Professional Documents

Culture Documents

en

Uploaded by

arianaseriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

en

Uploaded by

arianaseriCopyright:

Available Formats

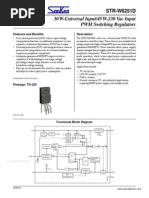

P1

P2

F2

F1

F3

F4

P3

INSTALLATION AND MAINTENANCE MANUAL FOR BPHEs

Sealing plates are used to seal off the space between the cover plate and the first

and last channel plate. The number of cover plates varies, e.g. with the type and

size of BPHE and its respective pressure rating.

Some BPHEs have a blind ring for the purpose of sealing off the space between

the channel plate and the cover plate. In some BPHEs the blind rings are

integrated in the cover plate and first/last channel plates.

GENERAL INFORMATION

Depending on material combinations, pressure ratings and functions, there are

several different types of Compact Brazed Heat Exchangers (BPHEs). The

standard materials are stainless steel, vacuum-brazed with a pure copper or

nickel-based filler.

The basic materials of construction indicate the type of fluids that SWEP's BPHEs

can be used with. Typical examples are: synthetic or mineral oil, organic solvents,

water (not seawater), glycol mixtures (ethylene and propylene glycol),

refrigerants (e.g. HCFC). Please note that if natural refrigerants (e.g. ammonia)

are employed, BPHEs with nickel-based brazing material must be used.

The front plate of SWEP's BPHE is marked with an

arrow. Either of an adhesive sticker type or embossed in

the cover plate. The purpose of this marker is to indicate

the front side of the BPHE and the location of the inner

and outer circuits/channels. With the arrow pointing up,

the left side (Port F1, F3) is the inner circuit and the right

side (Port F2, F4) is the outer circuit. For SWEP

asymmetric products one circuit is narrow while the

other is wide, which makes it additionally important to

correctly combine flow and circuit to reach design

performance. The asymmetric products include E5AS,

B9, B26, B56, D300 and D700.The inner circuit (Port F1,F3) is the narrow side

while the outer circuit (Port F2,F4) is the wide side for E5AS, B26 and B56.

Ports F1/F2/F3/F4 are situated on the front of the heat exchanger. Ports

P1/P2/P3/P4 are situated on the back. Note the order in which they appear.

CONSTRUCTION

The BPHE is in principle built up by a plate package of corrugated channel plates

between front and rear cover-plate packages. The cover plate packages consist

of sealing plates, blind rings and cover plates. The connections can be

customized to meet specific market and application requirements. During the

vacuum-brazing process, a brazed joint is formed at every contact point between

two plates. The design creates a heat exchanger that consists of two separate

circuits.

Material Combinations

There are different types of BPHE product categories depending on material

combinations and design pressures. The standard plate materials are stainless

steel, S, of AISI 316 type (1.4401 or 2343), vacuum-brazed with a pure copper

filler, C, or a nickel-based filler, N. Carbon steel can be used to some extent, e.g.

for certain types of connections. For demanding applications, the plates can be

made of SMO 254, a stainless steel with a higher content of molybdenum, M.

There are BPHEs available for standard pressure rating, S, high pressure rating,

H or ultra high pressure rating, U. The material and pressure denominations are

shown below.

B35H40/1P-XX-X

Pressure rating e.g.: L, low pressure;

S, standard pressure;

M, m-pressure;

H, high-pressure;

U, ultra high pressure Braze material e.g.: C, copper;

N, nickel alloy

Table 1: Examples of BPHEs with various material and design pressures

BPHE Categories Denomination Explanation

Standard BPHEs B25T/1P-SC-S B25T with stainless steel plates brazed

with copper. Standard pressure rating.

High Pressure BPHEs B25T/1P-SC-H B25T with stainless steel plates brazed

with copper. High pressure rating.

Nickel brazed BPHEs B10T/1P-SN-S B10T with stainless steel plates brazed

with nickel alloy. Standard pressure.

Mo-steel BPHEs B120T/1P-MC-S B120T with Mo-steel plates brazed with

copper. Standard pressure rating.

304-steel BPHEs B120T/1P-NC-S B120T with 304-steel brazed with copper.

Standard pressure rating.

BPHE Plates and Channel Types

Some BPHEs are available with different types of channel plates where the

herringbone pattern varies. The chevrons can be obtuse (creating a high theta

plate, H) or acute (creating a low theta plate, L).

Plates: H L Channels: H L M (MH&ML)

By mixing high and low theta plates, the thermal characteristics of the BPHE can

be modified.

FLOW CONFIGURATIONS

The fluids can pass through the heat exchanger in different ways. For parallel-

flow BPHEs, there are two different flow configurations: co-current or counter-

current.

Co-current flow

Counter-current flow

B9, B60 and D700 have a cross-flow configuration, instead of the parallel flow

normally found in BPHEs. In B9 and B60 the ports F1-F4 are equivalent to the

outer circuit and the ports F2-F3 are equivalent to the inner circuit. For D700 the

F5-F6 ports are the outer circuit and F1-F4 and F2-F3 are the inner circuits.

When using the B60 exchanger in single-phase applications, you receive the

same thermal performance regardless of the inlet/outlet arrangement due to its

quadratic shape and cross-flow arrangement. The choice of fluid stream on H and

L side is however dependent on the thermal and hydraulic performance

requirements. When applying B60 as condenser, it is important that the refrigerant

enters through port F2 and leaves through F3.

Freezing Protection

a) Use a filter < 1 mm, 16 mesh (see previous chapter on Strainers).

b) Use an antifreeze when the evaporation temperature is close to liquid-side

freezing.

c) Use a freeze protection thermostat and flow switch to guarantee a constant

water flow before, during and after compressor operation.

d) Avoid pump-down function.

e) When starting up a system, wait a moment before starting the condenser (or

have reduced flow through it).

Condensers

The refrigerant (gas) should be connected to

the upper left conn-ection, F1, and the

condensate to the lower left connection, F3.

The water/brine circuit inlet should be

connected to the lower right connection, F4,

and the outlet to the upper right connection,

F2.

BPHEs with UL approval for use with CO 2

according to UL files section II or VI. For use

with CO the system should include a pressure 2

relief valve on each side of the brazed plate

heat exchanger. The pressure relief valve

must be opened if the system pressure

reaches 0.9 design pressure.

F2

F1

F3

F4

Thanks to the normally very high

degree of turbulence in BPHEs

there is a self-cleaning effect in the

channels. However, in some

applications the fouling tendency

can be very high, e.g. when using

extremely hard water at high

temperatures. In such cases it is

always possible to clean the

exchanger by circulating a cleaning

liquid (CIP- Cleaning In Place). Use

a tank with weak acid, 5% phospho-

ric acid or, if the exchanger is fre-

quently cleaned, 5% oxalic acid.

Pump the cleaning liquid through

the exchanger.

STORAGE

BPHE

WARRANTY

SWEP offers a 12-month warranty from the date of installation, but in no case

longer than 15 months from the date of delivery. The warranty covers only

manufacturing and material defects.

DISCLAIMER

SWEP's BPHE performance is based on installation, maintenance and operating

conditions done in conformance with this manual. SWEP cannot assume any

liability for BPHEs that do not meet these criteria.

For further information, please consult SWEP's technical information or your local

SWEPcompany.

s are to be stored dry. The temperature should not be below 1C and not

over 50C for long term storage (more than 2 weeks).

The heat exchanger is not type-approved for fatigue loading

For tough installations we recommend factory-installed CIP connections/valves

for easy maintenance.

For optimum cleaning, the cleaning solution flow rate should be a minimum of 1.5

times the normal flow rate, preferably in a back-flush mode. After use, do not

forget to rinse the heat exchanger carefully with clean water. A solution of 1-2%

sodium hydroxide (NaOH) or sodium bicarbonate (NaHCO ) before the last rinse 3

ensures that all acid is neutralized. Clean at regular intervals .

Draining of heat exchanger

A drainage valve shall be positioned at a low position in relation to the heat

exchanger. Make sure that all relevant pumps are shut off. Shut off primary sides

valves. Shut off secondary sides valves. Empty the exchanger using drainage

valve.

Bleeding of heat exchanger

A bleeding valve shall be assembled on the warm side of the heat exchanger,

where the water has its lowest solubility of the gas. Make sure its positioned at a

high position in relation to the heat exchanger. Depending on the need, the

frequency of ventilation will differ.

For further information about cleaning of the BPHEs, please consult SWEP's CIP

information or your local SWEPcompany.

SWEP INTERNATIONAL AB

Box 105, SE-261 22 Landskrona, Sweden

Phone +46 418 40 04 00 Fax +46 418 292 95 Internet: www.swep.net E-mail:info@swep.net

CIP solution out

CIP solutions in

F1

F2

F4

F3

CLEANING OF THE BPHEs

9

2

0

9

9

-

9

5

3

0

R

8

P

r

i n

t e

d

o

n

1

0

0

%

r

e

c

y

c

l e

d

p

a

p

e

r . S

W

E

P

i s

a

I S

O

1

4

0

0

1

C

e

r

t i f i e

d

c

o

m

p

a

n

y

.

Channel plates

Cover

plate

Connections

Zero

hole

channel

plate

Cover

plate

Plate package

Plate material e.g.: N, stainless steel 304;

S, stainless steel 316;

M, Mo-steel L

L

H

H

L

L

H

H

=

F1

F1 F1

F6

F5

F2

F2

F2

F3

F3

F3

F4

F4

F4

B60 B9

D700

F1

F6

F5

F2

F3 F4

D700

Evaporator Condenser

Condenser

F2

F1

F3

F4

Water

outlet

Gas

outlet

Water

inlet

Liquid

inlet

The V-type BPHEs are equipped with a special

distribution device at the refrigerant inlet, i.e.

normally port F3. The purpose of the distribution

device is to evenly distribute the refrigerant in

the channel.

The refrigerant liquid should be connected to

the lower left connection (F3) and the

refrigerant gas outlet to the upper left

connection (F1). The water/brine circuit inlet

should be connected to the upper right

connection (F2) and the outlet to the lower right

connection (F4).

Expansion Valves

The expansion valve should be placed close to the inlet connection, whereas the

bulb should be mounted about 500 mm from the vaporized refrigerant outlet

connection. The pipe diameter between the expansion valve and the BPHE

should be the same as the diameter of the refrigerant liquid line.

For the evaporators, the pressure drop in the internal distribution system must be

added to the pressure drop in the expansion valve to arrive at the total pressure

drop. Normally, selecting the next larger size valve will give satisfactory

performance.

Evaporators; Three evaporator types (V, P, S)

Pipe Shear Force, Fs Tension Force, Ft Bending Moment, Mb Torque, Mt

Size (kN) (kp) (kN) (kp) (Nm) (kpm) (Nm) (kpm)

3.5 357 2.5 255 20 2 35 3.5

12 1224 2.5 255 20 2 115 11.5

1 11.2 1142 4 408 45 4.5 155 16

1 14.5 1479 6.5 663 87.5 9 265 27

1 16.5 1683 9.5 969 155 16 350 35.5

2 21.5 2193 13.5 1377 255 26 600 61

2 44.5 4538 18 1836 390 40 1450 148

3 55.5 5660 18.4 1876 575 59 2460 251

4 73 7444 41 4181 1350 138.5 4050 413.5

6" 169 17233 63 6424 2550 260 13350 1361

Different versions available

There are several different versions of the channel plate packages. Below are a

couple of examples.

Dual-Circuit BPHE (../D)

Two-Pass BPHE (../2P), which corresponds to two

units connected in series.

DESIGN CONDITIONS AND APPROVALS

The standard pressure rating used for SWEP BPHEs, i.e. for standard operating

pressure, is maximum 31 bar (3.1 MPa, 450 psi). SWEP offers a wide range of

pressure ratings based on applications, from low pressures (8 bar) up to high

pressures (140 bar). SWEP's standard maximum operating temperature is

225C (437F) for copper-brazed BPHEs, and 350C (660F) for Nickel brazed

BPHEs. However, as temperature and pressure are closely coupled, there is a

possibility to increase the pressure if the temperature is reduced. For details,

please check the label and other technical documentation.

SWEP's BPHEs are approved by a number of independent bodies, e.g.

Europe, Pressure Equipment Directive (PED)

USA, Underwriters Laboratories (UL)

Japan, The High Pressure Gas Safety Institute of Japan (KHK)

SWEP also has design approvals, e.g. from: Lloyds Register, Great Britain; Det

Norske Veritas (DNV), Norway; American Bureau of Shipping (ABS), USA;

Korean Register of Shipping (KR).

A number of SWEP's BPHEs are approved by the European approval PED

(Pressure Equipment Directive). For approved units the data on the label must

not be exceeded at any circumstances. The heat exchangers are designed for

use with fluids according to groupe1 in AFS 1999:4.

For operating conditions concerning the European approval PED, please see

Product sheets on www.swep.net. For more details on the respective approvals,

please contact SWEP.

LABELING SYSTEM AND OPERATING CONDITIONS

All s are equipped with an adhesive label which includes vital information

about the unit, e.g. type of heat exchanger (which indicates the basic BPHE

execution and material combination) and SWEP's item number. The label also

includes the serial number which is described below. The Operating Conditions;

state the maximum operating temperature and pressure as per the respective

approving organization.

BPHE

Bar-code serial number

2 00 11 715 2 0001

Number of circuits

Product code

Month 11, i.e. November

Year 00, i.e. 2000

Production Entity

Number in series

The engraved Serial Number

provides information about

where and when the BPHE

was produced.

MOUNTING

Never expose the unit to pulsations or excessive cyclic pressure or temperature

changes. It is also important that no vibrations are transferred to the heat

exchanger. If there is a risk of this, install vibration absorbers. For large

connection diameters, we advise you to use an expanding device in the pipeline.

It is also suggested that e.g. a rubber mounting strip should be used as a buffer

between the BPHE and the mounting clamp.

In single-phase applications, e.g. water-to-water or water-to-oil, the mounting

direction has little or no effect on the performance of the heat exchanger, but in

two-phase applications, the orientation of the heat exchanger becomes very

important. In two-phase applications, SWEP's BPHEs should be

mounted vertically, with the arrow on the front plate pointing upwards.

Several mounting suggestions for SWEPBPHEs are shown below.

Mounting stud bolts, in different versions and locations, are

available on the BPHEs as an option.

1. Supported from the bottom

2. Sheet metal bracket (rubber insert between bracket and exchanger)

3. Crossbar and bolts (rubber insert between the crossbar and exchanger)

4. Equipped with mounting stud bolts on the front or back cover plate

5. Support legs are available for some BPHEs

For smaller BPHEs it is also possible to mount the unit by simply suspending it

from the pipes/connections.

CONNECTIONS

All connections are brazed to the heat exchanger in the general vacuum

brazing cycle, a process which gives a very strong seal between the

connection and the cover plate. However, take care not to join the counterpart

with such force that the connection is damaged.

Depending on the application, there are a lot of options available for the

connections, different versions and locations, e.g. Compac flanges, SAE flanges,

Rotalock, Victualic, threaded connections and welding connections. It is

important to have the right international or local standard of connection, as they

not always are compatible.

Sealing surface

Rotalock Connections Victualic Connections Welding Connections

Flanges of DIN Type,

Compac flanges

Flanges of SAE Type SAE O-Ring Connections

Some connections have an external heel. The purpose of the heel is to simplify

the pressure and leakage testing of the BPHE in production.

Some connections are equipped with a special

plastic cap to protect the threads and sealing

surface of the connection and to prevent dirt and

dust from entering the BPHE. This plastic cap

should be removed with care, in order not to

damage the thread, sealing surface or any other

part of the connection. Use a screwdriver, pliers

or knife.

Threaded connections

Threaded connections can be female or male of well-known standards such as,

ISO-G, NPT and ISO 7/1. The exterior can also be hexagonal which is shown

below.

Externally Threaded

Connections (Male)

Internally Threaded

Connections (Female) of

Standard Type

Internally Threaded

Connections (Female)

with a Hexagonal Exterior

All BPHEs are vacuum-brazed with either a pure copper filler or a nickel-based

filler. Under normal soldering conditions (no vacuum), the temperature should not

exceed 800C (1470F). Too much heat could change the material structure

resulting in internal or external leakage at the connection. Because of this we

recommend that all soldering is made with silver solder containing min. 45%

silver. This type of solder has a relatively low soldering temperature and high

moistening and fluidity properties.

Soldering flux is used in order to remove oxides from the metal surface, and

thereby its property makes the flux potentially very aggressive. Consequently, it is

very important to use the correct amount of flux. Too much might lead to severe

corrosion, so no flux should be allowed to enter the BPHE.

Soldering connections are NOT recommended for welding, please choose

welding connections instead.

Soldering procedure

Degrease and polish the surfaces. Apply flux. Insert the copper tube into the

connection, hold in place and braze with min. 45% silver solder at max. 650C

(1200F). Do not direct the flame at the BPHE. Use a wet rag to avoid overheating

the BPHE. Protect the BPHE's interior (refrigerant side) from oxidation with N 2

gas. Warning: Excessive heating can lead to fusion of the copper and thus to the

destruction of the heat exchanger!

When SWEP supplies an adapter or flange which is soldered to the BPHE by the

customer, SWEPdoes not assume any responsibility for erroneous soldering nor

for any accidents that may occur during the process.

Combo Connection

SWEP's multifunctional BPHEs have the new Combo Connection, which improve

versatility and availability and makes it simpler for customers to find the right CBE

for their needs. The innovative Combo Connection combines a standard ISO-G

external thread with an internal soldering connection, enabling BPHEs to be

coupled to the system by threads or a soldering joint using the

same connection.

The soldering connections (sweat connections) are in principle

designed for pipes with dimensions in mm or inches. The

measurements correspond to the internal diameter of the

connections. Some of SWEP's soldering connections are

universal, i.e. fit both the mm and inch pipes. These are

denominated xxU, such as the 28U which fits both the 1 1/8

and 28.75 mm. Lifting instructions for larger BPHEs

Soldering Connections

Welding Connections

Welding is only recommended on specially de-

signed welding connections. All SWEP's welding

connections are executed with a 30 chamfer on

top of the connection. Do not weld on pipes on

other types of connections. The measurement in

mm corresponds to the external diameter of the

connection.

Welding Procedure

Protect the unit from excessive heating by:

a) using a wet cloth around the connection.

b) making a chamfer on the joining tube and

connection edges as shown.

+

Allowable Connection Loads for Pipe Assembly Conditions

Mb

Mt

The maximum allowable connection loads

given below are valid for low cycle fatigue. If

high cycle fatigue is involved special

analysis should be made.

Allowable connection loads for different pipe assembly conditions

Allowable Loads for Stud Bolt Assembly Conditions

Mounting stud bolts, in different versions and

locations, are available on the BPHEs as an option.

These stud bolts are welded to the unit. The

maximum allowable load on the stud bolts during

assembly are stated below.

Allowable loads for different stud bolt assembly conditions

M6 20,1 1400 3

M8 36,6 2600 8

M12 84,3 6000 27

Stud Bolt Stress Area, A (mm) Tension Force, Ft (N) Torque, Mt (Nm) s

STRAINERS

If any of the media contains particles larger than 1 mm (0.04 inch), we

recommend that a strainer with a size of 16-20 mesh (number of openings per

inch) is installed before the exchanger. The particles could otherwise block the

channels, causing bad performance, increased pressure drop and risk of

freezing.

INSULATIONS

Insulation for Refrigerant Applications

BPHE insulation is recommended for eva-

porators, condensers or district heating app-

lications, etc. For refrigeration, use extruded

insulation sheets, e.g. Armaflex or equivalent

which also can be supplied by SWEP.

Insulation for Heating Applications

For heating applications, various types of

insulation boxes can be used. The working

temperature range defines which insulation is

recommended. SWEP can supply some of these

insulation types as optional accessories.

Single-Phase Applications

Normally, the circuit with the highest tem-perature

and/or pressure should be connected on the left

side of the heat exchanger when the arrow is

pointing upwards. For example, in a typical water-

to-water application, the two fluids are connected

in a counter-current flow, i.e. the hot water inlet in

connection F1, outlet F3, cold water inlet F4,

outlet F2. This is because the right-hand side of

the heat exchanger contains one channel more

than the left-hand side, and the hot medium is

thus surrounded by the cold medium to prevent

heat loss.

F2

F3

F4

F1

INSTALLATION OF BPHEs IN DIFFERENT APPLICATIONS

Two-Phase Applications

In all refrigerant applications it is very important that every refrigerant channel is

surrounded by a water/brine channel on both sides. Normally the refrigerant side

must be connected to the left-hand side and the water/brine circuit to the right-

hand of the BPHE. If the refrigerant is incorrectly connected, to the first and last

channel instead of water/brine, the evaporation temperature will drop, with the

risk of freezing and very bad performance. SWEPBPHEs used as condensers or

evaporators should always be fitted with adequate connections on the refrigerant

side.

Dual-over-Two-Pass BPHE (../D2P)

1 2 3 4 5

Use TIG or MIG/MAG welding. When using electrical welding circuits, connect the

ground terminal to the joining tube, not to the back of the plate package. Internal

oxidation can be reduced by a small nitrogen flow through the unit.

Make sure no traces of copper are adjacent to the prepared joint. If grinding is

used for joint preparation, proper measures must be taken to prevent copper from

being ground into the stainless surface.

UNCStud Bolt Stress Area, As (in) Tension Force, Ft (lbf) Torque, Mt (lbfin)

1/4" 0.032 315 27

5/16" 0.053 585 71

1/2" 0.144 1349 239

Keep safety distance 3 m (10 ft) when lifting.

Lifting Heat Exchanger

from horizontal to

vertical position

Lifting in

horizontal

position

Lifting in

vertical

position

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 1.vendor List - Rev.6Document174 pages1.vendor List - Rev.6arianaseri100% (1)

- Neway International Group Head Office: CNC Equipment (Suzhou) Co.,LtdDocument18 pagesNeway International Group Head Office: CNC Equipment (Suzhou) Co.,LtdarianaseriNo ratings yet

- Data Sheet - UMEB - IP55Document2 pagesData Sheet - UMEB - IP55arianaseriNo ratings yet

- 5S Checklist ReaderDocument1 page5S Checklist ReaderarianaseriNo ratings yet

- 6 Polley Compabloc FDocument5 pages6 Polley Compabloc FarianaseriNo ratings yet

- OG Brochure - Alloys InsertDocument2 pagesOG Brochure - Alloys InsertarianaseriNo ratings yet

- لکش 1 یهد ششوپ کیتامش شیامن CVD و PVDDocument5 pagesلکش 1 یهد ششوپ کیتامش شیامن CVD و PVDarianaseriNo ratings yet

- Ma30 WDocument2 pagesMa30 WarianaseriNo ratings yet

- Sales Proposal Sales Proposal Template 1.doctemplate 1Document5 pagesSales Proposal Sales Proposal Template 1.doctemplate 1arianaseriNo ratings yet

- High Perf Metals Brochure v1Document5 pagesHigh Perf Metals Brochure v1arianaseriNo ratings yet

- CPDocument55 pagesCParianaseri100% (2)

- Training Session4 - Heat Recovery Steam GeneratorsDocument34 pagesTraining Session4 - Heat Recovery Steam GeneratorsarianaseriNo ratings yet

- PLATE & SHELL Heat Exchangers: A Shell & Tube AlternativeDocument4 pagesPLATE & SHELL Heat Exchangers: A Shell & Tube AlternativearianaseriNo ratings yet

- Experimental Determination of Fouling Factor On Plate Heat Exchangers in District Heating System PDFDocument8 pagesExperimental Determination of Fouling Factor On Plate Heat Exchangers in District Heating System PDFarianaseriNo ratings yet

- Grooved Kempchen PDFDocument11 pagesGrooved Kempchen PDFAnonymous Iev5ggSRNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ISO 2819-2018 Choque TérmicoDocument27 pagesISO 2819-2018 Choque TérmicoRosario Castaño100% (1)

- Module 5, PDFDocument287 pagesModule 5, PDFPethurajNo ratings yet

- Manual de Serviço Televisor LG 55LX6500 e 55LX6500-SD - Chassis LJ03RDocument68 pagesManual de Serviço Televisor LG 55LX6500 e 55LX6500-SD - Chassis LJ03RClaudio PietrantonioNo ratings yet

- Service Manual (Phillips 32 Led) 32ME303V - F7Document53 pagesService Manual (Phillips 32 Led) 32ME303V - F7cris2150% (1)

- Toshiba 40WL768 Ver.2 Service ManualDocument268 pagesToshiba 40WL768 Ver.2 Service Manualhoang tranvanNo ratings yet

- Mitsubishi Service ManualDocument70 pagesMitsubishi Service ManualMakhtar Seye100% (1)

- Yamaha RX v573 HTR 5065Document134 pagesYamaha RX v573 HTR 5065jiktorNo ratings yet

- Datasheet PDFDocument15 pagesDatasheet PDFperro sNo ratings yet

- Fittings and ValvesDocument6 pagesFittings and ValvesRheina lean ayoNo ratings yet

- Philips+HTS-3155 78 PDFDocument28 pagesPhilips+HTS-3155 78 PDFflavio eduardoNo ratings yet

- Module 4 - Laying of Underground Cables - T&GDocument42 pagesModule 4 - Laying of Underground Cables - T&GDeepak100% (2)

- 74HC Hct4046a CNVDocument34 pages74HC Hct4046a CNVmagicecstaticNo ratings yet

- Pioneer XV BD422b Service ManualDocument85 pagesPioneer XV BD422b Service ManualKamil Gocejna100% (1)

- JVC LCD Lt-19da1bj - BuDocument66 pagesJVC LCD Lt-19da1bj - BungoclinhdtddNo ratings yet

- DP-1520 SM PDFDocument496 pagesDP-1520 SM PDFIon JardelNo ratings yet

- Type Abz PDFDocument15 pagesType Abz PDFle khánhNo ratings yet

- Bright 1958 Automation and ManagementDocument25 pagesBright 1958 Automation and ManagementGrupo sufrimiento, salud mental y trabajo.No ratings yet

- TM10 450Document119 pagesTM10 450Christophe BrissonnetNo ratings yet

- Your Ultimate Guide To Choosing The Best Drone PCBDocument9 pagesYour Ultimate Guide To Choosing The Best Drone PCBjackNo ratings yet

- SVC6000 Service ManualDocument140 pagesSVC6000 Service ManualChristopher CollinsNo ratings yet

- Led - Everlight - 67 21S R2C D2030B8L31926Z6 2T - V1Document10 pagesLed - Everlight - 67 21S R2C D2030B8L31926Z6 2T - V1Carlos H. GojleviciusNo ratings yet

- Zx135us Workshop ManualDocument707 pagesZx135us Workshop ManualHalil Kara100% (3)

- Service Manual: Digital Video Camera RecorderDocument74 pagesService Manual: Digital Video Camera Recorderricahard61No ratings yet

- TE Connectivity Raychem S01 03 R DatasheetDocument7 pagesTE Connectivity Raychem S01 03 R DatasheetРоман ДяченкоNo ratings yet

- Kenmore Power Miser 9 #153.327466 ManualDocument32 pagesKenmore Power Miser 9 #153.327466 ManualjkwandmanNo ratings yet

- AR4 Robot ManulDocument289 pagesAR4 Robot ManulMohammad NasutionNo ratings yet

- Service Manual: Conditions of UseDocument44 pagesService Manual: Conditions of Usealvhann_1No ratings yet

- ASCEN SMT Conveyor List 0Document22 pagesASCEN SMT Conveyor List 0Igur EuiNo ratings yet

- Alpha CVP390 PDFDocument7 pagesAlpha CVP390 PDFSergio MoyaNo ratings yet