Professional Documents

Culture Documents

Installation, Operating and Servicing Instructions for ECO, HL and HLE Water Heaters

Uploaded by

Dan FelixOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation, Operating and Servicing Instructions for ECO, HL and HLE Water Heaters

Uploaded by

Dan FelixCopyright:

Available Formats

EN 1

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

Installation, Operating and

Servicing Instructions

ECO 100 / 130 / 160

HL 100 / 130 / 160 / 210 / 240

HLE 100 / 130 / 160 / 210 / 240

ECO - HL - HLE

EN 2

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

WARNING 3

Who should read these instructions 3

Symbols 3

Recommendations 3

Applicable standards 3

Warnings 3

Packing 3

INTRODUCTION 4

Description of the specifications 4

Description of operation 4

TECHNICAL CHARACTERISTICS 5

Operating condition 5

Wiring diagram 5

INSTALLATION INSTRUCTIONS 6

Installation 6

INSTALLATION 7

Dimensions 7

Central heating connections 7

Domestic hot water connection 8

COMMISSIONING 9

Filling the tank 9

Check to be carried out before start-up 9

Setting the thermostat 9

MAINTENANCE 10

Periodic checks by the user 10

Annual service 10

Replacement of the electric heating element of the HLE 10

Emptying 10

SPARE PARTS See at the end of this manual

INDEX

EN 3

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

WHO SHOULD READ THESE INSTRUCTIONS

These instructions should be read by:

- the specifying engineer

- the installer

- the user

- the service engineer

SYMBOLS

The following symbols are used in this manual:

It is important to switch the tank OFF before carrying out

any work.

There are no user accessible parts inside the tank casing.

APPLICABLE STANDARDS

The appliances carry the CE mark in accordance with the

standards in force in the various countries.

WARNINGS

This documentation is part of the information delivered with the

appliance and must be given to the user and stored in a safe

place!

An approved installer must carry out the assembly, commissioning,

maintenance and repair of the system, in accordance with current

standards in force.

ACV shall not accept any responsibility for damage caused by non-

compliant location of the system or by use of the parts or

connections not approved by ACV for this application.

The manufacturer reserves the right to change the

technical characteristics and specification of its

products without notice.

The availability of some versions and their accessories is

market dependant.

PACKING

Units are shipped ready to install, tested and packaged in a car-

board box.

Contents of the package

One hot water tank.

One multilingual technical instruction manual.

One wall-mounting kit with support and one flow diverter.

WARNINGS

RECOMMENDATIONS

Please, read carefully this manual before installing and

commissioning the tank.

It is prohibited to carry out any modifications to the inside of

the appliance without the manufacturers prior and written

agreement.

The product must be installed and serviced by trained

engineers, in compliance with current standards.

The installation must comply with the instructions in this

manual and with the codes and standards governing systems

for the production of hot water.

Any failure to follow instructions relating to tests and test

procedures may result in personal injury or risks of pollution.

To guarantee safe and correct operation of the appliance, it

is important to have it serviced and maintained every year by

an approved installer or maintenance company.

In case of anomaly, please call your service engineer.

The parts may only be replaced by genuine factory parts. You

will find a list of the spare parts and their reference number

ACV to the end of this document.

Danger of burns

Essential instruction for

the safety of persons

and the environment.

Danger of electrocution.

Essential instruction for

the correct operation of

the installation.

EN 4

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

DESCRIPTION OF THE SPECIFICATIONS

Tank-in-Tank system

Tank-in-Tank is a heat exchanger with a built-in accumulator, made

up of two concentric tanks: the inner tank contains domestic water

to be reheated (secondary) and the outer tank contains the heating

fluid (primary) which circulates between the two tanks and transfers

its heat to the domestic water.

Hot water exchanger accumulator

The inner tank is the heart of the tank: it is subject to the

aggressiveness of the supply water, to high pressures and to

variations in temperature. This tank is made of solid chrome-

nickel stainless steel (stainless steel 304 or duplex), fully welded

under argon protection using the Tungsten Inert Gas (T.I.G.)

technique.

Before assembly, the convex bottoms are pickled and passivated in

order to improve the tanks lifespan and in particular its resistance to

corrosion. The shell is corrugated all the way up using an exclusive

manufacturing process. This design gives considerable resistance to

pressure and limits the adherence of lime scale by allowing the tank

to expand and contract.

Outer tank

The outer tank containing water from the primary circuit arriving

from the boiler, is made of carbon steel STW 22.

Thermal Insulation

Soft polyurethane foam - 30 mm thickness.

Lining

Exterior of casing vinyl coated and polypropylene cap.

Electric heating element in HLE

The HLE tank is equipped with one 2200 W heating element

controlled by the thermostat of the HLE.

Description

1. Air valve

2. Steel STW 22 outer tank

3. Domestic hot water outlet

4. Pocket containing the control thermostat

5. Electric heating element 2200 W [HLE only]

6. Insulating foam

7. Polypropylene cap

8. Polyurethane foam insulation

9. Stainless steel (304 or Duplex) inner tank

10. Domestic water return

11. Outlet and return pipes for the heating fluid

12. Domestic cold water inlet

INTRODUCTION

DESCRIPTION OF OPERATION

Operating cycle

The thermostat is triggered and starts up the pump which loads the

heating fluid. This fluid circulates around the inside tank and heats

up the domestic water. When the required temperature is reached,

the thermostat stops the loading pump.

Losses when shut down in C/h

Models Losses in c/h

ECO 100 / HL 100 / HLE 100 T = 40C 0,28

ECO 130 / HL 130 / HLE 130 T = 40C 0,25

ECO 160 / HL 160 / HLE 160 T = 40C 0,23

HL 210 / HLE 210 T = 40C 0,21

HL 240 / HLE 240 T = 40C 0,21

Temperature losses with ambient T of 20C

OFF Reheating Running Tepping

Cold Water

Heating fluid

Domestic hot water

4

3

10

1

9

11

8

2

12

6

5

7

7

12

10

1

9

11

8

2

3

7

7

EN 5

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

TECHNICAL CHARACTERISTICS

Tank characteristics

ECO

100

ECO

130

ECO

160

HL

100

HL

130

HL

160

HL

210

HL

240

HLE

100

HLE

130

HLE

160

HLE

210

HLE

240

Total capacity L 105 130 161 105 130 161 203 242 105 130 161 203 242

Primary capacity L 30 31 35 30 31 35 39 42 30 31 35 39 42

Primary uid ow rate L/h 2100 2600 3500 2100 2600 3500 4200 5500 2100 2600 3500 4200 5500

Primary pressure drop mbar 17 22 37 17 22 37 45 51 17 22 37 45 51

Heating surface m

2

1,03 1,26 1,54 1,03 1,26 1,54 1,94 2,29 1,03 1,26 1,54 1,94 2,29

Tank performances

ECO

100

ECO

130

ECO

160

HL

100

HL

130

HL

160

HL

210

HL

240

HLE

100

HLE

130

HLE

160

HLE

210

HLE

240

Peak ow at 40C L/10 236 321 406 236 321 406 547 700 236 321 406 547 700

Peak ow at 60C L/10 117 161 209 117 161 209 272 337 117 161 209 272 337

Peak ow at 40C L/60 784 1063 1349 784 1063 1349 1820 2319 784 1063 1349 1820 2319

Peak ow at 60C L/60 384 549 689 384 549 689 913 1165 384 549 689 913 1165

Constant ow at 40C L/h 658 890 1132 658 890 1132 1527 1943 658 890 1132 1527 1943

Constant ow at 60C L/h 320 465 576 320 465 576 769 994 320 465 576 769 994

Pre-heating time minutes 24 22 22 24 22 22 20 20 24 22 22 20 20

Coefcient NL 1,0 2,1 3,0 1,0 2,1 3,0 5,2 11,8 1,0 2,1 3,0 5,2 11,8

Power drawn kW 23 31 39 23 31 39 53 68 23 31 39 53 68

Heating time with the 2,2 kW

heating element, from 10 to

60C

2 h 43 3 h 27 4 h 20 5 h 37 6 h 37

Running conditions: 85C Water intake T: 10C

OPERATING CONDITION

Maximum service pressure [tank filled with water]

- Heating circuit: 3 bar

- DHW circuit: 10 bar

Test pressure [tank filled with water]

- Heating circuit: 4,5 bar

- DHW circuit: 13 bar

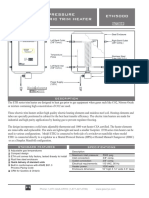

WIRING DIAGRAM

Operating temperature

- Maximum temperature: 90C

Water quality

Chlorides: < 150 mg/L [304 Stainless steel]

< 2000 mg/L [Duplex]

6 ph 8

c

1

2

N

L

1

L

1

N

2

1

7

2

1

2

3

4

5

6

1

2

3

4

5

6

c

1

2 c

1

2

3

4

6

5

HL

HLE

Br

Y/Gr

B

Br Br

Y/Gr

B

B

Br

Y/Gr

B

Br

B

Br Br W W

Y/Gr

B B B

B

G

B

R

G

Bk

Or

R

R

B Br

R

V

Br

Or

7

B. Blue

Bk. Black

Br. Brown

G. Grey

Or. Orange

R. Red

V. Violet

W. White

Y/Gr. Yellow/Green

1. 230 Volt connection cord

2. Control thermostat [60/90C]

3. Manual reset high limit thermostat [103C max.]

4. Summer/Winter switch

5. Domestic hot water priority relay

6. Electric heating element

7. Load pump [in option]

EN 6

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

INSTALLATION INSTRUCTIONS

INSTALLATION

This hot water tank should not be installed where it will be

exposed to outside weather conditions.

Choose the most appropriate location according to the position

of the boiler and the proximity of the domestic hot water distri-

bution system, in order to reduce heat losses and minimise the

pressure drops.

It may be installed either on the floor or on a wall using the

fixtures supplied, depending of the model.

Horizontal wall hung position with the domestic water connection

on the left side:

1. Mount the tank on the wall, using the supplied brackets.

2. Move if necessary the long PVCC dip tube in lower domestic

connection (see diagram below).

3. Install the ow diverter into the domestic hot-water connection.

ECO

HLE

HL

Horizontal wall hung position with the domestic water connection

on the right side:

1. Mount the tank on the wall, using the supplied brackets.

2. Move if necessary the long PVCC dip tube in lower domestic

connection (see diagram below).

3. Install the ow diverter into the domestic hot-water connection.

ECO

HLE

HL

Floor mounting :

Only for HL units.

1. Connect the cold water inlet to the tube with the long PVCC dip

tube (see diagram below).

2. This conguration does not require the plastic ow diverter.

HL HLE

Vertical wall hung position with the domestic water connection on

the bottom side:

1. Mount the tank on the wall, using the supplied brackets.

2. Install the ow diverter into the domestic cold-water connection

(see diagram below).

ECO

HL / HLE

The HLE models must be assembled with the heating

element to the bottom (DHW pipes to the bottom).

In horizontal configuration, the peak output and the

first hour continuous output will be reduced. In this

case, we recommend to oversize the tank.

EN 7

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

INSTALLATION

DIMENSIONS

ECO

100

ECO

130

ECO

160

HL

100

HL

130

HL

160

HL

210

HL

240

HLE

100

HLE

130

HLE

160

HLE

210

HLE

240

A mm 882 1042 1242 847 1007 1207 1479 1726 847 1007 1207 1479 1726

B mm 629 789 989 629 789 989 1261 1508 629 789 989 1261 1508

C mm 365 525 725 365 525 725 997 1244 365 525 725 997 1244

Weight empty [kg] 40 47 55 40 47 55 65 75 40 47 55 65 75

517

555

A

B

264

C

360

325

296

146

514

552

A

B

264

C

360

325

295

145

HL / HLE ECO

CENTRAL HEATING CONNECTIONS

PIPE DIMENSIONS

Models Central heating

ECO / HL / HLE 100 L 11/4

ECO / HL / HLE 130 L 11/4

ECO / HL / HLE 160 L 11/4

HL / HLE 210 L 11/4

HL / HLE 240 L 11/4

1. System filling valve

2. Safety valve calibrated to 3 bar

3. Expansion vessel

4. Drain cock

5. Isolation valve, heating system

6. Room thermostat

7. Optional boiler control [BC 01 or BC 03]

8. Boiler pump

9. Heating pump

10. 3-ways motorized mixing valve

11. Air valve of the primary circuit

5

5 5

1

8 9

4

2

3

6

7

5

11

Single tank with primary pump.

Horizontally mounted wall hung tank. (Excepted for the HLE)

5

5

5 5

1

8

10

4

2

3

6

7

Single tank with three ways motorized mixing valve.

Vertically mounted wall hung tank.

5

5

5 5

1

8 9

4

2

3

6

7

Single tank with primary pump.

Floor mounted tank. (HL only)

HLE tank used as electic domestic

hot water heater only

5

1

2

3

This connection

to be plugged.

Do not power the heating element ij the

oustide tank is not filled and drained.

EN 8

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

INSTALLATION

DOMESTIC HOT WATER CONNECTIONS

PIPE DIMENSIONS

Models

Cold / hot water

connections

Auxiliary connexion

ECO / HL / HLE 100 L 3/4 [M] 3/4 [F]

ECO / HL / HLE 130 L 3/4 [M] 3/4 [F]

ECO / HL / HLE 160 L 3/4 [M] 3/4 [F]

HL / HLE 210 L 3/4 [M] 3/4 [F]

HL / HLE 240 L 3/4 [M] 3/4 [F]

1. Isolating valve

2. Pressure reducer

3. Non-return valve

4. Expansion tank

5. Safety valve

6. Drain cock

7. Air vent

8. Thermostatic mixing valve

9. Circulation pump

10. Drawoff tap

11. Earth connection

The installation of a domestic safety unit is compulsory.

In order to avoid water dropping on the tank, the

domestic safety unit should not be placed directely

above the tank.

The third domestic water outlet can be used as a

return from the domestic hot water circulation loop.

Mains water kits could be in some countries due to

approval regulations.

To avoid all risk of corrosion connect the sanitary tank

directly in the earth.

Recommendations

The pipe feeding the tank with cold water must be fitted

with a safety unit comprising at least the following:

- An isolating valve [1]

- a non-return valve [3]

- a safety valve [4]: (set to < 10 bar)

- a sanitary expansion vessel of appropriate dimensions.

When the operating pressure exceeds 6 bar a pressure

reducer [2] must be installed before the safety unit.

Union fittings are recommended for easy removal of the

connections. Ideally the dielectric version is preferable

in order to protect the connections against corrosion in

the presence of dissimilar metals such as copper and

galvanised steel.

The installation of an expansion vessel avoids safety valve

runoff (loss of water).

Domestic hot water expansion vessel capacity:

5 Litres: for the following models: 100

8 Litres: for the following models: 130 / 160

12 Litres: for the following models: 210 / 240

Please see the technical instruction manual of the

expansion vessels manufacturer for further details.

2

7

5

1 1

4

10

6

1

3

9

1 1

3 3 1

8 11

2

7

5

6

1 1

4

8

10

1

3

9

1 1

3 3

1

11

Domestic hot water kit

A. Thermostatic mixing valve

B. Mixed water outlet

C. Cold water inlet

D. Drainage connection

E. Expansion vessel connection

S. Safety unit

TH. Outlet hot water tank

TC. Inlet cold water tank

Wall mounting

A

B

E

C

S

D

TC TH

Floor mounting

A

B

E

C

TC TH

S

D

Floor

mounting

Wall

mounting

EN 9

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

COMMISSIONING

Before pressurising the central heating tank (primary)

you should first pressurise the domestic hot water

tank (secondary).

Both the domestic hot water tank and the central

heating tank must be filled before using the tank.

FILLING THE TANK

Domestic hot water tank

1. Close the drain cock [6] of the DHW circuit.

2. Open the isolating valve [1] of the DHW circuit for the filling.

3. Bleed the air in the circuit by turning on a nearby hot water

tap [10] Fill the tank until the flow rate stabilises.

4. Turn off the hot water tap [10].

2

7

5

1 1

4

10

6

1

3

9

1 1

3 3 1

8 11

5

5

5 5

1

8

10

4

2

3

6

7

Central heating tank

1. Close the drain cock [4] on the tanks primary circuit.

2. Open the isolation valves [5] on the central heating circuit

connected to the boiler.

3. Bleed the air in the circuit by opening the air vent located on

the upper part of the tank.

4. Follow the instructions supplied with the boiler for filling.

5. When the tank is full and the air has been removed, the

bleed valve should be closed.

Ensure that the bleed valve is properly sealed.

6. If any antifreeze is needed in the primary circuit it mus be

compatible with Public hygiene rules and not be toxic.

A food-type Propylene Glycol is recommended.

Consult the manufacturer to ensure that the antifreeze is

compatible with the tanks construction materials.

Never use car antifreeze or undiluted antifreeze.

This can cause serious injury, death or damage to the

premises.

CHECKS TO BE CARRIED OUT BEFORE START-UP

Safety valves (domestic hot water) and (central heating)

correctly installed and discharge connected to the drains.

Domestic hot water tank and primary circuit filled with

water.

Air bleed correctly carried out on both circuits.

Air valve sealed.

Both hot and cold water pipes correctly connected to the

tanks hot water circuit.

Heating feed and return correctly connected to the tank.

The electrical cabling is correct.

The tanks thermostat is set according to the instructions

shown in Setting the thermostat.

Connections checked and free of leaks.

SETTING THE THERMOSTAT

Factory settings

The thermostat of the tank is factory preset to the minimum

recommended by the standards, over a range of settings from

60 to 90C.

To increase the temperature: turn the button clockwise.

To reduce the temperature: turn the button anticlockwise.

When adjusting the tanks thermostat, make sure that the

boiler temperature is set to a value at last 10C higher than

tanks thermostat.

Recommendations

There is a risk that bacteria including Legionella

pneumophila may develop if a minimum temperature

of 60C is not maintained both in storage and in the

hot water distribution network.

There is a risk of scalding from hot water!

ACV recommends the use of a thermostatic mixing

valve set to provide water at 60 C or less.

The water heated to wash clothes, dishes and for other

purposes can burn and cause serious injury.

Children, the elderly, the sick or the disabled are the most at

risk from burns due to very hot water. Never leave them on

their own in a bath or under the shower. Never allow young

children to turn on hot water taps or fill their own baths.

Set the water temperature appropriately according to the

intended use and plumbing codes.

When repeatedly drawing small amounts of hot water,

a stratification effect may develop in the tank.

The upper layer of hot water may then reach very high

temperatures. A thermostatic mixing valve will stop

water at excessivly high temperatures reaching the

outlets.

EN 10

661Y0400.F

E

N

G

L

I

S

H

F

R

A

N

C

A

I

S

N

E

D

E

R

L

A

N

D

S

E

S

P

A

O

L

I

T

A

L

I

A

N

O

D

E

U

T

S

C

H

MAINTENANCE

Domestic hot water tank

To empty the domestic hot water tank:

1. Switch off the electrical power supply to the tank.

2. Close the isolation valve [1].

3. Open the drain cock [6] and the air vent [7].

4. Allow the water to flow out into the drain.

5. After emptying, return the valves to their initial positions.

In order to allow emptying the valve [6] must be located

at the lowest point on the tank.

2

7

5

1 1

4

10

6

1

3

9

1 1

3 3 1

8 11

5

5

5 5

1

8

10

4

2

3

6

7

Central heating tank

To empty off the primary circuit:

1. Switch off the electrical power supply to the tank.

2. Close the shut-off valves [5] on the primary circuit.

3. Connect a hose to the drain valve [4].

4. Open the drain valve [4] and drain the hot water off.

5. To speed up the process, open the air vent located on the

upper part of the tank.

6. When the emptying is finished, close the drain cock again

then screw the air valve up again.

PERIODIC CHECKS BY THE USER

Check the pressure of the boilers pressure gauge: it should

be between 0.5 and 1.5 bar.

Carry out a monthly visual inspection of the valves,

connections and accessories in order to detect any leaks

or malfunctions.

Periodically check the air valve located on the upper part of

the tank to make sure that it is not leaking.

If you notice anything unusual, contact a technician or your

heating engineer.

ANNUAL SERVICE

The annual service, carried out by a technician, must include

the following:

Checking the air valve:

The air bleed can lead to water being added to the system.

Check the pressure on the boilers pressure gauge.

Manually activate the domestic hot water safety valve once

a year. This operation will lead to a discharge of hot water.

Before drawing any hot water through the safety unit,

make sure that the discharge goes directly to the drain

in order to avoid any risk of burning or damage.

The discharge pipe should be open to the atmosphere.

If the safety unit occasionally drips this may be due to an

expansion problem or to clogging of the valve.

Follow the circulators maintenance instructions.

Check that the valves, cocks, controllers and any electrical

accessories installed are working properly (see the

manufacturers instructions if necessary).

REPLACEMENT OF THE ELECTRIC HEATING

ELEMENT FOR THE HLE

Switch off and disconnect the mains power supply to the

appliance.

Drain the primary tank.

EMPTYING

Recommendations

Empty the tank if it is to be switched off for the winter

and there is a risk of frost conditions exposure.

If the central heating water (primary circuit) contains

any antifreeze, only the domestic hot water should be

drained.

Before draining off the domestic hot water, insulate

the tank to bring the central heating pressure (primary

circuit) down to 1 bar, in order to protect the tank

against a risk of collapsing.

If the central heating circuit does not contain any anti-

freeze, both the central heating and hot water circuits

should be drained.

661Y0400.F

ECO HL / HLE / HVS

B01

B04

B05

B06 B02

A01

A02

A03

A01

N

ECO

100

ECO

130

ECO

160

A01 497B5009 497B5009 497B5009

A02 497B0003 497B0005 497B0007

A03 51410243 51410244 51410245

N

HL

100

HL

130

HL

160

HL

210

HL

240

B01 49410170 49410170 49410170 49410170 49410170

B02 39554131 39554131 39554131 39554131 39554131

B03 497B0003 497B0005 497B0007 497B0009 497B0010

B04 51410183 51410184 51410185 51410186 51410187

B05 39438027 39438027 39438027 39438027 39438027

N

HLE / HVS

100

HLE / HVS

130

HLE / HVS

160

HLE / HVS

210

HLE / HVS

240

B01 49410170 49410170 49410170 49410170 49410170

B02 39554132 39554132 39554132 39554132 39554132

B03 497B0003 497B0005 497B0007 497B0009 497B0010

B04 51410183 51410184 51410185 51410186 51410187

B05 39438027 39438027 39438027 39438027 39438027

B06

5476D001

[HLE]

5476D001

[HLE]

5476D001

[HLE]

5476D001

[HLE]

5476D001

[HLE]

B03

661Y0400.F

ECO HL HLE HVS

55445006 55445006 55445006 55445006

49410036 49410036 49410036 49410036

54442045 54442045 54442045

54764009

54428107 54428107

54762004

55412023 55412023

24614157

24614158

51410180 51410180 51410180

51410181 51410181 51410181

51410216

You might also like

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- NT 664Y0200 C Alfa Sprint enDocument28 pagesNT 664Y0200 C Alfa Sprint enJosé MacedoNo ratings yet

- Installation, Operating and Servicing Instructions for ACV Hot Water TanksDocument10 pagesInstallation, Operating and Servicing Instructions for ACV Hot Water TanksmohamedkhalifehNo ratings yet

- Delta Performance MVDocument36 pagesDelta Performance MVJosé MacedoNo ratings yet

- Operating and Maintenance Manual For Power Burner Series Forced Draft Commercial Water HeaterDocument27 pagesOperating and Maintenance Manual For Power Burner Series Forced Draft Commercial Water HeaterAmir EbrahimNo ratings yet

- Triton Instaflow Stored Water Heater Installation GuideDocument21 pagesTriton Instaflow Stored Water Heater Installation GuideAlberto LeónNo ratings yet

- Boiler Sicc 209 SpteDocument8 pagesBoiler Sicc 209 SpteMarius Sofariu0% (2)

- 080912technical Manual New Tank EngDocument24 pages080912technical Manual New Tank EngTzagaraki AnnaNo ratings yet

- Heating-Cooling Units PDF Document Aqua Middle East FZCDocument12 pagesHeating-Cooling Units PDF Document Aqua Middle East FZCAdolfsmith69No ratings yet

- Boilermate ManualDocument12 pagesBoilermate Manualpaps33No ratings yet

- Manual Centrala Electrica Ekco.l1n487 PDFDocument20 pagesManual Centrala Electrica Ekco.l1n487 PDFKenneth Fleming100% (1)

- NT 664Y2500 B HeaMaster 71-101-201 EN PDFDocument44 pagesNT 664Y2500 B HeaMaster 71-101-201 EN PDFalex_cristiNo ratings yet

- No Frost Refrigerator Service ManualDocument22 pagesNo Frost Refrigerator Service Manualcinefil70No ratings yet

- W4000Document28 pagesW4000Alfredo CubaNo ratings yet

- Proflow Water Heater ManualDocument20 pagesProflow Water Heater ManualPedro BurkaNo ratings yet

- EH Manual EnglishDocument6 pagesEH Manual EnglishHasan CosalevNo ratings yet

- Ai Boiler Routine Maintenance Guide: AmerecDocument10 pagesAi Boiler Routine Maintenance Guide: Amerecأبو نبيل سلامNo ratings yet

- FWB J Installation and Operation ManualDocument16 pagesFWB J Installation and Operation ManualselvamejiaNo ratings yet

- 20 ACV Smart 600-800 Carte Tehnica CI 06.01.25 MLDocument6 pages20 ACV Smart 600-800 Carte Tehnica CI 06.01.25 MLSoficu DanielNo ratings yet

- Installation and ServiceDocument19 pagesInstallation and ServiceJosé Emilio D' LeónNo ratings yet

- Elgin Compresor TCM2062Document4 pagesElgin Compresor TCM2062VictorMiguelon100% (1)

- Ekco l1n487Document20 pagesEkco l1n487Petre MarianNo ratings yet

- UltracoolDocument4 pagesUltracoolYing Kei ChanNo ratings yet

- Ferroli F24 TECHNICAL AND SERVICE MANUALDocument52 pagesFerroli F24 TECHNICAL AND SERVICE MANUALyo8rmh100% (1)

- Service Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsDocument30 pagesService Manual MIH Series Condensing Units Heat Pump: 1.5 Tons To 5 TonsHenry Javier RíosNo ratings yet

- Service Ariston 081313462267Document12 pagesService Ariston 081313462267Service Pemanas AirNo ratings yet

- Technical Data Manual: Dual Coil Domestic Hot Water Storage Tank 79 and 119 USG / 300 and 450 LTRDocument12 pagesTechnical Data Manual: Dual Coil Domestic Hot Water Storage Tank 79 and 119 USG / 300 and 450 LTRthermosol5416No ratings yet

- Greenstar ZWB 7 27 HE Combi 47 311 55Document254 pagesGreenstar ZWB 7 27 HE Combi 47 311 55Dave Farrell0% (1)

- Ferroli F24 Combination Boiler ManualDocument48 pagesFerroli F24 Combination Boiler ManualtipudelacablutvNo ratings yet

- Model 5600SXT Downflow: Service ManualDocument48 pagesModel 5600SXT Downflow: Service ManualRodrigo SalazarNo ratings yet

- Navien ManualDocument28 pagesNavien Manualmarathon8caNo ratings yet

- Fulton Steam BoilerDocument46 pagesFulton Steam BoilerDonatas Bertasius100% (1)

- Whirpool - 6LBR5132EQ - Manual Servicio PDFDocument31 pagesWhirpool - 6LBR5132EQ - Manual Servicio PDFAldo TonatoNo ratings yet

- Water To Water Heat Pump Catalog - R134a - R410aDocument24 pagesWater To Water Heat Pump Catalog - R134a - R410aKCFUNGNo ratings yet

- Thermo NESLAB Manual P/N 000258 Rev. 11/08/00Document18 pagesThermo NESLAB Manual P/N 000258 Rev. 11/08/00Edinson Vallejo VidalNo ratings yet

- Triton Shower ManualDocument24 pagesTriton Shower ManualAmanda KinsellaNo ratings yet

- Service Manual Ariston T2Document52 pagesService Manual Ariston T2cris_43100% (1)

- C-Warm Selection GuideDocument20 pagesC-Warm Selection Guidejoe_tmpNo ratings yet

- Chiller RecipDocument4 pagesChiller RecipHerni SuharniriyantiNo ratings yet

- Isotemp Water Heater ManualDocument13 pagesIsotemp Water Heater ManualtowndockNo ratings yet

- Keston C40 C55 ManualDocument61 pagesKeston C40 C55 ManualwoodsdgNo ratings yet

- DIWH Series: Diko Elektrikli Cihazlar San. Ve Tic. A.ŞDocument19 pagesDIWH Series: Diko Elektrikli Cihazlar San. Ve Tic. A.ŞEric ToroNo ratings yet

- Manual Ingles n120Document12 pagesManual Ingles n120Aroldo Pérez CantoNo ratings yet

- Aer 534 QCDocument48 pagesAer 534 QCsunny_nsecNo ratings yet

- Microcombi 23/27 Mffi Installation and Servicing Instructions Type C BoilersDocument65 pagesMicrocombi 23/27 Mffi Installation and Servicing Instructions Type C BoilersfloriantudorNo ratings yet

- 1206 Combibeholdere 60-160Document16 pages1206 Combibeholdere 60-160Michael Tollund NielsenNo ratings yet

- Eternity T Installation GuideDocument28 pagesEternity T Installation GuidepsicodeNo ratings yet

- EOA 61 CMP User ManualDocument21 pagesEOA 61 CMP User ManualEl Anonimo50% (2)

- Waterco Ps HeatersDocument10 pagesWaterco Ps HeatersMarioEnriqueAlcocerÁvilaNo ratings yet

- 115 AllDocument8 pages115 Alljob_openings4094No ratings yet

- Hydropro 7000SXT Service ManualDocument43 pagesHydropro 7000SXT Service ManualintermountainwaterNo ratings yet

- Commercial Gas Water Heaters: BTR-151 (A) BTR-201 (A)Document2 pagesCommercial Gas Water Heaters: BTR-151 (A) BTR-201 (A)Viswanath NeswaNo ratings yet

- Deron Swimming Pool Heat Pump CatalogueDocument19 pagesDeron Swimming Pool Heat Pump Catalogueocean220220No ratings yet

- Service Manual Avant 167SKV-E5Document98 pagesService Manual Avant 167SKV-E5Daniel PelteaNo ratings yet

- PUHY P200 250YREM A Service HandbookDocument124 pagesPUHY P200 250YREM A Service HandbookGingubaNo ratings yet

- Installation & Servicing Instructions for Baxi Combi Instant 80e & 105e Gas BoilersDocument48 pagesInstallation & Servicing Instructions for Baxi Combi Instant 80e & 105e Gas BoilersKostas AstrinisNo ratings yet

- Utilities - Iom - Fl4338-Ipcx345 - FPG ChillerDocument32 pagesUtilities - Iom - Fl4338-Ipcx345 - FPG ChillerVijay RajaindranNo ratings yet

- Stiebel Eltron BrochureDocument4 pagesStiebel Eltron BrochureDesmondiceNo ratings yet

- Zoetrope Wind TurbineDocument16 pagesZoetrope Wind TurbineDan FelixNo ratings yet

- REW 20110901 Sep 2011Document148 pagesREW 20110901 Sep 2011Dan FelixNo ratings yet

- Revolutionary Server Systems For Streaming Over-The-Top: ChallengesDocument2 pagesRevolutionary Server Systems For Streaming Over-The-Top: ChallengesDan FelixNo ratings yet

- A Low-Cost, Open Source Wind TurbineDocument23 pagesA Low-Cost, Open Source Wind TurbineStephen LynchNo ratings yet

- Installation, Operating and Servicing Instructions for ECO, HL and HLE Water HeatersDocument12 pagesInstallation, Operating and Servicing Instructions for ECO, HL and HLE Water HeatersDan FelixNo ratings yet

- Draw Now 30 Easy Exercises For BeginnersDocument78 pagesDraw Now 30 Easy Exercises For BeginnersDanut Alexandru100% (1)

- Installation, Operating and Servicing Instructions for ECO, HL and HLE Water HeatersDocument12 pagesInstallation, Operating and Servicing Instructions for ECO, HL and HLE Water HeatersDan FelixNo ratings yet

- User Manual For Erato GP 20, Junkers Bosch SupraclassDocument27 pagesUser Manual For Erato GP 20, Junkers Bosch SupraclassestebanNo ratings yet

- Expresii Din Limba EnglezaDocument247 pagesExpresii Din Limba Englezahpples96% (28)

- The Solar UpdraftDocument9 pagesThe Solar UpdraftSagar KothariNo ratings yet

- Micro Hydro TemplateDocument1 pageMicro Hydro TemplatencharalaNo ratings yet

- Cusca IepuriDocument2 pagesCusca IepuriDan FelixNo ratings yet

- User Manual For Erato GP 20, Junkers Bosch SupraclassDocument27 pagesUser Manual For Erato GP 20, Junkers Bosch SupraclassestebanNo ratings yet

- Windows NT4 Server Commands: Quick Reference For Key Windows NT Administration ToolsDocument3 pagesWindows NT4 Server Commands: Quick Reference For Key Windows NT Administration ToolsDan FelixNo ratings yet

- User Manual For Erato GP 20, Junkers Bosch SupraclassDocument27 pagesUser Manual For Erato GP 20, Junkers Bosch SupraclassestebanNo ratings yet

- Contact: P Series P Series P Series P SeriesDocument4 pagesContact: P Series P Series P Series P SeriesDan FelixNo ratings yet

- User Guide: Smart Access Web ManagementDocument26 pagesUser Guide: Smart Access Web ManagementDan FelixNo ratings yet

- 02 Foods You Should Never EatDocument113 pages02 Foods You Should Never EatmrsorenNo ratings yet

- Flat Die Pellet MillDocument7 pagesFlat Die Pellet MillDan Felix100% (1)

- NR71314 Air Conditioning (7.13.14) Ver1.2 PDFDocument183 pagesNR71314 Air Conditioning (7.13.14) Ver1.2 PDFBabyface888No ratings yet

- MOPX Operation IsntructionsDocument28 pagesMOPX Operation IsntructionsEser67% (3)

- Paj - 2 - 5 Ton PDFDocument16 pagesPaj - 2 - 5 Ton PDFvickersNo ratings yet

- Fan Coil Unit CatalogDocument17 pagesFan Coil Unit CatalogHENRYNo ratings yet

- 2015 - Rectorseal Plumbing CatalogDocument64 pages2015 - Rectorseal Plumbing CatalogNelson VielmaNo ratings yet

- Innovative Buildings Klosterenga Oslo, NorwayDocument6 pagesInnovative Buildings Klosterenga Oslo, NorwayPranav Kumar ShrivastavaNo ratings yet

- Hitachi - AirExchange Instruction ManualDocument36 pagesHitachi - AirExchange Instruction ManualtheophiloNo ratings yet

- CTFA Microbiology Guidelines PDFDocument254 pagesCTFA Microbiology Guidelines PDFdhairyasheel100% (9)

- X Power Catalog 50 60hzDocument90 pagesX Power Catalog 50 60hzluisrequenat100% (1)

- Book 1 Basic Principles and Practices of PropaneDocument164 pagesBook 1 Basic Principles and Practices of Propanechkza50% (2)

- Fresh Facts ARTICALE - 2Document3 pagesFresh Facts ARTICALE - 2Anonymous XhkjXCxxsTNo ratings yet

- Pre-Purchase Inspection Report-MV QI SHANDocument22 pagesPre-Purchase Inspection Report-MV QI SHANTakis Rappas100% (1)

- Trim Heater PDFDocument2 pagesTrim Heater PDFsaadashfaq100% (1)

- Compresora Modelo 2475 Loc 14Document56 pagesCompresora Modelo 2475 Loc 14Stephanie Espinoza CastañedaNo ratings yet

- Engineered for tomorrow: Hitachi air conditioning heat recovery ventilationDocument2 pagesEngineered for tomorrow: Hitachi air conditioning heat recovery ventilationDavid O. AlmeidaNo ratings yet

- FEIST First Passive House KranichsteinDocument11 pagesFEIST First Passive House KranichsteinWolfgang FeistNo ratings yet

- Moisture Control Part 4Document36 pagesMoisture Control Part 4Karthik RajendrenNo ratings yet

- 4MXCDocument8 pages4MXCAnonymous ApjtcZ6YT6No ratings yet

- Air Outlet KMCDocument129 pagesAir Outlet KMCEngr.Mmosaad100% (2)

- Suzlon One Earth-1Document4 pagesSuzlon One Earth-1Arun AhlawatNo ratings yet

- Non IBR Boiler ManufacturerDocument3 pagesNon IBR Boiler ManufacturerutechprojectsNo ratings yet

- Home Energy Use Calculation Guide: Appliance Average Wattage Monthly KWH Your Monthly KWH EstimateDocument2 pagesHome Energy Use Calculation Guide: Appliance Average Wattage Monthly KWH Your Monthly KWH EstimateChandramouli JalliNo ratings yet

- Pig Management GuideDocument37 pagesPig Management GuideKim Chau100% (1)

- Mission Statement: Specializing Air Conditioning and Ventilating That Will Exceed YourDocument39 pagesMission Statement: Specializing Air Conditioning and Ventilating That Will Exceed YourGono JoshuaNo ratings yet

- MEP Works budgetary offer for Msheireb properties projectDocument8 pagesMEP Works budgetary offer for Msheireb properties projectAhmed Labib0% (1)

- Taco Outdoor Reset 100-40Document2 pagesTaco Outdoor Reset 100-40api-221502147No ratings yet

- Nail Salon GuideDocument23 pagesNail Salon GuideprobeautyassociationNo ratings yet

- Annex B Conveyor Schedule of Specs 20nov15Document3 pagesAnnex B Conveyor Schedule of Specs 20nov15Kalai SelvanNo ratings yet

- Power Plant ValveDocument63 pagesPower Plant Valvenjc6151100% (2)

- Design and Fabrication of Seed Dryer Using Waste Heat of VCR CycleDocument7 pagesDesign and Fabrication of Seed Dryer Using Waste Heat of VCR CycleIJRASETPublicationsNo ratings yet