Professional Documents

Culture Documents

Year II Soil Mechanics Lecture Notes

Uploaded by

Robert WalusimbiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Year II Soil Mechanics Lecture Notes

Uploaded by

Robert WalusimbiCopyright:

Available Formats

SOIL COMPACTION

Introduction

Soil compaction is the process of mechanically increasing the density of a soil

by packing the particles

closer together with a reduction in the volume of air; there is no significant c

hange in the volume of water in

the soil.

Compaction, as used here, implies dynamic compaction or densification by the app

lication of moving loads

to the soil mass. This is in contrast to the consolidation process for fine-grai

ned soil in which the soil is

gradually made more dense as a result of the application of a static load. The t

wo processes are compared

in Table 1.

Table 1: Comparison between compaction and consolidation processes

Compaction Consolidation

Similarities: The process leads to a closer packing of soil grains. Shear streng

th increases. Compressibility

and permeability decreases.

1. Is almost instantaneous 1. Is time dependent

2. Densification is due to reduction of air voids 2. Is due to expulsion of pore

water from voids

3. Soil is always unsaturated 3. Soil is saturated

4. For a specified compactive effort

densification takes place only up to a

certain limiting water content called

optimum moisture content (OMC)

4. No such limiting value of water content

Application

Construction of:

o Fills and embankments, loose soil is placed in layers ranging between 75 and 4

50 mm in

thickness, each being compacted to a specified standard by means of rollers, vib

rators or

rammers,

o

Roads,

o

Airfields,

o

Foundations.

Objectives/ benefits of compaction

o

Increases the shear strength of soil. This effect is highly desirable in that it

may allow the use of a

thinner pavement structure over a compacted subgrade or the use of steeper side

slopes for an

embankment than would otherwise be possible. For the same density, the highest s

trengths are

frequently obtained by using greater compactive efforts with water contents some

what below OMC

o

Densification by compaction prevents later consolidation and settlement of an em

bankment. This

does not necessarily mean that the embankment will be free of settlement; its we

ight may cause

consolidation of compressible soil layers that form the embankment foundation.

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

o

When soil particles are forced together by compaction, both the number of voids

contained in the

soil mass and the size of the individual void spaces are reduced. This change in

voids has an

obvious effect on the movement of water through the soil. One effect is to reduc

e the permeability,

thus reducing the seepage of water. Similarly, if the compaction is accomplished

with proper

moisture control, the movement of capillary water is minimized. This reduces the

tendency for the

soil to take up water and suffer later reductions in shearing resistance.

o

Soils in which volume change is a factor (e.g. expansive clays generally) may be

compacted so

that these effects are minimized.

Moisture Density Relationships

The degree of compaction of a soil is measured in terms of dry density (.d), i.e

. the mass of solids only per

unit volume of soil. The dry density of the soil is given by equation 1, . is th

e bulk density and . is water

content.

(1)

The dry density of a given soil after compaction depends on the water content an

d the energy supplied by

the compaction equipment (referred to as the compactive effort). Nearly all soil

s exhibit a similar

relationship between moisture content and dry density when subjected to a given

compactive. For each

soil, a maximum dry density develops at an OMC for the compactive effort used. T

he OMC at which

maximum density is obtained is the moisture content at which the soil becomes su

fficiently workable under

a given compactive effort to cause the soil particles to become so closely packe

d that most of the air is

expelled. For most soils (except cohesionless sands), when the moisture content

is less than optimum, the

soil is more difficult to compact. Beyond optimum, most soils are not as dense u

nder a given effort because

the water interferes with the close packing of the soil particles. Beyond optimu

m and for the stated

conditions, the air content of most soils remains essentially the same, even tho

ugh the moisture content is

increased.

The relationship in Figure 1 is valid for laboratory and field compaction. The m

aximum dry density is

frequently visualized as corresponding to 100 percent compaction for the given s

oil under the given

compactive effort.

Laboratory assessment of soil compaction

The soil is compacted in a cylindrical mould using a standard compactive effort

(i.e. a hammer is dropped

several times on a soil sample in a mould). The mass of the hammer, height of dr

op, number of drops,

number of layers of soil, and the volume of the mould are always specified. Tabl

e 2 gives the different

standard procedures for the compaction test.

Laboratory compaction tests are intended to model the field process, and to indi

cate the most suitable

moisture content for compaction (the optimum moisture content) at which the maximu

m dry density will be

achieved for a particular soil. Because of the limited size of the moulds in use

, laboratory compaction tests

require the exclusion of coarse soil particles.

After compaction using one of the standards shown in Table 2, the bulk density a

nd water content of the

soil are determined and the dry density calculated. For a given soil the process

is repeated at least five

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

times, the water content of the sample being increased each time. The dry densit

y is plotted against water

content and a curve of the form shown in Figure 1 is obtained.

Table 2: Compaction test comparisons

Standard Test type Blows

per

layer

No. of

Layers

Hammer

weight

(kg)

Hammer

drop

(mm)

Sample

size (kg)

Mould

volume

(cm3)

Mould

diameter

(mm)

BS1377:Part

4:1990

BS Light

(Proctor)

27 3 2.5 300 3 1000 105

BS1377:Part

4:1990

*BSHeavy 27 5 4.5 450 3/6 1000 105

AASHTO

T180

Modified

Proctor

25 5 4.5 450 3 1000 105

AASHTO

T180

56 5 4.5 450 6 2123 152

*For coarser material (i.e. particles 20-37.5mm) when a CBR mould (2300cm3) is u

sed, 62 blows shall be applied to each

layer.

(A) Typical moisture-density relationship (B) Real field data: KE; km 12+ 040

Figure 1: Typical Compaction curves

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

Shape of a compaction curve

The compaction curve in Figure 1 shows that for a particular method of compactio

n (i.e. a particular

compactive effort) there is a particular value of water content, known as the op

timum water content (OMC),

at which a maximum value of dry density (MDD) is obtained.

Reason for increase and decrease of the curve

Addition of water to the soil facilities easy movement of particles and their cl

oser packing and hence an

increase in density. However, beyond a certain limit the water becomes excessive

and tends to occupy

space which otherwise would have been occupied by solid parties. Hence, a decrea

se in dry density due to

additional void space.

Degree of compaction

If all the air in a soil could be expelled by compaction the soil would be in a

state of full saturation and the

dry density would be the maximum possible value for the given water content. How

ever, this degree of

compaction is unattainable in practice. The maximum possible value of dry densit

y is referred to as the

zero air voids dry density or the saturation dry density and can be calculated fro

m the expression given in

equation (2).

..........................................(2)

In general, the dry density after compaction at water content w to an air conten

t A can be calculated from

the following expression given in equation (3).

..(3)

Where;

.d is the dry density (kg/m3),

A is the air content (in %),

. is the water content (in %),

.. is the density of water (kg/m3),

Gs is the specific gravity of soil.

Figure 2 shows the relationship between zero air voids, dry density and water co

ntent (for Gs=2.65). The

curves relating dry density at air contents of 5 and 10% with water content are

also shown in Figure 2.

These curves enable the air content at any point on the experimental dry densityw

ater content curve to be

determined by inspection.

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

Figure 2: Air voids, dry density and water content relationships

Characteristics of soil on dry and wet side of OMC

The physical and behavioural characteristics of a compacted soil depend on wheth

er it is on the dry or wet

side of OMC. Table 3 gives an account of these differences.

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

Table 3: Characteristics of soil on dry and wet side of OMC

Soil characteristics Dry side of OMC Wet side of OMC

Soil structure flocculated dispersed

Coefficient of permeability upon saturation more less

Shear strength high low

Stress-strain behaviour brittle ductile

Compressibility more less

Compaction characteristics of various soils

The nature of a soil itself has a great effect on its response to a given compac

tive effort. Soils that are

extremely light in weight, such as diatomaceous earths and some volcanic soils,

may have maximum

densities under a given compactive effort as low as 900 kg/m3. Under the same co

mpactive effort, the

maximum density of a clay may be in the range of 1400 to 1600 kg/m3, while that

of a well-graded coarse

granular soil may be as high as 2100 kg/m3. Figure 3 shows the dry density water

content curves for a

range of soils.

Figure 3: Dry density-water content curves for a range of soil types

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

Variation of compactive effort

For each compactive effort used in compacting a given soil, there is a correspon

ding OMC and maximum

density. If the compactive effort is increased, the maximum density is increased

and the OMC is decreased.

This fact is illustrated in Figure 4, it shows that a higher compactive effort r

esults in a higher value of

maximum dry density and a lower value of optimum water content; however, the val

ues of air content at

maximum dry density are approximately equal.

(A) Rammer size (B) No. of blows

Figure 4: Dry density-water content curves for different compactive efforts

Field Compaction

The results of laboratory compaction tests are not directly applicable to field

compaction because the

compactive efforts in the laboratory tests are different, and are applied in a d

ifferent way, from those

produced by field equipment. Further, the laboratory tests are carried out only

on material smaller than

either 20 or 37.5mm. However, the maximum dry densities obtained in the laborato

ry using the 2.5-and

4.5-kg rammers cover the range of dry density normally produced by field compact

ion equipment. A

minimum number of passes must be made with the chosen compaction equipment to pr

oduce the required

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

value of dry density. This number, which depends on the type and mass of the equ

ipment and on the

thickness of the soil layer, is usually within the range 312. Above a certain num

ber of passes no significant

increase in dry density is obtained. In general, the thicker the soil layer the

heavier the equipment required

to produce an adequate degree of compaction.

There are two approaches to the achievement of a satisfactory standard of compac

tion in the field, known

as method and end-product compaction. In method compaction the type and mass of

equipment, the layer

depth and the number of passes are specified. In end-product compaction the requ

ired dry density is

specified: the dry density of the compacted fill must be equal to or greater tha

n a stated percentage of the

maximum dry density obtained in one of the standard laboratory compaction tests.

Method compaction is

used in most earthworks. End product compaction is normally restricted to pulver

ized fuel ash in general fill

and to certain selected fills.

Handling of Wet Soils

When the moisture content of the soil to be compacted greatly exceeds that neces

sary for the desired

density, some water must be removed. In some cases, the use of excessively wet s

oils is possible without

detrimental effects. These soils (coarse aggregates) are called free-draining so

ils, and their maximum dry

density is unaffected by moisture content over a broad range of moisture. Most o

ften, these soils must be

dried; this can be a slow and costly process. The soil is usually dried by manip

ulating and exposing it to

aeration and to the rays of the sun. Manipulation is most often done with cultiv

ators, plows, graders, and

rotary mixers. Rotary mixers, with the tail-hood section raised, permit good aer

ation and are very effective

in drying excessively wet soils. An excellent method that may be useful when bot

h wet and dry soils are

available is simply to mix them together.

Field compaction equipment

The following equipment are used to compact soils in the field; smooth-wheeled r

ollers, pneumatic-tyred

rollers, sheepsfoot rollers, grid rollers, vibratory rollers, vibrating plates a

nd power rammers. Some

equipment is shown in Figure 5.

Quality Control of Compaction works

Poor construction procedures can invalidate good pavement or embankment design.

Therefore, quality

control of construction procedures is as important to the final product as is pr

oper design. The purpose of

quality control is to ensure that the soil is being placed at the proper density

and moisture content to

provide adequate bearing strength (CBR) in the fill. This is accomplished by tak

ing samples or testing at

each stage of construction. The test results are compared to limiting values or

specifications, and the

compaction should be accepted or reworked based on the results of the density an

d moisture content tests.

One of the ways of checking the quality of a compacted surface is carrying out f

ield density tests. There are

a number of methods of measuring the bulk density in the field and are all detai

led in BS 1377: Part 4:

1990.

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

Two-axle, tandem steel-wheeled rollers Self-propelled, smooth-drum vibratory rol

ler

Static pneumatic tyre roller Static three steel wheel roller

Figure 5: Some of the rollers used for compacting soils in the field.

Assignment (Date of submission: Wednesday 12, March 2014)

Question 1

You are a field engineer for a construction services testing firm. Your current

job assignment is to evaluate

fill placement for a new roadway being constructed between Kampala and Jinja. Th

e project specifications

for the roadway require fill compaction to 98% of the AASHTO T180 compaction tes

t results. Your lab

manager sends you the results of Standard and Modified Proctor compaction testin

g on the fill being

placed. These results are presented in Table 4. Your field compaction test resul

ts for the second soil lift

taken at the intervals required by the project specifications are listed in Tabl

e 5.

Table 4: Laboratory test results

Moisture content (%)

Test 1 Test 2 Test 3 Test 4 Test 5

6.87 8.43 10.89 12.55 14.13

Dry density (kg/m3) 1834 1916 1926 1870 1796

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

Table 5: Field density results

Test section Direction Field density (kg/m3) Moisture content (%)

0+400 Right 1817 8.4

0+470 Centre 1852 8.2

0+550 Left 2186 6.8

I. From the provided information, determine the following:

o The compaction characteristics for the AASHTO T180 test,

o If the fill meets the compaction requirements at the two field density test lo

cations.

II.

Given that the specific gravity is 2.70 calculate the degree of saturation for t

he soil at the

optimum moisture content.

III.

If the soil were to be compacted at a moisture content of 11% calculate the air

content.

IV.

Apart from field density list other tests that may be carried out on samples of

compacted

soil, to check that an end product specification has been met.

Question 2

REFERENCES

British Standard 1377 (1990) Methods of Test for Soils for Civil Engineering Pur

poses, British

Standards Institution, London.

Clayton, C. R. I., Matthews, M. C., & Simons, N. E. (1995). Site Investigation (

2 ed.). London:

Blackwell Science, Oxford.

Craig, R. F. (2004). Soil Mechanics (7 ed.). London: Chapman and Hall.

Kaniraj, S.R.(2008). Design Aids in Soil Mechanics and Foundation Engineering. M

cGraw-Hill

Publishing Company Limited, New Delhi.

Department of Civil and Environmental Engineering, Year II lecture notes Robert

Tumwesige, 2014

You might also like

- Compaction Oct2010Document23 pagesCompaction Oct2010Akshthagowda848_1952No ratings yet

- Soils as a Key Component of the Critical Zone 3: Soils and Water CirculationFrom EverandSoils as a Key Component of the Critical Zone 3: Soils and Water CirculationGuilhem BourrieNo ratings yet

- Program: B.E Subject Name: Geo Technical Engineering Subject Code: CE-8002 Semester: 8thDocument20 pagesProgram: B.E Subject Name: Geo Technical Engineering Subject Code: CE-8002 Semester: 8thFreak.h3No ratings yet

- Soil CompactionDocument37 pagesSoil CompactionYsabelle Tagaruma100% (1)

- Geotechnical Lectures4Document19 pagesGeotechnical Lectures4Muhammad BasitNo ratings yet

- Soil Mechanics: Eotechnical NgineeringDocument33 pagesSoil Mechanics: Eotechnical NgineeringAyub Ali WehelieNo ratings yet

- Compaction TestDocument5 pagesCompaction TestDorn Adams100% (1)

- CVE 131 - CompactionDocument109 pagesCVE 131 - CompactionZxeroNo ratings yet

- Soil CompactionDocument6 pagesSoil CompactionJems MansuetoNo ratings yet

- Compaction TheoryDocument35 pagesCompaction TheoryMichael Zonshain100% (1)

- Chapter 5Document7 pagesChapter 5midju dugassaNo ratings yet

- Consolidation and Compressibility of SoilsDocument19 pagesConsolidation and Compressibility of SoilsvnkatNo ratings yet

- Soil Compaction Literature ReviewDocument31 pagesSoil Compaction Literature ReviewlearnafrenNo ratings yet

- Soil Compaction FundamentalsDocument6 pagesSoil Compaction FundamentalsAmir DNo ratings yet

- Soil Compaction: Understanding the Key FactorsDocument19 pagesSoil Compaction: Understanding the Key FactorsArthNo ratings yet

- Compaction of Soils 2013Document9 pagesCompaction of Soils 2013Nature NatureNo ratings yet

- Standard Proctor Compaction TestDocument7 pagesStandard Proctor Compaction TestshuhadaNo ratings yet

- Compaction LabDocument10 pagesCompaction LabKarl Todd100% (5)

- CompactionDocument14 pagesCompactionRajesh KhadkaNo ratings yet

- Compaction Properties of SoilsDocument12 pagesCompaction Properties of SoilsRoopesh KumarNo ratings yet

- Compaction NotesDocument11 pagesCompaction Notesc.gichobiiNo ratings yet

- 4.1 Soil Compaction 1Document35 pages4.1 Soil Compaction 1Musfiqur RahmanNo ratings yet

- Soil - Mechanics - Chapter - 4Document88 pagesSoil - Mechanics - Chapter - 4Jessee PinkmanNo ratings yet

- CompactionDocument17 pagesCompactionsourya_130No ratings yet

- CVE 131 1 Lecture 4 Soil CompactionDocument12 pagesCVE 131 1 Lecture 4 Soil CompactionZxeroNo ratings yet

- ) Is Given By:: and The Water Content WDocument2 pages) Is Given By:: and The Water Content WismailNo ratings yet

- Compaction of Soil - Definition, Principle and EffectDocument16 pagesCompaction of Soil - Definition, Principle and EffectafafaaaNo ratings yet

- CEEN3160 F10 Lab4 Proctor SandCone PDFDocument13 pagesCEEN3160 F10 Lab4 Proctor SandCone PDFAlisha GarciaNo ratings yet

- Compaction & Its Consequances PDFDocument12 pagesCompaction & Its Consequances PDFHamidullah Asady WardakNo ratings yet

- CompactionDocument8 pagesCompactionbrandon bernardNo ratings yet

- Geothecnical Engg 4 - SOIL COMPACTIONDocument56 pagesGeothecnical Engg 4 - SOIL COMPACTIONRenderizzah FloraldeNo ratings yet

- Soil CompactionDocument13 pagesSoil Compactionbishry ahamedNo ratings yet

- Assignment Top Sheet Department of Civil Engineering & TechnologyDocument6 pagesAssignment Top Sheet Department of Civil Engineering & TechnologyEngr MahwishNo ratings yet

- Compa DissDocument2 pagesCompa DissGowtham RagunathanNo ratings yet

- Soil Compaction: Factors, Tests, and Field Density DeterminationDocument20 pagesSoil Compaction: Factors, Tests, and Field Density DeterminationMiya GomezNo ratings yet

- Introduction To The Compaction of SoilsDocument16 pagesIntroduction To The Compaction of SoilsCHRISTOPHER UKPENo ratings yet

- Soil Compaction: Source: Principles of Geotechnical Engineering, 7 Edition By: Braja M. DasDocument41 pagesSoil Compaction: Source: Principles of Geotechnical Engineering, 7 Edition By: Braja M. DasJocydane PachecoNo ratings yet

- Factors Affecting Soil CompactionDocument3 pagesFactors Affecting Soil CompactionSaivenkateshBantupalli100% (1)

- Exp 6Document3 pagesExp 6Leah RiveraNo ratings yet

- CompactionDocument6 pagesCompactionDhananjay ShahNo ratings yet

- Fundamentals of Geotechnical Engineering Lecture OutlineDocument53 pagesFundamentals of Geotechnical Engineering Lecture OutlineTarun BhanotNo ratings yet

- Basic Physical Properties of SoilDocument20 pagesBasic Physical Properties of SoilTare ManNo ratings yet

- Chapter 4 CompactionDocument8 pagesChapter 4 CompactionAwokeNo ratings yet

- Soil Mechanics HandoutsDocument35 pagesSoil Mechanics HandoutsJayChristian QuimsonNo ratings yet

- Engineering Properties of SoilDocument30 pagesEngineering Properties of SoilChung MHNo ratings yet

- Soil Compaction TestDocument13 pagesSoil Compaction TestBiruk AkliluNo ratings yet

- Geotech Chapter 4Document16 pagesGeotech Chapter 4Casao JonroeNo ratings yet

- CE341 CE22 Wk03 4 Soil CompactionDocument143 pagesCE341 CE22 Wk03 4 Soil CompactionFaiaz Bin DelworNo ratings yet

- Soil CompactionDocument26 pagesSoil CompactionAlvin ConcepcionNo ratings yet

- Arijit Nandi Soil Mechanics-IIDocument4 pagesArijit Nandi Soil Mechanics-IIarijit nandiNo ratings yet

- Soil compaction principles, process and field compaction techniquesDocument2 pagesSoil compaction principles, process and field compaction techniquesSiti Munirah Binti ZainudinNo ratings yet

- Experiment To Conduct Compaction TestDocument9 pagesExperiment To Conduct Compaction TestAyaz BhattiNo ratings yet

- Soil Compaction & ConsistencyDocument35 pagesSoil Compaction & ConsistencyShekh Muhsen Uddin AhmedNo ratings yet

- Shear Strength and Compaction of SoilDocument15 pagesShear Strength and Compaction of SoilJohn Rafael R. CanoosNo ratings yet

- Compaction Test ReportDocument5 pagesCompaction Test ReportMahmoud Khalifa91% (22)

- Lecture 6 - Compaction & ConsolidationDocument42 pagesLecture 6 - Compaction & Consolidationelias assefaNo ratings yet

- Soil CompactionDocument18 pagesSoil CompactionLiza SyafitriNo ratings yet

- Bills of Quantities For Standard Residential House - 2 Bedroom-Type A PDFDocument13 pagesBills of Quantities For Standard Residential House - 2 Bedroom-Type A PDFHammad SalahuddinNo ratings yet

- Moisture Dry Density 4.3 1.819 6.1 1.849 8.5 2.072 10.3 2.017 11.8 1.931Document4 pagesMoisture Dry Density 4.3 1.819 6.1 1.849 8.5 2.072 10.3 2.017 11.8 1.931Robert WalusimbiNo ratings yet

- Best Evaluated Bidder for Paving Parking YardDocument1 pageBest Evaluated Bidder for Paving Parking YardRobert WalusimbiNo ratings yet

- Kaweeri Project PDFDocument1 pageKaweeri Project PDFRobert WalusimbiNo ratings yet

- My Notes For Design SoftwaresDocument4 pagesMy Notes For Design SoftwaresRobert WalusimbiNo ratings yet

- Determine Lime Content for Soil StabilizationDocument2 pagesDetermine Lime Content for Soil StabilizationRobert WalusimbiNo ratings yet

- Calculation For PH SolutionsDocument1 pageCalculation For PH SolutionsRobert WalusimbiNo ratings yet

- Badminton: A New Scoring SystemDocument1 pageBadminton: A New Scoring SystemRobert WalusimbiNo ratings yet

- Makerere RainfallDocument25 pagesMakerere RainfallRobert WalusimbiNo ratings yet

- Convert The Volume Counts To Equivalent Pcu Using The Factors Presented in The Table Below For Each IntervalDocument1 pageConvert The Volume Counts To Equivalent Pcu Using The Factors Presented in The Table Below For Each IntervalRobert WalusimbiNo ratings yet

- Moisture Dry Density 4.3 1.819 6.1 1.849 8.5 2.072 10.3 2.017 11.8 1.931Document4 pagesMoisture Dry Density 4.3 1.819 6.1 1.849 8.5 2.072 10.3 2.017 11.8 1.931Robert WalusimbiNo ratings yet

- Civil TranspDocument8 pagesCivil TranspSumit VermaNo ratings yet

- Piano ScalesDocument3 pagesPiano ScalesRobert WalusimbiNo ratings yet

- 23+000 24+000 8+000 1st Layer 2nd Layer 3rd Layer 4th Layer 5th Layer 6th Layer 7th Layer 8th Layer 9th LayerDocument1 page23+000 24+000 8+000 1st Layer 2nd Layer 3rd Layer 4th Layer 5th Layer 6th Layer 7th Layer 8th Layer 9th LayerRobert WalusimbiNo ratings yet

- The Full Stop: Punctuation ExplainedDocument7 pagesThe Full Stop: Punctuation ExplainedRobert WalusimbiNo ratings yet

- Rodney Kajjabwangu Job Application Janitorial Post Fame Lounge KampalaDocument1 pageRodney Kajjabwangu Job Application Janitorial Post Fame Lounge KampalaRobert WalusimbiNo ratings yet

- 1970 East African Court of Appeal CasesDocument882 pages1970 East African Court of Appeal CasesRobert Walusimbi100% (8)

- What Is Belkhayate Timing Indicator?: Buying/selling (Moments To Enter The Market) and Possible Reversal PointsDocument2 pagesWhat Is Belkhayate Timing Indicator?: Buying/selling (Moments To Enter The Market) and Possible Reversal PointsRobert WalusimbiNo ratings yet

- (1967) East Africa Law ReportsDocument1,115 pages(1967) East Africa Law ReportsRobert Walusimbi85% (27)

- (1968) East Africa Law ReportsDocument909 pages(1968) East Africa Law ReportsRobert Walusimbi91% (22)

- (1972) East Africa Law ReportsDocument760 pages(1972) East Africa Law ReportsRobert Walusimbi83% (18)

- ESAL AASHTO Design for Flexible PavementDocument2 pagesESAL AASHTO Design for Flexible PavementRobert Walusimbi100% (1)

- (1971) East Africa Law ReportsDocument750 pages(1971) East Africa Law ReportsRobert Walusimbi100% (8)

- (1966) East Africa Law ReportsDocument792 pages(1966) East Africa Law ReportsRobert Walusimbi91% (11)

- (1964) East Africa Law ReportsDocument990 pages(1964) East Africa Law ReportsRobert Walusimbi67% (9)

- 1965 East African Law Reports Volume 1Document1,093 pages1965 East African Law Reports Volume 1Robert Walusimbi82% (11)

- EA Law Reports 1963 Volume 1Document941 pagesEA Law Reports 1963 Volume 1Robert Walusimbi100% (14)

- (1961) East Africa Law ReportsDocument991 pages(1961) East Africa Law ReportsRobert Walusimbi71% (7)

- (1962) East Africa Law ReportsDocument1,061 pages(1962) East Africa Law ReportsRobert Walusimbi100% (1)

- EA Law Reports 1960 Volume 1Document1,299 pagesEA Law Reports 1960 Volume 1Robert Walusimbi75% (4)

- Wide-Lite Spectra VI Commercial Indoor Bulletin 1989Document4 pagesWide-Lite Spectra VI Commercial Indoor Bulletin 1989Alan MastersNo ratings yet

- Is 10500 SpecificationDocument10 pagesIs 10500 SpecificationbrahmishtanNo ratings yet

- A-Ele-Lst-000-47960-B - Cable Shedule For Pipeline Cathodic Protection SystemDocument44 pagesA-Ele-Lst-000-47960-B - Cable Shedule For Pipeline Cathodic Protection SystemBadiNo ratings yet

- Properties of Liquid FuelsDocument5 pagesProperties of Liquid FuelsAbigail MonisNo ratings yet

- Astm c1557Document10 pagesAstm c1557Roxana Elizabeth Valencia Navarrte100% (4)

- Running Head: Food Test Lab Report 1Document6 pagesRunning Head: Food Test Lab Report 1Jun Hong Tee100% (2)

- Advanced Level Problems: Q. No. 1 To 3 (3 Questions)Document78 pagesAdvanced Level Problems: Q. No. 1 To 3 (3 Questions)Saravanan BNo ratings yet

- TDS - HYDROCARBON RESIN SK-120 - PETRORESIN SK-120 - en - 12 PDFDocument1 pageTDS - HYDROCARBON RESIN SK-120 - PETRORESIN SK-120 - en - 12 PDFAndrei LazoNo ratings yet

- Org Chem LabDocument7 pagesOrg Chem LabCriselda CarinoNo ratings yet

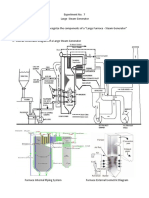

- Large Steam GeneratorDocument12 pagesLarge Steam GeneratorChe AguilarNo ratings yet

- Heat Transfer: Conservation of EnergyDocument28 pagesHeat Transfer: Conservation of EnergyAhmadJaffarGulfarazNo ratings yet

- Masterflow 648 CP GroutDocument4 pagesMasterflow 648 CP GroutAjit Singh RathoreNo ratings yet

- Biobased Materials For Paper Coating: Charles P. Klass Klass Associates Inc. Redington Beach, FLDocument32 pagesBiobased Materials For Paper Coating: Charles P. Klass Klass Associates Inc. Redington Beach, FLlucy.hughesNo ratings yet

- Waste management in Israel - background, policy, projects & opportunitiesDocument15 pagesWaste management in Israel - background, policy, projects & opportunitiesLuan NguyenNo ratings yet

- 01 Well Cementing - Day 1 PDFDocument131 pages01 Well Cementing - Day 1 PDFام فاطمة البطاط100% (1)

- Exxon™ Bromobutyl 2222: RubberDocument2 pagesExxon™ Bromobutyl 2222: RubberMaram YasserNo ratings yet

- 1 Brain Storm Chemistry Med FinalDocument7 pages1 Brain Storm Chemistry Med FinalShudhanshu KumarNo ratings yet

- WPS - 008Document11 pagesWPS - 008MAT-LIONNo ratings yet

- Saumyakanti Khatua Et Al - Plasmonic Nanoparticles-Liquid Crystal CompositesDocument7 pagesSaumyakanti Khatua Et Al - Plasmonic Nanoparticles-Liquid Crystal CompositesYlpkasoNo ratings yet

- Fsci Assignment ADocument29 pagesFsci Assignment ARaj PrateekNo ratings yet

- Environmental Engineering QuizDocument4 pagesEnvironmental Engineering QuizmikeengineeringNo ratings yet

- Shera PlanksDocument61 pagesShera Planksakankshas06No ratings yet

- Astm B117-19 (Corrosion)Document11 pagesAstm B117-19 (Corrosion)Andres DelaCruz100% (1)

- Effects of Heat Treatments On Steels For Bearing ApplicationsDocument7 pagesEffects of Heat Treatments On Steels For Bearing ApplicationsAshwani KansaraNo ratings yet

- Dynamic pile formulas estimate capacityDocument11 pagesDynamic pile formulas estimate capacityFaheem Ali AsgharNo ratings yet

- Chemkin PDFDocument44 pagesChemkin PDFmohamedIGCMONo ratings yet

- Me F211 1083 PDFDocument3 pagesMe F211 1083 PDFPranjal SrivastavaNo ratings yet

- Thermal Properties of Egyptian Stretched Knitted FabricsDocument4 pagesThermal Properties of Egyptian Stretched Knitted FabricsaymanNo ratings yet

- Marine Bilge Water Treatment SystemDocument11 pagesMarine Bilge Water Treatment Systemrobjsimon100% (3)

- FFF SolutionsDocument152 pagesFFF SolutionsMohammedAL-AthariNo ratings yet

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (57)

- Survival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosFrom EverandSurvival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosRating: 3.5 out of 5 stars3.5/5 (8)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The Storm of the Century: Tragedy, Heroism, Survival, and the Epic True Story of America's Deadliest Natural DisasterFrom EverandThe Storm of the Century: Tragedy, Heroism, Survival, and the Epic True Story of America's Deadliest Natural DisasterNo ratings yet

- Water to the Angels: William Mulholland, His Monumental Aqueduct, and the Rise of Los AngelesFrom EverandWater to the Angels: William Mulholland, His Monumental Aqueduct, and the Rise of Los AngelesRating: 4 out of 5 stars4/5 (21)

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- Smokejumper: A Memoir by One of America's Most Select Airborne FirefightersFrom EverandSmokejumper: A Memoir by One of America's Most Select Airborne FirefightersNo ratings yet

- The Weather Machine: A Journey Inside the ForecastFrom EverandThe Weather Machine: A Journey Inside the ForecastRating: 3.5 out of 5 stars3.5/5 (31)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4.5 out of 5 stars4.5/5 (4)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (586)

- 35 Miles From Shore: The Ditching and Rescue of ALM Flight 980From Everand35 Miles From Shore: The Ditching and Rescue of ALM Flight 980Rating: 4 out of 5 stars4/5 (21)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureFrom EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureRating: 5 out of 5 stars5/5 (124)

- Recording Unhinged: Creative and Unconventional Music Recording TechniquesFrom EverandRecording Unhinged: Creative and Unconventional Music Recording TechniquesNo ratings yet

- Packing for Mars: The Curious Science of Life in the VoidFrom EverandPacking for Mars: The Curious Science of Life in the VoidRating: 4 out of 5 stars4/5 (1395)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsFrom EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNo ratings yet

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (80)

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsFrom EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsNo ratings yet

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)