Professional Documents

Culture Documents

Risks of Flamable Materials

Uploaded by

shcnmartinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risks of Flamable Materials

Uploaded by

shcnmartinCopyright:

Available Formats

28 www.aiche.

org/cep April 2012 CEP

Back to Basics

M

ost chemical plants contain fammable materi-

als and face hazards related to the combustion

of these materials. Almost all of the 100 worst

chemical plant accidents involved fammable materials (1).

This demonstrates the need to manage the risk of fres and

explosions related to fammable materials.

Managing these risks requires an understanding of three

key concepts: the anatomy of the fre and explosion process;

the properties that characterize fammable materials; and the

procedures used to reduce fre and explosion hazards.

This article discusses gas and liquid fammability

hazards. Solids, including dusts, are more diffcult to char-

acterize and are not covered here. Furthermore, this is an

introduction, and additional references or expertise should

be consulted for major fammability hazards (2-4).

The anatomy of re

The necessary ingredients of a fre are a fuel, an oxidant,

and an ignition source (Figure 1). The fuel and oxidant

must be present at certain relative concentrations for a fre

to start, and the ignition source must be robust enough to

initiate a fre. The oxygen found in air is the most com-

mon oxidant, but other materials, such as chlorine, fuorine,

and nitrates, may also act as oxidants. Combustion always

occurs in the vapor phase; liquids are volatilized and solids

are decomposed prior to combustion.

The difference between a fre and an explosion is

the time frame of the event. Fires occur over a very long

time frame and have a relatively low energy release rate.

Explosions occur over a very short time frame usually

milliseconds or microseconds and the energy release rate

is very high.

Characterizing ammable materials

Flammable gases and liquids can be characterized based

on several properties (Table 1). These are not fundamental

properties, but rather each is a function of particular experi-

mental apparatuses and procedures. Thus, there is wide

variability in these properties. In addition, these properties

do not defne rigid boundaries between safe and unsafe

operation. All of these nuances must be carefully considered

when handling fammable materials.

Flammability limits. The two most important properties

of fammable gases are the upper fammability limit (UFL)

and the lower fammability limit (LFL). These are frequently

called the upper and lower explosion limits (UEL and LEL).

The LFL is the concentration of fuel vapor in air below

which combustion is not possible; the mixture is considered

too lean. The UFL is the fuel vapor concentration above

Flammable materials can cause res and

explosions if they are not handled properly.

Understanding these materials

and the risks they pose is the rst step

to mitigating re hazards.

Daniel A. Crowl

Michigan Technological Univ.

Minimize the Risks of

Flammable Materials

Ignition Source

O

x

i

d

a

n

t

F

u

e

l

p Figure 1. A re can only occur when a fuel, an oxidant, and an ignition

source are present.

Copyright 2012 American Institute of Chemical Engineers (AIChE)

CEP April 2012 www.aiche.org/cep 29

which combustion is not possible; in this case, the fuel is too

rich. Both the LFL and UFL have units of volume-percent

fuel in air.

The LFL and UFL are typically determined by mixing

the fammable gas in a closed vessel with an oxidant and

other gases, such as nitrogen, and then attempting to ignite

it. If the ignition is successful, the pressure inside the vessel

will frst increase rapidly to a maximum pressure and then

decrease as the gases are quenched and cooled on the vessel

wall. The percent pressure increase is determined by sub-

tracting the initial starting pressure from the maximum pres-

sure, dividing by the initial starting pressure, and multiplying

by 100. The fammability limits are based on an arbitrary

pressure increase. In the U.S., this is a 7% pressure increase,

as specifed by ASTM E918-83 (5). Standards organizations

in other countries have used 5% and even 10%. Figure 2 is a

typical plot of the maximum pressure vs. fuel concentration

determined by this method. The maximum pressure changes

as a function of fuel concentration. Other methods for defn-

ing these limits can be found in Ref. 6.

LFL and UFL values are typically reported at room

temperature and pressure. In general, the LFL decreases and

the UFL increases with increasing temperature. Increasing

pressure generally increases the UFL, but the LFL is mostly

unaffected. The quantitative estimation of the effects of

pressure and temperature on fammability limits is poorly

understood.

LeChateliers rule can be used to provide an initial

estimate of the fammability limits for mixtures of gases,

although experimental verifcation is always advised:

where LFL

mix

is the lower fammability limit of the mixture,

n is the number of combustible species, y

i

is the mole frac-

tion of combustible species i computed on a combustible-

species-basis only, and LFL

i

is the lower fammability limit

of the pure combustible species i.

Table 1. Flammability properties are useful for determining whether ammable mixtures will form (13).

Species LFL, vol% fuel UFL, vol% fuel Flashpoint, C LOC, vol% oxygen MIE, mJ AIT, C

V

a

p

o

r

s

Methane 5.0 15.0 188 12 0.28 600

Ethane 3.0 12.5 135 11 0.24 515

Propane 2.1 9.5 104 11.5 0.25 450

Hydrogen 4.0 75.0 5 0.018 400

Ammonia 16.0 25.0 651

Carbon Monoxide 12.5 74.0 5.5 609

Hydrogen Sulde 4.3 45.0 7.5 260

Acetylene 2.5 80.0 18 0.020 305

L

i

q

u

i

d

s

Hexane 1.2 7.5 23 12 0.248 234

Ethylene 2.7 36.0 136 10 450

Benzene 1.4 7.1 11 11.4 0.225 562

Ethanol 4.3 19.0 13 10.5 422

Methanol 7.5 36.0 11 10 0.140 463

Formaldehyde 7.0 73.0 53 430

Acetone 2.6 12.8 18 11.5 538

Styrene 1.1 6.1 32 9.0 490

Gasoline 1.4 7.6 43 12

10

0 2 4 6 8 10

LFL UFL

M

a

x

i

m

u

m

E

x

p

l

o

s

i

o

n

P

r

e

s

s

u

r

e

,

b

a

r

g

Fuel Concentration in Air, vol%

8

6

4

2

0

p Figure 2. The maximum explosion pressure during combustion changes

with fuel concentration.

Article continues on next page

LFL

mix

=

1

y

i

LFL

i i =1

n

1 ( )

Copyright 2012 American Institute of Chemical Engineers (AIChE)

30 www.aiche.org/cep April 2012 CEP

Back to Basics

A similar expression can be written for the upper fam-

mability limit.

LeChateliers rule is empirical and contains many

assumptions that may or may not be valid for a particular

situation (7). It is known to be more accurate for calculating

the LFL than the UFL.

Other properties that can be used to characterize famma-

ble gases include the limiting oxygen concentration (LOC),

the minimum ignition energy (MIE), and the auto ignition

temperature (AIT).

Limiting oxygen concentration. The LOC is the oxygen

concentration below which combustion is not possible at any

fuel concentration. The LOC has units of volume-percent

oxygen and is determined via the same closed-vessel appara-

tus used to determine the fammability limits.

Minimum ignition energy. The MIE is the minimum

energy of an ignition source, such as a spark, required to

ignite the vapor. This property varies widely. For fam-

mable vapors, a nominal value of 0.025 mJ is frequently

used. This is a very small amount of energy. In comparison,

a small coin dropped from a height of less than 1 mm has

more energy than this, and a spark that is just detectable to

the touch contains about 20 mJ of energy. These low values

indicate that ignition sources are plentiful. In fact, the elimi-

nation of ignition sources is not a robust method to prevent

fres and explosions, although ignition source reduction is

still essential.

Reference 8 provides a procedure for experimental deter-

mination of the MIE.

Autoignition temperature. The AIT is the temperature

above which adequate energy is available in the environment

to provide an ignition source. To determine the AIT, a small

quantity of fammable liquid is injected into a preheated

fask at a set temperature. The fask is observed over a

fxed period of time for visible combustion behavior (9). If

combustion is not observed, then the fask temperature is

increased until combustion occurs.

Flashpoint. A liquids vapor pressure is a measure of

the relative concentration of vapor in equilibrium with the

liquid. At high temperatures, fammable liquids will have

higher evaporation rates and higher vapor pressures, often

creating fammable mixtures above the surface of the liquid.

The fashpoint is the lowest temperature at which this vapor

forms an ignitable mixture with air. At the fashpoint, the

vapor will burn only briefy. At a much higher tempera-

ture, called the fre-point temperature, the liquid will burn

continuously. Since a fre or explosion can propagate from a

fash, the fashpoint temperature is the primary property used

to characterize liquid fammability.

Figure 3 is a schematic of the apparatus used to estimate

the fashpoint temperature based on the Cleveland open-

cup method (10). The liquid is placed in a small, open cup,

which is heated with a Bunsen burner. A wand with a small

fame at one end is moved back and forth above the liquid

surface, and the temperature of the liquid is increased until a

fash is observed. One problem with this method is that the

open cup is vulnerable to drafts, which remove the famma-

ble vapor. This problem can be avoided by using a closed-

cup method (11).

Figure 4 depicts the relationships among the proper-

ties used to characterize combustion and how they relate to

the saturation vapor pressure curve. The LFL intersects the

Vapor Pressure Curve

Flammable

Gas Liquid

Flashpoint Ambient AIT

LFL

LFL

UFL

UFL

C

o

n

c

e

n

t

r

a

t

i

o

n

(

V

a

p

o

r

P

r

e

s

s

u

r

e

)

Auto-

ignition

Zone

Temperature

p Figure 3. The Cleveland open-cup tester is commonly used to determine

ashpoint temperature (3).

p Figure 4. The LFL, UFL, AIT, and ashpoint are functions of temperature

and vapor pressure.

Thermometer

Open Cup with Liquid

Bunsen Burner

From Gas

Supply

Heating

Plate

Flame

Test Flame

Applicator

Copyright 2012 American Institute of Chemical Engineers (AIChE)

CEP April 2012 www.aiche.org/cep 31

saturation vapor pressure curve at the fashpoint temperature.

The AIT is the lowest temperature in an AIT zone. It is not

known what happens to the UFL, LFL, and AIT zone bound-

ary at high temperatures.

Many methods are available to estimate fammability

properties (2, 3). These prediction methods should be used

only for quick initial estimations and should not be used for

engineering design. In addition, because the temperature and

pressure effects are not well understood, experimental values

should be obtained at conditions as close as possible to the

actual process conditions.

For some partial oxidation reaction processes, the UFL is

a key operating parameter. The conversion effciency of the

reactor and the safety of the process depend on the precision

and accuracy of the UFL estimate. Typically, the process is

operated at vapor fuel concentrations well above the UFL to

prevent an explosion. However, as the fuel composition is

reduced and approaches the UFL, the reaction conversion,

and thus the yield, increases. In this case, there is an obvious

tension between safety and production, and achieving the

right balance requires a high degree of confdence in the

fammability data.

Published LFL and UFL data are available only for air

mixtures. However, situations that involve fammable non-

air mixtures are frequently encountered, such as when an

inert gas (e.g., nitrogen or carbon dioxide) is used to control

fammable concentrations. A triangle fammability diagram

is essential for these cases.

Triangle diagrams

Figure 5 is a typical triangle diagram for a fam-

mable mixture that contains nitrogen. The axes of the

diagram represent the concentrations of each of the

three components fuel, oxygen, and nitrogen. At

any point on the fgure, the concentrations must add

up to 100%. Most fammable materials demonstrate

a fammability zone (the shaded area in Figure 5)

that is, a region within which the mixture is fam-

mable at all concentrations.

The line connecting point A and point B is the

air line. This line runs from point A at the top of the

triangle (i.e., 100% fuel) to the point on the diagram

that corresponds to a concentration of 79% nitrogen

and 21% oxygen (i.e., pure air, point B) and represents

all possible concentrations of a fuel and air mixture.

The line connecting point C and point D is the

stoichiometric line. This line runs from the point

on the diagram corresponding to a concentration of

100% nitrogen (point D) to the oxygen axis and represents

all possible stoichiometric concentrations of a fuel and

oxygen mixture. The point at which the stoichiometric line

intersects the oxygen axis (point C) depends on the stoichi-

ometry of the reaction.

Consider, for example, the following reaction:

C

m

H

x

O

y

+ z O

2

m CO

2

+ (x/2) H

2

O

For this reaction, the stoichiometric line intersects the

oxygen axis at:

100

z

1+ z

2 ( )

The air line intersects the fammability zone at the fam-

mability limits (i.e., LFL and UFL). The LOC is found at the

point where a line parallel to the fuel axis just touches the

fammability zone; its value is read from the oxygen axis.

Triangle fammability diagrams are frequently used

in industrial facilities to determine whether a fammable

mixture will form during a procedure, such as inerting and

purging, taking vessels and equipment in and out of service,

and other common operations. Unfortunately, only a few

complete triangle fammability diagrams have been experi-

mentally determined, including methane and ethylene (12).

Triangle diagrams differ depending on the fuel and the inert

gas used. A triangle fammability diagram can be approxi-

mated (2, 3) using a limited amount of experimental data.

The following rules of thumb exist to help engineers use

Nitrogen

Flammability

Zone

UFL in Pure Oxygen

Air Line

20 40 60 80 100 0

20

40

80

100

80

60

40

20

0

0

O

x

y

g

e

n

F

u

e

l

LFL

UFL

LOC

100

S

to

ic

h

io

m

e

tric

L

in

e

60

A

A

B

D

C

LFL in

Pure Oxygen

u Figure 5. A triangle ammability diagram can be used to

determine ammable compositions for a non-air mixture.

Copyright 2012 American Institute of Chemical Engineers (AIChE)

32 www.aiche.org/cep April 2012 CEP

Back to Basics

triangle fammability diagrams for chemical plant operations.

Equations for these rules can be found in Refs. 2 and 3.

1. If two gas mixtures R and S are combined, the

composition of the resulting mixture (M) will lie on a line

connecting points R and S on the triangle fammability

diagram (Figure 6). The location of point M depends on the

relative molar content of R and S; if the molar content of

S in mixture M is higher than that of R, the composition of

the fnal mixture will be closer to point S.

2. If mixture R is continuously diluted with mixture S,

the mixture composition will move closer and closer to

point S along a straight line (as indicated by the arrow on

Figure 6). Eventually, at infnite dilution, the mixture

composition will be at point S.

3. For systems with composition points that fall on a

straight line that passes through an apex corresponding to

one pure component, the other two components are present

in a fxed molar ratio along the entire length of the line.

This is shown by the air line on Figure 5, where the ratio of

oxygen to nitrogen is always constant.

Using the triangle ammability diagram

Example 1. A vessel contains methane gas under

pressure. In preparation for a vessel-entry procedure, the

engineers must remove the methane from the vessel and

replace it with air in a way that does not produce a fam-

mable mixture.

Figure 7 depicts what would occur if the vessel is

opened, depressurized, and flled with air. The gas composi-

tion in the vessel has an initial value of 100% methane (point

A), and then follows the air line until it reaches pure air

(point B). This procedure creates a fammable mixture as

indicated by the concentration line entering the fammability

zone and poses a fre and explosion hazard.

Figure 8 is the triangle diagram for a procedure that

removes the methane without forming a fammable mix-

ture, avoiding the fammability zone. Starting with pure

methane at point A, nitrogen is introduced into the vessel

until the composition reaches point B. Then, air is added

until the composition reaches point C. This procedure

avoids the fammability zone. Equations are available to

estimate the concentration at point B (3).

A similar procedure can be used before placing the

p Figure 7. Taking a vessel that contains methane under pressure out of

service can form a ammable mixture if the proper procedure is not used.

In this case, the vessel is initially depressurized to atmospheric pressure

and then vented to the air. This procedure creates a ammable mixture.

p Figure 8. To avoid the ammability zone, nitrogen is added to the

pure fuel. When the vessel is vented with air, the system does not form

a ammable mixture.

Nitrogen

0

100

0

100

100

Flammable

UFL

LFL

Air Line

0

O

x

y

g

e

n

M

e

t

h

a

n

e

B

A

Start Here (All Fuel)

End Here (All Air)

Nitrogen

0

100

0

100

100

Flammable

UFL

LFL

Air Line

0

O

x

y

g

e

n

F

u

e

l

B

A

C

Nitrogen Added

Air Added

D

Fuel Added

B A

C

0 100

0

100 0

100

R

M

S

p Figure 6. As mixture R is diluted with mixture S, the concentration of the

combined mixture M follows a straight line between the compositions of the

two original mixtures.

Copyright 2012 American Institute of Chemical Engineers (AIChE)

CEP April 2012 www.aiche.org/cep 33

vessel back into service. In this case, the vessel initially

contains 100% air (point C). The frst step is to add

nitrogen into the tank, shifting the concentration along the

nitrogen axis to the right, eventually reaching point D. At

point D, fuel can now be added following the blue line to

point A, which is pure methane. This avoids the fammabil-

ity zone.

Example 2. A storage vessel containing a fuel is inerted

with pure nitrogen (i.e., no oxygen is present in the vapor).

A common misconception is that vapors in a storage vessel

that have been inerted with nitrogen will not become fam-

mable when the vapor escapes the vessel.

Figure 9 shows what happens when vapor escapes from

an inerted vessel. Point A represents the vapor composi-

tion in the vapor space of the vessel, and point B represents

pure air. The vapor space composition moves from point

A to point B as vapor escapes and mixes with air pass-

ing through the fammability zone. The use of an inert gas,

such as nitrogen, carbon dioxide, or others, is a convenient

way to control vapor concentrations to prevent fammable

atmospheres. More details on inerting and purging methods

are provided elsewhere (3).

Wrapping up

Flammable materials have been used and handled for a

long time, and a reasonable amount of data, mostly at room

temperature and pressure for pure species, are available.

Despite this, the fundamental basis for the properties that

characterize fammable materials is not well understood

and the effects of temperature, pressure, and composition

on these properties cannot be adequately predicted. A better

fundamental understanding would reduce the requirements

for costly experimentation to obtain data, and result in an

even better capability to handle these materials safely.

CEP

Literature Cited

1. Marsh Risk Consultants, The 100 Largest Losses, 1972

2001, 20th ed., Marsh Risk Consultants, Chicago, IL

(Feb. 2003).

2. Crowl, D. A., Understanding Explosions, John Wiley & Sons,

Hoboken, NJ (2003).

3. Crowl, D. A., and J. F. Louvar, Chemical Process Safety:

Fundamentals with Applications, 3rd ed., Prentice Hall, Upper

Saddle River, NJ (2011).

4. Center for Chemical Process Safety, Guidelines for Vapor

Cloud Explosion, Pressure Vessel Burst, BLEVE and Flash Fire

Hazards, 2nd ed., AIChE, New York, NY, and John Wiley &

Sons, Hoboken, NJ (2011).

5. American Society for Testing and Materials, Standard

Practice for Determining Limits of Flammability of Chemicals

at Elevated Temperature and Pressure, ASTM E918-83, ASTM,

Conshohocken, PA (2007).

6. Crowl, D. A., and Y. Jo, A Method for Determining the Flam-

mable Limits of Gases in a Spherical Vessel, Process Safety

Progress, 28 (3), pp. 227236 (Sept. 2009).

7. Mashuga, C. V., and D. A. Crowl, Derivation of LeChateliers

Mixing Rule for Flammable Limits, Process Safety Progress,

19 (2), pp. 112117 (Summer 2000).

8. American Society for Testing and Materials, Standard Test

Method for Minimum Ignition Energy and Quenching Distance

in Gaseous Mixtures, ASTM E582-07, ASTM, Conshohocken,

PA (2007).

9. American Society for Testing and Materials, Standard Test

Method for Autoignition Temperature of Liquid Chemicals,

ASTM E659-78, ASTM, Conshohocken, PA (2005).

10. American Society for Testing and Materials, Standard Test

Method for Flash and Fire Points by Cleveland Open Cup

Tester, ASTM D92-11, ASTM, Conshohocken, PA (2011).

11. American Society for Testing and Materials, Standard Test

Methods for Selection and Use of ASTM Standards for the Deter-

mination of Flash Point of Chemicals by Closed Cup Methods,

ASTM E502-7, ASTM, Conshohocken, PA (2007).

12. Mashuga, C. V., and D. A. Crowl, Application of the Flam-

mability Diagram for Evaluation of Fire and Explosion Hazards

of Flammable Vapors, Process Safety Progress, 17 (3),

pp. 176183 (Fall 1998).

13. Yaws, C. L. ed., Chemical Properties Handbook, McGraw-

Hill, New York, NY (1999).

DANIEL A. CROWL is the Herbert H. Dow Professor for Chemical Process

Safety at Michigan Technological Univ. in Houghton, MI. He has been

involved with process safety education and research since 1985. He is

the author or editor of several books on process safety, has produced

many SAChE modules and student certicate programs, and is a past

editor of AIChEs quarterly journal Process Safety Progress. He is a

member of the AIChE SAChE Committee, the 11a Committee on Loss

Prevention, the Chem-E-Car Rules Committee, and the ASTM E27

Committee on the Hazard Potential of Chemicals. He is a Fellow of

AIChE, the Center for Chemical Process Safety (CCPS), the ACS Div. of

Chemical Health and Safety, and the National Speleological Society.

He has received numerous awards, including most recently the Merit

Award from the Mary Kay OConnor Process Safety Center at Texas A&M

Univ. He holds a BS in fuel science from the Pennsylvania State Univ.

and an MS and PhD from the Univ. of Illinois.

p Figure 9. Fuel vapors in a vessel that is inerted with nitrogen may

become ammable when they escape and mix with air.

Nitrogen

0

100

0

100

100

Flammable

UFL

LFL

Air Line

0

O

x

y

g

e

n

F

u

e

l

A

B

Fire and Explosion

Hazard

Copyright 2012 American Institute of Chemical Engineers (AIChE)

You might also like

- X3 ND White PaperDocument22 pagesX3 ND White PaperBoyITBNo ratings yet

- HUAWEI MateBook X Pro User GuideDocument30 pagesHUAWEI MateBook X Pro User GuideshcnmartinNo ratings yet

- 2200e Engineering HandbookDocument92 pages2200e Engineering HandbookshcnmartinNo ratings yet

- Thermal Imaging For Science / R&DDocument44 pagesThermal Imaging For Science / R&DshcnmartinNo ratings yet

- Just Energy Q3 ReportDocument68 pagesJust Energy Q3 ReportshcnmartinNo ratings yet

- Chemisorption PosterDocument1 pageChemisorption PostershcnmartinNo ratings yet

- Nicola Pinna Atomic Layer Deposition 130118Document68 pagesNicola Pinna Atomic Layer Deposition 130118shcnmartinNo ratings yet

- GRE题库所有244道Issue提纲Document77 pagesGRE题库所有244道Issue提纲shcnmartinNo ratings yet

- Ulllted States Patent (19) (11) Patent Number: 6,013,597: Karim Et Al. (45) Date of Patent: Jan. 11, 2000Document10 pagesUlllted States Patent (19) (11) Patent Number: 6,013,597: Karim Et Al. (45) Date of Patent: Jan. 11, 2000shcnmartinNo ratings yet

- Digest of Ohio Vehicle Motor LawsDocument84 pagesDigest of Ohio Vehicle Motor LawsshcnmartinNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chap 1Document19 pagesChap 1Tapas Banerjee100% (1)

- DLL Template Wk3Document6 pagesDLL Template Wk3Reign MayorNo ratings yet

- DVC 99wierDocument2 pagesDVC 99wierMohamed ElmakkyNo ratings yet

- Boyle-s-Law-Lesson-Plan in ChemistryDocument3 pagesBoyle-s-Law-Lesson-Plan in ChemistryHavana Jabay SherrylynNo ratings yet

- Air DryersDocument99 pagesAir Dryersapi-384214360% (5)

- Geotechnics With GeosyntheticsDocument24 pagesGeotechnics With GeosyntheticsAnonymous VeDNBhNo ratings yet

- Thesis EliseCamilleChevallier Welding Plastic Strain PDFDocument211 pagesThesis EliseCamilleChevallier Welding Plastic Strain PDFHui DaiNo ratings yet

- Solid Dosage Forms: Tablets: Abhay ML Verma (Pharmaceutics)Document5 pagesSolid Dosage Forms: Tablets: Abhay ML Verma (Pharmaceutics)meet2abhayNo ratings yet

- Extraction Check Valve Afr AW-10-40Document6 pagesExtraction Check Valve Afr AW-10-40Shanmuganathan ShanNo ratings yet

- OLED Basics and Flexible DisplaysDocument18 pagesOLED Basics and Flexible DisplaysmuaheltNo ratings yet

- Metallurgy - Chapter (5) - Steels and Cast IronsDocument79 pagesMetallurgy - Chapter (5) - Steels and Cast IronsKarim Mamdouh100% (1)

- Advanced Materials for Turbofan Engine Fan BladesDocument9 pagesAdvanced Materials for Turbofan Engine Fan BladesAhmed KhasawnehNo ratings yet

- History of Cryogenics - A Cryo Central Resource From The CSA PDFDocument7 pagesHistory of Cryogenics - A Cryo Central Resource From The CSA PDFJaque BauerNo ratings yet

- Hydrogen ProbeDocument4 pagesHydrogen ProbemahiengNo ratings yet

- Ucalgary 2020 Du StevenDocument65 pagesUcalgary 2020 Du StevenmnasiroleslamiNo ratings yet

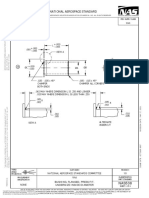

- National Aerospace Standard: Fed. Supply ClassDocument4 pagesNational Aerospace Standard: Fed. Supply ClassGlenn CHOU100% (1)

- Metalshield Info BrochureDocument12 pagesMetalshield Info Brochuresiva_nagesh_2No ratings yet

- B4 Fracture and Size EffectDocument7 pagesB4 Fracture and Size EffectClaudio Masjid MaktubNo ratings yet

- 5 Dental AmalgamDocument64 pages5 Dental AmalgamSmiley Josh100% (1)

- Exel International Group IncDocument56 pagesExel International Group InccristopherNo ratings yet

- TRUEDocument50 pagesTRUECLARISSA TAGUBANo ratings yet

- Rigid Pavement Design1Document21 pagesRigid Pavement Design1s100% (1)

- Design of Functionally Graded Dental Implant in The Presence of Cancellous BoneDocument7 pagesDesign of Functionally Graded Dental Implant in The Presence of Cancellous BoneRonin ZxxNo ratings yet

- Thermoplastic Elastomeric (TPE) Gasket Materials For Drain, Waste, and Vent (DWV), Sewer, Sanitary and Storm Plumbing SystemsDocument2 pagesThermoplastic Elastomeric (TPE) Gasket Materials For Drain, Waste, and Vent (DWV), Sewer, Sanitary and Storm Plumbing SystemsĐường Nguyễn ThừaNo ratings yet

- Bray Serie 35 - 36Document6 pagesBray Serie 35 - 36Oscar Horta PolaniaNo ratings yet

- Volume-I Part II SpecificationDocument118 pagesVolume-I Part II SpecificationHiren DesaiNo ratings yet

- Belzona 1111ps EnglDocument2 pagesBelzona 1111ps EnglNikolay GuerreroNo ratings yet

- Blast Resistant BuildingDocument35 pagesBlast Resistant Buildinggaurav jagtapNo ratings yet

- A 385 - 01 - Qtm4ns1sruqDocument10 pagesA 385 - 01 - Qtm4ns1sruqHans AbantoNo ratings yet

- TeccDocument8 pagesTeccChristian Galvez BarrantesNo ratings yet