Professional Documents

Culture Documents

Small Project Part 4 Minimum Materials, Engineering and Construction Requirements

Uploaded by

Poppe Musa0 ratings0% found this document useful (0 votes)

154 views43 pagesThis document provides minimum requirements for materials, engineering, and construction for a small project. It requires the contractor to meet or exceed all minimum standards and comply with applicable codes and regulations. Recycled materials are encouraged where possible. Performance testing will be conducted to verify construction and system performance meet requirements. The contractor must provide final design drawings incorporating geotechnical data and noting allowable soil bearing capacities.

Original Description:

guide

Original Title

Small Project

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides minimum requirements for materials, engineering, and construction for a small project. It requires the contractor to meet or exceed all minimum standards and comply with applicable codes and regulations. Recycled materials are encouraged where possible. Performance testing will be conducted to verify construction and system performance meet requirements. The contractor must provide final design drawings incorporating geotechnical data and noting allowable soil bearing capacities.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

154 views43 pagesSmall Project Part 4 Minimum Materials, Engineering and Construction Requirements

Uploaded by

Poppe MusaThis document provides minimum requirements for materials, engineering, and construction for a small project. It requires the contractor to meet or exceed all minimum standards and comply with applicable codes and regulations. Recycled materials are encouraged where possible. Performance testing will be conducted to verify construction and system performance meet requirements. The contractor must provide final design drawings incorporating geotechnical data and noting allowable soil bearing capacities.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 43

Small Project Part 4

Minimum Materials, Engineering and Construction Requirements

05/11

1. GENERAL RE!"REMEN#S: The requirements indicated here are minimum performance

requirements. More specific project functional and performance requirements, scope items and expected

quality levels over and aove the standards in !art " are identified in !art # of the $equest for !roposal

or %asic &rderin' ('reement. The )ontractor is encoura'ed to exceed the minimum requirements. The

)ontractor*s performance evaluation +ill e ased in part on enhancements to materials, en'ineerin',

desi'n and construction provided for the contract that exceed minimum requirements.

!art " is a 'eneral section. ,ot all items in !art " +ill e required for this project. -ee !art # for project.

specific requirements. -ee /&rder of !recedence0 para'raph in !art 1 for relationships et+een all parts

of the $2!.

3n 'eneral, unless other+ise indicated, )ontractor shall provide all laor, equipment and materials

necessary to complete the +or4 required for the contract. (ll +or4 shall e in conformance +ith all

applicale referenced criteria, construction standards, la+s and re'ulations, includin' applicale uildin'

and fire, life safety codes.

Rec$cled Materials Considerations%

(n (ffirmative !rocurement !ro'ram has een estalished +ithin the 2ederal 'overnment to

promote the purchase of products containin' recovered materials. This pro'ram promotes the

purchase of products containin' materials recovered from the solid +aste stream. The intent is to

conserve resources and reduce solid +aste y developin' mar4ets for recycled products and

encoura'in' manufacturers to produce quality recycled content products. The contractors shall

use products that meet or exceed the 5!( 'uideline standards for recovered content as required

y the 2ederal (cquisition $e'ulations 62($7. (vailaility lists of manufacturers and 5!(

research on product usa'e are on the )onstruction )riteria %ase 6))%7 at http://+++.cc.or'

under 8ocuments 9irary, ,(:2() )riteria. ( partial list of products containin' recycled

materials for possile use is as follo+s:

$oc4 ;ool 3nsulation

2ier'lass 3nsulation

)ellulose 3nsulation

-tructural 2ieroard and 9aminated !aperoard

)ement and )oncrete . )oal 2ly (sh

)arpet includin' ac4in's and cushions

2loor Tiles

$eprocessed and )onsolidated 9atex !aint.

1.1 MA#ER"ALS AN& ME#'(&S () C(NS#R!C#"(N. &nly ne+ materials and equipment shall e

installed in the +or4. (ll materials, equipment and appliances shall e of the current manufacturers*

products. ,o osolete or discontinued materials, equipment and appliances shall e used, except that

construction materials containin' recycled content as descried in !ara'raph 1 of this !art that

completely comply +ith all materials specifications found else+here in this !art may e used.

-mall !roject !art " . !a'e 1 of "#

1.* APPL"CA+LE C(&ES AN& S#AN&AR&S:

The desi'n and construction shall e in accordance +ith estalished construction practices, and the latest

revision/edition of the follo+in' referenced codes and standards. The term <9atest $evision/5dition< is

defined as the version as of the project a+ard date. $eferences are availale at +++.+d'.or'/ndm/.

The advisory provisions of all codes and standards shall e mandatory, as thou'h the +ord /shall0 had

een sustituted for /should0 +herever it appears. $eference to the /authority havin' jurisdiction0 shall e

construed to mean /)ontractin' &fficer0. )omply +ith the required and advisory portions of the current

edition of the standard at the time of contract a+ard. =2) 1.100.01, General Building Requirements is

the uildin' code 'uide and contains references to other =2)s and )odes that are to e used for all

sections in this contract. =2) 1.#00.0>,, Design Procedures, provides desi'n 'uidance and contains

references to other =2)s and )odes that are to e used for all sections in this contract.

1. =nified 2acilities )riteria 6=2)7 1.100.01, General Building Requirements

1. =2) 1.#00.0>,, Design Procedures

#. (merican ?as (ssociation 6(?(7.

". (ssociated (ir %alance )ouncil 6((%)7

5. ,ational 5nvironmental %alancin' %ureau 6,55%7

@. 3nternational Mechanical )ode 63M)7.

A. (merican -ociety of Beatin', $efri'eration, and (ir )onditionin' 5n'ineers 6(-B$(57

-tandards

C. -heet Metal and (ir )onditionin' )ontractors ,ational (ssociation 6-M(),(7

'uidelines.

>. 3nternational !lumin' )ode 63!)7.

10. 3lluminatin' 5n'ineerin' -ociety ,orth (merica 635-,(7 Bandoo4

11. ,ational 5lectrical Manufacturers (ssociation 6,5M(7.

11. 5lectronic 3ndustries (lliance 653(7

1#. Telecommunications 3ndustry (ssociation 6T3(7

1". (merican ;ood+or4 3nstitute

15. (rchitectural ;ood+or4 3nstitute

1@. (!( D The 5n'ineered ;ood (ssociation.

1A. -teel 8oor 3nstitute 6-837.

1C. (merican (luminum Manufacturers (ssociation 6((M(7

1>. ,ational ;ood ;indo+ and 8oor (ssociation 6,;;8(7.

20. NRCA, Roofing and Waterproofing Manual found at

http://www.nrca.net/rp/technical/manual/manual.aspx

11. (merican Bard+are (ssociation 6(B(7.

11. %uildin' Bard+are Manufacturers (ssociation 6%BM(7.

1#. 2ederal, -tate, )ounty, and local environmental re'ulations.

1". (-B$(5 -td. >0.1, Energy Standards for Buildings Except Low Rise Residential

Buildings

15. (merican -ociety of Testin' and Materials 6(-TM7

1@. (merican ;ater ;or4s (ssociation 6(;;(7

1A. ,ational 2ire !rotection (ssociation 6,2!(7 )odes and -tandards

1C. 3555 )1, National Electrical Safety Code

1., L(CA#"(N-SPEC")"C C(&ES AN& S#AN&AR&S% -ee !art #

1.4 &"SCREPANC"ES: ;hen discrepancies in the referenced standards and the contract requirements

occur, the more strin'ent requirements shall 'overn. The +ord /should0 in all ,2!( pulications shall e

interpreted as a requirement. The (uthority Bavin' Eurisdiction in the interpretation of the codes and

standards, and approvin' the exceptions allo+ed in the referenced standards, shall e the )ontractin'

&fficer, and the parties desi'nated y the )ontractin' &fficer.

-mall !roject !art " . !a'e 1 of "#

*. PER)(RMANCE #EC'N"CAL SPEC")"CA#"(NS

,ote: The para'raph numers used correspond +ith the numers used in =,32&$M(T 33/;or4

%rea4do+n -tructures 6;%-7 as listed in the ;hole %uildin' 8esi'n ?uide, ,avy 8esi'n %uild Master,

accessile at this +esite: +++.+d'.or'/ndm.

SECTION A. SUBSTRUCTURE

A10 FOUNDATION

2oundations shall e reinforced concrete slas.on.'rade +ith continuous strip footin's or isolated

spread footin's. )oncrete slas shall not e less than " inches in thic4ness and footin's shall not e

less than 1C inches elo+ the lo+est adjacent 'rade. 2oundations shall e desi'ned and constructed

of reinforced concrete. (ll desi'n and construction shall comply +ith 3%) and +ith applicale

requirements in -ection % -hell. 2or the purposes of interpretin' 3%) )hapter 1C, the /&+ner0 and

/%uildin' &fficial0 shall mean the /?overnment0, and the /(pplicant0 shall mean the

/)ontractor/8esi'ner of $ecord0.

1. Contractor-)oundation &esign% The 8esi'ner of $ecord shall evaluate the $2! data, and

otain and evaluate all additional data as required to support the desi'n and construction.

*. Geotec.nical Site &ata required in &esign &ra/ings% The )ontractorFs final desi'n dra+in's

shall include:

a. ,otes identifyin' the soil allo+ale earin' capacity used in desi'n.

. -usurface soil information, e it ?overnment provided or )ontractor otained, that

represents susurface conditions existin' on the project site 6such as orin' lo's, test pits,

laoratory test results and 'round+ater oservations7. The locations of all orin's shall e

indicated on the dra+in's.

,. Per0ormance 1eri0ication and Acce2tance #esting% :erification of satisfactory construction

and system performance shall e via !erformance :erification Testin', as detailed in this part of

the $2!.

a.Eart./or3% !erform quality assurance for earth+or4 in accordance +ith 3%) )hapter 1A.

-ee -ection ?10#0.

SECTION B. SHELL

%uildin' shell may e of any materials and desi'n allo+ed y applicale codes and standards,

suject to specific requirements that may e applicale to a particular (ctivity, such as the %ase

5xterior (rchitecture !lan 6%5(!7 and =2) ".010.01.

B10 SUPERSTRUCTURES

-uperstructure +or4 includes structural frames, earin' +alls, floors, roofs, roof canopies, and

alcony construction. =nless other+ise specified in !art #, superstructures may e desi'ned and

constructed usin' any materials or comination of different materials allo+ed y applicale codes and

standards. (ll desi'n and construction shall comply +ith 3%). -pecial inspection, testin', approvals,

certifications, oservations and quality assurance plans as prescried in )hapter 1A of the 3%) are

required.

-mall !roject !art " . !a'e # of "#

1. Concrete% (ll concrete shall e constructed in accordance +ith ()3 #01. )oncrete shall have a

1C.day minimum compressive stren'th of #,000 psi. -lump shall e et+een 1 and " inches in

accordance +ith (-TM )1"#. !rovide joints as required to minimiGe crac4in'. (ll concrete shall

e reinforced. !rovide joints as required y applicale ()3 standards. =nless other+ise specified

in !art # or as indicated y the contractin' officer, provide steel tro+el finish for all exposed floor

surfaces.

4. Masonr$%

.(ll concrete masonry shall e constructed in accordance +ith ()3 5#0.1. )oncrete

masonry shall have a minimum 1C.day compressive stren'th of 1500 psi. )oncrete masonry

units shall conform to (-TM )>0, 'rade (1. %ro4en loc4s are not allo+ed. =se only

standard siGe and shape loc4s. %loc4 may e cut +hen necessary. Mortar shall e Type -.

c. ;hen used, ric4 shall conform to (-TM )11@. 3n exposed construction, ro4en ric4 shall

not e allo+ed. -tandard siGe ric4 may e cut to fit jo condition. =se Type - mortar.

d.!rovide metal anchors for masonry and ric4, includin' veneer construction as required y

3%).

4. Structural Steel% -tructural steel exposed to +eatherin' shall e adequately protected to

prevent corrosion.

5. Steel dec3% -teel form dec4 shall have a ?>0 'alvaniGed finish, and must have a minimum 1@.

'a'e thic4ness. (ll other steel dec4 shall have a ?>0 'alvaniGed finish, and must have a

minimum 10.'a'e thic4ness.

6. Cold-0ormed metal 0raming% )old.formed steel studs, joists and trac4 shall e 'alvaniGed +ith a

minimum thic4ness of 10.'a'e.

7. 8ood 0raming% ;ood framin' memers shall e ne+ lumer, unless other+ise allo+ed y !art

#. Timer can e 8ou'las 2ir, 8ou'las 2ir.9arch, Bem.2ir, -outhern !ine or other structurally

competent species allo+ed y applicale codes and standards. ;ood framin' shall meet the

follo+in' minimum 'radin' requirements:

e.-tuds . H#

f. Eoists and rafters. H1

'.%eams, "x and lar'er . H1

h.!osts, "x and lar'er . H1

i. %loc4in' . H#

j. 2ascia, trim . H1

4. ;ood -tructural !anel -heathin' 65xterior ?lue7

l. $oof . (!( rated +ith span index of 1"/0 D minimum thic4ness I inch

m. ;alls . (!( rated +ith span index of #1/1@ D minimum thic4ness I inch

n.2loorin'. (!( rated +ith span index of "C/1" D minimum thic4ness #/" inch

B20 EXTERIOR ENCLOSURE

B2010 EXTERIOR WALLS

1. E9terior 8all Per0ormance%

o.1a2or #ransmission Anal$sis% !erform a jo specific vapor transmission analysis in

accordance +ith (-B$(5 >0.1 or ;=23. The conclusion of the analysis shall indicate the

-mall !roject !art " . !a'e " of "#

appropriate locations of needed vapor retarders, air arriers, and anticipated de+.point

locations in the exterior enclosure durin' different critical times of the year.

p.Ma9imum Air "n0iltration% The maximum allo+ale air lea4a'e for any material used as

part of the air arrier system for the opaque enclosure shall e 0.01 9/s/MJ K A5 !a

6liters/second per square meter at A5 !a pressure7 L0.00" cfm / sf at 1.5A psfM, as tested

accordin' to (-TM 5 11AC test protocol.

q.8ind Loads% !rovide +ind load calculations for exterior claddin' in accordance +ith

(-)5.A +ith comparative analysis of the claddin' system to e provided.

r. 8ater Penetration% ,o +ater penetration shall occur at a pressure of #> N'/m

1

6C psf7 of

fixed area +hen tested in accordance +ith (-TM 5 ##1.

s. "nsulating 1alue% The complete +all system shall have a minimum insulatin' value as

required y the uildin' code and as required to meet (-B$(5 -tandard >0.1 as modified y

the 5ner'y !olicy (ct of 1005.

:. Masonr$ 1eneer E9terior 8all Closure Com2onents% Masonry veneer shall include load

earin' and non.load earin' exterior +alls of the structure, and shall include colored mortar,

special shapes such as sills, headers, trim units and copin's of ric4 masonry, precast concrete,

concrete masonry units, or other approved material. =tiliGe %3( Technical ,otes to desi'n, detail,

and construct ric4 masonry +alls. -ustitute directive lan'ua'e in the place of %3( su''estive

lan'ua'e. The results of these +ordin' sustitutions chan'e this document to required

procedures. The veneer shall e tied to the ac4up +all system +ith a system that allo+s the

veneer to move independently of the ac4up +all system, +hile ein' structurally supported. The

masonry veneer shall allo+ for expansion and contraction of the veneer +ithout crac4in' the

exterior material.

t. Masonr$ 1eneer "nstallation% )onform to ()3 5#0.1 for masonry veneer installation,

includin' cold +eather construction. (ntifreeGe admixtures are not to e used.

u.Mortar% !rovide factory.tinted colored mortar conformin' to (-TM )1A0, unless 8&$

directs other+ise.

v. E92ansion;Control <oints% 9ocate expansion/control joints and seal +ith proper ac4in'

material and (-TM ) >10 polyurethane sealant, or preformed foam or rueriGed expansion

joint closure. )onform to =2) #.100.10 and %3( Technotes 1C, 1C(.

+. +ric3% shall e (-TM )11@, ?rade -;, type 2%-, or type 2%O for detail +or4. (-TM

)@A test ratin' shall e <,ot effloresced<. =se 2%( ric4 only for special architectural effects

requirin' a non.uniform siGe.

x. S2lit )aced or Ground )aced Masonr$% (-TM ) >0

y. Cast Stone #rim !nits% )ast -tone shall meet or exceed the requirements of (-TM )

1#@".

G. 8all Ca=it$% shall )omply +ith the and %3( Technical ,otes 11(, 11%, 11), 1C%

aa. #.roug.-8all )las.ing Com2onents% Throu'h.+all flashin' +ith +eep holes shall e

incorporated in cavity +all construction. 2lashin' shall e A ounce copper flashin' +ith a #

ounce ituminous coatin' on each side or a fier'lass faric onded on each side of the

copper sheetP 1@.ounce uncoated copper, 1C 'au'e Type #01 or #0" stainless steel is also

-mall !roject !art " . !a'e 5 of "#

acceptale. Q2lexile memrane flashin', plastic or !:).ased memrane flashin' is

prohiited.

. Rein0orcing in 1eneer La$er% $einforcin' in the veneer layer shall e 'alvaniGed in

accordance +ith (-TM ( 11#/(11#M, (-TM (15#/(15#M, or (-TM (@5#/(@5#M, R1A5

6?>07 coatin', and e of sufficient siGe to eliminate dama'e to the veneer layer from +ind

and other live and dead loads imposed on the veneer layer.

cc. Masonr$ Cleaning% )lean the masonry in accordance +ith manufacturerFs instructions

and %3( Technote 10.

1>. Metal 8all Panel E9terior Closure

!anels shall have factory applied, a4ed coatin' to the exterior and interior of metal +all panels

and metal accessories. 5xterior finish topcoat shall e of A0 percent polyvinylidene fluoride

6!:827 resin +ith not less than 0.C mil dry film thic4ness 682T7. 5xterior primer shall e standard

+ith panel manufacturer +ith not less than 0.C mil dry film thic4ness 682T7.

;all system and attachments shall resist +ind loads as determined y (-)5 A, +ith a factor of

safety appropriate for the material holdin' the anchor. Maximum deflection due to +ind on

aluminum +all panels shall e 1/@0. Maximum deflection due to +ind on steel +all panels and

'irts ehind aluminum or steel +all panels shall e limited to 1/110 of their respective spans,

except that +hen interior finishes are used the maximum allo+ale deflection shall e limited to

1/1C0 of their respective spans.

)onformations . ,on.insulated steel or aluminum +all panels shall have confi'urations for

overlappin' adjacent sheets or interloc4in' ris for securin' adjacent sheets and shall e

fastened to frame+or4 usin' concealed fasteners, or choose the option for exposed fasteners

+hen exposed fasteners are acceptale at the installation. 9en'th of sheets shall e sufficient to

cover the entire hei'ht of any unro4en +all surface.

dd. Steel 8all Panels:

17 Material and )oatin': 2orm sheets from steel conformin' to (-TM ( @5#/( @5#M,

-tructural ?rade "0, 'alvaniGed coatin' conformin' to (-TM ( >1"/( >1"M, )lass ?.

>0P aluminum.coated steel conformin' to -(5 (M- 50#@P or steel.coated +ith

aluminum.Ginc alloy conformin' to (-TM ( A>1/( A>1M, except that coatin' chemical

composition shall e approximately 55 percent aluminum, 1.@ percent silicon, and "#."

percent Ginc +ith minimum coatin' +ei'ht of 0.5 ounce per square foot.

17 ?a'e: Minimum 11 =.-. -tandard ?a'e for +all panels, ut in no case li'hter than

required to meet maximum deflection requirements specified.

ee. Aluminum 8all Panels:

17 Material and )oatin' . 2orm sheets of (lloy #00" or (lclad #00" conformin' to (-TM %

10> havin' proper temper to suit respective formin' operations.

17 Thic4ness . Minimum 0.C1 mm 60.0#1 inch7 nominal, ut in no case thinner than that

required to meet maximum deflection requirements specified.

ff."nsulated Aluminum or Steel 8all Panels% 3nsulated +all panels shall e steel or

aluminum factory.faricated units +ith insulatin' core et+een metal face sheets securely

fastened to'ether and uniformly separated +ith ri'id spacers. !anels shall have a factory

color finish. ;all panels shall have ed'e confi'urations +ith interloc4in' ris for securin'

-mall !roject !art " . !a'e @ of "#

adjacent panels. -ystem shall utiliGe factory faricated corners and trim pieces at

intersections +ith other materials. 3nsulated +all panels shall e fastened to frame+or4 usin'

concealed fasteners.

17 3nsulated -teel !anels . Rinc.coated steel conformin' to (-TM ( @5#/( @5#MP or

(luminum.Ginc alloy coated steel conformin' to (-TM ( A>1/( A>1M, (R 55 coatin'.

=ncoated +all panels shall e 0.@1 mm 60.01" inch7 thic4 minimum.

17 3nsulated (luminum !anels . (lloy conformin' to (-TM %10>, temper as required for

the formin' operation, minimum 0.C1 mm 60.0#1 inch7 thic4.

11. Stucco E9terior 8all Closure

''. Portland Cement Plaster% (-TM )150, 'ray !ortland cement Type 33 +ith 1# mm 61/1

inch7 maximum chopped al4ali resistant fier'lass strands, minimum 1.5 percent y +ei'ht to

cementP .@C 4' 61 1/1 pounds7 per sac4 of cement. 9ime shall conform to (-TM )10@, Type

-. -ystem shall utiliGe stainless steel or Ginc corner eads, E.eads and other accessories.

=nless specifically deleted, the system shall utiliGe an acrylic admixture or coatin' to 'ive

additional moisture suppression to control fun'us 'ro+th.

hh. E9terior "nsulation and )inis. S$stem ?E")S@% 53M( TM 101 and 01 53M( TM 101.C@.

532- shall e used as the non.primary or the primary exterior finish material only for projects

+here it is necessary to match existin' 532-.

1*. Precast Concrete 8all Panels% ()3 111.1 and ()3 #01. !)3 M,9.11@ or !)3 M,9.11A.

)oncrete shall have a minimum 1C.day compressive stren'th of 1C1 N'/cm

1

6"000 psi7. Eoints

shall include properly siGed and placed ac4in' material and fully loaded and tooled sealant joint

of no less than 1/" inch sealant material thic4ness.

1,. (t.er 8all )inis. S$stems

ii. 'oriAontal 8ood Siding% BoriGontal ;ood -idin': 8&) !- 10, exterior, lap type, @

inches +ide, maximum practicale len'ths, 11 mm 6A/1@ inch7 thic4, smooth face. (ll

surfaces of +ood sidin' and trim shall e shop coated +ith an al4yd primer.

-pecies and ?rades 1. ?rade 1 )ommon spruce.pine.firP ,59M(, ,9?(, ;)93%, or ;;!(.

1. ?rade !rime or 8 finish, pressure.preservative.treated hem.firP ,9?(, ;)93%, or ;;!(.

#. ?rade 8 -elect 6Suality7 eastern +hite pine, eastern hemloc4.alsam fir.tamarac4, eastern

spruce, or +hite +oodsP ,59M(, ,9?(, ;)93%, or ;;!(. ". ?rade 8 -elect northern

+hite cedarP ,59M( or ,9?(. 5. ?rade % T %, pressure.preservative.treated southern pineP

-!3%.

jj. 1in$l Siding S$stem% 3nte'rally colored, vinyl sidin' complyin' +ith (-TM 8 #@A>.

44. Manu0actured )aced Panels S$stems E9terior 8all Siding% ?lass 2ier $einforced

)ementitious !anels -ystem: -idin' made from fier.cement oard that does not contain

asestos fiersP complies +ith (-TM ) 11C@, Type (, ?rade 33P horiGontal or vertical pattern

in plain or eaded.ed'e style. Texture: $ou'h sa+n or smooth, factory primed.

14. E9terior 8all +ac3u2 Construction

ll. Concrete !nit Masonr$% !rovide concrete unit masonry to comply +ith ()3 5#0.1. 9oad.

earin' units: (-TM )>0, ,on.load earin'. units: (-TM )11>, Type 3 or 33. !rovide 'round

face units, split.faced units, 'round.faced units, or split.ried units for exposed exterior

-mall !roject !art " . !a'e A of "#

+alls. !rovide +ater repellent admixture to masonry units +here the exterior face of the units

+ill not receive a +aterproof coatin' such as paint

mm. &am22roo0ing% 8ampproof the cavity.facin' +ythe of the ac4up masonry

usin' asphaltic primer accordin' to (-TM 8 "1, if dampproofin' is not provided y a sprayed

on foam or other 8&$.approved memrane insulation system.

14. Load-+earing Metal )raming S$stem

3f permitted, provide load.earin' metal framin' includin' top and ottom trac4s, racin',

fastenin's, and other accessories necessary for complete installation. 2ramin' memers shall

have the structural properties indicated. ;here physical structural properties are not indicated,

they shall e as necessary to +ithstand all imposed loads. 8esi'n framin' in accordance +ith

(3-3 -?.@A#. 3nstallation shall e in accordance +ith 8&$.approved shop dra+in's and

manufacturer*s installation instructions.

15. E9terior Studs%

Max. 8eflection )riteria 5xterior 2inish

9/#@0 )ement !laster, ;ood :eneer, -ynthetic !laster, Metal

!anels

9/@00 %ric4 :eneer, -tone !anels

;all deflections shall e computed on the asis that studs +ithstand all lateral forces

independent of any composite action from sheathin' materials. -tuds auttin' +indo+s or

louvers shall also e desi'ned not to exceed 1/".inch maximum deflection and as required in

=2) ".010.01.

17 -tuds . (-TM ( 100#/(-TM ( 100#M, -tructural ?rade 50, Type B minimumP provide

R1C0 6?@07 'alvaniGed coatin' in accordance +ith (-TM ( @5#/(-TM ( @5#M. 8o not

expose studs to direct moisture contact

17 %racin' . !rovide horiGontal racin' in accordance +ith desi'n calculations and (3-3 -?.

@A#, consistin' of, as a minimum, runner channel cut to fit et+een and +elded to the

studs.

#7 -heathin' . !rovide sheathin' to +ithstand structural loads imposed on the +all

structure. )over sheathin' +ith either a 15 pound asphalt.impre'nated uildin' paper, or

air arrier as required y the +all moisture analysis. -heathin' shall e one of the

follo+in':

a7 !ly+ood : ).8 ?rade, 5xposure 1P

7 -tructural .=se and &-% !anelsP

c7 ?ypsum : (-TM ) A>/) A>M and (-TM ) 11AA/) 11AAM, 1# mm 61/1 inch7 thic4

fire retardant 6Type O7 15 mm 65/C inch7 thic4P 1.1 meters 6" feet7 +ide +ith square

ed'e for supports "00 mm 61@ inches7 o.c. +ith or +ithout corner racin' of framin'.

?ypsum sheathin' shall e faced +ith materials capale of resistin' six months of

+eatherin' exposure +ithout de'radation of the coverin' or the 'ypsum. -eal all

joints as recommended y the manufacturer.

16. 8ood )raming S$stem% (ll materials shall e 4iln.dried lumer complyin' +ith 8&) !- 10.

3nstallation shall e in accordance +ith (2T!( T11. -ystem shall use preservative pressure

treated lumer at sill plates and other memers in contact +ith concrete and masonry surfaces.

-mall !roject !art " . !a'e C of "#

nn. S2ecies and Grades% !rovide species and 'rades listed: 17 ?rade 1 )ommon spruce.

pine.firP ,59M(, ,9?(, ;)93%, or ;;!(: 17 ?rade 1 )ommon, hem.firP 8ou'las.firP ,9?(,

;)93%, or ;;!(P #7 ?rade 1 )ommon, southern pineP -!3%.

oo. S.eat.ing% -heathin' shall +ithstand structural loads imposed on the +all structure.

)over sheathin' +ith either a 15 pound asphalt.impre'nated uildin' paper, or air arrier as

required y the +all moisture analysis. -heathin' shall e as for Metal -tuds.

17. Cast-in-2lace Concrete S$stem% )oncrete construction must e in accordance +ith ()3 #01.

1:. "nsulation and 1a2or Retarder% 3nsulation, :apor $etarders, and (ir %arrier -ystems in or on

5xterior 5nclosure shall include: insulation, liquid, sheet or continuous film materials installed

separately in or on +all assemlies to provide resistance to heat loss/'ain, and vapor penetration.

pp. 1a2or retarder% )omply +ith (-TM )A55. 3ncorporate in the exterior +all system

+here required y vapor transmission calculations or de+ point analysis indicates the need or

in conditions of hi'h moisture exposure.

qq. +ituminous &am22roo0ing% %ituminous 8ampproofin' shall e (-TM 8"">, Type 3 or

Type 33 ituminous dampproofin' on the exterior surface of the interior +ythe of masonry in a

cavity +all 6ac4.up +all for masonry veneer7.

rr. +uilding Pa2er% 2- ==.%.A>0, Type 3, ?rade 8, -tyle 1.

ss. Air +arrier% %uildin' +rap consistin' of air arrier sheetin' complyin' +ith (-TM 5

1@AA, Type 1, not less than # mils thic4 +ith a permeance of not less than 5A5 n'/!a x s x

sq.m. 610 perms7. %uildin' +rap shall have a flame spread index of less than 15 in

accordance +ith (-TM 5 C". !rovide uildin' +rap over sheathin' of +ood or metal framed

construction to reduce air penetration and airorne vapor penetration. !rovide uildin' +rap

tape as recommended y the manufacturer for sealin' all joints in the uildin' +rap.

3nstallation shall e in accordance +ith manufacturer*s instructions. (ir arrier installation at

+indo+s shall e in accordance +ith (-TM 5 1111.

tt."nsulation S$stems% :ertical and horiGontal polystyrene insulation conformin' to (-TM

)5AC or ri'id polyisocyanurate oard +all insulatin' products conformin' to (-TM )5>1 or

mineral.fier lan4et insulation conformin' to (-TM ) @@5 shall e provided.

*>. Para2ets% (void parapets +hen possile, ut +hen necessary, provide parapets +ith the same

materials as the exterior +all construction. !rovide scuppers and +all ed'e accordin' to

-M(),(.

*1. E9terior Lou=ers and Screens% 3f required, provide louvers for -creened 5quipment 5nclosure

or as louvers for exterior doors.

-torm shutters shall comply +ith (-TM 5 1>>@.0#.

**. +alcon$ 8alls and 'andrails% %alcony +alls to match exterior construction. Bandrails to

comply +ith the 3%) and &-B(.

*,. E9terior So00its% 5xterior soffit system.

*4. E9terior Painting and S2ecial )inis.esB (ll paintin' and coatin' materials shall e lo+ :&).

!aintin' practices shall comply +ith applicale federal, state and local la+s enacted to insure

compliance +ith 2ederal )lean (ir -tandards. (pply coatin' materials in accordance +ith --!)

!( 1. --!) !( 1 methods are applicale to all sustrates.

-mall !roject !art " . !a'e > of "#

(ll paint shall e in accordance +ith the Master !ainters 3nstitute 6M!37 standards for the exterior

architectural surface ein' finished. The current M!3, <(pproved !roduct 9ist< +hich lists paint y

rand, lael, product name and product code as of the date of contract a+ard, +ill e used to

determine compliance +ith the sumittal requirements of this specification. !rovide paint

systems tested to /8etailed !erformance 9evel0 standard as defined y M!3.

*4. E9terior <oint Sealant% -ealant joint desi'n, primin', toolin', mas4in', cleanin' and application

shall e in accordance +ith the 'eneral requirements of -ealants: ( !rofessionals* ?uide from

the -ealant, ;aterproofin' T $estoration 3nstitute 6-;$37. (ll sealant shall conform to (-TM )

>10.

*5. Sun Control &e=ices% -un control devices shall e manufactured devices to provide sun control

on exterior +indo+s and storefronts. -un control devices shall e desi'ned and installed to

+ithstand the +ind loads prevailin' at the project site.

B2020 EXTERIOR WINDOWS

(ll +indo+s and doors in ne+ or existin' uildin's, +hich are suject to (nti.terrorism -tandards,

must e last.resistant as prescried in =2) ".010.01.

=nless other+ise allo+ed y !art #, +indo+s for ne+ facilities shall e aluminum. 3n uildin'

additions or renovations +indo+s shall match existin' +indo+ materials. 5xterior +indo+s

desi'n, dimension, and construction shall meet or exceed the requirements for (nti Terrorism

2orce !rotection requirements. 3n addition, exterior +indo+s shall meet or exceed 5ner'y -tar

requirements. The desi'n and placement of exterior +indo+s shall ta4e into considerations vie+,

natural li'ht, privacy, and protection for the occupants of the facilities. !rovide operale hard+are

and insect screen for exterior +indo+s. ;indo+s shall e faricated y manufacturers normally

involved in the manufacturin' of +indo+s and shall e of the current ma4e and model. ,o

osolete or discontinued +indo+s shall e used. !rovide +eather strippin', -T) and 33) ratin',

commensurate +ith the intended use of the facility. -umit catalo' information and

manufacturer*s specifications for approval y )ontractin' &fficer prior to purchase of +indo+s.

;indo+s shall consist of fixed and operale sash used sin'ly and in multiples. !rovide operale

sash in spaces occupied y people as a minimum. 3nclude operatin' hard+are, non.corrodin'

framed metal screens for operale sash, inte'rated linds set et+een 'lass panels and security

'rilles. !rovide jam support for lar'er +indo+s +here recommended y manufacturer.

1. Metal 8indo/s% (ll +indo+s shall conform to (,-3/((M(/;8M( 101. Metal +indo+s +ith

insulatin' 'lass shall have thermally ro4en frames and sash. 2actory finish aluminum +indo+s

and provide +ith aluminum frame screens +ith aluminum mesh at operale sash, hard+are and

loc4s, and tinted 'laGin'. (luminum screens shall comply +ith (,-3/-M( 100".

*. 8ood 8indo/s% )lad +ood and +ood +indo+s shall consist of complete units includin' sash,

'lass, frame, +eatherstrippin', insect screen, and hard+are. ;indo+ units shall meet the

requirements of ((M( 101, except maximum air infiltration shall not exceed 0.#0 )2M per linear

foot of sash crac4 +hen tested under uniform static air pressure difference of A.@@ N'/m

1

61.5A

psf7.

,. Store0ronts% !rovide one.story storefront system faricated from formed and extruded aluminum

and 'lass components for exterior use. =tiliGe the specific section of the -tandard 8esi'n.%uild

!erformance Technical -pecifications -ection %101001 for the storefront to e provided.

-torefront framin' shall meet or exceed the structural requirements, as measured in accordance

+ith (,-3/(-TM 5##0: 8esi'n system to +ithstand this as a minimum and comply +ith desi'n

pressure estalished +ithin the required (-)5 A.05 ;ind -peed )alculations determined y the

overall avera'e openin' +ithin the project.

-mall !roject !art " . !a'e 10 of "#

4. GlaAing% All e9terior glaAing s.all Ce insulating glass.

a7 )lear ?lass . Type 3, )lass 1 6clear7, Suality q" 6(7P

7 Beat.(sorin' ?lass . (-TM 10#@, Type 3, )lass 1 Suality q# 6select7 ray framesP

c7 ;ire ?lass . Type 33, )lass 1, 2orm 1, Suality qC Mesh m1 or 2orm 1, Suality qAP

d7 9aminated ?lass . (-TM 11A1, total thic4ness shall e nominally @ mm 61/" inch7P

e7 3nsulatin' ?lass =nits . Typically (-TM ) 10#@, Type 3, )lass 1, Suality q", minimum

@ mmP

f7 Tempered ?lass . (-TM ) 10"C, Nind 2T 6fully tempered7P

'7 !atterned ?lass . (-TM 10#@, Type 33, )lass 1 6translucent7, 2orm # 6patterned7,

Suality qA 6decorative7, 2inish f1 6patterned one side7, !attern p1 6'eometric7 5.55 mm

6A/#1 inch7 thic4.

B2030 EXTERIOR DOORS

5xterior doors shall e heavy duty insulated steel doors and frames for service access. 8oor

frames shall have +elded corners. =se heavy.duty overhead holder and closer to protect doors

from +ind dama'e. -teel shall have ?@0 'alvaniGed coatin' in accordance +ith (-TM ( >1"/(

>1"M and (-TM ( @5#/( @5#M +hen the jo site is located +ithin #00 feet from a ody of salt

+ater. !rovide commercial quality, coatin' )lass ( Ginc coatin' in accordance +ith (-TM (5>1

for other steel or steel s4in hollo+ metal doors at other locations. !rovide 4ic4plates on the inside

face of all exterior doors. ;eather.protect all exterior doors and related construction +ith lo+

infiltration +eatherstrippin' and sealants. !rovide threshold +ith offset to stop +ater penetration

+hile maintainin' accessiility compliance. )onform to the desi'n criteria of (-)5 A. -ee the

hard+are schedule for door hard+are requirements.

1. Steel &oors% 5xterior doors shall comply +ith (,-3 (150.C.1>>C 6-83.1007. Bard+are

preparation shall e in accordance +ith (,-3 (150.@. 8oors shall e hun' in accordance +ith

(,-3 (115.1@.

uu. 8oors $equired:

17 -tandard 8uty 8oors . 9evel 1, M-? H 10 63! 0.0#10, 0.C mm7, physical performance

9evel ), Model 1 or 1.

17 Beavy 8uty 8oors D M-? H 1C 63! 0,0"10, 1 mm7, physical performance 9evel %, Model 1

or 1.

#7 5xtra Beavy 8uty 8oors D 9evel #, M-? H1@, 60.05#0, 1.# mm7 physical performance

9evel (, Model 1, 1, or #.

"7 Maximum 8uty 8oors D 9evel " 63! 0.0@A0, 1.@ mm7, physical performance 9evel (,

Model 1 or 1.

vv. 3nsulated steel doors and frames are required for entrances to d+ellin' units, and may

also e specified as a )ontractorFs option to 9evel 1 standard hollo+ metal doors. 8o not use

+ood doors for exterior doors, unless they are fully protected from the elements, an exterior

'rade species, and specially finished. 3f +ood doors are used, provide in accordance +ith

-tandard 8esi'n.%uild !erformance Technical -pecification !ara'raph %10#001 1.

*6. Standard Steel )ramesB (,-3 ( 150.C. 2orm frames +ith +elded corners for installation in

exterior +alls. 2orm stops and eads of 10 'a'e steel. 2rames shall e set in accordance +ith

(-TM (150.11. (nchor all frames +ith a minimum of three jam anchors and ase steel anchors

per frame, Ginc.coated or painted +ith rust.inhiitive paint, not li'hter than 1C 'a'e. Mortar infill

-mall !roject !art " . !a'e 11 of "#

frames in masonry +alls, and infill +ith 'ypsum oard compound at each jam anchor in metal

frame +alls. &nly use surface exposed olted anchors in concrete +alls.

*7. &oor and )rame )inis.es% a7 5xterior 8oors, 2actory.!rimed and 2ield !ainted 2inish . 8oors

and frames shall e factory primed +ith a rust inhiitive coatin' as specified in (,-3 (150.C.

2actory prime doors on six sides of the doorP 7 5xterior 8oors ?alvaniGed 2inish .. -hall e

)ommercial Suality, )oatin' )lass (, Ginc coatin' in accordance +ith (-TM ( 5>1 +hen facility

is located further than >1 meters 6#00 feet7 from the ocean. ;hen facility is located +ithin >1

meters 6#00 feet7 of the ocean, provide ?@0 'alvaniGed coatin' in accordance +ith (-TM (

>1"/( >1"M and (-TM ( @5#/( @5#M.

*:. !2/ard Acting &oors%

=p+ard actin' doors shall e capale of +ithstandin' the desi'n +ind loadin' of (-)5 A.

!rovide 'alvaniGed steel trac4s not li'hter than 1" 'a'e for 50 mm 61 inch7 trac4s and not li'hter

than 11 'a'e for A5 mm 6# inch7 trac4. !rovide a positive loc4in' device and cylinder loc4 +ith

t+o 4eys on manually operated doors.

,>. (=er.ead and Roll-u2 &oors% 9ar'e exterior overhead and roll.up doors system shall consist of

manual or automatic exterior doors and door assemlies.

,1. Rolling Ser=ice &oors and Grilles% )oilin' overhead doors shall have minimum 11 'a'e

thermal insulated slats. 5lectric operators shall have three.utton s+itches conformin' to ,5M(

M? 1, ,5M( 3)- 1, and ,5M( 3)- 1, and auxiliary hand chain operation, +eather.strippin' and

+ind.loc4s. 8oors shall e capale of +ithstandin' the desi'n +ind loadin' of (-)5 A and still

operate normally. 2inish of the door shall e hot.dipped 'alvaniGed +ith a painted finish.

,*. Sectional (=er.ead &oors% -ectional overhead doors shall conform to ,(?8M 101,

$esidential or )ommercial or 3ndustrial door standards. 3f doors are electrically operated,

pushuttons shall e full.'uarded to prevent accidental operation, and include limit s+itches to

automatically stop doors at the fully open and closed positions. 9imit s+itch positions shall e

readily adjustale.

,,. 'ard/are% !rovide the services of a )ertified 8oor Bard+are )onsultant to prepare the door

hard+are schedule.

!rovide all ne+ hard+are +ith satin chrome finish throu'hout. Bard+are shall e commercial

'rade, suitale for the operational requirements and in compliance +ith life safety code and

handicapped accessiility requirements, similar in quality to the hard+are sho+n in )1010

3nterior 8oors and Bard+are elo+.

)oordination: !rovide a master 4eyin' system compatile +ith the existin' ase system.

!rovide an emer'ency access 4ey ox for exterior door fireman 4ey access. )oordinate +ith the

local authority and the )ontractin' &fficer to determine the local requirements for hard+are,

4eyin' and master 4eyin'.

B30 ROOFING

2or repair of existin' roofin', the cuttin' of the existin' roof shall e 4ept to a minimum and, +here

necessary, shall e made in a clean and orderly manner to prevent the appearance of a patch.

$epair all dama'e to existin' and ne+ roofin' caused y the +or4 of this )ontract at no additional

cost to the ?overnment. The +or4 shall e executed in such a manner as to maintain the inte'rity of

the existin' roofin' manufacturerFs +arranty.

-mall !roject !art " . !a'e 11 of "#

1. Pre-Roo0ing Con0erence% !rior to e'innin' roofin' +or4, the )ontractor shall hold a !re.

$oofin' )onference +ith the personnel directly responsile for the roofin' systems +or4, as +ell

as the roofin' manufacturer*s technical representative.

*. Roo0 &esign Assurance% 3f the roofin' project is si'nificant 6-i'nificant $oof D ( sin'le or 'roup

of uildin's 'reater than 1,"00 m

1

615,000 sf77, or +here extenuatin' circumstances of the roof

project such as uildin' use, content, safety, or visiility require a roofin' consultant, the

)ontractor shall utiliGe the services of a $e'istered $oof )onsultant 6$$)7 certified y the $oof

)onsultant 3nstitute, or a $e'istered !rofessional architect or 5n'ineer +ho specialiGes in roofin',

to approve the roof desi'n. The roof consultant must e en'a'ed in roofin' desi'n and roofin'

construction as his primary endeavor. The roof consultant shall verify in +ritin' that the desi'n

for the project is in accordance +ith the current edition of NRC Roofing and !aterproofing

"anual, =2)*s, and $2!, and standard industry practices and uildin' codes.

3f a $oof 8esi'n (ssurance )onsultant is needed, consider usin' a $e'istered $oof &server as

a S) specialist.

B3010 ROOF COVERINGS

$oof coverin's and procedures shall comply +ith the requirements of =2) #.110.0#, Roofing,

and ,$)(, Roofing and !aterproofing "anual found at

http://+++.nrca.net/rp/technical/manual/manual.aspx as the primary ,(:2() roofin' criteria.

$oof selection shall comply +ith =2) #.##0.01(, Design# Commentary on Roof Systems.

8etermine +ind uplift usin' +ind speed in accordance +ith (-)5.A.

1. S#EEP SL(PE R(() SDS#EMS% -teep slope systems shall e roofs +ith a pitch 'reater than

# in 11. -teep -lope -ystems are slate roofin', (sphalt -hin'les, $oof Tiles, 2oam -et Tiles,

Metal $oof !anels 6(rchitectural -tandin' -eam Metal $oofs on supported sustrate7, and

-tructural -tandin' -eam Metal $oof 6---M$7. (sphalt shin'les can only e used for

residential construction and li'ht commercial construction.

*. L(8 SL(PE R(() SDS#EMS% 9o+ slope systems shall e roofs +ith a pitch # in 11 or less.

9o+ slope roofin' systems shall e uilt.up asphalt roofin' 6a''re'ate surfaced, +ith modified

ituminous components7, modified ituminous memrane roofin' of a minimum of # plies +ith

a''re'ate surface or 'ranular surface modified itumen cap sheet, or structural standin' seam

metal roofin'. =se epdm systems only to match existin' construction.

,. R(() C(MP(NEN#S%

++. "nsulation% 2or existin' structures, provide insulation in accordance +ith (-B$(5 >0.1.

2or ne+ construction, provide $.#0 insulation in the ceilin's, attic spaces and soffit areas for

interior spaces. 3njected polyurethane and =rea 2ormaldehyde 2oam field applied shall not

e used. !rovide acoustical insulation aove +alls separatin' athroom/restrooms and

corridor and adjacent occupied spaces, and et+een offices and corridors. 3nsulation shall

have a minimum sound attenuation ratin' of -T).55.

3nsulation shall e !olyisocyanurate $i'id %oard 3nsulation , Mineral 2ier %lan4et 3nsulation

to conform to (-TM ) >>1, +ith ?lass Mat ?ypsum $oof %oard for use aove the dec4 or

insulation conformin' to (-TM ) 11AA/) 11AAM, +here necessary.

&nly on portions of the roof +here the slopin' of structure does not allo+ the minimum

slopes, provide a factory tapered roof insulation system to provide positive draina'e of roof

-mall !roject !art " . !a'e 1# of "#

system, and to include draina'e around curs, penetrations, and projections throu'h the roof

plane.

!rovide ?lass Mat !rotection %oard meetin' (-TM ) 11AA for use as a thermal arrier

6underlayment7 or protection oard for hot.mopped applications.

xx. 1a2or Retarder%D8etermine the need and location in the roof assemly for a vapor

retarder. ;here the mean Eanuary temperature is "0 de'rees 2ahrenheit or less, and the

expected interior relative humidity is "5U or 'reater, use a vapor retarder. &ther+ise, use

(-B$(5 >0.1 for the determination.

17 :apor $etarders as 3nte'ral 2acin' . (lloy conformin' to (-TM % 10>, or :apor

$etarders -eparate from 3nsulation . :apor retarder material shall e 10 mil polyethylene

sheetin' conformin' to (-TM 8 "#>A.

17 ( slip sheet is required to separate the roofin' panels from the insulation facin' +here

the facin' +ould e in direct contact +ith the roofin' panels. 3f a slip sheet is necessary

for use +ith a vapor retarder, use a 5 l. per 100 square feet rosin.siGed, unsaturated

uildin' paper.

yy. EP&M RuCCer +oots% 2lashin' devices around pipe penetrations shall e flexile, one.

piece devices molded from +eather.resistant 5!8M ruer.

GG. Pre0aCricated CurCs and Equi2ment Su22ort% !rovide !refaricated curs and

equipment supports shall e of structural quality, hot.dipped 'alvaniGed or 'alvaniGed sheet

steel, factory primed and prepared for paintin' +ith mitered and +elded joints. 3nte'ral ase

plates and +ater diverter cric4ets shall e provided. Minimum hei'ht of cur shall e C inches

aove finish roof.

aaa. )asteners% -hall meet all requirements of the ,$)( and 2actory Mutual

. 8ood Nailers% ;ood nailers shall e pressure.preservative.treated in

accordance +ith (;!( M1 -tandards, permanently mar4ed or randed, and installed flush

+ith the top of the adjacent insulation oard.

ccc.)las.ing and S.eet Metal% !rovide flashin' and sheet metal +or4 includin' scuppers,

splash pans, and sheet metal roofin'. 2lashin' and sheet metal shall e provided in

accordance +ith roof manufacturer*s printed installation instructions and in compliance +ith

,$)( and -M(),( recommendations. 2aricate 2lashin' and sheet metal components

from )opper, 9ead.)oated )opper sheet, -teel -heet, Rinc.)oated 6?alvaniGed7 . (-TM (

@5#/ ( @5#M, -tainless -teel . (-TM ( 1@A, Type #01 or #0", 18 finish, or !re.2inished

(luminum.

ddd. Gutters and &o/ns2outs% !rovide 'utters and do+nspouts compatile +ith

roofin' material and finish. )oncealed 6interior7 'utters and do+nspouts are prohiited.

!rovide splash 'uards at points of dischar'e.

eee. Roo0 (2enings and Su22orts% !rovide flashin's for roof openin's and

supports as recommended y the ,$)(. (ssure all penetration flashin's extend minimum

100 mm 6C inches7 aove the finished roof surface.

fff. Roof Hatc!"# !rovide roof hatch +here required y &-B(, and as access to roof +hen

roof mounted equipment is used or other routine roof maintenance is required.

-mall !roject !art " . !a'e 1" of "#

'''. GlaAed Roo0 (2enings% -4yli'hts and other 'laGed roof openin's shall e used

only to supplement interior li'htin' levels 6'enerally in steep slope or vertical applications7,

and other+ise, are discoura'ed from use.

hhh. Guards% !rovide rails or 'uards as required y the &-B(, the 3nternational

%uildin' )ode or other applicale safety standards.

iii. #ra00ic Pads% !rovide on roof system to protect roof from foot traffic. !rovide traffic pads

around roof mounted mechanical equipment and underneath removale mechanical

equipment access panels. Traffic pads shall e of compatile material to roof.

,4. (#'ER R(()"NG

jjj. L$%t&$&% P'ot!ct$o&# 9i'htnin' protection component penetrations and attachments

shall e sealed and flashed and anchored in a permanent manner and in a manner to avoid

the de'radation of the +aterti'ht inte'rity of the roof system.

444.Roo0 &rains ?E9isting@% ;here existin' roof drains are to e reused in roof replacement

construction, the contractor shall provide ne+, compatile flashin' materials, a ne+ drain

clampin' rin' and ne+ olts for anchora'e. $euse of existin' clampin' rin' and olts is

unacceptale.

SECTION C. INTERIORS

C10 INTERIOR CONSTRUCTION

C1010 PARTITIONS

1. )i9ed Partitions% +ood frameP li'ht 'a'e steel frameP concrete masonry complyin' +ith ()3

5#0.1/(-)5 @/TM- @01 and associated (-TM -tandardsP or cast.in.place concrete complyin'

+ith =2) 1.100.01, ()3 11A and ()3 #01/#01M. 3n addition, interior partitions shall comply +ith

tales for sound isolation and noise reduction in )hapter 1, /(rchitectural ?raphic -tandards0.

3nclude a statement of adherence to the applicale criteria.

?ypsum oard/stud partitions may e standard 'ypsum oard, moisture resistant, or impact

resistant. =se cement oard in sho+ers and other +et areas. $einforce points +here door4nos

can stri4e a +all and anchora'e points for +all mounted equipment.

,4. &emountaCle or Remo=aCle Partitions% shall e of materials allo+ed y code and shall e

anchored firmly to the structure to carry their o+n +ei'ht as +ell as impact forces and seismic

lateral forces. -ound Transmission )lass 6-T)7 ratin' and 3mpact 3solation )lass 633)7 ratin'

shall e in accordance +ith (-TM 5 >0 or (-TM 5 "1# for frequency data,, and shall meet the

requirements of the intended use in !art #.

,5. GlaAed Partitions and "nterior 8indo/s% shall e of the materials allo+ed y code 3%), and

shall comply +ith fire and smo4e separation requirements. !rovide safety 'laGin' and fire

resistant ratin' +here they are required.

C1020 INTERIOR DOORS

1. 8ood &oors% -tile and rail +ood doors shall e ;8M( 3.-.@(.01, premium or custom 'rade,

heavy duty or extra heavy duty. 2lush +ood doors shall e ;8M( 3.-.1(.0", premium or custom

'rade, heavy duty or extra heavy dutyP or ;8M( 3.-..>A 6!).5 5.ply particleoard core or -)9).

-mall !roject !art " . !a'e 15 of "#

5 5.ply structural composite lumer core7. 8oors adjacent to panelin' or mill+or4 shall comply

+ith correspondin' (;3 mill+or4 'rade. !rovide interior fire doors.

*. Steel doors% shall e (,-3 ( 150.C, 9evel 1, 6occasional use, lo+ ause types such as closet

doors +ithout loc4s7P 9evel 1, 6lo+ use, moderate ause types such as office/storeroom doors7P

9evel #, 6moderate use, hi'h ause types such as %5S sleepin' room doors7P 9evel ", 6hi'h use,

hi'h ause types such as corridors, stair+ays, assemly spaces, and main entry doors7, +ith a

physical performance level of V(*. Maximum door undercut shall not exceed 1> mm 6#/" inch7.

,. Sound "nsulated &oors and )rames% =tiliGe -ound 3nsulated 8oors and 2rames +ith sound

control +eatherstrippin' in rooms requirin' +all assemlies to e sound insulated +ith a -ound

Transmission )lass 6-T)7 ratin' as required. The -T) ratin' for the door and frame assemly

shall e not less than the +all assemly -T) ratin'.

4. Aluminum &oors and )rames% !rovide s+in'.type aluminum doors and frames complete +ith

framin' memers, transoms, side.lites, and accessories. 2aricate of (-TM % 111, (lloy @0@#.

T- for extrusions.

4. Steel &oor )rames% (,-3 ( 150.C. 2orm frames +ith +elded corners for installation in masonry

partitions and 4noc4.do+n field assemled corners for installation in metal stud and ?;%

partitions. 2rames shall e set in accordance +ith -83 105. 2orm stops and eads +ith 10

'au'e steel.

!rovide a minimum of three jam anchors and ase steel anchors per frame, Ginc.coated or

painted +ith rust.inhiitive paint, not li'hter the 1C 'au'e. -ecure frames to previously installed

concrete or masonry +ith expansion olts in accordance +ith -83 11.2. !rovide mortar infill of

frames in masonry +alls, and 'ypsum oard compound infill at each jam anchor in metal frame

+alls.

5. )ire doors% !rovide in conformance +ith ,2!( C0 an ,2!( 105. 2ire doors and frames shall

ear the lael of =9, 2M or ;B3 attestin' to the ratin' required. 8oor and frame assemlies shall

e tested for conformance per ,2!( 151 or =9 10% 6for neutral pressure7 or =9 10) 6for positive

pressure7. ;ood fire doors shall also comply +ith (-TM 5 151.

!rovide stainless steel astra'als complyin' +ith ,2!( C0 for fire.rated assemlies and ,2!(

105 for smo4e control assemlies.

6. "nterior &oor 'ard/are% !rovide the services of a certified door hard+are consultant to prepare

the door hard+are schedule. =nless other+ise noted, interior doors shall include latch, hin'es,

door stops and door silencers. !rovide closers and 4ic4 plates for fire.rated, corridor, stair+ay

and hi'h.use non.residential doors.

lll. 'inges . %BM( (15@.1, ?rade 1, 10C x 10C mm 6" 1/1 x " 1/1 inches7 +ith non.

removale pin or anti.friction earin' hin'es.

mmm. Loc3s and Latc.es . 2or non.residential uildin's use -eries 1000, &perational

?rade 1, -ecurity ?rade 1 for stair+ays, uildin' entrances, corridors, assemly spaces, and

other hi'h use interior doors. =se -eries "000, ?rade 1 for non.residential locations not

usin' -eries 1000 hard+are. 2or residential uildin's use -eries "000, ?rade 1 for interior

doors. a7 Mortise 9oc4s and 9atches . %BM( ( 15@.1#, -eries 1000, &peration ?rade 1,

-ecurity ?rade 1. 7 %ored 9oc4s and 9atches . %BM( ( 15@.1, -eries "000, ?rade 1, or

?rade 1.

-mall !roject !art " . !a'e 1@ of "#

nnn. E9it &e=ices . %BM( ( 15@.#, ?rade 1. Touch ars shall e provided in lieu of

conventional crossars and arms. =se manufacturer*s inte'ral touch ars in aluminum

storefront doors.

ooo. Card Ee$ Access - !rovide card 4ey type access units for specialiGed entries.

!rovide lithium attery po+ered, ma'netic stripe 4eycard loc4sets that are (,-3/%BM(

(15@.1#, -eries 1000, ?rade 1, mortise or (,-3/%BM( (15@.1, -eries "000, ?rade 1,

cylindrical loc4s, tamper resistant, =9 listed +ith 15 mm 61 inch7 thro+ deadolt, 1> mm 6#/".

inch7 thro+ latch olt, auxiliary dead.loc4in' latch, and @C.A5 mm 61.#/" inch7 ac4set.

!rovide hard+are 4eyin' compatile +ith the existin' ase.+ide 4eyin' system. $eplacement

interchan'eale cores shall e compatile +ith the %est 9oc4 system.

ppp. Ee$ CaCinet% !rovide a Ney )ainet +ith #0U over capacity.

C1030 SPECIALTIES

1. Com2artments, CuCicles, F #oilet Partitions% 2- (.(.@000#. !rovide toilet compartments at

multi.fixture toilet rooms of Type 3, -tyle %.)eilin' Bun', ).&verhead %raced, or 2.&verhead

raced.alcove. $einforce panels to receive partition.mounted accessories. =rinal screens shall

e 2- (.(.@000#. Type 333, -tyle (, floor supported and +all hun' or -tyle 8, +all hun'. ;all

hun' urinal screens shall e secured +ith continuous flan'es to urinal screen and +all. -teel and

!lastic toilet partitions shall have a recovered materials content of 10 to #0 percent. )hrome.

plated or stainless steel door latches and coat hoo4s. !rovide one coat hoo4 per compartment

door. 9atches and hin'es for handicapped compartments shall comply +ith =2(- T (8((?.

*. #oilet and +at. Accessories% !rovide toilet and ath accessories and install per (8((? and

manufacturers* requirements.

,. Mar3er +oards and #ac3 +oards% !rovide porcelain enamel mar4er oards fused to a nominal

1C 'au'e steel sheet and tac4 oards of cor4, +ith a tensile stren'th of at least "0 psi +hen

tested accordin' to (-TM 2 151, +ith +oven or vinyl coverin'.

4. "denti0$ing &e=ices% (ll interior doors shall have an identifyin' device. (ll handicap accessile

facilities shall utiliGe si'na'e +hich meets current (8((? requirements +ith re'ard to %raille,

raised characters, finishes 6contrast7, siGe and mountin' hei'ht. 3f room names are suject to

frequent chan'e, provide an interchan'eale strip to e utiliGed to facilitate removal and

replacement.

,6. Loc3ers% !rovide loc4ers to meet 2- ((.9.00"C@ 6$ev E7, enameled steel +ith special ases.

,7. S.el=ing% !rovide steel shelvin'.

,:. Counters% !rovide solid plastic or plastic laminate counter tops and ac4 splashes, (;3 )ustom

'rade.

4>. CaCinets% !rovide cainetry and mill+or4 items +ith associated accessories and hard+are.

)ainetry shall e (;3 premium or custom 'rade and have concealed hin'es +ith adjustale

standards for shelves.

41. Case/or3% !rovide all uilt.in premanufactured metal cainetry for specialiGed functions such as

laoratories, liraries, medical and dental facilities. )ase+or4 shall comply +ith Mil -td 1@>1.

4*. Closets% !rovide premanufactured or mill+or4 closets or prefaricated coat closets

-mall !roject !art " . !a'e 1A of "#

4,. )ire E9tinguis.er CaCinets% !rovide fire extin'uisher cainets. -iGe and locate fire extin'uisher

cainets to encase extin'uisher as required y ,2!( 10 T 101. 2ire extin'uishers +ill e

provided y the )ustomer.

44. )iresto22ing Penetrations% !rovide all sleeves, caul4in', and flashin' for firestoppin'

penetrations.

44. Entrance )loor Grilles and Mats% !rovide recessed pan or surface floor mats at main only or all

uildin' entrances.

45. (rnamental Metal 8or3% !rovide ornamental metal+or4

46. (t.er "nterior S2ecialties% MotoriGed projection screen shall e +all or ceilin' or aove.ceilin'

mountin'. !ull.do+n projection screens shall e provided in lieu of motoriGed projection screens

as approved y the (ctivity.

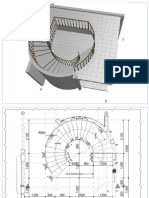

C20 STAIR CONSTRUCTION

!rovide interior and exterior stair construction. -tair desi'n, materials and construction shall

comply +ith 3%), and applicale codes and standards, includin' ,2!( 101. !rovide refu'e area

at top of stair in accordance +ith applicale (mericans +ith 8isaility (ct 8esi'n ?uide

requirements.

C30 INTERIOR FINISHES

C3010 WALL FINISHES

=nless other+ise noted in the $2!, primary +all finishes shall e painted 'ypsum +all oard.

!rovide fire resistive construction and finishes for fire separation et+een areas of the uildin' in

accordance +ith the latest adopted version of the 3%), and ,2!( 101. !rovide +ater resistant

cementitious oard at floors and +alls of tus and sho+ers.

1. Ceramic #ile% !rovide ceramic tile +all systems as defined in the Tile )ouncil of (merica 6T)(7

handoo4 for ceramic tile installation and materials for the service requirements listed. !rovide

installation and materials in accordance +ith (,-3 (10C/(11C series standards, except do not

use or'anic adhesives. !rovide manufacturer*s full ran'e of colors and styles. Tile shall e a

minimum of one 'rade aove ase 'rade. )oordinate +ith ceramic ath accessories for

modularity. 3nclude all trim pieces, caps, stops, and returns to complete installation.

*. 8allco=ering% :inyl +allcoverin' shall conform to AS#M )6:,, )ate'ory : Type 33, #A1 ' to @1"

' 61#.1 to 11 ounces7 total +ei'ht per square yard and +idth of 1#A0 mm 65" inches7. !rovide

(-TM 2A>#, )ate'ory :3, Type 333, @1" ' 611 ounces7 and aove to cover rou'h textured +alls

such as masonry. Bi'h performance faric +allcoverin' shall e +oven or non.+oven )lass (,

fire resistive material, a minimum of 111> mm 6"C inches7 +ide, +ith a soil repellent finish and a

minimum of #"0 ' 611 ounces7 per square yard exclusive of ac4in'. 0Tac4ale0 +all coverin'

shall e /self.healin'0 from tac4 penetration throu'h the coverin' into the sustrate. (coustical

+allcoverin' shall e textured, +oven or non.+oven, )lass ( fire resistive material +ith an acrylic

ac4in', a minimum of 111> mm 6"C inches7 +ide and a minimum of "5" ' 61@ ounces7 per

square yard. The material shall have an ,$) ratin' of .15 on 'ypsum oard in accordance +ith

(-TM )"1#.

C3020 FLOOR FINISHES

!rovide ne+ floorin' materials as required. (ll floorin' materials, adhesives, finish coats, sealers

and mortar materials shall meet or exceed 5!( requirements for toxic sustance content

-mall !roject !art " . !a'e 1C of "#

restrictions and air quality requirementsP and shall meet or exceed fire protection requirements,

such as smo4e and flame spread requirements. ;hen layin' roadloom carpets and resilient

floorin', use the +idest sheet materials availale to avoid or minimiGe the numer and extent of

seams. ;hen seams are required, locate seams at infrequent traffic areas. )ontractor is required

to sumit seam layout to )ontractin' &fficer for approval prior to installation.

1. Ceramic #ile% !rovide ceramic tile floor systems as defined in the Tile )ouncil of (merica 6T)(7

handoo4 for ceramic tile installation and materials for the service requirements listed. !rovide

installation and materials in accordance +ith (,-3 (10C/(11C series standards, except do not

use or'anic adhesives. !rovide manufacturer*s full ran'e of colors and styles. Tile shall e a

minimum of one 'rade aove ase 'rade.

!rovide ceramic or porcelain tile +ith a minimum rea4in' stren'th of 1014' 6#00 pounds7, (-TM

)@"C, and a maximum asorption rate of 0.5U, (-TM )#A#. Tile shall have a minimum

coefficient of friction 6+et and dry7 of 0.@, (-TM )101C.

*. Resilient )looring% -hall meet or exceed applicale (8( horiGontal requirements, and shall e

installed per manufacturer*s recommended methods and adhesives. !rovide manufacturers full

line of color and pattern selections, includin' multi.color patterns.

9inoleum -heet or Tile 2loorin' shall e 1.5 mm 60.10 inch7 'a'eP minimum 150 psi static load

limit, (-TM 2>A0P and +ith multi.color pattern and color extendin' throu'hout thic4ness, (-TM

210#", Type 3. $esilient homo'eneous vinyl sheet floorin' shall e commercial quality, 1.0 mm

60.0C0 inch7 overall 'a'e, +ith minimum 1.@ mm 6.0@@ inch7 thic4 +ear layer, protective urethane

finish, (-TM 21#0#, Type 33, ?rade 1, )lass (. $esilient vinyl composition tile shall e

commercial 'rade, # mm 6.115 inch7 'a'e, 2- --.T.#11% 617, Type 3:, )omp. 1, )lass 1,

throu'h pattern.

,. Car2et% )arpet manufacturer and installer shall e experienced, estalished and in 'ood

standin' +ith the industry. )arpet, roadloom or tile, shall e installed per the )arpet T $u'

3nstitute*s recommendations. )arpet shall e tufted, textured loop, cut/loop or tip sheared, a

minimum of 1@ oG. face +ei'ht, minimum density of @@00, 100U premium randed yarn. or

solution.dyed, Type @ or @.@ continuous hollo+ filament nylon. )arpet shall e multi.color and

patterned for soil and +ear hidin' properties. )arpet shall have hi'h performance ac4in'

+arranted a'ainst Gipperin', ed'e ravelin' and delamination, e anti.static and anti.microial.

)arpet shall meet 2lammaility ratin'sP 'enerate less than a "50 ratin', (-TM 5@@1P meet the

)ritical $adiant 2lux )lassification of not less than 0."5 ;/sq. cm., (-TM 5@"C. ;here indicated

in the room requirements, provide attached polyurethane cushion or separate polyurethane

cushion for doule stic4 pad installations, (-TM 1@@A and (-TM #@A@.

4. 8all +ase% !rovide porcelain or ceramic tile ase for porcelain or ceramic tile floor. !rovide

solid, throu'h color preformed ruer or vinyl ase for carpeted/resilient floorin' areas. !rovide a

sealant et+een ase and floor finish in all +et areas.

C3030 CEILING FINISHES

=nless other+ise noted in the room requirements, acoustical ceilin' panels shall e 1" inch y 1"

inch, +ith a minimum li'ht reflectance of .A5, )lass (, flame spread 15 or less and smo4e

development of 50 or less, (-TM 5C". (coustical ceilin' panels shall have minimum @0U

recycled content and conform to (-TM 511@". !anels shall have a factory.applied standard

+ashale painted finish or Type 3: +ith factory.applied plastic memrane.faced vinyl, 2orm: 1, 1

or #. !rovide square ed'e except as noted.

=nless other+ise noted in the room requirements for entrance loy, restrooms and sho+ers,

provide a painted, suspended 'ypsum oard ceilin'. 5xposed structural systems shall e painted.

-mall !roject !art " . !a'e 1> of "#

C30(0 PAINTING

(ll paintin' and coatin' materials shall e lo+ :&), comply +ith local air quality control la+s and,

re'ulationsP and conform to the Master*s !ainters 3nstitute*s 6M!37 rc$itectural% &nterior Systems

"anual and the M!3*s "aintenance and Repainting "anual recommendations for paint systems,

surface preparation and applications.

!rovide minimum of one prime coat and t+o finish coats. The prime coat shall not e comined

+ith texture or other coatin's. -eal and prime all surfaces to cover underlyin' stains or

discoloration that may affect finish paint. 2inish coats shall provide full covera'e of undercoats

and sustrates. (ll +alls and ceilin's in +et area shall have semi.'loss paint. (ll +ood or metal

cased openin's, door trims and casin's, +indo+ trims and casin', and other finish trim shall have

semi.'loss paint. (ll interior +alls and ceilin's shall have satin or e''shell finish. 2or previously

painted surfaces, prime all surfaces to ensure compatiility of finish coats. 8o not paint

prefinished surfaces except as noted.

!rovide 3nstitutional 9o+ &dor/9o+ :&) 9atex paint or Bi'h !erformance (rchitectural 9atex

systems as defined and approved y the M!3 -ystems Manual for the various sustrates required

to e painted.

Paint;Color Selection% !rovide paint systems tested to /8etailed !erformance 9evel0 standard

as defined y M!3. !aints shall e readily availale for purchase in standard colors.

SECTION D. SERVICES

D10 CONVE)ING 5levators and 5scalators . ,ot used

D20 PLU*BING

!rovide plumin' fixtures, appliances, and equipment complete and usale as required y !art #.

(ll plumin' fixtures, appliances and equipment, pipin', valves, accessories, and appurtenances

shall comply +ith 3nternational !lumin' )ode 63!)7 and all other applicale codes and

standards, includin' ener'y, +ater conservation, and local activity re'ulations and standards.

1. &omestic 8ater% !rovide (-TM % CC Type N or 9 copper tuin' and fittin's for pipe siGes "

inches or smaller. !rovide Type 9 tuin' aove 'round +ith solder fittin's. 2or uried pipin',

use Type N tuin' +ith solder fittin's, or )hlorinated polyvinyl chloride 6)!:)7 !lastic pipe,

fittin's, and solvent cement per (-TM 8 1C"@/8 1C"@M for siGes " inches and smaller.

!rovide mineral fier insulation +ith vapor arrier on domestic +ater 6hot and cold7 supply and

recirculation pipin'. !rovide re.circulatin' pumps or instantaneous +ater heaters for hot +ater

systems +ith fixtures 'reater than 100 ft from hot +ater source. !rovide +ater hammer arrestors

per !83 -T8 ;B.110 as required for rapid +ater shut off scenarios. (ll +ater valves except for

fixture shut off valves shall e (,-3 %1@.1C rass, full port all type. (ll plumin' fixtures shall

have separate shut off valves. (ll pipin' shall e concealed in +alls, attic spaces, or in cra+l

spaces under floors. !rovide access panels for valves ehind +alls. ,o under sla +ater pipin'

is allo+ed. 2ittin's for annealed copper tuin' shall conform to (,-3 %l@.11. -older and flux

shall e lead free. 5xposed exterior pipin' is prohiited unless other+ise not practical. !rovide

identification for pipin' and equipment.

*. 8all Penetrations% !ipin' +hich penetrates fire rated +alls shall e completely sealed to

maintain fire resistance inte'rity as required y )ode. !enetrations throu'h +alls that are not fire

rated shall e adequately supported and sealed. !ipe penetrations throu'h exterior +alls shall e

sleeved, caul4ed +ith +eatherproof sealant and provided +ith finish trim.

-mall !roject !art " . !a'e 10 of "#

D2010 PLU*BING FIXTURES

2ixtures shall e provided complete +ith fittin's, and chromium.plated, or nic4el.plated rass

6polished ri'ht or satin surface7 trim. (ll fixtures, fittin's, and trim, shall e from the same

manufacturer and shall have the same finish. (ccess panels shall e provided for all athtus

and sho+ers, except at exterior and party +alls and +here tu or sho+ers are ac4 to ac4.

!rovide cleanouts in accordance +ith the plumin' code. $otate or extend cleanouts required to

facilitate maintenance and clearin' of loc4a'e in +aste pipin'.

1. )aucets% (ll faucets shall e rass construction, +asherless type, +ith seals and seats

comined in one replaceale ceramic dis4 valve cartrid'e desi'ned to e interchan'eale +ith all

lavatories, athtus and 4itchen sin4s, or havin' replaceale seals and seats removale either as

a seat insert or as a part of a replaceale valve unit. 2aucets provided shall e of the same type

and manufacturer throu'hout the facility, unless other+ise noted. 9avatory faucets shall e =.-.

5nvironmental !rotection ('ency 65!(7 ;atersenseW certified and laeled athroom sin4

faucets.

*. 8ater Closets% ;ater closets shall e in accordance +ith (,-3 (111.1>.1, +ith trim conformin'

to (111.1>.5. ;ater closets shall e vitreous china and have an elon'ated o+l +ith trip lever,

unlined tan4, close coupled siphon jet, floor outlet +ith +ax 'as4et, flan'e and an anti.siphon float

valve. !rovide +hite closed front seat and cover for private toilets and open front seat cover for

pulic facilities. ;ater consumption shall e no 'reater than 1.@ 'allon maximum per complete

flushin' cycle. !rovide self.closin' meterin' type flush valve on flush valve type +ater closets,

unless electronic control is specified in !art #. Maximum flush volume shall not exceed 1.1C

'allon per flush 6?!27 6".C 9iter per flush 69!277 for sin'le function flush valves. 8ual function

flush valves shall provide a flush of 0.C to 1.@ ?!2 6#.0 to @.0 9!27 or 1.1C ?!2 6".C 9!27

avera'e for 1 lo+ volume flushes and one hi'h volume flush. Tan4 type +ater closets shall e

=.-. 5nvironmental !rotection ('ency 65!(7 ;atersenseW certified and laeled toilets.

*. !rinals% !rovide =.-. 5nvironmental !rotection ('ency 65!(7 ;atersenseW certified and

laeled ceramic.type urinals.

,on ;ater =se =rinals: (-M5 (111.1>.1, +hite vitreous china, +all.mounted, +all outlet, non.

+ater usin', inte'ral drain line connection, +ith sealed replaceale cartrid'e or inte'ral liquid seal

trap insert. The urinal and trap assemly shall maintain a sufficient arrier of a iode'radale

immiscile liquid to provide the trap seal and inhiit the ac4flo+ of se+er 'ases. 2or urinals that

use a replaceale cartrid'e, provide four additional cartrid'es for each urinal installed. !rovide

an additional quart of iode'radale liquid for each urinal installed. !rovide (-M5 (111.@.1M

concealed chair carriers. 3nstallation and testin' shall e in accordance +ith the manufacturers*

recommendations. 8rain lines that connect to the urinal outlet shall not e made of copper tue

or pipe. =rinal desi'n and installation shall e (8( compliant. -lope the sanitary se+er ranch

line for non.+ater use urinals a minimum of 1/".inch per foot. Manufacturer shall provide an

operatin' manual and on.site trainin' for the proper care and maintenance of the urinal.

,. La=atories% =nless other+ise specified y !art #, lavatories shall e inte'ral to the vanity

countertops. 5ach lavatory shall e provided +ith hot and cold +ater tempered y means of a

mixin' valve or comination faucet.

4. Sin3s% (-M5/(,-3 (111.1>.#M sin4, 10 'a'e stainless steel +ith inte'ral mountin' rim,

minimum dimensions of C"0 mm 6## inches7 +ide for t+o compartment or 5@0 mm 611 inches7

+ide for one compartment y 5@0 mm 611 inches7 front to rear, +ith led'e ac4 and undersides

coated +ith sound dampenin' material.

-mall !roject !art " . !a'e 11 of "#

4. 8ater Coolers% ($3 1010, +all.mounted, uler style, air.cooled condensin' unit, ".10 m9 per

second 6".0 'ph7 minimum capacity, stainless steel splash receptor, doule +all heat exchan'er,

and all stainless steel cainet. 3nstall in accordance +ith the manufacturers instructions.

5. S.o/ers% !rovide =.-. 5nvironmental !rotection ('ency 65!(7 ;atersenseW certified and

laeled sho+erheads connected to concealed pipe connected to copper alloy sin'le control type

mixin' valve +ith front access inte'ral scre+driver stops. (nchor the mixin' valves and the pipe

to each sho+erhead in +all to prevent movement. =nless other+ise specified y !art #, sho+ers

shall e supplied +ith +ater at a temperature no more than 110X2 y means of a pressure

alance, temperin' or mixin' valve.

6. Ser=ice sin3s% (-M5 (111.1>.1M, +hite enameled cast.iron or (-M5 (111.1>.1M +hite

vitreous china, +all mounted and floor supported y +all outlet cast.iron !.trap, minimum

dimensions of 5@0 mm 611 inches7 +ide y "5A mm 61C inches7 front to rear +ith 1#0 mm 6> inch7

splashac4, and stainless steel rim 'uard. !rovide (-M5 (111.1C.1M copper alloy ac4.

mounted comination faucets +ith vacuum rea4er and 10 mm 60.A5 inch7 external hose threads

7. Mo2 Sin3s% !re.cast terraGGo or (-M5 (111.1>.1M +hite vitreous china floor.mounted mop

sin4, >1" mm x >1" mm x #05 mm 6#@ inches x #@ inches x 11 inches7. TerraGGo shall e made

of marle chips cast in +hite !ortland cement to a compressive stren'th of not less than 15 m!a

6#@15 !-37 A days after castin'. !rovide rass ody drains +ith nic4el ronGe strainers cast

inte'ral +ith mop sin4. !rovide stainless steel rim 'uard for mop sin4. !rovide chrome.plated

exposed hot and cold +ater faucets (-M5 (111.15.M +all.mounted copper alloy faucets s+in'

spout +ith 10 mm 6#/" inch7 hose connection, vacuum rea4er, and pail hoo4. !rovide mop

han'er on +all aove sin4 suitale for four mops.

:. Laundr$ Sin3s% (,-3 R11".1, plastic, t+o compartment, minimum dimensions of 101@ mm +ide

y 5## mm 6"0 inches +ide y 11 inches7 front to rear, +ith floor.supported steel mountin' frame

secured to +all. !rovide (-M5 (111.1C.1M copper alloy centerset faucets, s+in' spout +ith

aerator, and stainless steel drain outlets +ith cup strainers, and "0 mm 61.5 inch7 adjustale !.

trap +ith drain pipin' to vertical vent stac4.

1>. Emergenc$ E$e/as.% (,-3 R#5C.1, +all.mounted self.cleanin', non.clo''in' eye and face

+ash +ith quic4 openin', full.flo+ valves, stainless steel eye and face +ash receptor. !rovide

copper alloy control valves. !ressure.compensated temperin' valve is required for emer'ency

fixtures, +ith leavin' +ater temperature setpoint adjustale throu'hout the ran'e 15.5 and #5

de'rees ) 6@0 to >5 de'rees 27 unless cold +ater supply meets temperature criteria.

D2020 DO*ESTIC WATER DISTRIBUTION

1. Natural Gas or Pro2ane )ired Storage 8ater 'eaters% !rovide hi'h efficiency stora'e type

natural 'as or propane fired +ater heaters per (,-3 R11.10.1 or (,-3 R11.10.# meetin' (?(

requirements. =nit efficiency shall meet or exceed that listed in the Title.1" -tandards. ;ater

heaters shall e equipped +ith 'lass.lined steel tan4s, minimum $.15 polyurethane foam

insulation, replaceale anodes, and adjustale ran'e thermostat to allo+ hot +ater settin's

et+een "# and A1 de'rees ) 6110 and 1@0 de'rees 27. ;ater heater +arranty shall e a

minimum of 10 years. !rovide vent in accordance +ith ,2!( 5". !rovide lo+ ,&x urners that

meet -)(SM8 requirements. 3nstall in accordance +ith manufacturer*s instructions and the

code. ;here earthqua4e loads are applicale, +ater heater supports shall e desi'ned and

installed for seismic forces in accordance +ith the 3nternational %uildin' )ode.

*. Electric 8ater 'eaters% !rovide electric +ater heaters +ith doule heatin' element per =9 1A".

=nit efficiency shall meet or exceed that listed for 25M! or 5,5$?Y-T($, or as listed in

-mall !roject !art " . !a'e 11 of "#

(-B$(5 >0.1, +hichever is 'reatest. ;ater heaters shall e equipped +ith 'lass.lined steel

tan4s, hi'h efficiency type, insulated +ith polyurethane foam insulation, replaceale anodes, and

adjustale ran'e thermostat to allo+ hot +ater settin's et+een "# and A1 de'rees )

,. &omestic 8ater +oilers% %oilers shall e desi'ned, tested, and installed per (-M5 )-8.1

6)ontrols and -afety 8evices7 and (-M5 %!:) 6%oiler and !ressure :essel )ode7. The oiler

shall meet the requirements of the =9 A>5, ,2!( C5, (,-3 RC#.#, and (-M5 )-8. %oilers must

e certified y ,aval !ersonnel or a contractor approved y the )ontractin' &fficer.

D2030 SANITAR) WASTE + VENT