Professional Documents

Culture Documents

Process For Adjusting The Sensor Technology of Cranes With Light Display en

Uploaded by

email4mobile100%(9)100% found this document useful (9 votes)

2K views17 pagesThe document provides instructions for adjusting various sensor technologies on cranes with an EKS 5 light display system. It describes processes for adjusting the main boom angle sensor, the inner and outer length sensors for the telescoping boom, the lower and upper pressure sensors, and the slewing angle sensor. Tables are included with starting and ending values for each sensor type for different crane models to aid in calibration. The instructions emphasize connecting an adjustment box and entering programming mode before adjusting sensor values.

Original Description:

instructions for canes sensors

Original Title

Process for Adjusting the Sensor Technology of Cranes With Light Display En

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides instructions for adjusting various sensor technologies on cranes with an EKS 5 light display system. It describes processes for adjusting the main boom angle sensor, the inner and outer length sensors for the telescoping boom, the lower and upper pressure sensors, and the slewing angle sensor. Tables are included with starting and ending values for each sensor type for different crane models to aid in calibration. The instructions emphasize connecting an adjustment box and entering programming mode before adjusting sensor values.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(9)100% found this document useful (9 votes)

2K views17 pagesProcess For Adjusting The Sensor Technology of Cranes With Light Display en

Uploaded by

email4mobileThe document provides instructions for adjusting various sensor technologies on cranes with an EKS 5 light display system. It describes processes for adjusting the main boom angle sensor, the inner and outer length sensors for the telescoping boom, the lower and upper pressure sensors, and the slewing angle sensor. Tables are included with starting and ending values for each sensor type for different crane models to aid in calibration. The instructions emphasize connecting an adjustment box and entering programming mode before adjusting sensor values.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 17

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 1

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of

Cranes with Light Display

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 2

Table of Contents

1. EKS 5 Adjustment Instructions ...........................................................................................................3

2. Process for Adjusting the Main Boom Angle ......................................................................................6

3. Process for Adjusting the Length Sensor Inner Drum........................................................................9

4. Process for Adjusting the Length Sensor Outer Drum .....................................................................11

5. Process for Adjusting the Pressure Sensor Lower Chamber ...........................................................12

6. Process for Adjusting the Pressure Sensor Upper Chamber ...........................................................14

7. Process for Adjusting the Slewing Angle Sensor (Slewing Range) ..................................................16

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 3

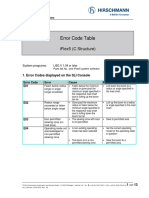

1. EKS 5 Adjustment Instructions

General Note

All of the drive units of the crane must be functioning. The hydraulics, ECOS and RCI control systems are

pre-adjusted with standard values.

Connecting the change-over box

Switch off ignition

Unscrew protective cover on the right at the bottom of the crane operators cab.

Connect change-over box (part No. 03056586) to the 15-pin (EKS/RCI) diagnostic plug connection in

the crane operators cab.

Fig. GROVE change-over box in crane operators cab

Attention! Pay attention to the description of the diagnostic plugs in older cranes!

As the RCI is not functioning during the adjusting process, particular care is required when

operating the crane. Pay particular attention to the hoist limit switch and outrigger and ensure that

the counterweight is sufficient.

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 4

Turn RS232 switch to 3+4.

Switch on ignition

Release write protection via interface (position the toggle switch in position 1 on the change-over

box).

Fig. GROVE change-over box

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 5

Adjustment: PIN input

Fig. EKS 5 light display

For the connection of the change-over box see EKS 5 Adjustment Instructions General Notes

Entering the programming mode

Activate keys + for the PIN input prompt.

INFO display flashes!

Input PIN via Num. Block keys to and confirm with <ENTER>

The input + is required to release the sensor equalisation

Rigging mode display flashes!

Enter address with Num. Block and confirm with <ENTER> key.

INFO display flashes!

The current value is displayed which is to be altered to

Confirm with <ENTER>

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 6

2. Process for Adjusting the Main Boom Angle

Adjust the base section to 0.0using an electronic spirit level.

Fig. Electronic spirit level with base section adjustment 0

Adjustment: starting value for angle sensor

Teach starting value with , . The display is automatically set to 0.0.

Display:

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 7

Only when process is being carried out with a pendulum potentiometer! If the process is being

executed with a digital angle sensor, this 80adjustment process is not required.

Using an electronic spirit level adjust the base section to 80.0.

Fig. Electronic spirit level with base section adjustment 80

Adjustment: end value for angle sensor

Check address 224 value 800

Teach end value with , . The value is automatically adjusted to 80.0.

Display:

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 8

A list of all of the types of cranes with the relevant adjustment data is given below for the main boom

angle:

Type of crane (GMK)

GMK

2035

GMK

3050

GMK

3050_1

GMK

3055

GMK

4075

GMK

4075_1

GMK

5100

GMK

5130

GMK

5200

GMK

6200

GMK

6220

GMK

6221

Starting

value

1300 1300 1300 0 1250 0 1250 0 1280 1280 1280 1200

End

value

4900 4900 4900 800 4800 800 4800 800 4850 4850 4850 4800

Stroke 800 800 800 800 800 800 800 800 800 800 800 800

Type of crane (GMK)

GMK

6250

GMK

6300

GMK

7450

Starting

value

1300 1300 1300

End

value

4800 4800 4800

Stroke 800 800 800

Table: GMK main boom adjustment data

Note:

The starting and end values in the table are not fixed values and are therefore just a guide!

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 9

3. Process for Adjusting the Length Sensor Inner Drum

Please comply with the sequence!

Attention: This adjusting process can only be carried out after the telescope lengths have been adjusted

in the ECOS (ESX) system!

Lock telescoping cylinder with telescope section 1 (telescope position 0 0 0 0 (0) ), derrick

boom up to approx. 80.

Adjustment: starting value for length sensor inner drum

Teach starting value with , .

Extend telescope section 4 to 100% and lock (or the maximum level, e.g. GMK3055 tele. 5).

Adjustment: end value for length sensor inner drum

Check address 264 enter the appropriate stroke (see table on next page; e.g..: for GMK3055 732)

Teach end value with , .

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 10

A list of all of the types of cranes with the relevant adjustment data is given below for the length sensor

inner drum:

Type of crane (GMK)

GMK

2035

GMK

3050

GMK

3050_1

GMK

3055

GMK

4075

GMK

4075_1

GMK

5100

GMK

5130

GMK

5180

GMK

5200

GMK

6200

GMK

6220

GMK

6221

Starting

value

1044 1044 1044 1049 1044 1044 1044 1044 1044 1044 1044 1044 1044

End value 3200 3200 3200 2635 2800 2970 3250 3150 3150 3150 3150 3150 3550

Stroke 666 707 707 732 887 887 1042 1054 1054 1054 1054 1054 1254

Type of crane (GMK)

GMK

6250

GMK

6300

GMK

7450

Starting

value

1044 1044 1044

End value 3500 3500 3500

Stroke 1247 1247 1247

Table: GMK length sensor inner drum adjustment data

Note:

The starting and end values in the table are not fixed values and are therefore just a guide!

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 11

4. Process for Adjusting the Length Sensor Outer Drum

Please comply with the sequence!

Retract all telescope sections to (0 - 0 - 0 0) (fully retract telescopic boom), derrick up to approx. 80.

Adjustment: starting value for length sensor outer drum

Teach starting value with , .

Extend all telescope sections fully and derrick boom up to approx. 80.

Adjustment: end value for length sensor outer drum

Check address 234 enter value from the following table; e.g.: GMK3055 3334

Adjustment: Teach end value with , .

A list of all of the types of cranes with the relevant adjustment data is given below for the length sensor

outer drum:

Type of crane (GMK)

GMK

2035

GMK

3050

GMK

3050_1

GMK

3055

GMK

4075

GMK

4075_!

GMK

5100

GMK

5130

GMK

5180

GMK

5200

GMK

6200

GMK

6220

GMK

6221

Starting

value

1044 1044 1044 1044 1044 1044 1044 1044 1044 1044 1044 1044 1044

End value 2800 3600 3600 3875 3900 3750 3350 4000 4000 4000 4000 4000 4650

Stroke 2016 2828 2828 3334 3200 3200 3820 4650 4650 4650 4650 4650 5650

Type of crane (GMK)

GMK

6250

GMK

6300

GMK

7450

Starting

value

1044 1044 1044

End value 3900 3900 3900

Stroke 4454 4454 4454

Table: GMK length sensor outer drum adjustment data

Note:

The starting and end values in

the table are not fixed values

and are therefore just a guide!

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 12

5. Process for Adjusting the Pressure Sensor Lower Chamber

Please comply with the sequence!

Adjustment: Starting value of the pressure sensor lower chamber

Lower boom onto the boom support

Make pressure sensor lower chamber pressureless via the bleeder screw of the safety lowering valve.

Fig. bleeder screw; Example: GMK3055 safety lowering valve on the derricking cylinder

Adjustment: Teach starting value with , .

Read physical value on Info Display must be less than 1.5 bar

Note:

If the value exceeds 1.5 bar, then unscrew the sensor and tighten again with a torque wrench or if the

value stays the same (over 1.5 bar) replace sensor.

Check: end value for pressure sensor lower chamber

Check address 204 value 350 (bar) (see table on next page)

The end values are not taught but are preset

Read starting value for address 200 and 201 e.g. 1024 + 4096 (stroke) = 5120 (end value for address

202 or 203)

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 13

A list of all of the types of cranes with the relevant adjustment data is given below for the pressure sensor

lower chamber:

Type of crane (GMK)

GMK

2035

GMK

3050

GMK

3050_!

GMK

3055

GMK

4075

GMK

4075_1

GMK

5100

GMK

5130

GMK

5180

GMK

5200

GMK

6200

GMK

6220

GMK

6221

Starting

value

1024 1024 1024 1024 1024 1024 1024 1024 1024 1024 1024 1024 1024

End value 5120 5120 5120 5120 5120 5120 5120 5120 5120 5120 5120 5120 5120

Stroke 350 350 350 350 350 350 350 350 350 350 350 350 350

Type of crane (GMK)

GMK

6250

GMK

6300

GMK

7450

Starting

value

1024 1024 1024

End value 5120 5120 5120

Stroke 350 350 350

Table: GMK pressure sensor lower chamber adjustment data

Note:

The starting and end values in the table are not fixed values and are therefore just a guide!

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 14

6. Process for Adjusting the Pressure Sensor Upper Chamber

Please comply with the sequence!

Lower boom onto the boom support

Make pressure sensor upper chamber pressureless via the bleeder screws of the cylinder.

Fig. Cylinder bleeder screw for pressure sensor upper chamber

Adjustment: starting value for pressure sensor upper chamber (concerns cranes with pressure

sensor upper chamber)

Teach starting value with , .

Read physical value on Info display must be less than 1.5 bar

Note: If the value exceeds 1.5 bar, then unscrew the sensor and tighten again with a torque wrench, or if

the value stays the same (over 1.5 bar) replace sensor.

Attention: No pressure sensor upper chamber exists for the GMK 3055 crane!

Adjustment: end value for pressure sensor upper chamber (concerns cranes with pressure sensor

upper chamber)

Check address 214 value 350 (bar)

The end values are not taught, but are preset

Read starting value for address 210 e.g. 1024 + 4096 (stroke) = 5120 (end value for address 212)

General Note

When changing the new pressure sensors with a screw cap and in the case of new cranes, the pressure

sensors must be configured with EasyCAN.

If the pressure sensors are detected by EasyCAN, they must also be configured.

See also EKS adjustment list Address 206, 207 and 216 Status must be on 2.

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 15

A list of all of the types of cranes with the relevant adjustment data is given below for the pressure sensor

upper chamber:

Type of crane (GMK)

GMK

2035

GMK

3050

GMK

3050_1

GMK

3055

GMK

4075

GMK

4075_1

GMK

5100

GMK

5130

GMK

5180

GMK

5200

GMK

6200

GMK

6220

GMK

6221

Starting

value

1024 1024 1024 1024 1024 1024 1024 1024 1024 1024 1024 1024 1024

End value 5120 5120 5120 5120 5120 5120 5120 5120 5120 5120 5120 5120 5120

Stroke 350 350 350 350 350 350 350 350 350 350 350 350 350

Type of crane (GMK)

GMK

6250

GMK

6300

GMK

7450

Starting

value

1024 1024 1024

End value 5120 5120 5120

Stroke 350 350 350

Table: GMK pressure sensor upper chamber adjustment data

Note:

The starting and end values in the table are not fixed values and are therefore just a guide!

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 16

7. Process for Adjusting the Slewing Angle Sensor (Slewing Range)

Please comply with the sequence!

The crane is rotated to the back and locked in the 0.0position.

Adjustment: starting value for slewing angle sensor

Teach starting value with , .

Info display:

The crane is locked forward in the 180.0position (not in the case of the 5130)

Note: Slew right check of 0.0must display a positive (+) value left negative (-).

Adjustment: end value for the slewing angle sensor

Check address 272 value 180 () see table on next page (stroke)

Teach end value with , .

Info display:

Note:

* In the case of ATTO-CANOpen sensors, the sensor must first be configured with EasyCAN.

During adjustments, only the position 0locked to the back is operated and taught. The

position 180forwards does not have to be taught.

EKS 5 Technical Description

Process for Adjusting the Sensor Technology of Cranes

with Light Display

TK4/Training Centre 01.02.2005

Page 17

A list of all of the types of cranes with the relevant adjustment data is given below for the slewing angle

sensor:

Type of crane (GMK)

GMK

2035

GMK

3050

GMK

3050_1

GMK

3055

GMK

4075

GMK

4075_1

GMK

5100

GMK

5130

GMK

5180

GMK

5200

GMK

6200

GMK6

220

GMK

6221

GMK

6250

Starting

value

2048 2048 2048 2048 2048 2048 2048 2048 2048 2048 2048 2048 2048 2048

End value 2377 2377 2377 2377 4096 3848 4096 4096 4096 4096 6144 6144 6144 6144

Stroke 180 180 180 180 180 180 180 180 180 180 180 180 180 180

Type of crane (GMK)

GMK

6250

GMK

6300

GMK

7450

Starting

value

2048 2048 2048

End value 6144 6144 4096

Stroke 180 180 180

Table: GMK slewing angle sensor adjustment data

Note:

The starting and end values in the table are not fixed values and are therefore just a guide!

You might also like

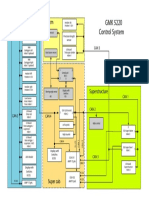

- GMK 5100 Gear Control SystemDocument14 pagesGMK 5100 Gear Control Systemالمهندسوليدالطويل83% (6)

- AC100 Training Manual Ver 2 0 PDFDocument382 pagesAC100 Training Manual Ver 2 0 PDFما ضاقت الا لتفرج80% (5)

- DS-160 Fault CodesDocument9 pagesDS-160 Fault CodesKrum KashavarovNo ratings yet

- Services Manual Lmi SystemDocument76 pagesServices Manual Lmi SystemAngel Dlsg80% (5)

- 2-5 New Error Codes PDFDocument13 pages2-5 New Error Codes PDFdacem torres cruz100% (1)

- Grove GMK Training PDFDocument297 pagesGrove GMK Training PDFnurfathoni100% (4)

- Om - en - Atf 220G-5Document1,078 pagesOm - en - Atf 220G-5xrurabus100% (29)

- GMK5220 Super Pressure AdjustmentsDocument9 pagesGMK5220 Super Pressure AdjustmentsAngel Dlsg100% (2)

- Carrier Malfunctions - EU PDFDocument44 pagesCarrier Malfunctions - EU PDFrenat100% (1)

- DS350 Tadano Faun 1368Document61 pagesDS350 Tadano Faun 1368Mohamed Harb100% (2)

- New ECOSDocument95 pagesNew ECOSAhmed Hassan Abo Asem100% (11)

- GMK 5100 ECOS Error Codes V2Document9 pagesGMK 5100 ECOS Error Codes V24g lite100% (1)

- DAF 95 XF Electric Manual 1997 YearDocument348 pagesDAF 95 XF Electric Manual 1997 Yearvik_md100% (3)

- Propvalve eDocument38 pagesPropvalve eMohamed Rashed100% (1)

- Service Technicians Information Supplement: Revised January 1997Document48 pagesService Technicians Information Supplement: Revised January 1997Lucas Romero50% (2)

- GMK 3050 Pneumatic System: Deutsche GROVEDocument6 pagesGMK 3050 Pneumatic System: Deutsche GROVEDaniel Castillo PeñaNo ratings yet

- 6200 - 1 Superstructure MalfunctionsDocument82 pages6200 - 1 Superstructure Malfunctionsrenat100% (1)

- Super HydraulicDocument17 pagesSuper HydraulicDaniel Castillo Peña100% (2)

- Tadano Load Sensor Repair ManualDocument11 pagesTadano Load Sensor Repair ManualRaja SekarNo ratings yet

- ECOS 1 PresentationDocument87 pagesECOS 1 PresentationLuis Jose Lloban100% (1)

- DS350 Tadano Faun 1368Document61 pagesDS350 Tadano Faun 1368Bqdcc6100% (9)

- ECOS Data Report 3063Document13 pagesECOS Data Report 3063Sarra Chouchene0% (1)

- ECOS Error Codes - 5220Document24 pagesECOS Error Codes - 5220Benjamín Sancho Contreras100% (3)

- Vdocuments - MX - Pat 2 Manual PDFDocument504 pagesVdocuments - MX - Pat 2 Manual PDFDanilo Marin100% (1)

- TADANO-FAUN RTF 80-4 Part D 2 Hydraulic Circuit ChassisDocument8 pagesTADANO-FAUN RTF 80-4 Part D 2 Hydraulic Circuit Chassiseshopmanual TigaNo ratings yet

- EKS4 Simulation - DINDocument16 pagesEKS4 Simulation - DINazamen0% (2)

- Liccon II Components: Progress in MotionDocument25 pagesLiccon II Components: Progress in MotionAly AbdelhamedNo ratings yet

- Manual de Servicio LTM1070 Parte 2 GruaDocument192 pagesManual de Servicio LTM1070 Parte 2 GruaYorland92% (12)

- IFLEX2 ISCOUT Grove RT TM Service Manual English 1Document64 pagesIFLEX2 ISCOUT Grove RT TM Service Manual English 1Mohamed Rashed100% (1)

- Wiring Carrier - ENDocument118 pagesWiring Carrier - ENFarai Chamisa100% (3)

- Ecos System Description GMK 4075: Error CodesDocument31 pagesEcos System Description GMK 4075: Error CodesArsène TIA MANNo ratings yet

- GMK Schematic HandbookDocument55 pagesGMK Schematic HandbookYukki Badamgarav100% (10)

- Technical Information LTM 1030/2: Outline of The Components With Identification (BMK)Document28 pagesTechnical Information LTM 1030/2: Outline of The Components With Identification (BMK)josselin quatrainNo ratings yet

- Sabp P 053Document16 pagesSabp P 053Hassan MokhtarNo ratings yet

- Warning!!: Grove Manitowoc National Crane PotainDocument4 pagesWarning!!: Grove Manitowoc National Crane Potainrodolfof_31100% (1)

- AC60 Training Manual Intranet1.3 PDFDocument954 pagesAC60 Training Manual Intranet1.3 PDFDemagUral50% (2)

- Superstructure Malfunctions - EUDocument78 pagesSuperstructure Malfunctions - EUazamenNo ratings yet

- BHEL SeminarDocument50 pagesBHEL Seminarsen_subhasis_58No ratings yet

- Arabic English Legal Dictionary (Book 1)Document45 pagesArabic English Legal Dictionary (Book 1)atefsharia89% (9)

- Pat Iflex5Document83 pagesPat Iflex5aren_mendoza100% (3)

- Matlab Robotics ToolboxDocument20 pagesMatlab Robotics ToolboxRajesh RavindranNo ratings yet

- ErrorCodes 5220 V01 06Document24 pagesErrorCodes 5220 V01 06Sarra Chouchene100% (1)

- VST Plug-Ins SDK 2.0Document84 pagesVST Plug-Ins SDK 2.0email4mobileNo ratings yet

- DHB - 99904-01-02 LICCON2 PDFDocument75 pagesDHB - 99904-01-02 LICCON2 PDFMgc Elektronik100% (2)

- Carrier Hyd Schematic - 1 - With GraphicsDocument1 pageCarrier Hyd Schematic - 1 - With GraphicsAhmed Hassan Abo AsemNo ratings yet

- Technical Manual SLI-System DS350C English PDFDocument12 pagesTechnical Manual SLI-System DS350C English PDFstephen prosser100% (2)

- ECOS Error Codes 5130-1Document23 pagesECOS Error Codes 5130-1Benjamín Sancho Contreras100% (4)

- Eks 83Document4 pagesEks 83leo100% (4)

- ECOS Connection PrincipleDocument1 pageECOS Connection PrincipleSarra ChoucheneNo ratings yet

- ECOS Training NotesDocument13 pagesECOS Training Notesazamen100% (3)

- Tadano AML M1 M2-TR (MkII Connection Instructions)Document5 pagesTadano AML M1 M2-TR (MkII Connection Instructions)Daniel AguirreNo ratings yet

- DS350 Error CodesDocument12 pagesDS350 Error Codesefrain revillaNo ratings yet

- Meeting and Interview MinutesDocument5 pagesMeeting and Interview MinutesRadoslav RobertNo ratings yet

- Grove Rev 1Document7 pagesGrove Rev 1duongpndng100% (3)

- Generative+Design+Report Final 91818Document51 pagesGenerative+Design+Report Final 91818Lavinia BucaNo ratings yet

- VISIO-GMK 5220 SteuerungssystemDocument1 pageVISIO-GMK 5220 SteuerungssystemSarra ChoucheneNo ratings yet

- Errorcodes EKS5 enDocument20 pagesErrorcodes EKS5 engrineldo8480% (5)

- DHB - 99904-01-02 LICCON2 PDFDocument75 pagesDHB - 99904-01-02 LICCON2 PDFJohn Carmona89% (9)

- BMK 1250-6.1 enDocument116 pagesBMK 1250-6.1 enEdilson100% (1)

- The Impact of Technology On Learning EnvironmnentDocument7 pagesThe Impact of Technology On Learning EnvironmnentAhmad Ali75% (4)

- 5220 ECOS Components PDFDocument25 pages5220 ECOS Components PDFEduardo Alves80% (5)

- Ecos System Description GMK 4075: Error CodesDocument31 pagesEcos System Description GMK 4075: Error CodesMohamed RashedNo ratings yet

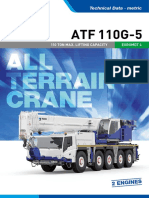

- ATF110G-5 EM4 1 Specifications 022015Document52 pagesATF110G-5 EM4 1 Specifications 022015Mulatua Sirait100% (1)

- TV Sharp 70GS66E Chassis Da-100Document46 pagesTV Sharp 70GS66E Chassis Da-100habamarioNo ratings yet

- 72gf66e PDFDocument56 pages72gf66e PDFAutogrederNo ratings yet

- Ss CTC AmetekDocument8 pagesSs CTC AmetekRamses CanoNo ratings yet

- TE500231 UkDocument52 pagesTE500231 UkJo ArpNo ratings yet

- 3 172 570 EN 20080417 Vol 2Document130 pages3 172 570 EN 20080417 Vol 2email4mobileNo ratings yet

- Bernoulli NumbersDocument5 pagesBernoulli Numbersemail4mobileNo ratings yet

- Deriving Relativistic Momentum and EnergyDocument15 pagesDeriving Relativistic Momentum and Energyemail4mobileNo ratings yet

- هندسة البرمجياتDocument27 pagesهندسة البرمجياتal_badwiNo ratings yet

- Kapitel 1 - Einleitung - EngDocument12 pagesKapitel 1 - Einleitung - Engemail4mobileNo ratings yet

- Recruiters Guide EngDocument15 pagesRecruiters Guide EngAndrea Baron SNo ratings yet

- FFmpeg Compilation in Windows 10Document4 pagesFFmpeg Compilation in Windows 10Columbus CountyNo ratings yet

- Unit 7Document7 pagesUnit 7Thao PhanNo ratings yet

- Negative Feedback - Operational AmplifiersDocument3 pagesNegative Feedback - Operational AmplifiersShailaja UdtewarNo ratings yet

- Applicationpedia - Snipping Tools To Take A Screenshot On WindowsDocument9 pagesApplicationpedia - Snipping Tools To Take A Screenshot On WindowsOecil KritingzNo ratings yet

- Mil HDBK 1390 - LoraDocument31 pagesMil HDBK 1390 - Lorakaiser777No ratings yet

- IO-Link Interface DescriptionDocument22 pagesIO-Link Interface DescriptionJoão Vitor TeixeiraNo ratings yet

- AURIX™ TC39xXX/TC39xXP: Product BriefDocument2 pagesAURIX™ TC39xXX/TC39xXP: Product BriefmikipejaNo ratings yet

- User Manual: Integrated Stall Rental E-Government Management System (ISRMS)Document20 pagesUser Manual: Integrated Stall Rental E-Government Management System (ISRMS)Celesamae Tangub VicenteNo ratings yet

- Semiconductor Main MemoryDocument15 pagesSemiconductor Main MemoryBereket TarikuNo ratings yet

- Config Cisco 881 Isla PartidaDocument4 pagesConfig Cisco 881 Isla PartidaJohan Frederick FoitzickNo ratings yet

- ResumeDocument4 pagesResumeSandeep LakkumdasNo ratings yet

- Akash Updated ResumeDocument3 pagesAkash Updated ResumeAkash PatilNo ratings yet

- Computer Chapter 13Document45 pagesComputer Chapter 13Md. Sakib HossainNo ratings yet

- Galgotias University Mail - FWD: Reg. B.Tech CSE 3rd Year Project MTE Schedule, Reviewer List and GuidelinesDocument2 pagesGalgotias University Mail - FWD: Reg. B.Tech CSE 3rd Year Project MTE Schedule, Reviewer List and GuidelinesSasuke UchiaNo ratings yet

- CEH v10 Exam ADocument27 pagesCEH v10 Exam ABryan Wat KimsNo ratings yet

- Lesson 17-Optimization Problems (Maxima and Minima Problems)Document18 pagesLesson 17-Optimization Problems (Maxima and Minima Problems)Jhonnel CapuleNo ratings yet

- Solution Manual For C How To Program 7 e 7th Edition Paul Deitel Harvey DeitelDocument24 pagesSolution Manual For C How To Program 7 e 7th Edition Paul Deitel Harvey DeitelMrMatthewChavezarcb100% (36)

- Sumter CountyDocument10 pagesSumter CountyThomas MatesNo ratings yet

- SO Snippet ENASEDocument10 pagesSO Snippet ENASEamanswaraj007No ratings yet

- SST 1700bDocument34 pagesSST 1700bDabi YannNo ratings yet

- Meghan Ficarelli ResumeDocument1 pageMeghan Ficarelli ResumemegficNo ratings yet

- Thomson THG540Document36 pagesThomson THG540Tibi SloviNo ratings yet

- Chapter 3Document9 pagesChapter 3Iris SaraNo ratings yet