Professional Documents

Culture Documents

Linear LT3590

Uploaded by

CiobanuClaudiuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Linear LT3590

Uploaded by

CiobanuClaudiuCopyright:

Available Formats

LT3590

1

3590f

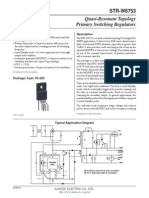

TYPICAL APPLICATION

FEATURES

APPLICATIONS

DESCRIPTION

48V Buck Mode

LED Driver in SC70

and 2mm x 2mm DFN

The LT

3590 is a xed frequency buck mode converter

specically designed to drive up to 10 LEDs in series from

a 48V DC source. Series connection of the LEDs provides

identical LED currents of up to 50mA, resulting in uniform

brightness and eliminating the need for ballast resistors.

A xed frequency, current mode architecture results in

stable operation over a wide range of input voltage and

output voltage.

The high switching frequency of 850kHz permits the use

of tiny, low prole inductors and capacitors. A single pin

performs both shutdown and accurate LED dimming

control. The power switch, Schottky diode and control

circuitry are all contained inside a space saving SC70

package or 2mm 2mm DFN package to allow a small

converter footprint and lower parts cost.

Buck Mode Driver for Ten White LEDs

4.5V to 55V Input Voltage Range

Up to 50mA LED Current

80mA, 55V Switch

Internal Schottky Diode

15A Supply Current in Shutdown

500A Supply Current Operating, Not Switching

Switching Frequency: 850kHz

200mV Feedback Voltage with 5% Accuracy

CTRL Input Performs Dimming and Shutdown

91% Efciency (10 LEDs, 50mA)

Requires Only 1F Output Capacitor

8-Lead SC70 Package

6-Lead 2mm 2mm DFN Package

LED Fixed Signage

Trafc Signs

Neon Sign Replacement

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

V

IN

48V

CONTROL CTRL

V

IN

4

50mA

LT3590

VREG SW

LED

GND

1F

0.1F

1F

3590 TA01a

470H

Conversion Efciency

LED CURRENT (mA)

0

E

F

F

I

C

I

E

N

C

Y

(

%

)

70

80

90

30 50

60

50

40

10 20 40

100

3590 TA01b

LT3590

2

3590f

ABSOLUTE MAXIMUM RATINGS

Input Voltage (V

IN

) ..................................... 0.3V to 55V

LED Voltage ............................................... 0.3V to 55V

CTRL Voltage ................................................. 0V to 6.0V

VREG Voltage ................................................. 0V to 4.0V

Operating Junction Temperature Range

(Note 2) ...............................................40C to 85C

(Note 1)

Maximum Junction Temperature........................... 125C

Storage Temperature Range ...................65C to 150C

Lead Temperature (Soldering, 10 sec)

SC 8 Package Only ............................................ 300C

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3590EDC#PBF LT3590EDC#TRPBF LCNZ 6-Lead (2mm 2mm) Plastic DFN 40C to 85C

LT3590ESC8#PBF LT3590ESC8#TRPBF LCPB 8-Lead Plastic SC70 40C to 85C

Consult LTC Marketing for parts specied with wider operating temperature ranges.

Consult LTC Marketing for information on non-standard lead based nish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specications, go to: http://www.linear.com/tapeandreel/

TOP VIEW

VREG

LED

V

IN

CTRL

GND

SW

DC PACKAGE

6-LEAD (2mm 2mm) PLASTIC DFN

4

5 7

6

3

2

1

SW 1

GND 2

GND 3

GND 4

8 V

IN

7 LED

6 VREG

5 CTRL

TOP VIEW

SC8 PACKAGE

8-LEAD PLASTIC SC70

T

JMAX

= 125C,

JA

= 75C/W TO 95C/W T

JMAX

= 125C,

JA

= 65C/W TO 85C/W,

JC

= 20C/W

EXPOSED PAD (PIN 7) IS GND, MUST BE SOLDERED TO PCB

PIN CONFIGURATION

ORDER INFORMATION

LT3590

3

3590f

ELECTRICAL CHARACTERISTICS

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LT3590E is guaranteed to meet performance specications

from 0C to 85C junction temperature. Specications over the 40C

to 85C operating junction temperature range are assured by design,

characterization and correlation with statistical process controls.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage 4.5 V

LED Current Sense Voltage (V

IN

- V

LED

) 190 200 210 mV

Sense Voltage Load Regulation I

LED

= 10mA to 50mA 5 mV

Quiescent Current ON, No Switching V

LED

= 47.7V 500 700 A

Quiescent Current in Shutdown V

CTRL

= 0V 15 20 A

Switching Frequency 650 850 1050 kHz

Maximum Duty Cycle 90 %

Switch Current Limit 80 115 150 mA

Switch V

CESAT

I

SW

= 50mA 500 mV

Switch Leakage Current V

SW

= 48V 1 2 A

V

CTRL

for Full LED Current 1.5 V

V

CTRL

to Shut Down IC 100 mV

V

CTRL

to Turn on IC 150 mV

CTRL Pin Bias Current V

CTRL

= 1V, Current Out of Pin 100 nA

LED Pin Bias Current V

LED

= 47.8V 9 14 A

LDO Voltage V

REG

I

VREG

= 1mA 3.1 3.3 3.5 V

LDO Load Regulation I

VREG

= 0mA to 1mA 17 mV

LDO Current Limit 1.5 mA

Schottky Forward Drop I

SCHOTTKY

= 50mA 0.8 V

Schottky Leakage Current V

R

= 48V 4 A

The denotes the specications which apply over the full operating

temperature range, otherwise specications are at T

A

= 25C, V

IN

= 48V, V

CTRL

= 3.3V, unless otherwise noted.

LT3590

4

3590f

SWITCH CURRENT (mA)

20

S

W

I

T

C

H

S

A

T

U

R

A

T

I

O

N

V

O

L

T

A

G

E

(

V

)

0.6

0.7

100

0.5

0.4

0.2

40 60 80

0.3

0.8

3590 G01

40C

25C

125C

SCHOTTKY FORWARD CURRENT (mA)

0

S

C

H

O

T

T

K

Y

F

O

R

W

A

R

D

D

R

O

P

(

V

)

0.8

0.9

1.0

200

0.7

0.6

0.4

50 100 150

0.5

1.2

1.1

3590 G02

40C

25C

125C

V

IN

(V)

0

10

S

H

U

T

D

O

W

N

C

U

R

R

E

N

T

(

A

)

12

14

16

18

20

10 20 30 40

3590 G03

50 60

V

CTRL

= 0V

T

A

= 25C

TEMPERATURE (C)

50

S

H

U

T

D

O

W

N

C

U

R

R

E

N

T

(

A

)

25

18

14

25 0 50

12

10

20

16

75 100 125

3590 G04

V

CTRL

= 0V

V

IN

= 48V

0

400

Q

U

I

E

S

C

E

N

T

C

U

R

R

E

N

T

(

A

)

450

500

550

600

10 20 30 40

3590 G05

50 60

V

IN

(V)

V

CTRL

= 3.3V

T

A

= 25C

TEMPERATURE (C)

50

S

C

H

O

T

T

K

Y

L

E

A

K

A

G

E

C

U

R

R

E

N

T

(

A

)

25

1.0

25 0 50

0.5

0

2.0

1.5

75 100 125

3590 G06

V

IN

= 48V

V

IN

= 24V

V

IN

= 4.5V

1s/DIV

V

SW

20V/DIV

I

L

20mA/DIV

3590 G07

V

IN

= 48V

I

LED

= 50mA

10 WHITE LEDs

L = 470H (COILCRAFT)

40s/DIV

CTRL

5V/DIV

I

LED

50mA/DIV

V

SW

50V/DIV

I

L

50mA/DIV

3590 G08

V

IN

= 48V

I

LED

= 50mA

10 BLUE LEDs

TYPICAL PERFORMANCE CHARACTERISTICS

Switch Saturation Voltage

(V

CESAT

) Schottky Forward Voltage Drop

Shutdown Quiescent

Current vs V

IN

Shutdown Quiescent Current

vs Temperature Quiescent Current Schottky Leakage Current

Switching Waveform Transient Response

LT3590

5

3590f

TYPICAL PERFORMANCE CHARACTERISTICS

Sense Voltage (V

IN

V

LED

)

vs V

CTRL

Switching Current Limit

vs Duty Cycle

Switching Current Limit

vs Temperature

Sense Voltage (V

IN

V

LED

)

vs V

IN

Sense Voltage (V

IN

V

LED

)

vs Temperature

Switching Frequency over

Temperature

Internal Regulator

Line Regulation

Internal Regulator

Load Regulation

Internal Regulator

V

REG

vs Temperature

V

CTRL

(V)

0

S

E

N

S

E

V

O

L

T

A

G

E

(

V

I

N

-

V

L

E

D

)

0.20

2

0.15

0.10

0

0.5 1 1.5

0.05

0.25

3590 G09

V

IN

= 48V

I

LED

= 50mA

T

A

= 25C

DUTY CYCLE (%)

0

120

130

140

80

110

100

20 40 60 100

90

80

150

S

W

I

T

C

H

I

N

G

C

U

R

R

E

N

T

L

I

M

I

T

(

m

A

)

3590 G10

T

A

= 25C

TEMPERATURE (C)

50

S

W

I

T

C

H

I

N

G

C

U

R

R

E

N

T

L

I

M

I

T

(

m

A

)

25

110

90

25 0 50

80

150

140

130

120

100

75 100 125

3590 G11

V

IN

(V)

0

206

204

202

200

198

196

194

30 50 10 20 40 60

V

I

N

-

V

L

E

D

(

m

V

)

3590 G12

I

LED

= 50mA

10 WHITE LEDs

T

A

= 25C

TEMPERATURE (C)

50

V

I

N

-

V

L

E

D

(

m

V

)

206

25

200

196

25 0 50

194

204

202

198

75 100 125

3590 G13

TEMPERATURE (C)

50

S

W

I

T

C

H

I

N

G

F

R

E

Q

U

E

N

C

Y

(

K

H

z

)

25

900

800

25 0 50

750

700

1000

950

850

75 100 125

3590 G14

V

IN

= 48V

V

IN

(V)

0

3.40

3.35

3.30

3.25

3.20

30 10 20 40 60 50

V

R

E

G

(

V

)

3590 G15

V

CTRL

= 3.3V

I

LOAD

= 1mA

V

CTRL

= 0V

I

LOAD

= 0V

T

A

= 25C

I

LOAD

(mA)

0

3.40

3.35

3.30

3.25

3.20

0.6 0.2 0.4 0.8 1

V

R

E

G

(

V

)

3590 G16

V

CTRL

= 0V

I

LED

= 0V

V

CTRL

= 3.3V

I

LED

= 50mA

T

A

= 25C

TEMPERATURE (C)

50

3.20

T

R

E

G

(

V

)

3.25

3.30

3.35

3.40

25 0 25 50

3590 G17

75 100 125

V

CTRL

= 3.3V

I

LOAD

= 1mA

LT3590

6

3590f

BLOCK DIAGRAM

PIN FUNCTIONS

SW (Pin 1/Pin 3): Switch Pin. Minimize trace area at this

pin to minimize EMI. Connect the inductor at this pin.

GND (Pins 2, 3, 4/Pin 2): Ground Pins. All ground pins

should be tied directly to local ground plane. Proper

soldering of these pins to the PCB ground is required to

achieve the rated thermal performance.

CTRL (Pin 5/Pin 1): Dimming and Shutdown Pin.

Connect it below 100mV to disable the switcher. As the

pin voltage is ramped from 0V to 1.5V, the feedback volt-

age (V

IN

- V

LED

) ramps from 0mV to 200mV, controlling

the LBD current.

I

V V

R

LED

IN LED

=

1

VREG (Pin 6/Pin 6): Internally Generated 3.3V Regulated

Output Pin. Must be locally bypassed with a 0.1F X5R

capacitor.

LED (Pin 7/Pin 5): Connection point for the anode of the

highest LED and the sense resistor.

V

IN

(Pin 8/Pin 4): Input Supply Pin. Must be locally by-

passed.

Exposed Pad (NA/Pin 7): Ground. The Exposed Pad

should be soldered to the PCB ground to achieve the

rated thermal performance.

(SC70/DFN)

Figure 1. Block Diagram

+

R Q

S

SW

LED

L1

470H

C3

0.1F

C2

1F

R1

6.8

V

IN

48V

C1

1F

V

OUT

V

IN

PWM

REG

VREG

RAMP

GENERATOR

850kHz

OSCILLATOR

GND CTRL

CONTROL

3590 F01

ISNS

+

+

VREF

1.25V

START-UP

CONTROL

EAMP

A = 6.25

LT3590

7

3590f

OPERATION

The LT3590 uses a constant-frequency, current mode

control scheme to provide excellent line and load regula-

tion. Operation can be best understood by referring to the

Block Diagram.

At power-up, the bandgap reference, the start-up bias, and

the regulator are turned on. If CTRL is pulled higher than

150mV, the switching converter sub-blocks including the

oscillator, the PWM comparator and the error amplier

are also turned on. At the start of each oscillator cycle,

the power switch Q1 is turned on. Current ows through

the inductor and the switch to ground, ramping up as the

switch stays on. A voltage proportional to the switch cur-

rent is added to a stabilizing ramp and the resulting sum

is fed into the positive terminal of the PWM comparator.

When this voltage exceeds the level at the negative input of

the PWM comparator, the PWM logic turns off the power

switch. The level at the negative input of the PWM com-

parator is set by the error amplier EAMP, and is simply

an amplied version of the difference between the V

IN

and

V

LED

voltage and the bandgap reference. In this manner,

the error amplier sets the correct peak current level in

inductor L1 to keep the output in regulation. The CTRL

pin is used to adjust the reference voltage.

The LT3590 enters into shutdown when CTRL is pulled

lower than 100mV.

Input Voltage Range

The minimum input voltage required to generate a particular

output voltage in an LT3590 application is limited by either

its 4.5V limit or by its maximum duty cycle. The duty cycle

is the fraction of time that the internal switch is on and is

determined by the input and output voltages:

DC

V V

V V V

LED D

IN SW D

=

+

+

Where V

D

is the forward voltage drop of the catch diode

(~0.8V) and V

SW

is the voltage drop of the internal switch

at maximum load (~0.5V). Given DC

MAX

= 0.9, this leads

to minimum input voltage of:

V

V V

DC

V V

IN MIN

LED D

MAX

SW D ( )

( )

=

+

+

The maximum input voltage is limited by the absolute

maximum V

IN

rating of 55V.

Pulse-Skipping

For LED strings with a low number of LEDs (1, 2, or 3),

the LT3590 can drive currents without pulse-skipping as

long as the voltage across the LED and sense resistor is

greater than roughly 15% of the input supply voltage. If

the LED voltage plus sense resistor is less than 15% of

the input supply, the device will begin skipping pulses.

This will result in some low frequency ripple, although

the LED current remains regulated on an average basis

down to zero.

Discontinuous Current Mode

The CTRL pin, in conjunction with the sense resistor,

can be used to program the LED current as discussed

under Applications Information. The LT3590 can drive a

10-LED string at 10mA LED current operating in continu-

ous conduction mode, using the recommended external

components shown in the front page application circuit

with the sense resistor equal to 10. As current is further

reduced, the regulator enters discontinuous conduction

mode. The photo in Figure 2 details circuit operation driving

ten LEDs at 2mA load. During the discharge phase, the

inductor current reaches zero. After the inductor current

reaches zero, the SW pin exhibits ringing due to the LC

tank circuit formed by the inductor in combination with

the switch and the diode capacitance. This ringing is not

harmful; far less spectral energy is contained in the ringing

than in the switch transitions. The ringing can be damped

by application of a 3k resistor across the inductor, al-

though this will degrade efciency.

Figure 2. Switching Waveforms

400ns/DIV

V

SW

20V/DIV

I

L

10mA/DIV

3590 F02

V

IN

= 48V

I

LED

= 2mA

10 WHITE LEDs

L = 470H (MURATA)

LT3590

8

3590f

Inductor Selection

A 220H inductor is recommended for most LT3590 ap-

plications with V

IN

< 25V and 470H is recommended for

applications with V

IN

> 25V. Although small size and high

efciency are major concerns, the inductor should have

low core losses at 850kHz and low DCR (copper wire

resistance). Several manufacturers and inductor series

that meet these criteria are listed in Table 1. The efciency

comparison of different inductors is shown in Figure 3.

Table 1. Inductor Manufacturers

VENDOR

PART

SERIES

INDUCTANCE

RANGE (H)

(RELEVANT TO

THIS PART)

DIMENSIONS

(mm)

Coilcraft

www.coilcraft.com

DO1605

LPS4012

LPS3010

1812FS

MSS5131

100 TO 680

100 TO 680

100 TO 330

100 TO 680

100 TO 390

5.4 4.2 1.8

4.0 4.0 1.2

3.0 3.0 0.9

5.1 5.1 3.1

Sumida

www.sumida.com

CDC4D20 100 TO 680 4.8 4.8 2.0

Toko

www.tokoam.com

LLQ1608

LLQ2012

100 TO 270

100 TO 680

Wrth Elektronik

www.we-online.com

WE-PD2

TYPE M

WE-PD2

TYPE L

100 TO 220

100 to 470

5.2 5.8 4.5

7.0 7.8 5.0

Coiltronics

www.cooperet.com

CTX32C 100 to 330 2.5 3.2 2.2

Murata

www.murata.com

LQH32M

LQH43M

100 to 560

100 to 680

3.2 2.5 2.0

4.5 3.2 2.0

APPLICATIONS INFORMATION

Figure 3. Efciency Comparison of Different Inductors

Capacitor Selection

The small size of ceramic capacitors make them ideal

for LT3590 applications. X5R and X7R types are recom-

mended because they retain their capacitance over wider

voltage and temperature ranges than other types such as

Y5V or Z5U. A 1F input capacitor and a 0.1F regulator

capacitor are sufcient for most applications. For the

output capacitor, 1F is generally recommended, but if

the voltage across the capacitor exceeds 10V, a 0.47F

capacitor may be used instead. For applications driving

one or two LEDs a 2.2F output capacitor is needed.

Table 2 shows a list of several ceramic capacitor manufac-

turers. Consult the manufacturers for detailed information

on their entire selection of ceramic parts.

Table 2: Recommended Ceramic Capacitor Manufacturers

Taiyo Yuden (408) 573-4150

www.t-yuden.com

AVX (803) 448-9411

www.avxcorp.com

Murata (714) 852-2001

www.murata.com

Kemet (408) 986-0424

www.kemet.com

LED CURRENT (mA)

0

92

90

88

86

84

30 10 20 40 50

E

F

F

I

C

I

E

N

C

Y

(

%

)

3590 F03

TDK SLF70145-471MR22-PF

MURATA QH32CN471K23

MURATA LQH43CN471K03

COILCRAFT LP06013-474KLB

COILCRAFT 1008PS-474KLB

COILCRAFT LPS4012-474ML

V

IN

= 48V

10 LEDs

FRONT PAGE

APPLICATION

CIRCUIT

LT3590

9

3590f

Programming LED Current

The feedback resistor (R1 in Figure 1) and the sense volt-

age (V

IN

- V

LED

) control the LED current.

I

V V

R

LED

IN LED

=

1

The CTRL pin controls the sense reference voltage as

shown in the Typical Performance Characteristics. For

CTRL higher than 1.5V, the sense reference is 200mV,

which results in full LED current. In order to have accu-

rate LED current, precision resistors are preferred (1%

is recommended). The formula and table for R1 selection

are shown below.

R

mV

I

LED

1

200

=

Table 3. R1 Theoretical Value for 200mV Sense

I

LED

(mA) R1 ()

10 20

20 10

30 6.8

40 5.0

50 4.0

Dimming Control

There are three different types of dimming control circuits.

The LED current can be set by modulating the CTRL pin

with a DC voltage, a ltered PWM signal or directly with

a PWM signal.

APPLICATIONS INFORMATION

Using a DC Voltage

For some applications, the preferred method of brightness

control is a variable DC voltage to adjust the LED current.

The CTRL pin voltage can be modulated to set the dim-

ming of the LED string. As the voltage on the CTRL pin

increases from 0V to 1.5V, the LED current increases from

0 to I

LED

. As the CTRL pin voltage increases beyond 1.5V,

it has no effect on the LED current.

The LED current can be set by:

I

LED

=

200mV

R1

,when V

CTRL

> 1.5V

I

LED

=

V

CTRL

6.25 R1

,when V

CTRL

< 1.25V

Feedback voltage variation versus control voltage is

shown in Figure 4.

Using a Filtered PWM Signal

A variable duty cycle PWM can be used to control the

brightness of the LED string. The PWM signal is ltered

(Figure 5) by a RC network and fed to the CTRL pin.

The corner frequency of R1, C1 should be much lower

than the frequency of the PWM signal. R1 needs to be

much smaller than the internal impedance in the CTRL

pin which is 100k.

Figure 4. Dimming and Shutdown Using CTRL Pin

V

CTRL

(V)

0

V

I

N

-

V

L

E

D

(

V

)

0.10

0.15

2.0

3590 F04

0.05

0

0.5 1.0 1.5

0.25

0.20

Figure 5. Dimming Control Using a Filtered PWM Signal

PWM

kHz TYP

CTRL

C1

1F

R1

10k

3590 F05

LT3590

LT3590

10

3590f

Direct PWM Dimming

Changing the forward current owing in the LEDs not only

changes the intensity of the LEDs, it also changes the color.

The chromaticity of the LEDs changes with the change in

forward current. Many applications cannot tolerate any

shift in the color of the LEDs. Controlling the intensity of

the LEDs with a direct PWM signal allows dimming of the

LEDs without changing the color. In addition, direct PWM

dimming offers a wider dimming range to the user.

Dimming the LEDs via a PWM signal essentially involves

turning the LEDs on and off at the PWM frequency. The

typical human eye has a limit of ~60 frames per second.

By increasing the PWM frequency to ~80Hz or higher,

the eye will interpret that the pulsed light source is con-

tinuously on. Additionally, by modulating the duty cycle

(amount of on-time), the intensity of the LEDs can be

controlled. The color of the LEDs remains unchanged in

this scheme since the LED current value is either zero or

a constant value.

The time it takes for the LED current to reach its pro-

grammed value sets the achievable dimming range for a

given PWM frequency. For example, the settling time of

the LED current in Figure 6 is approximately 50s for a

48V input voltage. The achievable dimming range for this

application and 100Hz PWM frequency can be determined

using the following method.

Example:

= =

= = =

100 50

1 1

100

0 01

Hz t s

t s

D

SETTLE

PERIOD

,

.

iim Range

t

t

s

s

Min

PERIOD

SETTLE

.

: = = =

0 01

50

200 1

.

Duty Cycle

t

t

s

s

SETTLE

PERIOD

= = 100

50

0 01

1000 0 5

100 0 5 100

=

=

. %

% . % Duty Cycle Range at Hz

The calculations show that for a 100Hz signal the dimming

range is 200 to 1. In addition, the minimum PWM duty

cycle of 0.5% ensures that the LED current has enough

time to settle to its nal value. Figure 7 shows the dim-

ming range achievable for three different frequencies with

a settling time of 50s.

APPLICATIONS INFORMATION

Figure 7. Dimming Range Comparison

of Three PWM Frequencies

Figure 6. Direct PWM Dimming Waveforms

I

LED

20mA/DIV

V

SW

20V/DIV

PWM

5V/DIV

V

IN

= 48V

4 LEDs

2ms/DIV

3590 F06

PWM DIMMING RANGE

1 10 100 1000

3590 F07

100Hz

10kHz

1kHz

LT3590

11

3590f

3590 F08

V

REG

V

REG

V

REG

CTRL

CTRL

C3

C2

C1

V

IN

V

IN

V

IN

LED

R1

L1

LED

OUT

SW

SW

OUT

GND

GND

GND

CTRL

GND

5

6

7

8

4

3

2

1

4

5 7

6

3

2

1

R1

L1

C3

C2

C1

CTRL

GND

V

REG

V

IN

(a) SC70 Package (b) 2mm 2mm DFN Package

Figure 8. Recommended Component Placement

APPLICATIONS INFORMATION

The dimming range can be further extended by changing

the amplitude of the PWM signal. The height of the PWM

signal sets the commanded sense voltage across the sense

resistor through the CTRL pin. In this manner both analog

dimming and direct PWM dimming extend the dimming

range for a given application. The color of the LEDs no

longer remains constant because the forward current of

the LED changes with the height of the CTRL signal. For

the ten LED application described above, the LEDs can be

dimmed rst, modulating the duty cycle of the PWM signal.

Once the minimum duty cycle is reached, the height of the

PWM signal can be decreased below 1.5V down to 150mV.

The use of both techniques together allows the average

LED current for the ten LED application to be varied from

50mA down to less than 50A.

Internal Voltage Regulator

The LT3590 has a 3.3V onboard voltage regulator capable

of sourcing up to 1mA of current for use by an external

device. This feature may be used to power-up a controller

from the LT3590. The 3.3V is available even during shut-

down. It is required to place a 0.1F capacitor from V

REG

to ground. The regulator current is limited to 1.5mA.

Board Layout Considerations

As with all switching regulators, careful attention must be

paid to the PCB board layout and component placement.

To prevent electromagnetic interference (EMI) problems,

proper layout of high frequency switching paths is essen-

tial. Minimize the length and area of all traces connected

to the switching node pin (SW). Keep the sense voltage

pins (V

IN

and LED) away from the switching node. Place

the output capacitor, C2, next to the V

IN

pin. Always use

a ground plane under the switching regulator to minimize

interplane coupling. Recommended component placement

is shown in Figure 8.

LT3590

12

3590f

48V Supply for 5 LED String, 30mA Current Conversion Efciency

TYPICAL APPLICATIONS

24V Supply for a 5 LED String, 30mA Current

V

IN

48V

CONTROL

>1.5V

L1: MURATA LQH32CN-391

CTRL

V

IN

R1

6.8

30mA

LT3590

VREG SW

LED

GND

C2

1F

C3

0.1F

C1

1F

3590 TA03a

L1

470H

V

IN

24V

CONTROL

>1.5V

L1: MURATA LQH32CN-221

CTRL

V

IN

R1

6.8

30mA

LT3590

VREG SW

LED

GND

C2

1F

C3

0.1F

C1

1F

3590 TA04a

L1

220H

48V Supply for 6 LED String, 50mA Current Conversion Efciency

V

IN

48V

CONTROL

>1.5V

L1: MURATA LQH32CN221K03

CTRL

V

IN

R1

4

6

LEDs

50mA

LT3590

VREG SW

LED

GND

C2

1F

C3

0.1F

C1

1F

3590 TA02a

L1

470H

Conversion Efciency

LED CURRENT (mA)

0

E

F

F

I

C

I

E

N

C

Y

(

%

)

70

80

90

30 50

60

50

40

10 20 40

100

3590 TA02b

LED CURRENT (mA)

0

100

90

80

70

60

50

40

15 25 5 10 20 30

E

F

F

I

C

I

E

N

C

Y

(

%

)

3590 TA03b

LED CURRENT (mA)

0

100

90

80

70

60

50

40

15 25 5 10 20 30

E

F

F

I

C

I

E

N

C

Y

(

%

)

3590 TA04b

LT3590

13

3590f

LED CURRENT (mA)

0

E

F

F

I

C

I

E

N

C

Y

(

%

)

55

60

65

30 50

50

45

40

10 20 40

70

75

80

3590 TA05b

12V

24V

Conversion Efciency

TYPICAL APPLICATIONS

V

IN

12V OR 24V

CONTROL

>1.5V

CTRL

V

IN

R1

4

50mA

LT3590

VREG SW

LED

GND

C2

2.2F

C3

0.1F

C1

1F

3590 TA05a

L1

220H

12V or 24V Supply for a Single LED, 50mA Current

Conversion Efciency 48V Supply for Two Strings of 10 LEDs, 25mA Current

V

IN

48V

CONTROL

>1.5V

CTRL

V

IN

R1

4

25mA

LT3590

VREG SW

LED

GND

C2

1F

C3

0.1F

C1

1F

3590 TA06a

L1

470H

25mA

Conversion Efciency 12V Supply for a 3 LED String, 50mA Current

V

IN

12V

CONTROL

>1.5V

L1: MURATA LQH32CN-221

CTRL

V

IN

R1

4

50mA

LT3590

VREG SW

LED

GND

C2

1F

C3

0.1F

C1

1F

3590 TA07a

L1

220H

LED CURRENT (mA)

0

40

E

F

F

E

C

I

E

N

C

Y

(

%

)

50

60

70

80

90

100

5 10 15 20

3590 TA06b

25

LED CURRENT (mA)

0

E

F

F

I

C

I

E

N

C

Y

(

%

)

70

80

90

30 50

60

50

40

10 20 40

100

3590 TA07b

LT3590

14

3590f

PACKAGE DESCRIPTION

DC Package

6-Lead Plastic DFN (2mm 2mm)

(Reference LTC DWG # 05-08-1703)

2.00 0.10

(4 SIDES)

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WCCD-2)

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

0.38 0.05

BOTTOM VIEWEXPOSED PAD

0.56 0.05

(2 SIDES)

0.75 0.05

R = 0.115

TYP

1.37 0.05

(2 SIDES)

1 3

6 4

PIN 1 BAR

TOP MARK

(SEE NOTE 6)

0.200 REF

0.00 0.05

(DC6) DFN 1103

0.25 0.05

1.42 0.05

(2 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

0.61 0.05

(2 SIDES)

1.15 0.05

0.675 0.05

2.50 0.05

PACKAGE

OUTLINE

0.25 0.05

0.50 BSC

0.50 BSC

PIN 1

CHAMFER OF

EXPOSED PAD

LT3590

15

3590f

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representa-

tion that the interconnection of its circuits as described herein will not infringe on existing patent rights.

PACKAGE DESCRIPTION

SC8 Package

8-Lead Plastic SC70

(Reference LTC DWG # 05-08-1639 Rev )

1.15 1.35

(NOTE 4)

1.80 2.40

0.15 0.27

8 PLCS (NOTE 3)

SC8 SC70 0905 REV

1.80 2.20

(NOTE 4)

0.50 BSC

PIN 1

PIN 8

0.80 1.00

1.00 MAX

0.00 0.10

REF

NOTE:

1. DIMENSIONS ARE IN MILLIMETERS

2. DRAWING NOT TO SCALE

3. DIMENSIONS ARE INCLUSIVE OF PLATING

4. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH

AND METAL BURR

5. MOLD FLASH SHALL NOT EXCEED 0.254mm

6. DETAILS OF THE PIN 1 IDENTIFIER ARE OPTIONAL,

BUT MUST BE LOCATED WITHIN THE INDEX AREA

7. EIAJ PACKAGE REFERENCE IS EIAJ SC-70 AND JEDEC MO-203

VARIATION BA

2.8 BSC

0.30

MAX

0.50

REF

RECOMMENDED SOLDER PAD LAYOUT

PER IPC CALCULATOR

1.8 REF

1.00 REF

INDEX AREA

(NOTE 6)

0.10 0.18

(NOTE 3)

0.26 0.46

GAUGE PLANE

0.15 BSC

0.10 0.40

LT3590

16

3590f

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

FAX: (408) 434-0507

www.linear.com LINEAR TECHNOLOGY CORPORATION 2007

LT 0707 PRINTED IN USA

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1932 Constant Current, 1.2MHz, High Efciency White LED Boost

Regulator

V

IN

: 1.0V to 10.0V, V

OUT(MAX)

= 34V, Dimming Analog/PWM,

I

SD

< 1A, ThinSOT Package

LT3003 Three Channel LED Ballaster with PWM Dimming V

IN

: 3.0V to 48.0V, Dimming 3,000:1 True Color PWM,

I

SD

<5A, MSOP-10 Package

LT3465/A Constant Current, 1.2/2.7MHz, High Efciency White LED Boost

Regulator with Integrated Schottky Diode

V

IN

: 2.7V to 16.0V, V

OUT(MAX)

= 34V, Dimming Analog/PWM,

I

SD

<1A, ThinSOT Package

LT3466/-1 Dual Constant Current, 2MHz, High Efciency White LED Boost

Regulator with Integrated Schottky Diode

V

IN

: 2.7V to 24.0V, V

OUT(MAX)

= 40V, Dimming 5mA, I

SD

<16A,

3mm 3mm DFN-10

LT3474 36V, 1A (I

LED

), 2MHz,Step-Down LED Driver V

IN

: 4.0V to 36V, V

OUT(MAX)

= 13.5V, Dimming 400:1 True Color

PWM, I

SD

<1A, TSSOP16E Package

LT3475 Dual 1.5A(I

LED

), 36V, 2MHz, Step-Down LED Driver V

IN

: 4.0V to 36V, V

OUT(MAX)

= 13.5V, Dimming 3,000:1 True Color

PWM, I

SD

<1A, TSSOP20E Package

LT3476 Quad Output 1.5A, 2MHz High Current LED Driver with 1,000:1

Dimming

V

IN

: 2.8V to 16.0V, V

OUT(MAX)

= 36.0V, Dimming 1,000:1 True

Color PWM, I

SD

<10A, 5mm 7mm QFN-10

LT3478/-1 4.5A, 2MHz High Current LED Driver with 3,000:1 Dimming V

IN

: 2.8V to 36.0V, V

OUT(MAX)

= 40.0V, Dimming 1,000:1 True

Color PWM, I

SD

<10A, 5mm 7mm QFN-10

LT3486 Dual 1.3A, 2MHz High Current LED Driver V

IN

: 2.5V to 24.0V, V

OUT(MAX)

= 36.0V, Dimming 1,000:1 True

Color PWM, I

SD

<1A, 5mm 3mm DFN, TSSOP-16E Package

LT3491 Constant Current, 2.3MHz, High Efciency White LED Boost

Regulator with Integrated Schottky Diode

V

IN

: 2.5V to 12.0V, V

OUT(MAX)

= 27V, Dimming 300:1 True Color

PWM, I

SD

<8A, 2mm 2mm DFN-6, SC70 Package

LT3496 Triple Output 750mA, 2.1 MHz High Current LED Driver with 3,000:1

Dimming

V

IN

: 3.0V to 30.0V, V

OUT(MAX)

= 40.0, Dimming 3,000:1 True

Color PWM, I

SD

<1A, 4mm 5mm QFN-28

LT3497 Dual 2.3MHz, Full Function LED Driver with Integrated Schottkys and

250:1 True Color PWM Dimming

V

IN

: 2.5V to 10.0V, V

OUT(MAX)

= 32, Dimming 250:1 True Color

PWM, I

SD

<12A, 2mm 3mm DFN-10

LT3498 20mA LED Driver and OLED Driver Integrated Schottkys V

IN

: 2.5 to 12.0V, V

OUT(MAX)

= 32, Dimming Analog/PWM,

I

SD

<8.5A, 2mm 3mm DFN-12

LT3517 1.3A, 2.5MHz High Current LED Driver with 3,000:1 Dimming V

IN

: 3.0V to 30.0V, Dimming 3,000:1 True Color PWM, I

SD

<1A,

4mm 4mm QFN-16

LT3518 2.3A, 2.5MHz High Current LED Driver with 3,000:1 Dimming V

IN

: 3.0V to 30.0V, Dimming 3,000:1 True Color PWM, I

SD

<1A,

4mm 4mm QFN-16

LT3591 Constant Current, 1MHz, High Efciency White LED Boost Regulator

with Integrated Schottky Diode and 80:1 True Color PWM Dimming

V

IN

: 2.5V to 12.0V, V

OUT(MAX)

= 40, Dimming 80:1 True Color

PWM, I

SD

<9A, 2mm 3mm DFN-8

ThinSOT and True Color PWM are trademarks of Linear Technology Corporation.

TYPICAL APPLICATION

24V Supply for 6 LED String, 50mA Current Conversion Efciency

V

IN

24V

CONTROL

>1.5V

L1: MURATA LQH32CN-221

CTRL

V

IN

R1

4

50mA

LT3590

VREG SW

LED

GND

C2

1F

C3

0.1F

C1

1F

3590 TA08a

L1

220H

LED CURRENT (mA)

0

E

F

F

I

C

I

E

N

C

Y

(

%

)

75

80

85

30 50

70

65

60

10 20 40

90

95

100

3590 TA08b

You might also like

- 3685 FBDocument24 pages3685 FBPravin MevadaNo ratings yet

- Isolated Flyback Switching Regulator W - 9V OutputDocument16 pagesIsolated Flyback Switching Regulator W - 9V OutputCasey DialNo ratings yet

- 3490fa-Single Cell 350ma LED DriverDocument12 pages3490fa-Single Cell 350ma LED DrivernevdullNo ratings yet

- LM350 DatasheetDocument12 pagesLM350 DatasheetOmarVelasquezC.No ratings yet

- Transition-Mode PFC Controller: 1 FeaturesDocument17 pagesTransition-Mode PFC Controller: 1 Featuresadriancho66No ratings yet

- Document - SG3525A DDocument10 pagesDocument - SG3525A Donlinerahul823405No ratings yet

- EN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated InductorDocument16 pagesEN5322QI: 2 A Voltage Mode Synchronous Buck PWM DC-DC Converter With Integrated Inductorcatsoithahuong84No ratings yet

- 375612fb PDFDocument24 pages375612fb PDFAbood AliNo ratings yet

- Driver Bobina de Encendido VB326SPDocument9 pagesDriver Bobina de Encendido VB326SPteroplasNo ratings yet

- 105k 250v CeramicDocument20 pages105k 250v CeramicOVALLEPANo ratings yet

- L 6565Document17 pagesL 6565tatatabuchoNo ratings yet

- ADP3338 Data SheetsDocument16 pagesADP3338 Data SheetstarpinoNo ratings yet

- FaDocument20 pagesFaVishwanath ShervegarNo ratings yet

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDocument10 pagesNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) : High Voltage Ignition Coil Driver Power I.CDocument9 pagesObsolete Product(s) - Obsolete Product(s) : High Voltage Ignition Coil Driver Power I.CFer NandoNo ratings yet

- LTC 1625Document24 pagesLTC 1625Sakura KunNo ratings yet

- LM78L15ADocument12 pagesLM78L15ALêĐìnhDanhNo ratings yet

- LM3530 High Efficiency White LED Driver With Programmable Ambient Light Sensing Capability and I C-Compatible InterfaceDocument45 pagesLM3530 High Efficiency White LED Driver With Programmable Ambient Light Sensing Capability and I C-Compatible Interfacethoth2487No ratings yet

- VND 7 N 04Document30 pagesVND 7 N 04Juan Guillermo MansillaNo ratings yet

- STR W6753 DatasheetDocument8 pagesSTR W6753 DatasheetjgerabmNo ratings yet

- STR W6735Document14 pagesSTR W6735proctepNo ratings yet

- Quad Low Side Driver: DescriptionDocument17 pagesQuad Low Side Driver: DescriptionDan EsentherNo ratings yet

- MP1542 r1.5Document11 pagesMP1542 r1.5Joshua KochNo ratings yet

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6735Document13 pagesQuasi-Resonant Topology Primary Switching Regulators: STR-W6735perro sNo ratings yet

- 8205Document16 pages8205sonytinNo ratings yet

- L5970DDocument10 pagesL5970Droozbehxox100% (1)

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6756Document8 pagesQuasi-Resonant Topology Primary Switching Regulators: STR-W6756perro sNo ratings yet

- Microstepping DMOS Driver With Translator: Description Features and BenefitsDocument18 pagesMicrostepping DMOS Driver With Translator: Description Features and BenefitsSaid BoubkerNo ratings yet

- LT 3693Document24 pagesLT 3693Zoltán BaranyaiNo ratings yet

- DC-DC Converter Controller Technical OverviewDocument9 pagesDC-DC Converter Controller Technical OverviewMick NimalNo ratings yet

- Boost Controller With Power Factor CorrectionDocument14 pagesBoost Controller With Power Factor CorrectionChiseledPrawnNo ratings yet

- Distributed byDocument42 pagesDistributed bydennyjoelNo ratings yet

- LCD221SD Service ManualDocument41 pagesLCD221SD Service Manual1cvbnmNo ratings yet

- Low Power Dual Operational Amplifiers Az358/358CDocument13 pagesLow Power Dual Operational Amplifiers Az358/358CMarissa ValdezNo ratings yet

- Single Synchronous Buck PWM DC-DC ControllerDocument16 pagesSingle Synchronous Buck PWM DC-DC Controllerbachet56No ratings yet

- 5V-0.5A Very Low Drop Regulator With Reset: DescriptionDocument6 pages5V-0.5A Very Low Drop Regulator With Reset: DescriptionDan EsentherNo ratings yet

- Datasheet STR 6757Document11 pagesDatasheet STR 6757Walter CarreroNo ratings yet

- Features Description: LTC3810 100V Current Mode Synchronous Switching Regulator ControllerDocument38 pagesFeatures Description: LTC3810 100V Current Mode Synchronous Switching Regulator ControllerCenkGezmişNo ratings yet

- LD7523 DS 00Document18 pagesLD7523 DS 00Eduardo LaloNo ratings yet

- VumetroDocument28 pagesVumetroJavier Gallegos IbarraNo ratings yet

- AZ324Document10 pagesAZ324Franklim Miranda Dos SantosNo ratings yet

- Thb7128 InstructionsDocument9 pagesThb7128 InstructionsanhxcoNo ratings yet

- Features Description: LTC3522 Synchronous 400ma Buck-Boost and 200ma Buck ConvertersDocument20 pagesFeatures Description: LTC3522 Synchronous 400ma Buck-Boost and 200ma Buck ConvertersCop RaptiNo ratings yet

- S Feature D Escriptio: LTC1255 Dual 24V High-Side MOSFET DriverDocument16 pagesS Feature D Escriptio: LTC1255 Dual 24V High-Side MOSFET DriverMuhammed AsimNo ratings yet

- LM2727/LM2737 N-Channel FET Synchronous Buck Regulator Controller For Low Output VoltagesDocument22 pagesLM2727/LM2737 N-Channel FET Synchronous Buck Regulator Controller For Low Output VoltagesselocaNo ratings yet

- Jameco Part Number 51182NSC: Distributed byDocument13 pagesJameco Part Number 51182NSC: Distributed byHimanshuDixitNo ratings yet

- Data SheetDocument7 pagesData Sheetitamar_123No ratings yet

- 700ma H V A C R W E C: IGH Oltage Djustable Urrent Egulator ITH Nable OntrolDocument6 pages700ma H V A C R W E C: IGH Oltage Djustable Urrent Egulator ITH Nable OntrolNathan WilliamsNo ratings yet

- LTC1073fa DatasheetDocument16 pagesLTC1073fa DatasheetKushal KshirsagarNo ratings yet

- LM 3914 Data SheetDocument29 pagesLM 3914 Data SheetWalter RiveroNo ratings yet

- 12V DC To 40V DC Converter Circuit DiagramDocument10 pages12V DC To 40V DC Converter Circuit DiagramAhdiat Darmawan LubisNo ratings yet

- 8051 SchematicDocument37 pages8051 SchematicShabeeb Ali OruvangaraNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- FAN5622 / FAN5624 / FAN5626 Linear LED Drivers With Single-Wire Digital InterfaceDocument13 pagesFAN5622 / FAN5624 / FAN5626 Linear LED Drivers With Single-Wire Digital InterfaceCiobanuClaudiuNo ratings yet

- O Led Technology o Led TechnologyDocument34 pagesO Led Technology o Led TechnologyCiobanuClaudiuNo ratings yet

- Display Technology OverviewDocument37 pagesDisplay Technology OverviewAlessandro ArientiNo ratings yet

- Organic Light-Emitting Diode (OLED) Technology: Materials, Devices and Display TechnologiesDocument11 pagesOrganic Light-Emitting Diode (OLED) Technology: Materials, Devices and Display TechnologiesZayid Mohammed UNo ratings yet

- 11 Leo Novaled TU DresdenDocument23 pages11 Leo Novaled TU DresdenCiobanuClaudiuNo ratings yet

- RICS New Rules of Detailed MeasurementDocument6 pagesRICS New Rules of Detailed MeasurementmkjailaniNo ratings yet

- Pran Lukas TDocument2 pagesPran Lukas TmisanthropoNo ratings yet

- (Prelim 1ST Lesson) Fundamentals in Food Service OperationsDocument30 pages(Prelim 1ST Lesson) Fundamentals in Food Service OperationsLiza MaryNo ratings yet

- Learn Enough Custom DomainsDocument139 pagesLearn Enough Custom DomainsRenan VieiraNo ratings yet

- Secret Tips For WhatsappDocument2 pagesSecret Tips For WhatsapppalapyeNo ratings yet

- Survey Report For Lasho & Loikaw Hospital ProjectDocument288 pagesSurvey Report For Lasho & Loikaw Hospital Projectlwin_oo2435No ratings yet

- Five Approaches To Organizational DesignDocument6 pagesFive Approaches To Organizational DesignDolly ParhawkNo ratings yet

- Consumer Protection Act Conclusion and SuggestionsDocument13 pagesConsumer Protection Act Conclusion and SuggestionsDevesh Antil0% (6)

- Environmental Pollution Analysis and Prediction of Influential Factors: A Data-Driven InvestigationDocument14 pagesEnvironmental Pollution Analysis and Prediction of Influential Factors: A Data-Driven InvestigationIJAR JOURNALNo ratings yet

- Infante v Aran Builders Venue DisputeDocument3 pagesInfante v Aran Builders Venue DisputedingNo ratings yet

- Web Engineering Coursework Assignment - UK University BSC Final YearDocument11 pagesWeb Engineering Coursework Assignment - UK University BSC Final YearTDiscoverNo ratings yet

- BP Golden Rules of SafetyDocument10 pagesBP Golden Rules of SafetyAzad Namazov100% (1)

- 3.C Redesigning Poverty Alleviation Organization in Kendari TurnitinDocument14 pages3.C Redesigning Poverty Alleviation Organization in Kendari Turnitinzen dartNo ratings yet

- Bus Ethics Soc Res Q3 M1Document16 pagesBus Ethics Soc Res Q3 M1William Arnold RañosaNo ratings yet

- Mid Term 2 Fall 2014Document1 pageMid Term 2 Fall 2014Mahmoud Ahmed TawfikNo ratings yet

- Tems Investigation 9.0.4 Devices-4-1Document8 pagesTems Investigation 9.0.4 Devices-4-1dilligas1234No ratings yet

- 1 ZzfeDocument8 pages1 ZzfeScuderia Redin100% (1)

- SDWP 046Document47 pagesSDWP 046Marius AngaraNo ratings yet

- Black BookDocument9 pagesBlack Book148 Kanchan SasaneNo ratings yet

- Report On RERA ImpactsDocument30 pagesReport On RERA ImpactsEmperor MinatiNo ratings yet

- DIN-8SW8: Crestron Green Light™ DIN Rail High-Voltage Switch Operations & Installation GuideDocument32 pagesDIN-8SW8: Crestron Green Light™ DIN Rail High-Voltage Switch Operations & Installation Guidewid ndoNo ratings yet

- The Interaction Between Public and Private International Law Some New Trends Gautam Narasimhan William V JohnDocument14 pagesThe Interaction Between Public and Private International Law Some New Trends Gautam Narasimhan William V Johnsyuhada fadilahNo ratings yet

- HRM HeinzDocument14 pagesHRM HeinzAkshay TyagiNo ratings yet

- Sample Complaint Letter Bank Fees IIDocument2 pagesSample Complaint Letter Bank Fees IIRoshan Khan100% (1)

- Lom LogDocument47 pagesLom LogMarlon CameyNo ratings yet

- 2018 Book KnowledgeManagementInTheSharin PDFDocument290 pages2018 Book KnowledgeManagementInTheSharin PDF16803244No ratings yet

- ANIMOMETERDocument2 pagesANIMOMETERKarthikeyan VisvakNo ratings yet

- Is-3961 - 5 Recommended Current Ratings For CableDocument15 pagesIs-3961 - 5 Recommended Current Ratings For Cablemailbkrao100% (2)

- Or2016 s07 Transportation Problem Pt1 HandoutDocument26 pagesOr2016 s07 Transportation Problem Pt1 HandoutAnonymous M4AFjrPhuNo ratings yet

- International Business Trade Lesson 1Document25 pagesInternational Business Trade Lesson 1Kristen IjacoNo ratings yet