Professional Documents

Culture Documents

Structural - Engineering Gurit Composite

Uploaded by

ChusnadiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural - Engineering Gurit Composite

Uploaded by

ChusnadiCopyright:

Available Formats

Composite Structural

Engineering

The competitive edge Gurits Structural Engineering Department (formerly SP Technologies

ltd.) was formed out of SP Systems in 1988. To realise the benets of composites, the engineering

design input became a consultancy rather than technical product support. Initially the main

application was for racing yachts, which provided a hot-bed for development. The philosophy was

to apply an aeronautical-style design/analysis to an industry that needs a faster design to build

time. With the recent acquisition of High Modulus, this capability has been further enhanced.

Staffed by more than 60 personnel worldwide, with graduates from a range of disciplines

and nationalities, Gurit can provide local support, often in the native language.

Whilst technical expertise is essential, the strong practical background of Gurits engineering

team means that the engineering design is turned into buildable structures. On-site

engineering support strengthens this background and provides an additional link in the

design process. This, combined with the expertise of the Composite Processing, Prototyping

and Materials Development departments enable a full composite solution, which is far more

likely to deliver the best all-round solution.

Composite

Processing

Materials

Manufacturing

Structural

Design

New Materials

SPRINT

Airstream

Kitting

Preforms

Prototyping

Integrated Solution

Cost effective

High Performance

Realise benets of

technology

Parts

Component

Manufacturing

Optimisation

Geometry & Size

Dening process &

material choice

Process Engineering

Material

Design

Multiaxials

Global Support

The range of projects worked on covers any

large composite structural application and

has included:

Raceboats

Superyachts

Wind turbines

Underwater turbines

Civil Engineering

Architectual features

The systems used in-house include:

ISO 9001 controlled.

AutoCAD

SolidWorks

Patran/Nastran with laminate Modeller

Hypermesh

In excess of 3000 projects covering a wide range of different composite structures have been undertaken spanning

a period of over 30 years. In addition to high prole raceboats such as Americas Cup, Open 60s and Volvo 70s Gurit have been

involved in the complete cross section of marine craft including military power boats, production cruisers, and some of the

worlds most spectacular composite superyachts.

Whilst Gurit is most widely recognised for its marine expertise, under the brand SP-High Modulus, Gurits past engineering

portfolio also includes innovative engineering of structures, some of which had never been tackled in composites before.

Gurit believe that, for the most integrated approach, tasks should

be carried out in-house, however involvement can be tailored to

suit individual project needs. Areas include:

Conceptual design

Laminate design & optimisation

Analysis using in-house tools, SP calculations etc.

FEA

CAD

Prototyping

On-site engineering support

Proof tests

Data acquisition

Classification Society / Certification Authority Liason

Engineering consultancy contracts are generally set up independently of material

sales. However, being part of a composite material manufacturing company means

that Gurits engineering team have always had a culture of understanding composite

processing and providing the link between the design concept and the builder.

From the heritage of consultancy project work, Gurits engineers are passionate about

the projects that they manage.

For each project, a main point of contact is established at Gurit, and that engineer

has a team supporting them from FEA specialists to CAD draughtsmen with senior

engineers providing guidance and overseeing the work.

As computing power has steadily grown, FEA is increasingly used as a

design tool to save weight, improve reliability and to give greater insight into

the behaviour of complex structures. Using this technique Gurit can predict

phenomena ranging from deections and stresses through to buckling and

natural frequency analysis.

Whilst often associated with engineering of advanced racing yachts, FEA

now nds use in the complete cross section of Gurits engineering expertise.

Whether you have a composite bridge, a production power boat, a wind turbine

or something that has never been engineered in composites before, FEA helps

Gurit to develop an optimised solution and avoid structural surprises.

FEA/CAD

Gurit engineers have been at the forefront of composites analysis using Finite Element

Analysis for over 20 years. Gurit have heavily invested in 3-D Cad, and FEA software

culminating in the current use of market leading software Nastran/Patran and Hyper Works.

UK

St Cross Business Park

Newport, Isle of Wight

United Kingdom PO30 5WU

T +44 (0) 1983 828 000

F +44 (0) 1983 828 100

E gurit@gurit.com

9 South Point, Ensign Way,

Hamble, Hampshire

United Kingdom, SO31 4RF

T +44 (0) 23 8045 8446

F +44 (0) 23 8045 7489

E gurit@gurit.com

Canada

175, Rue Pladeau

Magog QC

J1X 5G9 Canada

T +1 819 847 2182

F +1 819 847 2572

E info-na@gurit.com

USA

2843 South County Trail,

Suite A4, East Greenwich,

RI 02818, USA

T +1 401 331 4392

F +1 212 419 9498

E gurit@gurit.com

Australia

Unit 1A, 81 Bassett Street

Mona Vale NSW 2103

Australia

T +61 (0) 2 9979 7248

F +61 (0) 2 9979 6378

E info-au@gurit.com

New Zealand

32 Canaveral Drive, Albany 0630

Private Box 302-191, North

Harbour

Auckland, New Zealand

T +64 (0) 9 415 6262

F +64 (0) 9 415 7262

E gurit@gurit.com

Please go to www.gurit.com for further information

and to download the following:

Product Data Sheets 'How to' Videos

News/Case Studies Composite Guides

Events Schedules Contact Details

Credit: Il Mostro - Sally Collison, Cyrus One - Andr Minkema

You might also like

- Summary:: Steitoff Dyatt Engineering LimitedDocument4 pagesSummary:: Steitoff Dyatt Engineering LimitedShyBokxNo ratings yet

- CV TirthaDocument4 pagesCV TirthaYuuvraj SinghNo ratings yet

- Thesis On Advanced Manufacturing TechnologyDocument5 pagesThesis On Advanced Manufacturing Technologyshannongutierrezcorpuschristi100% (2)

- CATIA For Yacht BrochureDocument4 pagesCATIA For Yacht Brochurepal_malayNo ratings yet

- QuEST Global Engineering Profile NewDocument2 pagesQuEST Global Engineering Profile NewArchitNo ratings yet

- CPP Corporate OverviewDocument57 pagesCPP Corporate OverviewMibzar SantosNo ratings yet

- Road Construction Research PapersDocument6 pagesRoad Construction Research Papersafnhceivhbpbdw100% (1)

- CompanyProfile PDFDocument21 pagesCompanyProfile PDFKasturie PillayNo ratings yet

- Ajay TomarDocument3 pagesAjay TomarAjay TomarNo ratings yet

- STAMOD Engineering ServicesDocument40 pagesSTAMOD Engineering ServicesvikasgodageNo ratings yet

- CV Design Engineer seeking opportunitiesDocument5 pagesCV Design Engineer seeking opportunitiesaditya_pandey_77No ratings yet

- Altair Product Design Composite DesignDocument2 pagesAltair Product Design Composite DesignRoberto LopezNo ratings yet

- The Race For More OilDocument10 pagesThe Race For More Oilk1m1mak1No ratings yet

- Transmisii de TractoareDocument16 pagesTransmisii de TractoareCochintu Radu100% (1)

- Petrochem: Oil & Gas, Petrochemical, and RefiningDocument4 pagesPetrochem: Oil & Gas, Petrochemical, and RefiningGene Citrone Jr.No ratings yet

- Cyient - Oil and Gas IndustryDocument8 pagesCyient - Oil and Gas Industrycyient_analyticsNo ratings yet

- Oil and gas engineering firm provides project management servicesDocument22 pagesOil and gas engineering firm provides project management serviceszhangj5100% (1)

- Program Ics Jam 2012Document28 pagesProgram Ics Jam 2012Rahul SenNo ratings yet

- Thesis Production EngineeringDocument6 pagesThesis Production Engineeringafktgvllsgajfw100% (2)

- CV DimitrisServis GeneralDocument2 pagesCV DimitrisServis GeneralDimitris ServisNo ratings yet

- Proposal For UTeM Falculty of Engineering TechnologyDocument7 pagesProposal For UTeM Falculty of Engineering TechnologyWinsonLimHuiWahNo ratings yet

- Proposal For TVET MalaysiaDocument21 pagesProposal For TVET MalaysiaWinsonLimHuiWah100% (1)

- TOGAF - PresentationDocument102 pagesTOGAF - PresentationLuis YañezNo ratings yet

- Utilization of Petronas PTSDocument25 pagesUtilization of Petronas PTSفضيلة عبدالرحمن100% (1)

- Summer Training Project: Employee AttritionDocument15 pagesSummer Training Project: Employee AttritionAnKit SacHanNo ratings yet

- Wood Group Mustang Magazine Spring 2012Document48 pagesWood Group Mustang Magazine Spring 2012Kyaw Kyaw AungNo ratings yet

- Venkadachalapathy Thangavel: LinkedinDocument4 pagesVenkadachalapathy Thangavel: Linkedinvenkatachalapathy.thNo ratings yet

- Pembangkit Listrik Tenaga SampahDocument8 pagesPembangkit Listrik Tenaga SampahVinas KusdinarNo ratings yet

- Dissertation Topics in Highway EngineeringDocument8 pagesDissertation Topics in Highway EngineeringWriteMyPersuasivePaperKansasCity100% (1)

- Daliform Group Corporate ImageDocument8 pagesDaliform Group Corporate ImageDaliform GroupNo ratings yet

- TECH-2A - Consultant - S Organization - PPG ConsultantsDocument6 pagesTECH-2A - Consultant - S Organization - PPG Consultantsjadan tupuaNo ratings yet

- Analysis and Design of Apartment Building PDFDocument30 pagesAnalysis and Design of Apartment Building PDFpramods_8100% (1)

- GPO Brochure PDFDocument14 pagesGPO Brochure PDFkart87No ratings yet

- Off Shore Drilling NotesDocument15 pagesOff Shore Drilling NotesAamir LokhandwalaNo ratings yet

- Research Paper On Pneumatic Can CrusherDocument5 pagesResearch Paper On Pneumatic Can Crusherniisexgkf100% (1)

- Director Engineering in Detroit MI Resume Shashank KarnikDocument3 pagesDirector Engineering in Detroit MI Resume Shashank Karnikshashankkarnik100% (1)

- Fume Hood Canada Government Design SpecificationsDocument100 pagesFume Hood Canada Government Design Specificationscgoveia3No ratings yet

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Smartplant: Intelligent Engineering With Effi Cient SupportDocument8 pagesSmartplant: Intelligent Engineering With Effi Cient SupportfrancisblessonNo ratings yet

- Insight - IntergraphDocument53 pagesInsight - IntergraphOmar Eladel Mahmoud100% (1)

- Durability SOCDocument2 pagesDurability SOCLTE002No ratings yet

- UtilitiesDocument2 pagesUtilitiesAfif NugrohoNo ratings yet

- Elson ResumeDocument7 pagesElson ResumeRashid Ahmed ShaikhNo ratings yet

- 1600 GB WEB PDFDocument21 pages1600 GB WEB PDFmahantmtechNo ratings yet

- Graduate Oil Gas Chemical 201213Document3 pagesGraduate Oil Gas Chemical 201213rohitzoomNo ratings yet

- Madhusudhan JapanDocument5 pagesMadhusudhan JapanAditya NaikNo ratings yet

- GT Strudl BrochureDocument4 pagesGT Strudl BrochureRomeoSánchezNo ratings yet

- Casting Simulation SolutionsDocument16 pagesCasting Simulation SolutionsAncutzelu23No ratings yet

- Associate Project Manager: Be Production, Mba (Finance)Document4 pagesAssociate Project Manager: Be Production, Mba (Finance)AmitNo ratings yet

- 110919clough PresentationDocument52 pages110919clough PresentationPachern YangyuenNo ratings yet

- GuritDocument16 pagesGuritKamlesh DalavadiNo ratings yet

- Plaster of Paris (Brief Detailed About Project Report)Document2 pagesPlaster of Paris (Brief Detailed About Project Report)bikash_88No ratings yet

- Gantrail Corporate Brochure-3Document7 pagesGantrail Corporate Brochure-3rian-jiee-tauwwa-8573No ratings yet

- CHRT Corp BackgrounderDocument1 pageCHRT Corp BackgrounderBalamuruganNo ratings yet

- JotamTechnologies ProfileDocument12 pagesJotamTechnologies ProfileProjecte2No ratings yet

- Pavement Testing EquipmentDocument134 pagesPavement Testing EquipmentCooper Technology100% (1)

- Engineering Applications: A Project Resource BookFrom EverandEngineering Applications: A Project Resource BookRating: 2.5 out of 5 stars2.5/5 (1)

- Risk Navigation Strategies for Major Capital Projects: Beyond the Myth of PredictabilityFrom EverandRisk Navigation Strategies for Major Capital Projects: Beyond the Myth of PredictabilityNo ratings yet

- Exploring Bentley STAAD.Pro CONNECT Edition, 3rd EditionFrom EverandExploring Bentley STAAD.Pro CONNECT Edition, 3rd EditionRating: 5 out of 5 stars5/5 (3)

- Petroleum Refinery Relocation Projects: 5-Phases of Project ManagementFrom EverandPetroleum Refinery Relocation Projects: 5-Phases of Project ManagementNo ratings yet

- Safety Engineering IIDocument2 pagesSafety Engineering IIChusnadiNo ratings yet

- 1 Inspection Report Dump Truck Da 1038 LaDocument2 pages1 Inspection Report Dump Truck Da 1038 LaChusnadiNo ratings yet

- Civil Engineering BooksDocument1 pageCivil Engineering BooksChusnadiNo ratings yet

- Safety Health and Environmental EbookDocument1 pageSafety Health and Environmental EbookChusnadiNo ratings yet

- Handbooks Alternatif Dari PriyatnoDocument1 pageHandbooks Alternatif Dari PriyatnoChusnadiNo ratings yet

- Welding Standard For Formula StudentDocument1 pageWelding Standard For Formula StudentChusnadiNo ratings yet

- Behavior Theory ABC Model by Thomas KrausDocument28 pagesBehavior Theory ABC Model by Thomas KrausChusnadiNo ratings yet

- How To Use A Wire MeasuringDocument2 pagesHow To Use A Wire MeasuringChusnadiNo ratings yet

- Panduan Instalasi Listrik RumahDocument240 pagesPanduan Instalasi Listrik Rumahlamenty55100% (1)

- Automotive Ebooks YahoooDocument2 pagesAutomotive Ebooks YahoooChusnadiNo ratings yet

- 15 Juli 2014 InspectorDocument3 pages15 Juli 2014 InspectorChusnadiNo ratings yet

- 21 Juli 2014 Sub Sea Construction TestDocument1 page21 Juli 2014 Sub Sea Construction TestChusnadiNo ratings yet

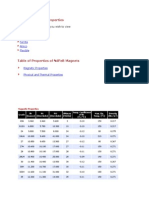

- Magnet Materials PropertiesDocument6 pagesMagnet Materials PropertiesChusnadiNo ratings yet

- NIOSH FACE Reports Provide Workplace Fatality Prevention Through Design RecommendationsDocument2 pagesNIOSH FACE Reports Provide Workplace Fatality Prevention Through Design RecommendationsChusnadiNo ratings yet

- Mechanical Inspector Course e LearningDocument1 pageMechanical Inspector Course e LearningChusnadiNo ratings yet

- Mechanical Engineering Books 29 April 2014Document1 pageMechanical Engineering Books 29 April 2014ChusnadiNo ratings yet

- MSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionDocument2 pagesMSA American Eagle V-Gard Freedom Series Hard Cap With Fas-Trac SuspensionChusnadiNo ratings yet

- Marine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5Document1 pageMarine Safety Guidance Marine Engineering Practice Series Vol 1 Part 5ChusnadiNo ratings yet

- Oq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceDocument3 pagesOq &gs - L : Orleans, LA. Cincinnati, OH: U.S. Department of Health, Education, and Welfare, Public Health ServiceChusnadiNo ratings yet

- Design GuideDocument29 pagesDesign GuideChusnadiNo ratings yet

- 95 Members: Kegiatan para Alumni SMA TRIMURTI..Document1 page95 Members: Kegiatan para Alumni SMA TRIMURTI..ChusnadiNo ratings yet

- Construction Risk Strategist ConferenceDocument2 pagesConstruction Risk Strategist ConferenceChusnadiNo ratings yet

- Popov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952Document1 pagePopov E P, Mechanical of Material, Prentice Hall, Inc. 1952 Mechanical of Material by Popov E.P, Prentice Hall Inc 1952ChusnadiNo ratings yet

- Code Buckling PlateDocument6 pagesCode Buckling PlateChusnadiNo ratings yet

- Below Hooks 19 June 2014Document4 pagesBelow Hooks 19 June 2014ChusnadiNo ratings yet

- Crystal Growth Technology: K. Byrappa T. Ohachi (Eds.)Document8 pagesCrystal Growth Technology: K. Byrappa T. Ohachi (Eds.)ChusnadiNo ratings yet

- Chassis Stiffness CalculationDocument1 pageChassis Stiffness CalculationChusnadiNo ratings yet

- Modern Safety Management 2 Juli 2014Document2 pagesModern Safety Management 2 Juli 2014ChusnadiNo ratings yet

- Design of Pressure Vessel Project ReportDocument137 pagesDesign of Pressure Vessel Project ReportAnand Bhandarkar75% (4)

- Index of Materials Science and Engineering HandbookDocument1 pageIndex of Materials Science and Engineering HandbookChusnadiNo ratings yet

- Plyometric Training Programs For Young Soccer Players: A Systematic ReviewDocument7 pagesPlyometric Training Programs For Young Soccer Players: A Systematic ReviewsteNo ratings yet

- Calmark - Birtcher 44 5 10 LF L DatasheetDocument2 pagesCalmark - Birtcher 44 5 10 LF L DatasheetirinaNo ratings yet

- Basic Facts For Homebooks Stage 7Document3 pagesBasic Facts For Homebooks Stage 7api-311857762No ratings yet

- SECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSDocument2 pagesSECURE ROAD BLOCKERS PREVENT VEHICLE ATTACKSMuhammad Tahir QamarNo ratings yet

- Writing Emails Part 1 Informal British English Teacher Ver2Document7 pagesWriting Emails Part 1 Informal British English Teacher Ver2Madalina MandiucNo ratings yet

- Grupo Stoncor Description - Stonhard Carboline Fibergrate PDFDocument22 pagesGrupo Stoncor Description - Stonhard Carboline Fibergrate PDFAndres OsorioNo ratings yet

- MN00119 Unicom LT User ManualDocument45 pagesMN00119 Unicom LT User ManualPhilipp A IslaNo ratings yet

- Acer Veriton S480G Service ManualDocument90 pagesAcer Veriton S480G Service ManualAndreea Georgiana ChirilaNo ratings yet

- 10 ExtSpringsDocument27 pages10 ExtSpringsresh27No ratings yet

- CA Ashish Dewani - Resume-1Document2 pagesCA Ashish Dewani - Resume-1Payal JainNo ratings yet

- Ajp Microproject ReportDocument9 pagesAjp Microproject ReportRushikesh KanseNo ratings yet

- Theories of SelfDocument5 pagesTheories of SelfTd Devi AmmacayangNo ratings yet

- Laser Communications Offer High-Performance Inter-Satellite LinksDocument18 pagesLaser Communications Offer High-Performance Inter-Satellite LinksAnukriti LeeNo ratings yet

- Flap System RiginDocument12 pagesFlap System RiginHarold Reyes100% (1)

- PLC SCADA ASSIGNMENT SsDocument10 pagesPLC SCADA ASSIGNMENT SsShadab AhmadNo ratings yet

- Graffiti Model Lesson PlanDocument9 pagesGraffiti Model Lesson Planapi-286619177100% (1)

- TLUD Handbook, Paul Anderson, V.2010Document19 pagesTLUD Handbook, Paul Anderson, V.2010satyakaamsNo ratings yet

- Basf Masteremaco Application GuideDocument15 pagesBasf Masteremaco Application GuideSolomon AhimbisibweNo ratings yet

- Vaje 3 - Macionis in PlummerDocument2 pagesVaje 3 - Macionis in PlummerLazar DjondricNo ratings yet

- 5e Lesson Plan s16 - MagnetsDocument6 pages5e Lesson Plan s16 - Magnetsapi-317126609No ratings yet

- PC 4 Product List 2019 - Pc4Document28 pagesPC 4 Product List 2019 - Pc4ShNo ratings yet

- Caring Seedlings TLE Weekly PlanDocument3 pagesCaring Seedlings TLE Weekly PlanMarjorie RaymundoNo ratings yet

- OSC - 2015 - Revised - Oct (Power Cables) PDFDocument118 pagesOSC - 2015 - Revised - Oct (Power Cables) PDFIván P. MorenoNo ratings yet

- Enabling Keycloak Metrics - KeycloakDocument3 pagesEnabling Keycloak Metrics - Keycloakhisyam darwisNo ratings yet

- Mid SemDocument1 pageMid SemvidulaNo ratings yet

- Ethics in ResearchDocument21 pagesEthics in Researchmukku_raviNo ratings yet

- Catering Reserving and Ordering System with MongoDB, Express, Node.js (39Document5 pagesCatering Reserving and Ordering System with MongoDB, Express, Node.js (39radha krishnaNo ratings yet

- Explosive Ordnance DisposalDocument13 pagesExplosive Ordnance DisposalZelwisNo ratings yet

- Teodora Sarkizova: Certificate of AchievementDocument2 pagesTeodora Sarkizova: Certificate of AchievementAbd El-RahmanNo ratings yet

- Mental AspectDocument29 pagesMental AspectBenjii CarlosNo ratings yet