Professional Documents

Culture Documents

Biogas Agitators: Our Service Range For Increased Biogas Production

Uploaded by

anotimpub0 ratings0% found this document useful (0 votes)

22 views8 pagesGIANTMIX FR has been specially designed to optimize the biological process in digester and afterfermenters with almost constant substrate levels. Almost all of maintenance duties can be carried out from the outside, which means that opening the digester or dismounting the unit is not necessary. The drive side with the electric motor and transmission is accessible from the outside; only the shaft tube and propeller are within the fermenter and in an optimal position for thorough mixing.

Original Description:

Original Title

2010-12-04 Broschuere Biogas Web US

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGIANTMIX FR has been specially designed to optimize the biological process in digester and afterfermenters with almost constant substrate levels. Almost all of maintenance duties can be carried out from the outside, which means that opening the digester or dismounting the unit is not necessary. The drive side with the electric motor and transmission is accessible from the outside; only the shaft tube and propeller are within the fermenter and in an optimal position for thorough mixing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

22 views8 pagesBiogas Agitators: Our Service Range For Increased Biogas Production

Uploaded by

anotimpubGIANTMIX FR has been specially designed to optimize the biological process in digester and afterfermenters with almost constant substrate levels. Almost all of maintenance duties can be carried out from the outside, which means that opening the digester or dismounting the unit is not necessary. The drive side with the electric motor and transmission is accessible from the outside; only the shaft tube and propeller are within the fermenter and in an optimal position for thorough mixing.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

BIOGAS AGITATORS

Our service range

for increased biogas production

B

I

O

G

A

S

2

The Giantmix FR has been specially

designed to optimize the biological

process in digester and afterfermen-

ters with almost constant substrate

levels. The Giantmix FR serves to

prevent the formation of floating

and sinking substrate layers

ensure that the substrate maintains

an equal temperature throughout

distribute nutrients for the biologi-

cal process homogeneously

enable more efficient gas flow out

of the substrate

One advantage of the design of the

Giantmix is that almost all of main-

tenance duties can be carried out

from the outside, which means that

opening the digester or dismounting

the unit is not necessary.

The drive side with the electric motor

and transmission is accessible from

the outside; only the shaft tube and

propeller are within the fermenter

and in an optimal position for tho-

rough mixing.

GIANTMIX FR Propeller Agitators

B

I

O

G

A

S

For closed concrete digester

For mounting through wall or roof

TECHNICAL DATA:

FR 3 6 (390 rpm)

FR 1 (190 rpm)

Ex-motors of rated output 7.5 kW at 190 rpm (3-phase 50 cycles)

or 230 rpm (3-phase 60 cycles) 750 U/min

Propeller diameter 800 mm

Other models available: FR3 6

Ex-motors of rated output 11/15/18.5 and 22 kW at 390 rpm (3-phase 50 cycles)

or 470 rpm (3-phase 60 cycles) for hazardous zone 2

13.5 kW power output for hazardous zone 1

Two-step spur gear (combined transmission unit with PTO connection)

Bearing housing with mechanical seal of SiC/SiC, thrusting forces

from the propeller absorbed by two taper roller bearings

Agitator shaft tube dia. 101.6 in AISI 304 (V2A) or AISI 316 (V4A) stainless steel,

thickness 4.0 or 5.7 mm

Tube lengths from 2 to 4 m

Sealing plates in 3 sizes in AISI 304 (V2A) or AISI 316 (V4A) stainless steel

Sealing membrane EPDM 60

For immersion depths to 4 m below maximum substrate level

Propeller diameters from 580 to 700 mm in AISI 304 (V2A) stainless

or hardened steel

Inclination adjustment by upper control arm,

toothed rack with winch or hydraulic drive

Tractor-driven configuration available

Stainless steel rain covers optional

3

For technical reasons due to static,

the Giantmix FR cannot be directly

mounted to the wall of a steel dige-

ster.

Errecting a scaffold to support the

weight and absorb the thrusting for-

ces is a possible solution to compen-

sate for this limitation. This could

double as a service platform.

Aswell, a favoured application is

fixed mounting through the lower

part of the digester wall. It is inten-

ded mainly to prevent sinking sub-

strate layers from forming and

achieves thorough mixing.

GIANTMIX FR Propeller Agitators

B

I

O

G

A

S

For closed steel digester

For mounting through digester wall

TECHNICAL DATA:

FR 3 6 (390 rpm)

FR 1 (190 rpm)

Ex-motors of rated output 7.5 kW at 190 rpm (3-phase 50 cycles)

or 230 rpm (3-phase 60 cycles) 750 U/min

Propeller diameter 800 mm

Other models available: FR3 6

Ex-motors of rated output 11/15/18.5 and 22 kW at 390 rpm (3-phase 50 cycles)

or 470 rpm (3-phase 60 cycles) for hazardous zone 2

13.5 kW power output for hazardous zone 1

Two-step spur gear (combined transmission unit with PTO connection)

Bearing housing with mechanical seal of SiC/SiC, thrusting forces

from the propeller absorbed by two taper roller bearings

Agitator shaft tube dia. 101.6 in AISI 304 (V2A) or AISI 316 (V4A) stainless steel

thickness 4.0 or 5.7 mm

Tube lengths from 2 to 4 m

Sealing plates in 3 sizes in AISI 304 (V2A) or AISI 316 (V4A) stainless steel

Sealing membrane EPDM 60

For immersion depths to 7 m below maximum substrate level

Propeller diameters from 580 to 700 mm in AISI 304 (V2A) stainless

or hardened steel

Inclination adjustment by upper control arm,

toothed rack with winch or hydraulic drive

Tractor-driven configuration available

Stainless steel rain covers optional

4

A great advantage with the Giantmix

AMT is that the electrical, and many

technical components are accessible

from the outside. Hence, the AMT, to-

gether with its solid construction

provides optimal operational safety.

Retro-fitting is also possible provi-

ding the structural characteristics of

the digester are adequate.

GIANTMIX FR Propeller Agitators

B

I

O

G

A

S

For closed concrete digester

For mounting through wall or roof

TECHNICAL DATA:

AMT 7 (270 rpm)

AMT 5 (130 rpm)

Geared Ex-motors of rated output up to 15 kW at 130 rpm (3-phase 50 cycles)

or 160 rpm (3-phase 60 cycles) for hazerdous zone 2

Propeller diameter up to 1,200 mm in hardened steel

Other models available: AMT 7

Geared Ex-motors of rated output up to 28 kW at 270 rpm (3-phase 50 cycles)

or 330 rpm (3-phase 60 cycles) for hazardous zone 2

Transmission designed for 30 kW (safety factor 5)

Bearing housing with mechanical seal of SiC/SiC, thrusting forces from the propeller

absorbed by two taper roller bearings 30312 (60/130)

Agitator shaft tube dia. 220 x 8 AISI 316 (V4A) stainless steel

Tube lengths up to 7 m

Sealing plates in AISI 304 (V2A) or AISI 316 (V4A) stainless steel

Sealing membrane EPDM 60

For immersion depths to 6 m below maximum substrate level

Propeller diameter 850 MS mm in hardened steel

Hydraulic inclination adjustment with hand pump

5

The OPTIMIX agitators, together with

various installation fixtures, are suit-

able for substrate mixing in biogas

fermenters or residue storage facili-

ties.

All of the submersible motor agita-

tors have been approved for ATEX

zone 2. Alternative model 2A is fabri-

cated entirely in AISI 304 (V2A) stain-

less steel and has been approved for

zone 1.

Various installation fixtures are avai-

lable, depending on individual requi-

rements, for example: we can build

stainless steel masts with a swivel

function and height adjustment from

outside, to meet your individuel

needs.

All the component parts are designed

and manufactured at the SUMA fac-

tory. Modifications and individual de-

sign requirements do not constitute

a problem.

OPTIMIX Propeller Agitators

with Submersible Motors

B

I

O

G

A

S

For closed concrete digester

For mounting through fermenter wall

TECHNCAL DATA:

OPTIMIX UG / 3G / 2A

Submersible mixer of rated output 4/7.5/11/15 and 25 kW at 380 rpm

(3-phase 50 cycles) or 460 rpm (3-phase 60 cycles) rpm - for hazardous zone 2

Submersible mixer of rated output 25 kW at 270 rpm

(3-phase 50 cycles) or 430 rpm (3-phase 60 cycles) - for a hazardous zone 2

Special version in stainless steel with 13.5 kW for hazardous zone 1 at 380 rpm

(3-phase 50 cycles) or 460 rpm (3-phase 60 cycles) 13.5 kW power output for

hazardous -zone 1

Epicyclic gear transmission

Motor bracket with SUMA 4-roller carriage

Bearing housing with mechanical seal of SiC/SiC

3 lubricating oil circuits for motor, transmission and bearing housing

Built-in temperature sensor

Special microbe-resistant cable (screened cable available, if required)

Propeller in galvanized, hardened or stainless steel (AISI 304/V2A)

Cable run with cable clips and strain relief fittings behind mast

Guide mast with gas-tight wall lead-through consisting of:

Square-sectioned tube

Floor-mount for dowel type fixing

Sideways adjustment through slewing ring from outside

Height adjustment with winch and 8 mm diameter

stainless steel wire rope (AISI 316/V4A)

Wall brackets on inside and outside

6

The Rekordmix B1 has been specially

developed for biogas plants built

around a large covered lagoon.

Retro-fitting is also possible.

The Rekordmix serves to optimize the

biological process by:

preventing the formation of floa-

ting and sinking substrate layers

ensuring that the substrate main-

tains an equal temperature

throughout

distributing nutrients for the bio-

logical process homogeneously

enabling more efficient gas flow

out of the substrate mass

Specification:

Shaft unit with electric motor, shaft

tube with bearing and sealing block

of low-maintenance modular con-

struction.

All important components are manu-

factured in stainless steel. To protect

the gas storage membrane inside the

bay, the propeller is fitted with a pro-

tective ring. An oil reservoir serves

the lubrication and the maintenance

indicator.

A mounting bracket for securing the

unit to the substructure is included

within the scope of delivery.

Height of the unit is set at the frame.

A rubber sealing membrane, secured

by a metal ring fastened to the mem-

brane ensures a gas-tight installation.

Through the rubber seal, the agitator

unit is mechanically separated from

the gas membrane to prevent ripping

and tearing of the membrane.

B1 Electric Agitator

B

I

O

G

A

S

For lagoons with gas storage membrane cover

TECHNICAL DATA:

REKORDMIX B1

Stainless steel (AISI 304/V2A) shaft tube with a diameter of 70 x 3 mm, 3.75 m long

Hardened steel propeller 275 mm in diameter

Stainless steel protective ring (AISI 304/V2A)

Motor power output: 4 kW at 950 rpm (3-phase 50 cycles)

or 1,140 rpm (3-phase 60 cycles)

Bearing housing with a mechanical seal of SiC/SiC, thrusting forces from the propel-

ler absorbed by two taper roller bearings

Sealing membrane EPDM 60

Agitator frame permits inclination and height adjustment

An oil reservoir monitors and lubricates seal and bearings

The unit does not come with power cables and control unit

A substructure (foundation) is required for mounting the unit

7

The Giantmix Z6 is the agitator for

open bays and lagoons, especially

those of residue storage in biogas

plants, in which difficult operating

conditions demand high-performance

tractor power.

The Giantmix Z6 has been developed

to suit the 240 HP and above tractor

generation. The Z6 is designed to

satisfy the demands for durability

over long periods.

The design concept of the shaft unit

bearings, proven over decades, has

naturally been adopted and incorpo-

rated into a practical modular con-

struction.

The compatible frame design has

been designed for a universal 3-point

connection.

For optimal alignment of the agita-

tor, the inclination can also be adju-

sted by the two parallel hydraulic

cylinders.

Traktor-driven agitator Z6

B

I

O

G

A

S

For open biogas residue storage / lagoons

TECHNICAL DATA:

GIANTMIX Z6

Galvanized steel shaft tube diameter 194 x 6 mm

Tube lengths from 7.5 to 9.0 m

Propeller diameter from 700 to 850 mm

Suitable for tractor power from> 160 kW

Bearing housing with mechanical seal of SiC/SiC60 mm shaft end diameter

Thrusting forces from the propeller absorbed by two taper

roller bearings 30312 ( 60/ 130)

Power take-off connection is solely 1-3/4" (6)

The drive shaft within the agitator tube is a 70 mm diameter splined hollow

tube with multiple bearings

B

I

O

G

A

S

CONTACT

SUMA Rhrtechnik GmbH

Martinszeller Str. 21

GERMANY - 87477 Sulzberg

Fon: +49 8376 92131-0

Fax: +49 8376 9 2131-19

info@suma.de

www.suma.de

YOUR DEALER

You might also like

- WEG NemapremiumDocument11 pagesWEG NemapremiumGualaNo ratings yet

- Viking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsDocument12 pagesViking Heavy Duty Pumps: SERIES 4193 AND 493 Steel ExternalsBenicio Joaquín Ferrero BrebesNo ratings yet

- TATA Ring Granulator Technical Features SEODocument5 pagesTATA Ring Granulator Technical Features SEOVijayakumar AtthuluriNo ratings yet

- WEG Turbogenerators St20 and St40 Lines 50019094 Brochure EnglishDocument8 pagesWEG Turbogenerators St20 and St40 Lines 50019094 Brochure EnglishVelu SamyNo ratings yet

- GS3BA Series High Efficiency Air Conditioner: Technical SpecificationsDocument4 pagesGS3BA Series High Efficiency Air Conditioner: Technical Specificationstrien15No ratings yet

- Catalogue AEEBDocument12 pagesCatalogue AEEBsetiawanayNo ratings yet

- Electrical Machines Block 2Document23 pagesElectrical Machines Block 2Aravind PadhiNo ratings yet

- Decanter CC 450 458 enDocument2 pagesDecanter CC 450 458 enJonathan Arboleda Genes100% (1)

- SubmersiblePropellerPump VUPX E10359Document8 pagesSubmersiblePropellerPump VUPX E10359hafezasadNo ratings yet

- B3888D3Document4 pagesB3888D3anon_78283445No ratings yet

- Sluice Gate ValveDocument15 pagesSluice Gate ValveRinia DurrsakeNo ratings yet

- MOTORES WEG 02 2014 Us100 Brochure EnglishDocument28 pagesMOTORES WEG 02 2014 Us100 Brochure EnglishRamiro NavarroNo ratings yet

- Ik12max3 Pga Eng WebDocument4 pagesIk12max3 Pga Eng Websjalife1No ratings yet

- 351 Equipo de PerforacionDocument3 pages351 Equipo de Perforacionmisael_arielNo ratings yet

- WEG Three Phase Induction Motors Master Line 50019089 Brochure EnglishDocument12 pagesWEG Three Phase Induction Motors Master Line 50019089 Brochure EnglishEhsan MoheimaniNo ratings yet

- Traction Motor Type Tm4907Bz: Technical DataDocument12 pagesTraction Motor Type Tm4907Bz: Technical DataPratibha Patel100% (1)

- Brochure 1100 PDFDocument6 pagesBrochure 1100 PDFDavid CarvalhoNo ratings yet

- Ac Metric MotorsDocument5 pagesAc Metric MotorsZoebairNo ratings yet

- Submersible Propeller Pump Type ABS VUPXDocument8 pagesSubmersible Propeller Pump Type ABS VUPXAgus SalmanNo ratings yet

- Integral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Document12 pagesIntegral Pilot (External Exhaust) Threaded or Quick Mount Connection 3/4 To 1 1/2Lê Duy MinhNo ratings yet

- Ebaa 1100Document6 pagesEbaa 1100sureshmaya88No ratings yet

- GE Large Induction MotorsDocument8 pagesGE Large Induction MotorsidontlikeebooksNo ratings yet

- ABS Submersible Mixer RW 200, 50HzDocument2 pagesABS Submersible Mixer RW 200, 50Hzalisya.blwsNo ratings yet

- Technical Specifications For Centrifugal Pumps PDFDocument12 pagesTechnical Specifications For Centrifugal Pumps PDFVicky GautamNo ratings yet

- 4030 / 4280 Series: End Suction PumpsDocument8 pages4030 / 4280 Series: End Suction PumpsShrikant WalseNo ratings yet

- Equipment:: Figure 1: Vertical Turbine PumpDocument8 pagesEquipment:: Figure 1: Vertical Turbine PumphamizanNo ratings yet

- 4530 Spec SheetDocument2 pages4530 Spec SheetLye YpNo ratings yet

- As TDS 60Hz MetricDocument4 pagesAs TDS 60Hz MetricMarko Antonio AguilarNo ratings yet

- KAT Gouging System - Arcair N7500Document2 pagesKAT Gouging System - Arcair N7500Th NattapongNo ratings yet

- Compact End Suction PumpsDocument8 pagesCompact End Suction PumpsRohith RavindranathNo ratings yet

- Goulds 3186: High-temperature/Pressure Paper Stock/ Process PumpsDocument8 pagesGoulds 3186: High-temperature/Pressure Paper Stock/ Process PumpsGorea AndreiNo ratings yet

- WEG Three Phase Induction Motors M Line 50019089 Brochure EnglishDocument12 pagesWEG Three Phase Induction Motors M Line 50019089 Brochure Englishhossein447No ratings yet

- Everything you need to know about DAX turbogeneratorsDocument4 pagesEverything you need to know about DAX turbogeneratorsELYOU89100% (1)

- 3885 SpecDocument2 pages3885 Specm_engineer09No ratings yet

- Kunkle OverviewDocument8 pagesKunkle Overviewsamix999No ratings yet

- Cokebuster: A Proven SolutionDocument11 pagesCokebuster: A Proven Solutionengg_mech77No ratings yet

- WEG TurbogeneratorsDocument8 pagesWEG TurbogeneratorsHarsha VardhanNo ratings yet

- GouldsDocument11 pagesGouldsKaren Isabel Ambiado Rivas100% (1)

- YCM GT SeriesDocument30 pagesYCM GT SeriesCNC SYSTEMSNo ratings yet

- Advantage Brake EngDocument12 pagesAdvantage Brake EngNaveen ParthasarathyNo ratings yet

- LC SCDocument28 pagesLC SChardik033No ratings yet

- Aurora PumpsDocument12 pagesAurora PumpsM Alim Ur RahmanNo ratings yet

- Agende Motoare Asincrone Leroy-SomerDocument22 pagesAgende Motoare Asincrone Leroy-SomerVlad MoisiencoNo ratings yet

- Adjustable Roller HangerDocument1 pageAdjustable Roller HangerSyed Kamal FareedeeNo ratings yet

- Brochure Track Drills BucyrusDocument12 pagesBrochure Track Drills BucyrusWashington Huallpa100% (1)

- Portable welding and gas/plasma cutting machineDocument4 pagesPortable welding and gas/plasma cutting machineCarlos PadillaNo ratings yet

- Imo Pump 3DDocument6 pagesImo Pump 3DHadi Utomo100% (1)

- ABS Submersible Wastewater Pump AS 0530-0841: ApplicationsDocument4 pagesABS Submersible Wastewater Pump AS 0530-0841: Applicationsas3ateNo ratings yet

- Aurora Pump 6-491-12aDocument28 pagesAurora Pump 6-491-12ajuan yenqueNo ratings yet

- G554T LocalDocument2 pagesG554T LocalAmardeep HansdaNo ratings yet

- Honda / AcuraDocument7 pagesHonda / Acuracrower_scribdNo ratings yet

- 1 M2QA - IEC StandardDocument28 pages1 M2QA - IEC StandardgabrielNo ratings yet

- Series21&41 CatalogDocument16 pagesSeries21&41 CatalogWillin08No ratings yet

- MEPF BOQ - AZURE TargetDocument33 pagesMEPF BOQ - AZURE TargetUpendra ChariNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- TOX FinePress 45 201201 enDocument16 pagesTOX FinePress 45 201201 enSirbu SorinNo ratings yet

- Citizen A16VI Machine SpecificationsDocument2 pagesCitizen A16VI Machine SpecificationscmganklNo ratings yet

- Syphon For Pressure Measuring Instruments Model 910.15: ApplicationsDocument4 pagesSyphon For Pressure Measuring Instruments Model 910.15: Applicationsluis carlos martin contrerasNo ratings yet

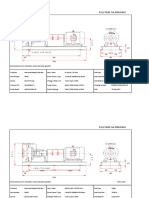

- GA Drawings of Industrial PumpsDocument9 pagesGA Drawings of Industrial PumpsTheepa SubramaniamNo ratings yet

- Morgana Digifold Service ManualDocument55 pagesMorgana Digifold Service Manualpfequip100% (1)

- Equipment Rental RatesDocument17 pagesEquipment Rental RatesHeide Dacyon100% (2)

- Preliminary Heat Exchanger Sizing: These Calculations Are Provided For Educational Use Only - USE AT YOUR OWN RISKDocument4 pagesPreliminary Heat Exchanger Sizing: These Calculations Are Provided For Educational Use Only - USE AT YOUR OWN RISKRaol VarshabenNo ratings yet

- Pneumatic Systems: Aircraft High-Pressure Pneumatic SystemsDocument14 pagesPneumatic Systems: Aircraft High-Pressure Pneumatic SystemsAndreas.G100% (1)

- Systems: Chapter B-6Document22 pagesSystems: Chapter B-6stolehaNo ratings yet

- Emoving and Installing TurbochargerDocument7 pagesEmoving and Installing TurbochargerDamir MiholićNo ratings yet

- Parts Docs KOMATSU D65 Px16Document966 pagesParts Docs KOMATSU D65 Px16Mayki100% (11)

- Steam System Properties and Energy SavingsDocument34 pagesSteam System Properties and Energy SavingsArnav KothiyalNo ratings yet

- Pc3 Clamp DrawingDocument4 pagesPc3 Clamp DrawingSujin SujiNo ratings yet

- Structural Analysis of Mast of Special Rotary Drilling Rig For Transmission LineDocument5 pagesStructural Analysis of Mast of Special Rotary Drilling Rig For Transmission LineBruno SantosNo ratings yet

- Product Information: Valvoline™ HD Nitrite Free Coolant RTUDocument2 pagesProduct Information: Valvoline™ HD Nitrite Free Coolant RTUmcalidonio5656No ratings yet

- Manual Recambios 3.152.4 (CM51027) PDFDocument149 pagesManual Recambios 3.152.4 (CM51027) PDFValoys MirandaNo ratings yet

- Computational Study of Effects of Jet Fans On The Ventilation of A Highway PDFDocument9 pagesComputational Study of Effects of Jet Fans On The Ventilation of A Highway PDFZine ModelsNo ratings yet

- Bourdon Gauge - BellowDocument14 pagesBourdon Gauge - BellowBikram RoyNo ratings yet

- System Head in Metric UnitsDocument7 pagesSystem Head in Metric UnitsrammysiNo ratings yet

- Instructions On Installation, Operation and Maintenance For Kirloskar Magnetic Drive Pump - "ROMAK"Document54 pagesInstructions On Installation, Operation and Maintenance For Kirloskar Magnetic Drive Pump - "ROMAK"manojkumar8621No ratings yet

- Powerplant Quizlet 492Document63 pagesPowerplant Quizlet 492Jecah Angelu S. SaquianNo ratings yet

- Pressure Vessel Rupture 1571662927 PDFDocument9 pagesPressure Vessel Rupture 1571662927 PDFbilalak1990No ratings yet

- PDF The 2017 Aisi Cold Formed Steel Design Manual - CompressDocument11 pagesPDF The 2017 Aisi Cold Formed Steel Design Manual - Compressfreddy noya plata0% (1)

- Oil Free Compressor Manual 132 KWDocument33 pagesOil Free Compressor Manual 132 KWrubiodegoNo ratings yet

- Din 6914-10.9 PDFDocument2 pagesDin 6914-10.9 PDFvpjagannaathNo ratings yet

- The Manual of Fastening EN 8100 PDFDocument106 pagesThe Manual of Fastening EN 8100 PDFOleh SmolovyiNo ratings yet

- Parts List for Vacuum Systems with Location, Brand and Model DetailsDocument68 pagesParts List for Vacuum Systems with Location, Brand and Model DetailsJose Gregorio Lira SerranoNo ratings yet

- Properties of Fluids ExplainedDocument13 pagesProperties of Fluids ExplainedGie Andal0% (3)

- Fire Test Report: ANSI/API Standard 607, 6th Edition, 2010 ISO 10497: 2010Document16 pagesFire Test Report: ANSI/API Standard 607, 6th Edition, 2010 ISO 10497: 2010jamil voraNo ratings yet

- Stress Analysis Bolted JointDocument11 pagesStress Analysis Bolted JointGustavoYippeekayyayGusNo ratings yet