Professional Documents

Culture Documents

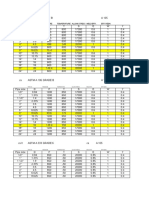

Performance Data: Curve 14.00 1BB065, 2BB065

Uploaded by

texwan_Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Data: Curve 14.00 1BB065, 2BB065

Uploaded by

texwan_Copyright:

Available Formats

Section:

2000 CC Pumps

Date: November 2004

Performance Data Curve 14.00

Differential Pressure (PSI)**

* (PSI x .069 = BAR) (PSI x .070 = kgf/cm

2

) (USGPM x .2271 = M

3

/HR) (HP x .746 = kW)

Models: 1BB065, 2BB065

Use appropriate HP and pressure scales

for the number of stages required.

NOTE: Pressure limits rated at 87 psi

per stage (70 Duro). 2 Stage models

limited to 130 psi.

Capacity Horsepower 70 Durometer Hardness 55 Durometer Hardness Data Based on Water @ 68F

U

S

G

P

M

M

3

/

H

R

0

0 10 20 30 40 50 60 70 80 90

0 20 40 60 80 100 120 140

10

20

30

40

50

100

200

250

150

50

0

5

10

7.5

2.5

12.5

0

5

10

15

20

25

GPM @ 300 RPM

GPM @ 350 RPM

GPM @ 100 RPM

H

P @

100 R

PM

H

P

@

2

0

0

R

P

M

H

P

@

3

0

0

R

P

M

H

P

@

3

5

0

R

P

M

1 Stage

2 Stage

1

S

t

a

g

e

2

S

t

a

g

e

GPM @ 200 RPM

1 STG 5 10 10

2 STG 7.5 15 15

RPM 150 300 350

NPSH Required (Ft.) 1.90 3.80 5.5

Minimum

Recommended

Motor HP

HP ADDER/100 RPM

Fine Medium Coarse

16 Mesh 16 to 9 Mesh 9 to 4 Mesh

(.039") (<1mm) (.039" to .076") (1-2mm) (.078" to .185") (2-5mm)

% Number of Stages

Solids 1 2 1 2 1 2

10 .48 .62 .59 .76 .99 1.29

HP ADDER/100 RPM/STAGE

Viscosity (Centipoise)

1 2,500 5,000 10,000

0 2.10 2.80 3.90

TABLE II VISCOSITY (NEWTONIAN FLUIDS):

FLUID TEMPERATURE 70F 100F 125F 150F 175F 200F

HORSEPOWER MULTIPLIERS

- Standard Size Rotor 1.00 1.10 1.30 1.60 2.00 2.50

- Undersized Rotor 0.75 0.80 0.85 0.95 1.10 1.60

(Degrees F =

9

/5 C + 32)

HORSEPOWER ADDITIVES:

Shown below are HP additives for both water base slurries and for viscous materials. To use these tables, first determine which table

applies to your product and enter that table with the appropriate fluid characteristics. Determine the HP additive per 100 RPM and

multiply it by the speed of your pump divided by 100. Add the resulting figure to the HP for water from the curve on the preceding

page or to the minimum HP for starting from the table at the top of the preceding page, whichever is larger.

If your product is a combination of a slurry and viscous material, determine the appropriate HP additive from both tables below and

use whichever is greater.

TABLE I WATER BASE SLURRIES:

HORSEPOWER MULTIPLIERS:

For applications involving temperatures greater than 200F, consult the factory.

Models: 1BB065, 2BB065

Pump horsepower from the reverse side can be broken into three components: drive end, rotor/stator, and hydraulic.

Temperature affects the rotor/stator HP component only. For applications involving temperatures above 70F, it is necessary to

adjust the rotor/stator HP component of the horsepower obtained from the reverse side (i.e., the greater of the water HP

or Minimum Recommended HP). This new horsepower is referred to as the Temperature Corrected Horsepower.

Rotor/stator horsepower can be found from the curve on the previous page. It is the HP at zero pressure for the corresponding

RPM and number of stages.

To calculate the Temperature Corrected Horsepower, subtract the rotor/stator HP from the greater of the water or minimum

recommended HP. This gives you the drive end/hydraulic HP. Multiply the rotor/stator HP by the appropriate temperature

multiplier listed below. Add this adjusted value to the drive end/hydraulic HP to get the total Temperature Corrected Horsepower.

2004 by Moyno, Inc.

Moyno, Inc. is a Unit of Robbins & Myers, Inc. Printed in U.S.A.

You might also like

- Performance Data: 345 1 BB, BCDocument2 pagesPerformance Data: 345 1 BB, BCtexwan_No ratings yet

- Performance Data: 220 1, 2 Ba, BB, BCDocument2 pagesPerformance Data: 220 1, 2 Ba, BB, BCtexwan_No ratings yet

- Performance Data: 175 1, 2 Ba, BB, BCDocument2 pagesPerformance Data: 175 1, 2 Ba, BB, BCtexwan_No ratings yet

- 2000CC Curves8.00 2-09Document2 pages2000CC Curves8.00 2-09texwan_No ratings yet

- HR E577rDocument6 pagesHR E577rAnton RenaldoNo ratings yet

- G3412 - 450 KW Performance DataDocument3 pagesG3412 - 450 KW Performance DataJacob De CasillasNo ratings yet

- Chapter - 09 ESP Design ExamplesDocument16 pagesChapter - 09 ESP Design Examplesdewidar1234100% (11)

- Final Documentation Sungdong SY Hull S3109, S3109 Air Compressor SSM 41010956Document23 pagesFinal Documentation Sungdong SY Hull S3109, S3109 Air Compressor SSM 41010956Raúl Oscar LedesmaNo ratings yet

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDocument3 pagesGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyEzequiel Juarez BenítezNo ratings yet

- Oil Coolers: Air CooledDocument12 pagesOil Coolers: Air CooledHenry RogersNo ratings yet

- Selection: Semi-Hermetic Reciprocating Compressors: Input ValuesDocument5 pagesSelection: Semi-Hermetic Reciprocating Compressors: Input ValuesoozNo ratings yet

- Condensate Pumps and Energy Recovery PDFDocument17 pagesCondensate Pumps and Energy Recovery PDFPhani Raj MNo ratings yet

- Hitachi ChillerDocument8 pagesHitachi Chillertrantrunghoa1984No ratings yet

- Modul Air Fluid Coolers 1800Document12 pagesModul Air Fluid Coolers 1800Roger AklNo ratings yet

- Startup Paralel Turbo CompressorDocument24 pagesStartup Paralel Turbo Compressorilmu2No ratings yet

- LPBP HPSU Document PDFDocument131 pagesLPBP HPSU Document PDFGanga PrasadNo ratings yet

- AE1327Document13 pagesAE1327Maria DazaNo ratings yet

- A. Bitzer 4FES-3Y-40SDocument6 pagesA. Bitzer 4FES-3Y-40SĐiện IceNo ratings yet

- BITZER Output data summaryDocument10 pagesBITZER Output data summarySaša ColićNo ratings yet

- Project Survey: Selected CompressorsDocument6 pagesProject Survey: Selected CompressorsMr. RfNo ratings yet

- 4NES-14Y Bitzer 4NCS-12.2YDocument13 pages4NES-14Y Bitzer 4NCS-12.2YMiroslaw LabudaNo ratings yet

- BITZER Output Data: Created On: 11.05.2023 13:44:33Document14 pagesBITZER Output Data: Created On: 11.05.2023 13:44:33Erymanthus NgânNo ratings yet

- 2011 MrSlimDocument28 pages2011 MrSlimAntónio ViegasNo ratings yet

- MPDFDocument30 pagesMPDFDriza RabieNo ratings yet

- Duties & Responsibilities of Shift EngineerDocument35 pagesDuties & Responsibilities of Shift EngineerNaveen ChodagiriNo ratings yet

- 710 Tier 2Document172 pages710 Tier 2Armando RodriguezNo ratings yet

- Air Source Heat Pump Technical ManualDocument28 pagesAir Source Heat Pump Technical ManualWayne Grey100% (3)

- Bitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFDocument7 pagesBitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFAgus CahyonoNo ratings yet

- Z Series: Pump Assemblies Custom Built To Your Replacement or New Installation RequirementsDocument8 pagesZ Series: Pump Assemblies Custom Built To Your Replacement or New Installation RequirementsWalter Pachi Venegas AriasNo ratings yet

- Curvas Capacidad CompresoresDocument7 pagesCurvas Capacidad CompresoresOscar Arciniegas PerezNo ratings yet

- Fan Secimi HesabıDocument11 pagesFan Secimi HesabıOguzhanKNo ratings yet

- MDBFPDocument21 pagesMDBFPRaja Vignesh100% (1)

- Suzuki SwiftDocument7 pagesSuzuki SwiftAsher GinsbergNo ratings yet

- Daikin - RXYQ-PBTJ VRVIII 208-230 Heat Pump PDFDocument64 pagesDaikin - RXYQ-PBTJ VRVIII 208-230 Heat Pump PDFLuis DomdNo ratings yet

- 51371180104Document21 pages51371180104GuillermoadairNo ratings yet

- Grundfos Selectric BrochureDocument2 pagesGrundfos Selectric Brochuremihaitoader69No ratings yet

- Features: How To Order (AOC-08 Models Only)Document4 pagesFeatures: How To Order (AOC-08 Models Only)CarmenLinoBedoyaNo ratings yet

- Selection: Semi-Hermetic Screw Compressors HS: Input ValuesDocument5 pagesSelection: Semi-Hermetic Screw Compressors HS: Input ValuesTedy ChriswandaNo ratings yet

- Compact Semi-Hermetic Twin Screw Air ConditionersDocument13 pagesCompact Semi-Hermetic Twin Screw Air ConditionersZaid Samha100% (1)

- Compressor BITZER Open TypeDocument6 pagesCompressor BITZER Open Typejorge castilloNo ratings yet

- Hydraulic AmplifierDocument4 pagesHydraulic AmplifierLuis Jonathan Bahamaca FernandezNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©Kamel BelhibaNo ratings yet

- Presentation BP Casing PressDocument25 pagesPresentation BP Casing PressSufian R EllabbadNo ratings yet

- 60 Ton Per HR Advance Empire Boiler Operation ManualDocument15 pages60 Ton Per HR Advance Empire Boiler Operation Manualrozg788152100% (1)

- 4CES-9 R404A t0 - 7 TC 45Document4 pages4CES-9 R404A t0 - 7 TC 45Tedy ChriswandaNo ratings yet

- 250EDJ 7BAR Local PART 1Document9 pages250EDJ 7BAR Local PART 1algadi123No ratings yet

- HR E576qDocument12 pagesHR E576qIsanka SathsaraneeNo ratings yet

- RCH +D + +F+¡ (+ ) PDFDocument38 pagesRCH +D + +F+¡ (+ ) PDFSyamil DzulfidaNo ratings yet

- Workshoo Stanadyne 05872Document4 pagesWorkshoo Stanadyne 05872Kevin TtitoNo ratings yet

- Select FlatPlate Heat Exchangers for Close Approach ApplicationsDocument2 pagesSelect FlatPlate Heat Exchangers for Close Approach Applicationshappale2002No ratings yet

- SS-AEPF Goodman Air ConditionerDocument8 pagesSS-AEPF Goodman Air ConditionerArmando EnriquezNo ratings yet

- 4CES-6Y Bitzer PDFDocument7 pages4CES-6Y Bitzer PDFEm GomezNo ratings yet

- Trane AnalisisDocument13 pagesTrane AnalisisHendri PoerbaNo ratings yet

- SS-250-115, IM-225, IM-375 Product ManualDocument21 pagesSS-250-115, IM-225, IM-375 Product ManualMisael YermiaNo ratings yet

- Lowara Grupuri de Pompare - Ghvseries-Td-En PDFDocument120 pagesLowara Grupuri de Pompare - Ghvseries-Td-En PDFmariuspiNo ratings yet

- GE Industrial Systems Motor Selection GuideDocument4 pagesGE Industrial Systems Motor Selection GuideErick Daniel Toyo MarinNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Steam TurbineDocument8 pagesSteam TurbineWalid FattahNo ratings yet

- Valves Brame HydrogenengineeriDocument3 pagesValves Brame Hydrogenengineeritexwan_No ratings yet

- Williams W Series Pump IomDocument25 pagesWilliams W Series Pump Iomtexwan_No ratings yet

- EHB en 9-MaterialsDocument0 pagesEHB en 9-MaterialsAquos78No ratings yet

- Leser PSV SizingDocument83 pagesLeser PSV SizingjrfmlNo ratings yet

- Hrd-f02!02!0412 Bio Data DC (Rev 02)Document1 pageHrd-f02!02!0412 Bio Data DC (Rev 02)texwan_No ratings yet

- EHB en File 2.2-Loading-PrincipleDocument1 pageEHB en File 2.2-Loading-Principletexwan_No ratings yet

- EHB en 10-ConnectionsDocument102 pagesEHB en 10-Connectionstexwan_No ratings yet

- EHB en 0-IntroductionDocument0 pagesEHB en 0-IntroductionAquos78No ratings yet

- EHB en 11 Quality and Environmental ManagementDocument23 pagesEHB en 11 Quality and Environmental Managementtexwan_No ratings yet

- EHB en 10-ConnectionsDocument102 pagesEHB en 10-Connectionstexwan_No ratings yet

- Leser PSV SizingDocument83 pagesLeser PSV SizingjrfmlNo ratings yet

- Turbo Tutorial API 619 5thDocument33 pagesTurbo Tutorial API 619 5thmishraengg100% (2)

- EHB en 2 Design FundamentalsDocument30 pagesEHB en 2 Design FundamentalstdecebalusNo ratings yet

- EHB en 6 Installation and Plant DesignDocument64 pagesEHB en 6 Installation and Plant Designtexwan_No ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- EHB en 3-TerminologyDocument32 pagesEHB en 3-Terminologytexwan_No ratings yet

- EHB en 1 History and Basic FunctionDocument0 pagesEHB en 1 History and Basic FunctionAquos78No ratings yet

- Bisnis SapiDocument5 pagesBisnis SapiIlham AdinusaNo ratings yet

- D 512Document1 pageD 512texwan_No ratings yet

- 22 G3512 C555Document4 pages22 G3512 C555texwan_No ratings yet

- BAV BAVM 9510-070-EnDocument23 pagesBAV BAVM 9510-070-Entexwan_No ratings yet

- Previews HI 9 6 1 2012 PreDocument12 pagesPreviews HI 9 6 1 2012 Pretexwan_100% (2)

- Engineer Manual 1110-2-3105 Changes 1 and 2 Pumping Stations GuideDocument171 pagesEngineer Manual 1110-2-3105 Changes 1 and 2 Pumping Stations GuideMuhammad Irfan AwanNo ratings yet

- Propane PropertiesDocument4 pagesPropane Propertiestexwan_No ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- DeaDocument2 pagesDeatexwan_No ratings yet

- Design of Triplex Plunger Pump for Local ManufacturingDocument56 pagesDesign of Triplex Plunger Pump for Local ManufacturingManatchai BattōsaiNo ratings yet

- Pipe Flow Design 1: Results DataDocument7 pagesPipe Flow Design 1: Results Datatexwan_No ratings yet

- Ansi Atex LR CompleteDocument148 pagesAnsi Atex LR Completetexwan_No ratings yet

- ASTM Pipe Material Specifications ChartDocument14 pagesASTM Pipe Material Specifications ChartKim JungdaeNo ratings yet

- Exam SolutionsDocument11 pagesExam SolutionsLacey Prestwood100% (1)

- 11 Fluids SDocument26 pages11 Fluids SapocalypticNo ratings yet

- Gas Law ProblemsDocument10 pagesGas Law ProblemstoffahmaxwellNo ratings yet

- Sales Bulletin American Meter 4510Document12 pagesSales Bulletin American Meter 4510rieza_fNo ratings yet

- 4 Design Calculation ASME AD2000 - WeberDocument19 pages4 Design Calculation ASME AD2000 - WeberguslohNo ratings yet

- Manual de Instalación Bomba Quintuplex Pentair MA-300Document32 pagesManual de Instalación Bomba Quintuplex Pentair MA-300zayagoraNo ratings yet

- Fluid Mechanics 2Document12 pagesFluid Mechanics 2Acads by NagiNo ratings yet

- Engineering Synoptic ViewDocument1 pageEngineering Synoptic Viewmathew1965No ratings yet

- Artificial Lift Methods Comparison Table PDFDocument11 pagesArtificial Lift Methods Comparison Table PDFmeilani5No ratings yet

- Engineering Design Guideline - Fluid FlowDocument64 pagesEngineering Design Guideline - Fluid FlowVijay Rajaindran100% (1)

- Meen 611 Meen 619 Meen 622 Meen 627 Meen 629 Meen 631 Meen 642 Meen 643 Meen 644 Meen 665 Meen 679Document3 pagesMeen 611 Meen 619 Meen 622 Meen 627 Meen 629 Meen 631 Meen 642 Meen 643 Meen 644 Meen 665 Meen 679Manish VankudreNo ratings yet

- Guideline For Prevention and Safe Handling of HydratesDocument11 pagesGuideline For Prevention and Safe Handling of Hydrateshitm357No ratings yet

- Week 12 of Aqs110 Fluid Mechanics PDFDocument8 pagesWeek 12 of Aqs110 Fluid Mechanics PDFvigneshNo ratings yet

- Vapour Absorption Refrigeration Systems ExplainedDocument15 pagesVapour Absorption Refrigeration Systems ExplainedSatheesh ChandranNo ratings yet

- 2001 Kettles - Cantarells Akal C Complex OTC 13177Document9 pages2001 Kettles - Cantarells Akal C Complex OTC 13177Rosario P SerranoNo ratings yet

- Beka-Max (Crushers & Screeners)Document16 pagesBeka-Max (Crushers & Screeners)Jose Luis Atao SantiagoNo ratings yet

- Research Proposal: Name: Waqar Rafiq Registration:2018-MS-MED-23Document9 pagesResearch Proposal: Name: Waqar Rafiq Registration:2018-MS-MED-23Waqar RafiqNo ratings yet

- Electric Company : Drying Procedure For PipelinesDocument19 pagesElectric Company : Drying Procedure For Pipelineschandrakit047No ratings yet

- Physical Chemistry 2nd Edition Ball Solution ManualDocument17 pagesPhysical Chemistry 2nd Edition Ball Solution Manualrobyn96% (27)

- API Data SheetsDocument7 pagesAPI Data SheetsalfruizpNo ratings yet

- HVAC, fire fighting, plumbing and compressed air products and suppliersDocument2 pagesHVAC, fire fighting, plumbing and compressed air products and suppliersIswadi Bin ZulkarnainNo ratings yet

- Natural Gas Based Hydrogen Production WiDocument16 pagesNatural Gas Based Hydrogen Production WiManuel PavanNo ratings yet

- Fluid Mechanics: 2CL303 6 Semester Civil EngineeringDocument14 pagesFluid Mechanics: 2CL303 6 Semester Civil EngineeringkiranNo ratings yet

- City Gas Handbook On Gas SupplyDocument54 pagesCity Gas Handbook On Gas SupplyjacleeNo ratings yet

- Dissolved Gas Analysis of Overheating FaultDocument4 pagesDissolved Gas Analysis of Overheating FaultTedy MTNo ratings yet

- Qip JP 04 Engine CharacteristicsDocument36 pagesQip JP 04 Engine CharacteristicspepeNo ratings yet

- Industrial hydraulic accumulator guideDocument50 pagesIndustrial hydraulic accumulator guidentinossNo ratings yet

- Density and Pressure 1 QP-5 PDFDocument1 pageDensity and Pressure 1 QP-5 PDFSalmuel SmithNo ratings yet