.71 = 716 N/mm

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Bibliography

Continuous handling equipment Nomenclature, ISO 2148-1974

Belt Conveyors for Bulk Materials, Calculations by CEMA 5th Edition

Kulinowski, Kasza: Wykady Conveyors, www.kmg.agh.edu.pl

www.conveyorbeltguide.com

IDLER CATALOG, Superior Industries, LLC

g - Acceleration due to gravity,

32.2 ft/sec

2

www.kmg.agh.edu.pl

piotr.kasza@agh.edu.pl, piotr.kulinowski@agh.edu.pl Department of Mining, Dressing and Transport Machines AGH tel/fax +48126335162

Questions?

You might also like

- Belt Conveyor Seminar OverviewDocument20 pagesBelt Conveyor Seminar OverviewWalther LaricoNo ratings yet

- Boiler Tube GradesDocument12 pagesBoiler Tube Gradesfelram100% (1)

- Calculation CEMA 5 - Parte1Document5 pagesCalculation CEMA 5 - Parte1Angel AlvarezNo ratings yet

- Rex High Performance Chain Bucket Elevator ManualDocument170 pagesRex High Performance Chain Bucket Elevator ManualJohnNo ratings yet

- Ernest Hemingway's Life Experiences Shaped His WritingDocument18 pagesErnest Hemingway's Life Experiences Shaped His WritingfelramNo ratings yet

- Ernest Hemingway's Life Experiences Shaped His WritingDocument18 pagesErnest Hemingway's Life Experiences Shaped His WritingfelramNo ratings yet

- Bulk Material Handling Belt-Conveyor-CatalogDocument21 pagesBulk Material Handling Belt-Conveyor-CatalogjayNo ratings yet

- Mobile and Crawler CranesDocument7 pagesMobile and Crawler CranesPetru AncaNo ratings yet

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsFrom EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNo ratings yet

- KWS Cat PDFDocument126 pagesKWS Cat PDFThaveep RatanakuhaNo ratings yet

- Bucket ElevatorDocument6 pagesBucket ElevatorbetojulioNo ratings yet

- Apron Weigh Feeder Technical ManualDocument15 pagesApron Weigh Feeder Technical ManualShariq KhanNo ratings yet

- Welding Handbook Maritime UnitorDocument552 pagesWelding Handbook Maritime UnitorPeter BournelisNo ratings yet

- Bucket ElevatorsDocument16 pagesBucket Elevatorssdmel100% (3)

- CHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORDocument2 pagesCHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORdeddy ariyanto100% (1)

- Calculation CEMA 5 - Parte2Document5 pagesCalculation CEMA 5 - Parte2Angel AlvarezNo ratings yet

- Erection Guidelines For 500 MW Boiler Pressure PartsDocument150 pagesErection Guidelines For 500 MW Boiler Pressure Partsyanloyan80% (5)

- Belt Feeder Calc. Pns Line 1Document4 pagesBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- Conveyor BeltsDocument22 pagesConveyor BeltsFavorSea Industrial Channel LimitedNo ratings yet

- Heat Recovery Steam Generators Optimized For Any ApplicationDocument7 pagesHeat Recovery Steam Generators Optimized For Any ApplicationKVVNo ratings yet

- Selecting The Proper Conveyor Belt: Single Pulley DriveDocument18 pagesSelecting The Proper Conveyor Belt: Single Pulley Drivettr_1983No ratings yet

- Design, Fabrication and Testing of A Low Headroom Conveyor Transfer ChuteDocument132 pagesDesign, Fabrication and Testing of A Low Headroom Conveyor Transfer ChuteJakesNo ratings yet

- Bucket Elevator Calculation - Rev. 1Document8 pagesBucket Elevator Calculation - Rev. 1Jose David Jurado100% (4)

- Pan Conveyors PDFDocument20 pagesPan Conveyors PDFChristian Makande100% (2)

- Apron Feeder Application Datasheet enDocument1 pageApron Feeder Application Datasheet enVaijayanti JoshiNo ratings yet

- Pressure-Resistant Gravimetric Coal Feeder CatalogueDocument10 pagesPressure-Resistant Gravimetric Coal Feeder CataloguesuparnabhoseNo ratings yet

- AUMUND Belt Bucket Elevator Overcomes Coarse Material ChallengesDocument53 pagesAUMUND Belt Bucket Elevator Overcomes Coarse Material Challengesnathaniel villanueva100% (1)

- Screw Conveyor Engineering Guide Pt1Document17 pagesScrew Conveyor Engineering Guide Pt1vijayendraNo ratings yet

- Double Chain Conveyor Construction DrawingDocument22 pagesDouble Chain Conveyor Construction DrawingendriaberNo ratings yet

- Pipe ConveyorDocument4 pagesPipe ConveyorDIBYENDU MONDALNo ratings yet

- Belt Bucket Elevator DesignDocument14 pagesBelt Bucket Elevator Designking100% (1)

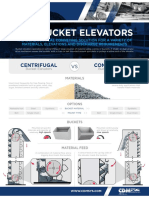

- CDM Bucket Elevators: Centrifugal ContinuousDocument2 pagesCDM Bucket Elevators: Centrifugal ContinuousOcta IrawanNo ratings yet

- Bucket Elevator Calculation for Quang Trach 1 Thermal Power PlantDocument8 pagesBucket Elevator Calculation for Quang Trach 1 Thermal Power PlanthbookNo ratings yet

- Belt Tension CalculationDocument5 pagesBelt Tension Calculationmanoj983@gmail.comNo ratings yet

- Safety Valve NoiseDocument7 pagesSafety Valve NoisefelramNo ratings yet

- The Evolution of the Pipe-ConveyorDocument9 pagesThe Evolution of the Pipe-ConveyorJohnjun ChenNo ratings yet

- A Double Roll Crusher AppliedDocument7 pagesA Double Roll Crusher AppliedAnonymous bmFsuvNo ratings yet

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiNo ratings yet

- Welcome: Advanced Bulk Material Conveying Technologies in Cement IndustryDocument15 pagesWelcome: Advanced Bulk Material Conveying Technologies in Cement Industry1977julNo ratings yet

- Extract From The Book Belt FeederDocument93 pagesExtract From The Book Belt FeederPushp Dutt100% (1)

- 04 Pipe ConveyorsDocument77 pages04 Pipe Conveyorsbetojulio100% (2)

- BANDO Eng. CatalogDocument44 pagesBANDO Eng. Catalogatm_o40% (5)

- Bucket Elevator Vs AirliftDocument10 pagesBucket Elevator Vs AirliftSunil D Pujari100% (1)

- DOWNHILL BELT CONVEYOR SPEED CONTROLDocument9 pagesDOWNHILL BELT CONVEYOR SPEED CONTROLShipra ShaliniNo ratings yet

- BELT CONVEYOR - Discharge TrajectoryDocument3 pagesBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteNo ratings yet

- Sidewall Belt Conveyor PDFDocument21 pagesSidewall Belt Conveyor PDFNyx RubyNo ratings yet

- Bucket Elevators Catalogue: Gambarotta GschwendtDocument64 pagesBucket Elevators Catalogue: Gambarotta GschwendtRICARDOALEXBORGESNo ratings yet

- Chute Calculation ExampleDocument1 pageChute Calculation ExampleBimal DeyNo ratings yet

- Wagons Modern Bulk Material HandlingDocument4 pagesWagons Modern Bulk Material Handlingparuchurivenkat5272No ratings yet

- Beumer Chain Bucket Elevator enDocument8 pagesBeumer Chain Bucket Elevator enArghya BasakNo ratings yet

- Conveyor CalculationsDocument10 pagesConveyor CalculationsCristhian PortocarreroNo ratings yet

- AUMUND Asia (H.K.) Limited: Cockburn Cement Limited AustraliaDocument14 pagesAUMUND Asia (H.K.) Limited: Cockburn Cement Limited AustraliaNicolas Recio Fdez-Tresguerres100% (1)

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Document19 pagesKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNo ratings yet

- Catalogue R I Tang Đ NG Cơ Rulmeca PDFDocument8 pagesCatalogue R I Tang Đ NG Cơ Rulmeca PDFRulmeca Việt Nam100% (1)

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesDocument22 pagesFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramNo ratings yet

- Bucket ElevatorDocument72 pagesBucket Elevatorselmagis100% (2)

- Apron Feeder PDFDocument3 pagesApron Feeder PDFabdulloh_99100% (1)

- I Feeder Application Design CalculationsDocument2 pagesI Feeder Application Design Calculationsarsaniose100% (1)

- FAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgDocument4 pagesFAM Apron Feeders: WWW - Fam.de Förderanlagen MagdeburgriteshsamantrayNo ratings yet

- STD Line: Product DescriptionDocument16 pagesSTD Line: Product DescriptionrpmNo ratings yet

- Calculation CEMA 5 - Parte3Document5 pagesCalculation CEMA 5 - Parte3Angel AlvarezNo ratings yet

- Calculation CEMA 5 - Parte4Document5 pagesCalculation CEMA 5 - Parte4Angel AlvarezNo ratings yet

- Bucket ElevatorDocument9 pagesBucket Elevatorkoripella_prasadNo ratings yet

- SAMSON Eco-Hopper - March 2013Document8 pagesSAMSON Eco-Hopper - March 2013Guilherme Pierre PaivaNo ratings yet

- Materials Handling: Section 10Document24 pagesMaterials Handling: Section 10Hamid MojiryNo ratings yet

- R 2 PwayDocument36 pagesR 2 PwayAbhilashPadmanabhanNo ratings yet

- Motor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12From EverandMotor Truck Logging Methods Engineering Experiment Station Series, Bulletin No. 12No ratings yet

- Cv-113-Us Ma1 Desup CopesDocument8 pagesCv-113-Us Ma1 Desup CopesPat AuffretNo ratings yet

- 3 3 1 LC Desuperheater SolutionsDocument4 pages3 3 1 LC Desuperheater SolutionsfelramNo ratings yet

- Broad Portfolio of Desuperheating SolutionsDocument8 pagesBroad Portfolio of Desuperheating Solutionshrh_pogcNo ratings yet

- CV 1164 Us Sa 35 Desup CopesDocument4 pagesCV 1164 Us Sa 35 Desup CopesfelramNo ratings yet

- Bulk Solids Handling BrochureDocument20 pagesBulk Solids Handling BrochurefelramNo ratings yet

- Pipe Flange BoltingDocument8 pagesPipe Flange BoltingayoungaNo ratings yet

- Material Properties For DesignersDocument124 pagesMaterial Properties For Designersৰিতুপর্ণ HazarikaNo ratings yet

- She La PersimmonsDocument6 pagesShe La PersimmonsfelramNo ratings yet

- Moor - Air Pollution ControlDocument4 pagesMoor - Air Pollution ControlfelramNo ratings yet

- Persimmon Tannin Composition and Function: Tianying Zhang, Gang Li and Haizhen Mo Chunxiang ZhiDocument4 pagesPersimmon Tannin Composition and Function: Tianying Zhang, Gang Li and Haizhen Mo Chunxiang ZhifelramNo ratings yet

- 1962 - Van Hengel - The Occurrence of InversionDocument5 pages1962 - Van Hengel - The Occurrence of InversionfelramNo ratings yet

- Condition and Life Assessment of a Power Station BoilerDocument2 pagesCondition and Life Assessment of a Power Station BoilerfelramNo ratings yet

- Silencer ApplicationDocument196 pagesSilencer ApplicationMisaghNo ratings yet

- Biomass Principles DPalmer 170310Document58 pagesBiomass Principles DPalmer 170310felramNo ratings yet

- Topic - Connections - Typical Joints PDFDocument56 pagesTopic - Connections - Typical Joints PDFKanako NozawaNo ratings yet

- Removal of Color in Cane Juice ClarificationDocument8 pagesRemoval of Color in Cane Juice ClarificationFederico LeonNo ratings yet

- Flow Considerations in Industrial Silencer DesignDocument8 pagesFlow Considerations in Industrial Silencer DesignktsnlNo ratings yet

- Boiler Study GuideDocument27 pagesBoiler Study GuideAjish Rajan TNo ratings yet

- C00226 ModelDocument1 pageC00226 ModelfelramNo ratings yet

- Wed 0800 NarendranathDocument23 pagesWed 0800 NarendranathMarita RamirezNo ratings yet

- WRD Ot Clarifier Calculations 445211 7Document118 pagesWRD Ot Clarifier Calculations 445211 7felramNo ratings yet

- ATACA Recent Developments - 0410110659Document20 pagesATACA Recent Developments - 0410110659felramNo ratings yet