Professional Documents

Culture Documents

Additives To Clay - Organic Additives

Uploaded by

David Peiró0 ratings0% found this document useful (0 votes)

27 views5 pagesEarth is a multi-component system usually consisting of stones, sand, silt, clay, water and, near the ground surface, organic humus. Earth has some disadvantages - it has relatively low compressive strength, tensile strength and abrasion resistance. Good and durable earth buildings can be built provided certain precautions are taken.

Original Description:

Original Title

Additives to Clay - Organic Additives

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentEarth is a multi-component system usually consisting of stones, sand, silt, clay, water and, near the ground surface, organic humus. Earth has some disadvantages - it has relatively low compressive strength, tensile strength and abrasion resistance. Good and durable earth buildings can be built provided certain precautions are taken.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views5 pagesAdditives To Clay - Organic Additives

Uploaded by

David PeiróEarth is a multi-component system usually consisting of stones, sand, silt, clay, water and, near the ground surface, organic humus. Earth has some disadvantages - it has relatively low compressive strength, tensile strength and abrasion resistance. Good and durable earth buildings can be built provided certain precautions are taken.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Practical Action, The Schumacher Centre, Bourton on Dunsmore, Rugby, Warwickshire, CV23 9QZ, UK

T +44 (0)1926 634400 | F +44 (0)1926 634401 | E infoserv@practicalaction.org.uk | W www.practicalaction.org

______________________________________________________________________________________________

Practical Action is a registered charity and company limited by guarantee.

Company Reg. No. 871954, England | Reg. Charity No.247257 | VAT No. 880 9924 76 |

Patron HRH The Prince of Wales, KG, KT, GCB

ADDITIVES TO CLAY

ORGANIC ADDITIVES

DERIVED FROM NATURAL SOURCES

Introduction

Earth has been used for building

for thousands of years throughout

the world spanning a diverse range

of climates and cultures. Earth

itself is a multi-component system

usually consisting of stones, sand,

silt, clay, water and, near the

ground surface, organic humus.

Structural stability of earth

buildings is maintained by the

structural integrity of the sand and

stone framework, by the pore

filling capacity of the silt and,

most importantly, by the binding

qualities of the clay, which are in

turn influenced by the moisture

content of the soil.

Compared with some building materials earth can be considered to have some disadvantages

it has relatively low compressive strength, tensile strength and abrasion resistance. It may

also lose a lot of its rigidity in the presence of water. Nevertheless it is very cheap, very

widely available, environmentally friendly, strongly linked to local cultures and traditions and,

with skilful construction, can contribute significantly to the aesthetic appeal and user comfort

of buildings.

Good and durable earth buildings can be built provided certain precautions are taken. These

precautions will depend on local conditions and structural requirements, but can broadly be

classified into four categories:

Soil selection

Different soils can have very different characteristics. The quality of a soil for building is

strongly dependant on grain size distribution and excluding humus.

Soil preparation and construction methods

Builders should be familiar with soil pulverising, proportioning, mixing, maturing and curing

as well as masonry techniques.

Building design

The design should take account of the properties of the raw material by appropriate load

distribution and structural dimensions, and by incorporating protective elements against

damp, rain, impact and abrasion. Protection can be achieved by adding more durable but

complimentary materials at places such as the wall base, roof overhang and the copings, and

by using plasters and renders.

Figure 1 Surface stabilisation of soil with palm oil,

Nigeria. Photo credit: CRATerre/EAG

Additives to clay - Organic Practical Action

2

Improving the raw material quality

Different treatments or additives, collectively known as stabilisation, can modify the

properties of soils to control their shrinkage and swelling characteristics and so improve the

binding ability of the clay in the soil. These stabilisation methods are described in this

leaflet.

Compaction

Compaction increases the soils density and hence its strength and resistance to mechanical

damage. It also reduces water absorption but, with the associated reduction in porosity,

durability may be reduced.

Compaction is done in a mould or form:

statically (i.e. in a single pressing), with cylindrical rollers, wheeled rollers or presses;

dynamically (i.e. repeated), with tampers or rammers, vibrating rammers or pick

hammers;

surface, with a beater mainly for floors or roofs, although sometimes used on rammed

earth walls before they dry.

Effectiveness of compaction depends on applied pressure or energy, soil type and water

content.

Vegetable additives

Fibres

Fibres are widely used when

building with earth. Generally

fibres can be most easily mixed

in with the soil if it is in a plastic

or liquid state that is not too dry.

The fibres act to increase the

tensile strength, reduce density,

accelerate drying and reduce

cracking by dispersing stresses.

Fibres vary in shape, size,

strength, elasticity and their

bond strength with earth, so

possible improvements with

different types of fibre will vary,

as will the amount of a particular

fibre required. Usual proportions

range between 1 and 4% by

weight, representing in bulk a

volume which can be as high as the volume of soil.

The most common fibres used include straw, for example from wheat, rice or barley. The

chaffs or husks of these crops can also be used. Other suitable vegetable fibres include hay,

hemp, millet, sisal, filao needles, and elephant grass. Cow dung and, less frequently, horse

and camel dung have also been used as additives because they contain short fibres which

make the soil workable for plastering and rendering. Synthetic fibres such as colophane,

steel or glass wool have found very limited application. Best results are obtained with fibre

reinforcement if the wet mix is prepared several days before use.

One drawback of vegetable fibre is variable durability. Dry fibres will generally last a very long

time but when wet they are liable to rot. Also some are attacked by insects, especially

termites, but others are not and often local knowledge exists to identify the most resistant

types.

Figure 2: Soil-based render - stabilised with bark of Nr,

Nigeria. Photo credit: CRATerre/EAG

Additives to clay - Organic Practical Action

3

Vegetable Oils and Fats

The best additives of this type are those which dry, thereby harden, quickly and are insoluble

in water. Such additives include coconut, cotton and linseed oil as well as castor oil which

is very expensive. Kapok, palmitic oil and shea butter have also been tried, but with variable

results, so local trials are recommended. Shea butter can repel termites, and an addition of

around 3% is recommended, although it can also be painted or sprayed on surfaces.

Tannins

Tannins often act to disperse clay particles so that they coat sand grains in the soil more

evenly and, also help to break up clay lumps during compaction as well as reducing

permeability of the soil and improving water resistance.

The amount of tannin required varies from a small percentage of the mixing water for the

most active types to completely replacing the mixing water in the case of decoctions

solutions obtained by boiling the natural products. In some regions of West Africa a decoction

of the bark of the Nr tree (parkia biglobosa) is used for surface protection and it can also

be used to stabilise gravelly soils with good results. Other tannins are prepared from the bark

of oak, chestnut and scorpioid acacia.

Gum arabic

This is a product obtained from the acacia tree. It acts primarily as a flocculant, that is it

helps to form flocs of clay particles within the soil which help to increase dry compressive

strength and slow down water absorption, hence reducing shrinkage. However, it is soluble in

water and so offers little protection to long-term moisture exposure. It is best used inside a

building, added at 5 to 10% proportions.

Palmo copal

Copal is a resin obtained from certain tropical trees. It is usually added at 3 to 8%

concentration to sandy soils. One variety, manilla copal, has waterproofing qualities.

Sap and latexes

The latex of certain trees, such as euphorbia, hevea rubber and concentrated sisal juice,

reduces permeability slightly and improves cohesion. Proportions between 3 and 15% are

normally used and best results are achieved with neutral rather than acidic soils. The juice

squeezed from banana leaves, which is subsequently precipitated by mixing with lime to

clean it, is another material which has similar properties.

Molasses

Dehydrated sugar molasses contain aldehydes which can be converted into polymers at high

temperatures with the aid of phenolic catalysts. The resinous material obtained is similar to

asphalt and other resins in its effects. It improves the strength and reduces permeability.

Normally a proportion of about 5% is used.

Animal additives

Care must be taken with animal products. In particular it is important that the animal has not

suffered from a contagious disease for humans, such as anthrax.

Fibres

Hair and fur from animals are used with plasters and renders to reduce shrinkage and improve

adhesion and impact resistance.

Excrements

These can contain chemicals such as phosphoric acid and potassium minerals which have

beneficial effects. In addition excrements contain fibres. Additions of up to a third are

possible, or even half for a finishing mix. Cow, horse or camel dungs are normally used. Goat

dung can be used to lighten the soil. It is normal practice to leave a soil and dung mix to

ferment for several days before use.

Additives to clay - Organic Practical Action

4

Urine

Horse urine, added to a soil, reduces its shrinkage and makes it more resistant to erosion. It

can replace the mixing water and is sometimes mixed in with straw before adding to soil. The

strong smell disappears on drying.

Blood

Animal blood, preferably in fresh rather than powdered form, can be an effective additive

when combined with lime or polyphenols.

Casein

Proteinic casein, in the form of whey a product formed by the souring of milk, sometimes

mixed with animal blood, can be used for stabilisation. Milk powder has also been used. One

proprietary mix is known as Poulhs soup and is a mixture of diluted casein and brick dust

beaten to a paste.

Animal glues

These improve strength and water resistance. They are made by boiling the skins and bones

of animals in water.

Termite mounds

Termite mound material can be mixed with soil for a stabilising effect. Termite mounds are

cemented with a cellulosic binder produced by the insects.

Oils and fats

Fish oil and animal fats can serve as waterproofing agents with stearates being the active

component. Proportions from 5% are used but the effect can be variable.

The need for additives

It should be noted that there is not always a need to add stabilisers. Soil properties will

dictate need and there are many examples across the world of the effective use of

unstabilised soil. Stabilisers also add significantly to cost.

If a stabiliser is deemed necessary the choice of which one to use will depend on a number of

factors including:

the part of the building on which the soil is used and its exposure to the elements

the property of the soil which needs improving; e.g. dry strength, wet strength, water

erosion, abrasion resistance, surface protection, etc.

the level of improvement required

the quantity of stabiliser required

the cost and availability of the stabiliser

whether production of the stabiliser is carried out locally or whether it needs to be

imported.

The precise quantities of additives often need to be determined empirically by trial and error

for each particular situation. The results of laboratory tests often cannot be transferred

directly to field practice, although they do provide useful guidance and a starting point for

field tests. In the field, relatively simple and inexpensive tests such as the observation of the

durability of blocks on soaking in water, and the use of a simple press to assess the load a

block can carry in flexure can provide information on stabiliser requirements. As preparation

of soil mixes and their use for building is often carried out under less rigorous conditions than

for testing a judicious compensatory increase in stabiliser dosage is recommended.

Additives to clay - Organic Practical Action

5

References and further reading

Clay as a Binder Practical Action Technical Brief

Mud as a Mortar Practical Action Technical Brief

Mud Plasters and Renders Practical Action Technical Brief

Additives to Clay: Minerals and Synthetic Additives Practical Action Technical Brief

Earth Construction, Practical Action Publishing, 1994. ISBN: 9781853391934

Building with Earth CRATerre, Mud Village Society, Delhi, India, 1990.

Building with Earth, A handbook Second Edition, John Norton, Practical Action Publishing,

1997.ISBN 9781853393372

Soil Preparation Equipment (product information), GTZ

Earth building materials and techniques, Select Bibliography, CRATerre, GTZ, 1991.

The Basics of Compressed Earth Blocks, CRATerre, GTZ, 991.

Appropriate Building Materials, A Catalogue of Potential Solutions, R. Stulz, K. Mukerji,

Practical Action Publishing/SKAT, 1993 ISBN 9781853392252

Stabilization of Clay Soils by Portland Cement or Lime - A Critical Review of Literature, S.

Bhattacharja, J.I. Bhatty & H.A. Todres, Portland Cement Association, Research &

Development Information, Serial No. 2066, 2003,

Compressed Earth Blocks: Vol. 1, Manual of Production, Vince Rigassi, CRATerre-EAG, GTZ,

1985

Contacts

CRATerre

Maison Levrat (Parc Fallavier)

B. P. 53, F-38092 Villefontaine -CEDEX

France

Tel: +33 474 954391

Fax: +33 474 956421

Website: http://craterre.org/

CRATerre is the international centre for earth construction at the school of Architecture in

Grenoble.

Auroville Earth Institute

Auroshilpam, Auroville 605 101,

T.N. India

Tel: +91 413 262 3064 / 262 3330

Fax: +91 413 262 2886

Website: http://www.earth-auroville.com/

This technical brief was originally prepared for basin, Building Advisory Service

and Information Network.

For further information contact:

Practical Action

The Schumacher Centre

Bourton-on-Dunsmore

Warwickshire

CV23 9QZ

United Kingdom

Tel: +44 (0)1926 634400

Fax: +44 (0)1926 634401

E-mail: inforserv@practicalaction.org.uk

Website: http://practicalaction.org/practicalanswers/

This Technical Brief is possible thanks to the collaboration of DFID-UK and The Tony Bullard Trust.

Practical Action is a development charity with a difference. We know the simplest ideas can have the

most profound, life-changing effect on poor people across the world. For over 40 years, we have been

working closely with some of the worlds poorest people - using simple technology to fight poverty and

transform their lives for the better. We currently work in 15 countries in Africa, South Asia and Latin

America.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Japanese For Busy People 2 (Kana Version)Document301 pagesJapanese For Busy People 2 (Kana Version)Mayvin Seeneevassen100% (25)

- Japanese For Busy People 2 (Kana Version)Document301 pagesJapanese For Busy People 2 (Kana Version)Mayvin Seeneevassen100% (25)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Tutorial Sim MechanicsDocument840 pagesTutorial Sim MechanicsHernan Gonzalez100% (4)

- By Emile Alline: Technical Art by Fred WolffDocument4 pagesBy Emile Alline: Technical Art by Fred WolffJim100% (3)

- Vray For Sketchup User GuideDocument33 pagesVray For Sketchup User GuideSophie MondonedoNo ratings yet

- Ancon Channel & Bolt FixingsDocument20 pagesAncon Channel & Bolt FixingsatiattiNo ratings yet

- Shop SupervisionDocument38 pagesShop SupervisionSakura Yuno Gozai80% (5)

- 9-Lesson 5 Direct and Indirect SpeechDocument8 pages9-Lesson 5 Direct and Indirect Speechlaiwelyn100% (4)

- Green From The Ground UpDocument338 pagesGreen From The Ground UpMihail Koprivchin100% (2)

- Green From The Ground UpDocument338 pagesGreen From The Ground UpMihail Koprivchin100% (2)

- Language Culture and ThoughtDocument24 pagesLanguage Culture and ThoughtLý Hiển NhiênNo ratings yet

- Adverb Affirmation Negation LessonDocument4 pagesAdverb Affirmation Negation LessonMire-chan Bacon100% (1)

- EtomDocument1 pageEtomarthryxNo ratings yet

- 2017 Amazing Sky CalendarDocument26 pages2017 Amazing Sky CalendarDavid PeiróNo ratings yet

- Astronomy DelightsDocument364 pagesAstronomy DelightsDavid PeiróNo ratings yet

- Vernacular Buildings in A Changing WolrdDocument165 pagesVernacular Buildings in A Changing WolrdDavid PeiróNo ratings yet

- Livingscapes - Integration of Buildings and Land To Sustainable Productive Systems - North 2001Document9 pagesLivingscapes - Integration of Buildings and Land To Sustainable Productive Systems - North 2001David PeiróNo ratings yet

- Analysis of Historic Rammed Earth Construction PDFDocument8 pagesAnalysis of Historic Rammed Earth Construction PDFDavid PeiróNo ratings yet

- Construccion Con Fardos de PajaDocument24 pagesConstruccion Con Fardos de PajaDavid PeiróNo ratings yet

- Livingscapes - Integration of Buildings and Land To Sustainable Productive Systems - North 2001Document9 pagesLivingscapes - Integration of Buildings and Land To Sustainable Productive Systems - North 2001David PeiróNo ratings yet

- Green - Ing Away From Sustainability Hahn 2010Document11 pagesGreen - Ing Away From Sustainability Hahn 2010David PeiróNo ratings yet

- Earth Building in Scotland - Past, Present, and Future - Morton and Little 2001Document18 pagesEarth Building in Scotland - Past, Present, and Future - Morton and Little 2001David PeiróNo ratings yet

- Livingscapes - Integration of Buildings and Land To Sustainable Productive Systems - North 2001Document9 pagesLivingscapes - Integration of Buildings and Land To Sustainable Productive Systems - North 2001David PeiróNo ratings yet

- Builders Without Borders - An Overview - Kennedy 2001Document9 pagesBuilders Without Borders - An Overview - Kennedy 2001David PeiróNo ratings yet

- HR MasterlistDocument6 pagesHR MasterlistLeychelle AnnNo ratings yet

- Mindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicDocument13 pagesMindfulness With Collegiate Gymnasts - Effects On Flow, Stress and Overall Mindfulness LevelsNicholas P. Cherupa,, Zeljka VidicGABRIELNo ratings yet

- Test Unit 7 m.2Document6 pagesTest Unit 7 m.2Petchara SridakunNo ratings yet

- COP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDocument4 pagesCOP Oil: For Epiroc Components We Combine Technology and Environmental SustainabilityDavid CarrilloNo ratings yet

- Prelims in NSTPDocument2 pagesPrelims in NSTPJanine Alexis TividadNo ratings yet

- ADL MATRIX STRATEGY FOR BPCL'S GROWTHDocument17 pagesADL MATRIX STRATEGY FOR BPCL'S GROWTHSachin Nagar100% (1)

- Stage TwoDocument34 pagesStage TwoThar LattNo ratings yet

- Mil B 49430BDocument36 pagesMil B 49430Bparam.vennelaNo ratings yet

- The Eukaryotic Replication Machine: D. Zhang, M. O'DonnellDocument39 pagesThe Eukaryotic Replication Machine: D. Zhang, M. O'DonnellÁgnes TóthNo ratings yet

- Click To Edit Master Title Style: Uggas, Heinz Gerhard A. Sabroso, Dionisio Jr. L. Reyes, Jeboy ODocument21 pagesClick To Edit Master Title Style: Uggas, Heinz Gerhard A. Sabroso, Dionisio Jr. L. Reyes, Jeboy ODionisio SabrosoNo ratings yet

- Proposed - TIA - 1392 - NFPA - 221Document2 pagesProposed - TIA - 1392 - NFPA - 221Junior TorrejónNo ratings yet

- DC CheatsheetDocument2 pagesDC CheatsheetRashi SinghNo ratings yet

- CSE (With SPL)Document65 pagesCSE (With SPL)parthasarathycseNo ratings yet

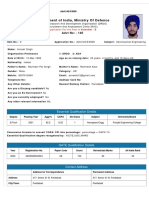

- DrdoDocument2 pagesDrdoAvneet SinghNo ratings yet

- MST 2 ReviewerDocument4 pagesMST 2 ReviewerAizha NarioNo ratings yet

- Detect Plant Diseases Using Image ProcessingDocument11 pagesDetect Plant Diseases Using Image Processingvinayak100% (1)

- Information HandoutsDocument6 pagesInformation HandoutsPooja Marwadkar TupcheNo ratings yet

- A Sample of Directory or Instruction:: World Temperatures February 16Document1 pageA Sample of Directory or Instruction:: World Temperatures February 16eksaNo ratings yet

- A Review On Micro EncapsulationDocument5 pagesA Review On Micro EncapsulationSneha DharNo ratings yet

- CHEE319 Tutorial 4 SolnDocument13 pagesCHEE319 Tutorial 4 SolnyeshiduNo ratings yet

- DANA 6800-1 Parts ManualDocument4 pagesDANA 6800-1 Parts ManualDude manNo ratings yet

- Use DCP to Predict Soil Bearing CapacityDocument11 pagesUse DCP to Predict Soil Bearing CapacitysarvaiyahimmatNo ratings yet