Professional Documents

Culture Documents

35

Uploaded by

phankhoa83Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

35

Uploaded by

phankhoa83Copyright:

Available Formats

Thread and Connector Identification

Page 340 Q U A L I T Y H O S E A N D F I T T I N G S

How to Use this Section

This section is intended as an aid to identifying the most popular threads on hydraulic hose couplings and adaptors,

and hydraulic equipment.

BSP, Metric, American and Japanese thread sizes can be very similar. It is important to measure and match every

criteria of thread diameter, thread pitch, seating or sealing type (including angle of seats if present) to accurately

determine thread type.

Procedure

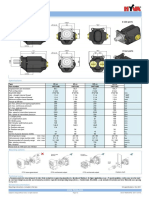

Step 1. Investigation

Check for any markings on fitting or equipment which may be a clue to thread type. Country of origin may provide a clue.

Europe Check DIN/BSP UK/Australia Check BSP

America Check NPT/JIC/UNO/ORFS Japan Check JIS

All RYCO parts have a unique part number stamped on to aid identification.

Step 2. Visual Inspection

Depending on whether the male or female thread or both are available, different features will aid identification.

Are threads parallel or tapered?

Is there an O Ring or a washer seal?

If cone seats are present are they concave or convex?

Type and position on fittings.

Step 3. Measure Threads

With a calliper, measure the thread diameter. OD of male threads

ID of female threads

Using a thread gauge, determine the number of threads per inch.

If thread gauge is not available, measure pitch from crest to crest of adjacent threads, or count the

number of threads in 1/4" and multiply by four for threads per inch.

Chart at bottom of page may assist.

Step 4. Seat Angle Measurement

Using a seat gauge, determine the angle of the seat.

Some fittings have dual seats (eg. JIC 37 & SAE 45) and some have radiused cone.

Step 5. Conclusion

Match the measurements taken against those in the tables herein that appear to be similar to the coupling under consideration.

A final check can be achieved by mating with an actual coupling of the same thread.

TPI (Threads

Per Inch)

28 27 24 20 19 18 16 14 12 11.5 11 8 16.9 12.7

PITCH IN mm 0,91 0,94 1,06 1,27 1,34 1,4 1,59 1,81 2,12 2,21 2,31 3,18 1,5 2,0

ID

THREAD

GAUGE

SEAT

GAUGE

OD

RHC0206AUS Rel. Dec 02

Thread and Connector Identification

Page 341 Q U A L I T Y H O S E A N D F I T T I N G S

F

i

l

t

e

r

s

I

n

t

r

o

H

o

s

e

C

o

u

p

l

i

n

g

s

A

d

a

p

t

o

r

s

A

c

c

e

s

s

o

r

i

e

s

T

e

c

h

n

i

c

a

l

inch - TPI mm inch mm inch mm inch mm inch

-02 1/8 - 28 9,5 0.37 9,6 0.38 8,4 0.33 8,6 0.34

-04 1/4 - 19 12,8 0.50 13,0 0.51 11,2 0.44 11,9 0.47

-06 3/8 - 19 16,3 0.64 16,5 0.65 14,7 0.59 15,2 0.60

-08 1/2 - 14 20,4 0.80 20,8 0.82 18,3 0.72 19,1 0.75

-10 5/8 - 14 22,5 0.89 22,8 0.90 20,6 0.81 20,8 0.82

-12 3/4 - 14 25,9 1.02 26,3 1.04 23,9 0.94 24,6 0.97

-16 1 - 11 32,6 1.28 33,1 1.30 29,7 1.17 30,7 1.21

-20 1.1/4 - 11 41,1 1.62 41,8 1.64 38,6 1.52 39,4 1.55

-24 1.1/2 - 11 47,0 1.85 47,7 1.88 44,5 1.75 45,5 1.79

-32 2 - 11 58,6 2.31 59,5 2.34 56,4 2.22 57,4 2.26

-40 2.1/2 - 11 74,1 2.92 75,1 2.95 71,9 2.83 72,6 2.86

-48 3 - 11 86,6 3.41 87,9 3.46 84,6 3.33 85,4 3.36

BSPT & BSPP THREADS

BSP is BRITISH STANDARD PIPE Also known as Whitworth 55 Thread Form

BSPT is BRITISH STANDARD PIPE TAPER Thread form per AS 1722.1, BS 21, ISO 7

BSPP is BRITISH STANDARD PIPE PARALLEL Thread form per AS 1722.2, ISO 228

BSPT male threads seal against threads of fixed BSPT female.

Contact is made on the flanks of the threads.

Use of a thread sealant is recommended for BSPT male to

BSPT female connections.

Measure the BSPT male thread OD and female thread ID at

the first full thread near the end of the fitting.

BSPT male and BSPP male with conical 30 seat (60 included

angle) seal against matching conical 30 seat

of BSPP female swivel.

BSPP O Ring male connector has straight threads and O Ring

with metal Retaining Ring. It seals against flat external surface

of BSPP female port.

BSPP male, with chamfer to locate Bonded Seal also seals

against flat external surface of BSPP female port.

Surface irregularities require a Spot Face to ensure effective

sealing. Elbows and tees have Lock Nut to allow orientation of

fitting to required direction.

BSPP male and BSPP female flat face swivel require a suitable

soft washer between faces to seal.

For low working pressure.

BSPT & BSPP Threads Dimensions

Thread size refers to the

nominal bore of the pipe.

Subtract approx. 1/4" (6mm)

from thread diameter

measurement for nominal

pipe size.

Pitch is Threads Per Inch (TPI).

"Gas", "R" & "G" also refer

to BSP. "Male Iron (Pipe)"

may be BSP or NPT.

BSPT & BSPP DASH BSPT MALE BSPP MALE BSPT FEMALE BSPP FEMALE

SIZE & PITCH SIZE THREAD OD THREAD OD THREAD ID THREAD ID

RHC0206AUS Rel. Dec 02

Thread and Connector Identification

Page 342 Q U A L I T Y H O S E A N D F I T T I N G S

NPT & NPS THREADS

NPT is NATIONAL PIPE TAPER (AMERICAN) Thread form per ANSI/ASME B1.2.01

NPS is NATIONAL PIPE STRAIGHT (PARALLEL) Thread form per ANSI/ASME B1.2.01

NPTF is NATIONAL PIPE TAPER FOR FUEL Thread form per SAE J476

NPSM is NATIONAL PIPE STRAIGHT MECHANICAL Thread form per ANSI/ASME B1.2.01

National Pipe threads are similar in function to BSP threads but are not generally interchangeable.

NPTF threads (also known as Dryseal) are an improvement to NPT. Controlled truncation of threads

mean the metal to metal thread seal is at root and crest of threads, in addition to flanks of threads.

Use of thread sealant is recommended for NPT male and NPT female connection.

Thread size refers to the nominal bore of the pipe.

Subtract approx. 1/4"(6mm) from thread measurement for nominal pipe size.

Pitch is Threads Per Inch (TPI).

NPT THREAD DASH MALE THREAD FEMALE

SIZE & PITCH SIZE MINOR OD THREAD ID

inch - TPI mm inch mm inch

-02 1/8 - 27 9,9 0.39 8,4 0.33

-04 1/4 - 18 13,2 0.52 11,2 0.44

-06 3/8 - 18 16,6 0.65 14,7 0.58

-08 1/2 - 14 20,6 0.81 17,8 0.70

-12 3/4 - 14 26,0 1.02 23,4 0.92

-16 1 - 11.1/2 32,5 1.28 29,5 1.16

-20 1.1/4 - 11.1/2 41,2 1.62 38,1 1.50

-24 1.1/2 - 11.1/2 47,3 1.86 43,9 1.73

-32 2 - 11.1/2 59,3 2.33 56,4 2.22

-40 2.1/2 - 8 71,5 2.82 69,1 2.72

-48 3 - 8 87,3 3.44 84,8 3.34

NPS THREAD DASH FEMALE

SIZE SIZE THREAD ID

inch - TPI mm inch

1/8 - 27 8,6 0.34

1/4 - 18 11,9 0.47

3/8 - 18 15,0 0.59

1/2 - 14 19,1 0.75

3/4 - 14 24,6 0.97

1 - 11.1/2 30,5 1.20

1.1/4 - 11.1/2 39,4 1.55

1.1/2 - 11.1/2 45,5 1.79

2 - 11.1/2 57,4 2.26

2.1/2 - 8 68,8 2.71

3 - 8 84,6 3.33

-02

-04

-06

-08

-12

-16

-20

-24

-32

-40

-48

NPT Threads NPS Threads

Measure NPT male thread OD and NPT female thread ID at

first full thread near end of fitting.

Thread and Connector Identification

Page 343 Q U A L I T Y H O S E A N D F I T T I N G S

F

i

l

t

e

r

s

I

n

t

r

o

H

o

s

e

C

o

u

p

l

i

n

g

s

A

d

a

p

t

o

r

s

A

c

c

e

s

s

o

r

i

e

s

T

e

c

h

n

i

c

a

l

JIC 37 FLARE & UN O RING (O RING BOSS) THREADS

JIC is JOINT INDUSTRIES COUNCIL SAE J514

UN is UNIFIED NATIONAL SAE J192

JIC & UN O Ring (O Ring Boss) thread forms are the same (ASME B1.1). Method of

sealing differs.

JIC male has 37 flare which seals against 37 seat in female.

UN O Ring (O Ring Boss) seals with O Ring compressed

between hex boss of UN male and 12/15 tapered bore of

UN (O Ring Boss) female port. For elbows and tees, Backup

Washer and Lock Nut allow orientation of fitting to

required direction.

JIC & UN O Ring Threads

Thread size is actual measurement of male

thread and pitch is Threads Per Inch (TPI).

MALE THREAD DASH MALE FEMALE TUBE

OD & PITCH SIZE THREAD OD THREAD ID SIZE

inch - TPI mm inch mm inch inch

-05 5/16 - 24 UNF 7,9 0.31 6,9 0.27 1/8

-06 3/8 - 24 UNF 9,5 0.38 8,5 0.33 3/16

-07 7/16 - 20 UNF 11,1 0.44 9,9 0.39 1/4

-08 1/2 - 20 UNF 12,7 0.50 11,4 0.45 5/16

-09 9/16 - 18 UNF 14,3 0.56 13,0 0.51 3/8

-12 3/4 - 16 UNF 19,1 0.75 17,5 0.69 1/2

-14 7/8 - 14 UNF 22,2 0.88 20,3 0.80 5/8

-17 1.1/16 - 12 UN 27,0 1.06 24,9 0.98 3/4

-19 1.3/16 - 12 UN 30,2 1.19 28,2 1.11 7/8

-21 1.5/16 - 12 UN 33,3 1.31 31,2 1.23 1

-26 1.5/8 - 12 UN 41,3 1.63 39,1 1.54 1.1/4

-30 1.7/8 - 12 UN 47,6 1.88 45,5 1.79 1.1/2

-40 2.1/2 - 12 UN 63,5 2.50 61,5 2.42 2

JIC male can also be used with RYCO S134 J-Lok Female Nut

and Flareless Olive on imperial OD tubing.

JIC male can also seal against 37 flared tubing with JIC nut

and sleeve.

Thread and Connector Identification

Page 344 Q U A L I T Y H O S E A N D F I T T I N G S

4. Komatsu Style Flange Fitting JIS B 8363

The Komatsu style Flange fitting is nearly identical to and fully

interchangeable with the SAE Code 61 flange fitting*.

In all sizes the O Ring dimensions are different.

When replacing a Komatsu style flange with an SAE style

flange, an SAE style O Ring must always be used.

*5/8 is not in the SAE Standards.

JIS is JAPANESE INDUSTRIAL STANDARD

There are four popular coupling styles in Japan.

Thread form per JIS B 0207

Refer to BSPT section for dimensions of threads.

3. Komatsu 30 flare (Female Internal Cone Seat).

Threads commonly used on Komatsu equipment 30 cone

have metric thread form.

JIS THREADS

40,5 -4215 M42 x 1,5

34,5 -3615 M36 x 1,5

31,5 -3315 M33 x 1,5

28,5 -3015 M30 x 1,5

22,5 -2415 M24 x 1,5

20,5 -2215 M22 x 1,5

16,5 -1815 M18 x 1,5

12,5 -1415 M14 x 1,5

mm mm

MALE THREAD DASH FEMALE

OD & PITCH SIZE THREAD ID

2. JIS 30 Flare (Female Internal Cone Seat).

This connection uses a 60 concave (inverted) seat and

British Standard Pipe Parallel threads. They are not

interchangeable with BSPP conical seat couplings,

because the cone seats are opposite.

1. JIS Tapered Pipe Thread.

The Japanese tapered pipe thread connector is identical

to and interchangeable with the BSPT (tapered)

connector. The Japanese male thread does not have a

30 Flare, and will not mate with the BSPP female swivel

with conical seat.

The seal on the Japanese tapered pipe thread connector

is made on the threads. Use of a thread sealant is

recommended.

Thread form per JIS B 0203 (identical to BSPT)

Thread form per JIS B 0202 (identical to BSPP)

Refer to BSPP section for dimensions of threads.

METRIC ISO

Also known as METRIC FRENCH GAZ 24

These seal on a 24 cone seat located

internally on the male connector using

straight fine metric threads.

The French GAZ series uses fractional

number metric OD tubing, as shown in

the table.

(There is another French metric series, called

Millimetrique series, that uses whole number

metric OD tubing, and is not

shown here.)

The male will mate with a straight thread

female swivel with spherical nose seat.

The same male also mates with flareless

tube, Tube Nut and Compression Olive

(Cutting Ring). Tightening of the female

nut compresses the olive causing it cut

into the tube, thereby forming a seal

between the tube, olive and 24 male cone.

MALE THREAD DASH MALE FEMALE TUBE

OD & PITCH SIZE THREAD OD THREAD ID SIZE

inch - TPI mm inch mm

M20 x 1,5 18,5 0.72 13,25

M24 x 1,5 22,5 0.88 16,75

M30 x 1,5 28,5 1.12 21,25

M36 x 1,5 34,5 1.35 26,75

M45 x 1,5 43,5 1.71 33,50

M52 x 1,5 50,5 1.98 42,25

mm inch

20,0 0.78

24,0 0.94

30,0 1.18

36,0 1.41

45,0 1.77

52,0 2.04

-20

-24

-30

-36

-45

-52

Thread and Connector Identification

Page 345 Q U A L I T Y H O S E A N D F I T T I N G S

F

i

l

t

e

r

s

I

n

t

r

o

H

o

s

e

C

o

u

p

l

i

n

g

s

A

d

a

p

t

o

r

s

A

c

c

e

s

s

o

r

i

e

s

T

e

c

h

n

i

c

a

l

METRIC DIN THREADS

DIN is DEUTSCHE INDUSTRIE NORMEN Thread form per DIN 3853

(GERMAN INDUSTRIAL STANDARD) 24 Cone Seat per DIN 3861

O Ring Seal per DIN 3865

Bonded Seal and Port per DIN 3852-1

DKL is DICHT KEGEL LEICHT (Metric Light Series 24 Cone)

DKS is DICHT KEGEL SCHWER (Metric Heavy Series 24 Cone)

DKOL is DICHT KEGEL O RING LEICHT (Metric Light O Ring Series 24 Cone)

DKOS is DICHT KEGEL O RING SCHWER (Metric Heavy O Ring Series 24 Cone)

DKM is DICHT KEGEL METRIC (Metric 60 Cone)

This DIN connection comes in a Light Series (DKL/DKOL) and

a Heavy Series (DKS/DKOS). Some thread sizes in each series

are the same but the Tube OD of the Heavy Series is smaller

and has a thicker tube wall. Because the tube and sealing

cone are different sizes, Light and Heavy Series are NOT

interchangeable.

The DIN male 24 internal cone seat will seal with flareless

female swivel fittings. These female fittings use either a

spherical nose (DKL/DKS) or an O Ring seal (DKOL/DKOS)

located on their outward facing 24 cone. Female DKL sizes

up to and including M26 have a universal 24/60 cone and

can be used in place of female DKM fittings with 60 cone.

The same male also mates with the DIN system Metric Tube,

Tube Nut and Compression Olive (Cutting Ring).

Tightening of the female nut compresses the olive causing it

cut into the tube, thereby forming a seal between the tube,

olive and 24 male cone.

The same male used with a metal Bonded Seal will mate

with a DIN 3852-1 metric threaded port with spotface.

DKM 60 CONE SEAT

The DIN male 60 internal cone seat will mate with

DKL/DKM female universal 24/60 cone fittings up to and

including size M26 and DKM female 60 cone fittings from

size M30 up.

*These DKL Light Series Female Connections can be used in place of DKM Female.

Note: in above tables, pitch is included in DASH SIZE.

For HOSE COUPLINGS and most ADAPTORS, pitch is not included in the DASH SIZE.

mm

10,5

12,5

14,5

16,5

18,5

20,5

22,5

24,5

28,0

34,0

40,0

43,0

50,0

-1215*

-1415*

-1615*

-1815*

-2215*

-2615*

-3020

-3620

-4520

-5220

mm

6

8

10

12

15

18

22

28

35

42

mm

7,5

9,5

11,5

14,0

17,0

20,0

24,0

30,0

37,5

44,5

-1415

-1615

-1815

-2015

-2215

-2415

-3020

-3620

-4220

-5220

mm

6

8

10

12

14

16

20

25

30

38

mm

7,5

9,5

12,0

14,0

16,0

18,0

22,5

27,5

32,5

40,5

mm

8,2

10,3

12,3

13,8

15,8

19,8

24,8

29,9

37,9

mm

M12 x 1,5

M14 x 1,5

M16 x 1,5

M18 x 1,5

M20 x 1,5

M22 x 1,5

M24 x 1,5

M26 x 1,5

M30 x 2,0

M36 x 2,0

M42 x 2,0

M45 x 2,0

M52 x 2,0

FEMALE LIGHT SERIES - DKL/DKOL HEAVY SERIES - DKS/DKOS

MALE THREAD THREAD

OD & PITCH ID DASH SIZE TUBE OD D1 DIA DASH SIZE TUBE OD D1 DIA D2 DIA

Thread and Connector Identification

Page 346 Q U A L I T Y H O S E A N D F I T T I N G S

MALE THREAD DASH MALE FEMALE TUBE

OD & PITCH SIZE THREAD OD THREAD ID SIZE

ORFS THREADS SAE J1453

ORFS is O RING FACE SEAL

ORFS system consists of ORFS Male with

O Ring in Face, and seals against

Flat Seated ORFS Female Swivel Nut fitting.

The Swivel Nut can be slipped back to

help installation in tight situations.

The prominent position of the O Ring

on the Male fitting makes it easy to

inspect the condition of the O Ring.

inch - TPI mm inch inch

9/16 - 18UNF 12,9 0.51 1/4

11/16 - 16UN 16,0 0.63 3/8

13/16 - 16UN 19,1 0.75 1/2

1 - 14UNS 23,6 0.93 5/8

1.3/16 - 12UN 28,2 1.11 3/4

1.7/16 - 12UN 34,3 1.35 1

1.11/16 - 12UN 40,6 1.60 1.1/4

2 - 12UN 48,8 1.92

mm inch

14,3 0.56

17,3 0.68

20,6 0.81

25,4 1.00

30,0 1.18

36,3 1.43

42,7 1.68

51,8 2.00 1.1/2

-09

-11

-13

-16

-19

-23

-27

-32

mm

6

10

13

16

20

25

32

40

50

INCH

1/4

3/8

1/2

5/8

3/4

1

1.1/4

1.1/2

2

DASH

-06

-10

-13

-16

-20

-25

-32

-40

-50

mm

15

20

24

26

29

39

46

55

64

inch

0.59

0.79

0.94

1.02

1.14

1.53

1.81

2.16

2.52

mm

5,1

5,1

5,1

5,1

5,1

7,1

7,1

7,1

7,1

inch

0.2

0.2

0.2

0.2

0.2

0.28

0.28

0.28

0.28

mm

8

13

17

19

22

29

36

45

54

inch

0.31

0.51

0.67

0.75

0.87

1.14

1.42

1.77

2.13

mm

-

-

-

-

9

13

13

13

13

inch

0.35

0.51

0.51

0.51

0.51

mm

-

-

-

-

22

29

36

45

54

inch

0.87

1.14

1.42

1.77

2.13

NOMINAL NOM. MALE OD RYCOLOK STAPLE SIZE RYCO SUPERLOK STAPLE SIZE

SIZE & FEMALE ID G G S S G G S S

RYCOLOK & RYCO SUPERLOK SAE J1467

RYCOLOK are also called CLIP FASTENER & STAPLE

The RYCOLOK male connector uses an O Ring and backup

washer, and seals on the smooth bore of the female.

The connection is held together by the staple.

The male staple groove (G) aligns with the drilled holes of the

female allowing the staple to be inserted. RYCOLOK and RYCO

SUPERLOK use different width staples and are therefore NOT

interchangeable.

Thread and Connector Identification

Page 347 Q U A L I T Y H O S E A N D F I T T I N G S

F

i

l

t

e

r

s

I

n

t

r

o

H

o

s

e

C

o

u

p

l

i

n

g

s

A

d

a

p

t

o

r

s

A

c

c

e

s

s

o

r

i

e

s

T

e

c

h

n

i

c

a

l

SAE THREADS

SAE is SOCIETY OF AUTOMOTIVE ENGINEERS

SAE 45 FLARE SAE J512

SAE male has 45 flare which seals against 45 seat in female.

Male can also seal against 45 flared tubing with nut and sleeve.

7/16 - 20, 1/2 - 20, 3/4 - 16 & 7/8 - 14 are the same thread form as

JIC 37 flare. Some fittings in these sizes have both JIC 37 & SAE 45 seats.

These fittings are commonly used in refrigeration, automotive applications and low pressure applications.

SAE 45 INVERTED FLARE SAE J512

SAE PILOT O RING SEALS

Pilot Male Swivel

Pilot Female Swivel

MALE THREAD DASH MALE FEMALE TUBE

OD & PITCH SIZE THREAD OD THREAD ID SIZE

inch - TPI mm inch mm inch inch

-05 5/16 - 24 7,9 0.31 6,8 0.27 1/8

-06 3/8 - 24 9,5 0.38 8,4 0.33 3/16

-07 7/16 - 20 11,1 0.44 9,9 0.39 1/4

-08 1/2 - 20 12,7 0.50 11,4 0.44 5/16

-10 5/8 - 18 15,9 0.63 14,2 0.56 3/8

-12 3/4 - 16 19,1 0.75 17,5 0.69 1/2

-14 7/8 - 14 22,2 0.88 20,6 0.81 5/8

-17 1.1/16 - 14 27,0 1.06 24,9 0.98 3/4

MALE THREAD DASH MALE FEMALE TUBE

OD & PITCH SIZE THREAD OD THREAD ID SIZE

MALE THREAD DASH MALE FEMALE TUBE

OD & PITCH SIZE THREAD OD THREAD ID SIZE

MALE THREAD DASH MALE FEMALE TUBE

OD & PITCH SIZE THREAD OD THREAD ID SIZE

7/16 0.63 16,0 0.69 17,5 -11 11/16 - 18

3/8 0.56 14,2 0.63 15,9 -10 5/8 - 18

5/16 0.45 11,4 0.50 12,7 -08 1/2 - 20

1/4 0.39 9,9 0.44 11,1 -07 7/16 - 24

inch inch mm inch mm inch - TPI

- 10 0.81 20,6 0.88 22,2 -14 7/8 - 18

- 8 0.70 17,8 0.75 19,0 -12 3/4 - 18

- 6 0.56 14,2 0.63 15,9 -10 5/8 - 18

Dash inch mm inch mm inch - TPI

- 10 0.81 20,6 0.88 22,2 -14 7/8 - 14

- 8 0.69 17,5 0.75 19,0 -12 3/4 - 16

- 6 0.56 14,2 0.63 15,9 -10 5/8 - 18

Dash inch mm inch mm inch - TPI

RHC0206AUS Rel. Dec 02

Thread and Connector Identification

Page 348 Q U A L I T Y H O S E A N D F I T T I N G S

SAE O RING FLANGE CODE 61 & CODE 62 SAE J518

RYCO Code 62C fittings conform to the flange OD and bolt hole patterns of SAE Code 62 but require special flange

clamp halves.

The RYCO Code 62C flange heads are thicker than SAE Code 62 and measure T = 14,2mm (0.559) in all sizes.

RYCO Code 62C flanges have similar dimensions to the Caterpillar XT-5 and XT-6 range of flanges.

Cat Caterpillar, XT-5 , XT-6 Caterpillar.

*5/8 is used by Komatsu.

CODE 62

NOM.

FLANGE DASH

SIZE SIZE B T F G PORT THREAD & BOLT LENGTH

inch

1/2 -08

mm

30,2

mm mm

6,73 17,5

mm

38,1

UNC

5/16 - 18

METRIC

M8 x 1,25

*5/8 -10 34,0 6,73 19,8 42,9 5/16 - 18 M8 x 1,25

3/4 -12 38,1 6,73 22,2 47,6 3/8 - 16 M10 x 1,5

1 -16 44,5 8,00 26,2 52,4 3/8 - 16 M10 x 1,5

1.1/4 -20 50,8 8,00 30,2 58,7 7/16 - 14 M10 x 1,5

1.1/2 -24 60,3 8,00 35,7 69,8 1/2 - 13 M12 x 1,75

2 -32 71,4 9,53 42,9 77,8 1/2 - 13 M12 x 1,75

2.1/2 -40 84,1 9,53 50,8 88,9 1/2 - 13 M12 x 1,75

3 -48 101,6 9,53 61,9

inch

0.69

0.78

0.88

1.03

1.19

1.41

1.69

2.00

2.44 106,4 5/8 - 11 M16 x 2,0

1/2 -08 31,7 7,75 18,2 40,5 5/16 - 18 M8 x 1,25

3/4 -12 41,3 8,76 23,8 50,8 3/8 - 16 M10 x 1,5

1 -16 47,6 9,53 27,8 57,2 7/16 - 14 M12 x 1,75

1.1/4 -20 54,0 10,29 31,8 66,7 1/2 - 13 M14 x 2,0

1.1/2 -24 63,5 12,57 36,5 79,4 5/8 - 11 M16 x 2,0

2 -32 79,4

1.25

1.63

1.88

2.12

2.50

3.13 12,57

0.305

0.345

0.375

0.405

0.495

0.495 44,5

0.72

0.94

1.09

1.25

1.44

1.75 96,8

1.59

2.00

2.25

2.63

3.13

3.81 3/4 - 10 M20 x 2,5

inch

1.19

1.34

1.50

1.75

2.00

2.38

2.81

2.31

4.00

inch

1.50

1.69

1.88

2.06

2.31

2.75

3.06

3.50

4.19

3/4 -12 41,3 14,20 23,8 50,8 3/8 - 16 M10 x 1,5

1 -16 47,6 14,20 27,8 57,2 7/16 - 14 M12 x 1,75

1.1/4 -20 54,0 14,20 31,8 66,7 1/2 - 13 M14 x 2,0

1.1/2 -24 63,5

1.63

1.88

2.12

2.50 14,20

0.559

0.559

0.559

0.559 36,5

0.94

1.09

1.25

1.44 79,4

2.00

2.25

2.63

3.13 5/8 - 11 M16 x 2,0

inch

0.265

0.265

0.265

0.315

0.315

0.315

0.375

0.375

0.375

inch

1.1/4

1.1/4

1.1/4

1.1/2

1.1/2

1.1/2

1.3/4

1.3/4

1.1/4

1.1/2

1.3/4

1.3/4

2.1/4

2.3/4

1.3/4

1.3/4

2

2.1/2

mm

35

35

35

40

45

45

45

45

35

40

45

45

60

70

45

45

50

60

PORT BOLT LENGTH PORT BOLT

CODE 61

RYCO CODE 62C

The male connector has a flange head with an O Ring

groove on the face. The female can be a flange block or

port with smooth face to accept the O Ring, and four

threaded bolt holes in a rectangular pattern.

The connection is held together using either a split or

solid flange clamp, fitted over the male flange head and

drawn up to the female port using the four bolts. This

compresses the O Ring forming a seal between the male

flange and the flat female port face.

SAE J518, DIN 20066, ISO/DIS 6162 & JIS B 8363 are all

interchangeable, except for bolt sizes.

Thread and Connector Identification

Page 349 Q U A L I T Y H O S E A N D F I T T I N G S

F

i

l

t

e

r

s

I

n

t

r

o

H

o

s

e

C

o

u

p

l

i

n

g

s

A

d

a

p

t

o

r

s

A

c

c

e

s

s

o

r

i

e

s

T

e

c

h

n

i

c

a

l

T T

NOM. EXCEPT BLIND

FLANGE DASH BLIND FLANGES

SIZE SIZE L W F G A FLANGES S967/S968

NOM.

FLANGE DASH SOCKET HEAD SOCKET HEAD

SIZE SIZE CAP SCREW CAP SCREW

SAE FLANGE BLOCKS SAE J518

inch mm mm mm mm mm mm inch mm

CODE 61

CODE 61

1/2 -08 56 48 17,5 38,1 13 16 16

5/16 - 18 x 1.1/4

3/4 -12 65 50 22,2 47,6 19 18 16

3/8 - 16 x 1.1/2

1 -16 70 60 26,2 52,4 25 18 19

3/8 - 16 x 1.1/2

1.1/4 -20 79 68 30,2 58,7 32 21 18

7/16 - 14 x 1.3/4

1.1/2 -24 93 78 35,7 69,8 38 25 20

1/2 - 13 x 1.3/4

2 -32 102 90 42,9 77,8 51 25 20

1/2 - 13 x 1.3/4

CODE 62

CODE 62

3/4 -12 71 60 23,8 50,8 19 21 19

3/8 - 16 x 1.1/2

1 -16 81 70 27,8 57,2 25 25 24

7/16 - 14 x 1.3/4

1.1/4 -20 95 78 31,8 66,7 32 27 27

1/2 - 13 x 1.3/4

1.1/2 -24 112 94 36,5 79,4 38 30 30

5/8 - 11 x 2

2 -32

1/2 -08

3/4 -12

1 -16

1.1/4 -20

1.1/2 -24

2 -32

3/4 -12

1 -16

1.1/4 -20

1.1/2 -24

2 -32

134

inch

2.20

2.56

2.76

3.11

3.66

4.02

2.80

3.19

3.74

4.41

5.28 114

inch

1.89

1.97

2.36

2.68

3.07

3.54

2.36

2.76

3.07

3.70

4.49 44,5

inch

0.69

0.88

1.03

1.19

1.41

1.69

0.94

1.09

1.25

1.44

1.75 96,8

inch

1.50

1.88

2.06

2.31

3.06

3.50

2.00

2.25

2.63

3.13

3.81 51

inch

0.51

0.75

0.98

1.26

1.50

2.01

0.75

0.98

1.26

1.50

2.01 37

0.63

0.71

0.71

0.83

0.98

0.98

0.83

0.98

1.06

1.18

1.46 28

inch

0.63

0.63

0.75

0.71

0.79

0.79

0.75

0.94

1.06

1.18

1.10

3/4 - 10 x 2.1/2

M8x1.25 X 30

M10x1.5 X 35

M10x1.5 X 35

M10x1.5 X 40

M12x1.75 X 45

M12x1.75 X 45

M10x1.5 X 40

M12x1.75 X 45

M14x2.0 X 45

M16x2.0 X 50

M20x2.5 X 70

UNC x inch METRIC x mm inch

You might also like

- Thread Connector IdentificationDocument11 pagesThread Connector IdentificationbearNo ratings yet

- Thread and Port GuideDocument44 pagesThread and Port GuidejlrdlgNo ratings yet

- Thread Chart: Horizon Industrial 1190 S.E. Century Dr. Lees Summit, Mo 64063 888-866-2501 816-554-6167 (FAX) 1Document4 pagesThread Chart: Horizon Industrial 1190 S.E. Century Dr. Lees Summit, Mo 64063 888-866-2501 816-554-6167 (FAX) 1jkhgvdj mnhsnjkhgNo ratings yet

- Measuring Threads and Seat AnglesDocument13 pagesMeasuring Threads and Seat AnglesRoberto Vera RamosNo ratings yet

- BS 21 - Pressure Tight Pipe Thread JointsDocument8 pagesBS 21 - Pressure Tight Pipe Thread JointsHARSHANo ratings yet

- Thread IdentificationDocument13 pagesThread IdentificationPhilip RappéNo ratings yet

- Teknopoli: North American ConnectionsDocument39 pagesTeknopoli: North American ConnectionsKishor JadhavNo ratings yet

- Identifying Threads Identifying Threads: How To Use The CaliperDocument6 pagesIdentifying Threads Identifying Threads: How To Use The CaliperkyletgerberNo ratings yet

- Thread&End Connection Id GuideDocument54 pagesThread&End Connection Id GuidePRUDHOMME100% (1)

- ContinentalDocument76 pagesContinentalVIVEK UPADHYAYNo ratings yet

- General information on hose fitting part numbers, thread types and dimensionsDocument6 pagesGeneral information on hose fitting part numbers, thread types and dimensionsFelix RanillaNo ratings yet

- Quality Hose Fittings GuideDocument86 pagesQuality Hose Fittings Guidesharafudheen_sNo ratings yet

- BSP Identification PDFDocument3 pagesBSP Identification PDFrefaeNo ratings yet

- NPT Thread ChartDocument2 pagesNPT Thread Chartprabu_v50% (2)

- Adaptor Connector Types and Sizes Made EasyDocument76 pagesAdaptor Connector Types and Sizes Made EasyjovicasurNo ratings yet

- Hydraulic Fitting Thread Chart - El MejorDocument17 pagesHydraulic Fitting Thread Chart - El MejorJavierNo ratings yet

- AG - Hyfdraulic Fittings Guideline - 2017 05 09Document14 pagesAG - Hyfdraulic Fittings Guideline - 2017 05 09CAT CYLINDERNo ratings yet

- Hydraulic AdapterswebpageDocument48 pagesHydraulic AdapterswebpageBilly ZununNo ratings yet

- BSP vs NPT: A guide to British Standard Pipe and National Pipe ThreadsDocument3 pagesBSP vs NPT: A guide to British Standard Pipe and National Pipe ThreadshadiNo ratings yet

- BSPP & T Thread DimsDocument2 pagesBSPP & T Thread DimsDilip SudevNo ratings yet

- Selecting and Measuring Pipe & Fittings: Thread Type CompatibilityDocument1 pageSelecting and Measuring Pipe & Fittings: Thread Type CompatibilityITLHAPNNo ratings yet

- NPT ThreadDocument3 pagesNPT ThreadaniruddhkrsharmaNo ratings yet

- National Pipe ThreadDocument10 pagesNational Pipe ThreadLodyNo ratings yet

- Tchart PDFDocument3 pagesTchart PDFferdyak1No ratings yet

- Hydraulics (Eaton) - How To Identify Fluid Ports and ConnectorsDocument48 pagesHydraulics (Eaton) - How To Identify Fluid Ports and ConnectorsDoug RoordaNo ratings yet

- Identificación de RoscasDocument7 pagesIdentificación de RoscasEduNo ratings yet

- 37° Tube Fittings: Instrumentation SolutionsDocument9 pages37° Tube Fittings: Instrumentation SolutionsNilesh MistryNo ratings yet

- Graseras AlemitesDocument37 pagesGraseras Alemitesjoroma58No ratings yet

- Precision Hardware: Recision Ndustrial OmponentsDocument25 pagesPrecision Hardware: Recision Ndustrial OmponentsAtinderbir Singh DeoNo ratings yet

- Thread TypeDocument4 pagesThread Typevikram_007No ratings yet

- BSP ThreadsDocument3 pagesBSP ThreadssatphoenixNo ratings yet

- Maryland Metrics: Technical Data ChartDocument10 pagesMaryland Metrics: Technical Data ChartchethanNo ratings yet

- Titan Intl Thread Chart DownloadDocument11 pagesTitan Intl Thread Chart DownloadpatsernyukNo ratings yet

- E2 Coupl Ident ChartDocument1 pageE2 Coupl Ident Chartaerohead34No ratings yet

- NPT &NPTF Thread TappingDocument1 pageNPT &NPTF Thread TappingHamid HojatiNo ratings yet

- Hydraulic Fittings Thread GuideDocument6 pagesHydraulic Fittings Thread Guidecryptocoin lendNo ratings yet

- BSPT Thread Sizes & TypesDocument3 pagesBSPT Thread Sizes & TypesuttampokharkarNo ratings yet

- Aeroquip Thread Identification GuideDocument12 pagesAeroquip Thread Identification GuideRaghavendra DeshpandeNo ratings yet

- Thread ID Course - OficialDocument63 pagesThread ID Course - OficialBruno SalasNo ratings yet

- Mall Pipe ThreadsDocument14 pagesMall Pipe Threadsanac_mathNo ratings yet

- Threads and Sealing MethodsDocument80 pagesThreads and Sealing MethodsabdulmuhaimenNo ratings yet

- Thread Specifications GuideDocument30 pagesThread Specifications GuidesoparlNo ratings yet

- Pressure Ratings Guide for Hydraulic FittingsDocument2 pagesPressure Ratings Guide for Hydraulic FittingsTezalea RobletoNo ratings yet

- ROSCASDocument3 pagesROSCASDilucom EspeciasNo ratings yet

- Engineering Thread DataDocument26 pagesEngineering Thread DataJaveed A. KhanNo ratings yet

- Drill Stem Components GuideDocument28 pagesDrill Stem Components Guidechonubobby100% (1)

- PIPE THREAD DimensionDocument2 pagesPIPE THREAD DimensionAriel AnascoNo ratings yet

- NPT, Nps & - ThreadsDocument3 pagesNPT, Nps & - ThreadsklashincoviskyNo ratings yet

- Pres RateDocument2 pagesPres RatescemanjuNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionFrom EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo ratings yet

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderFrom EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderRating: 5 out of 5 stars5/5 (2)

- Isuzu NHR NKR NPRDocument704 pagesIsuzu NHR NKR NPRJorge Luis Espino Cruz94% (77)

- Freightliner Con Ddec PDFDocument1,898 pagesFreightliner Con Ddec PDFEdj Salas100% (10)

- K3V112DT Instruction Manual OverviewDocument40 pagesK3V112DT Instruction Manual Overviewjuanchis650100% (7)

- Basic Trouble Shooting KomatsuDocument40 pagesBasic Trouble Shooting Komatsuphankhoa83No ratings yet

- HG K3V K5V Series Parts Diagrams Catalog WebDocument26 pagesHG K3V K5V Series Parts Diagrams Catalog Webphankhoa83No ratings yet

- Theory of Asset Pricing - PennacchiDocument582 pagesTheory of Asset Pricing - PennacchiMubin Memon100% (1)

- K3VLTechnical BrochureDocument32 pagesK3VLTechnical BrochureBala Krishnan NataNo ratings yet

- D4ALDocument119 pagesD4ALPablo Campos67% (6)

- 336145573 Daewoo DE12 T TI мануал PDFDocument169 pages336145573 Daewoo DE12 T TI мануал PDFAvaa AmgaaNo ratings yet

- K3V112DT Instruction Manual OverviewDocument40 pagesK3V112DT Instruction Manual Overviewjuanchis650100% (7)

- K3VLTechnical BrochureDocument32 pagesK3VLTechnical BrochureBala Krishnan NataNo ratings yet

- New Generation Volvo Diesel Engine Fundamentals Classroom Training enDocument408 pagesNew Generation Volvo Diesel Engine Fundamentals Classroom Training enmliugong95% (43)

- Tong Quan Veh RMDocument23 pagesTong Quan Veh RMphankhoa83No ratings yet

- ContentsDocument3 pagesContentsphankhoa83No ratings yet

- ForewordsDocument8 pagesForewordsphankhoa83No ratings yet

- Basics 2016Document81 pagesBasics 2016andy131078No ratings yet

- Tool Catalog Ei18e 11020Document370 pagesTool Catalog Ei18e 11020phankhoa83100% (1)

- Danh Sach Bom Chuyen DauDocument1 pageDanh Sach Bom Chuyen Dauphankhoa83No ratings yet

- PV-PU-REC-04-V06 Purchase Order Request (DA)Document1 pagePV-PU-REC-04-V06 Purchase Order Request (DA)phankhoa83No ratings yet

- Technical Information: FAG Deep Groove Ball Bearings With An Integrated SensorDocument6 pagesTechnical Information: FAG Deep Groove Ball Bearings With An Integrated Sensorphankhoa83No ratings yet

- 01OHTELCDocument32 pages01OHTELCjose10001No ratings yet

- Mon CS Ngon Ngu TA PDFDocument1 pageMon CS Ngon Ngu TA PDFphankhoa83No ratings yet

- 705 1237 1 PBDocument4 pages705 1237 1 PBphankhoa83No ratings yet

- FAG BearingDocument4 pagesFAG BearingBasem100% (2)

- Theory of Asset Pricing - PennacchiDocument582 pagesTheory of Asset Pricing - PennacchiMubin Memon100% (1)

- Key List SEAS82-83Document12 pagesKey List SEAS82-83phankhoa83No ratings yet

- Writing For The Technical ProfessionsDocument557 pagesWriting For The Technical Professionsnewfut93% (14)

- Unit 2 Bankingkey BookboomingDocument8 pagesUnit 2 Bankingkey BookboomingTrình Thục YênNo ratings yet

- Key Esp Unit 1Document3 pagesKey Esp Unit 1Bò SữaNo ratings yet

- Swagelok Pipe FittingsDocument24 pagesSwagelok Pipe Fittingsgacm98100% (1)

- PowerCoil Inserts Installation InstructionsDocument1 pagePowerCoil Inserts Installation InstructionsAce Industrial SuppliesNo ratings yet

- Topdrive Service ManualDocument236 pagesTopdrive Service ManualScott SmithNo ratings yet

- TST Lattice TowerDocument26 pagesTST Lattice TowerAsheptya KurniawanNo ratings yet

- 12 - Cast Iron Tapping MachinesDocument14 pages12 - Cast Iron Tapping MachinesaurabloodNo ratings yet

- Svmfsvaf Manual 1Document102 pagesSvmfsvaf Manual 1omar farukNo ratings yet

- Standard Knurling SpecificationsDocument3 pagesStandard Knurling SpecificationsCHAITANYANo ratings yet

- Case Loader 721d Repair ManualDocument20 pagesCase Loader 721d Repair Manualvanessa100% (34)

- OneSteel Pipe Fittings - Final - LoRes PDFDocument49 pagesOneSteel Pipe Fittings - Final - LoRes PDFSARSAN NDTNo ratings yet

- Bulletin #D2 - English: DSE9002 (Revised)Document3 pagesBulletin #D2 - English: DSE9002 (Revised)ΑΠΟΣΤΟΛΙΑ ΜΑΤΣΟΥΚΑNo ratings yet

- Differences Between NPT, BSPP and BSPT SealsDocument2 pagesDifferences Between NPT, BSPP and BSPT Sealssujit5584No ratings yet

- HALCO 2020catalogue Hammer+BitDocument33 pagesHALCO 2020catalogue Hammer+BitHodumi JosefNo ratings yet

- Fastener Technical Data & Charts: To Our Customers - .Document27 pagesFastener Technical Data & Charts: To Our Customers - .ludaNo ratings yet

- Aerospace Products BrochureDocument15 pagesAerospace Products BrochurejesszeusNo ratings yet

- 2.05 Bench Fitting To Support 206 BMDocument61 pages2.05 Bench Fitting To Support 206 BMScott TrainorNo ratings yet

- Guide to HSFG bolts for Indian railway bridgesDocument16 pagesGuide to HSFG bolts for Indian railway bridgesUpaliFernando100% (1)

- 145gpcvp02 AcDocument2 pages145gpcvp02 AcAdi PriyantoNo ratings yet

- HeliCoil CatalogueDocument34 pagesHeliCoil CatalogueAnh LeNo ratings yet

- Loctite Catalogue 6023 AamDocument30 pagesLoctite Catalogue 6023 AamAndre FaccinNo ratings yet

- Pipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsDocument16 pagesPipe Fittings: 1/16 To 1 In. Sizes 316 Stainless Steel, Brass, and Carbon Steel NPT, ISO/BSP, and SAE ThreadsMehmet YılmazNo ratings yet

- Design Helical PilesDocument11 pagesDesign Helical PilesCrystal Smith- Crissy GrayNo ratings yet

- KVT Drahtgewindeeinsaetze en 05-2015 Web-CatalogDocument24 pagesKVT Drahtgewindeeinsaetze en 05-2015 Web-CatalogWK SinnNo ratings yet

- Liebherr TL 445-10 Telescopic Handler Service Repair Manual PDFDocument56 pagesLiebherr TL 445-10 Telescopic Handler Service Repair Manual PDFjfjkskemmdm0% (1)

- Product Guide 2009 BDDocument31 pagesProduct Guide 2009 BDAdrian BercanNo ratings yet

- Asme B 18.2.2Document41 pagesAsme B 18.2.2Luis MontoyaNo ratings yet

- List of ISO StandardsDocument30 pagesList of ISO StandardsanikeitNo ratings yet

- Modu Tek CatalogDocument184 pagesModu Tek Catalogiskierdo10No ratings yet

- 15A03401 Machine Drawing PDFDocument2 pages15A03401 Machine Drawing PDFAbhi RamNo ratings yet

- AU Catalogue - Bolts, Nuts, Washers PDFDocument28 pagesAU Catalogue - Bolts, Nuts, Washers PDFEng MBNo ratings yet

- TFP260 05 2017Document4 pagesTFP260 05 2017elraflesNo ratings yet