Professional Documents

Culture Documents

6a24a3bf68fa3eb9f5f1059d45f7a1ea

Uploaded by

qidohs0 ratings0% found this document useful (0 votes)

39 views13 pageste

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentte

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views13 pages6a24a3bf68fa3eb9f5f1059d45f7a1ea

Uploaded by

qidohste

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

CONCEPTUAL MODEL OF BUSINESS PROCESS RE-ENGINEERING: A

CASE STUDY OF A CARGO COMPANY IN MALAYSIA

Syafrani Fithri and Jamaiah H. Yahaya

Faculty of Information Science and technology

University Kebangsaan Malaysia, Bangi 43600

Selangor, Malaysia

Sfithri23@gmail.com, jhy@ftsm.ukm.my

ABSTRACT

Faced with the growth of business enterprises

as well as consideration of the increasing

competition in freight business to Indonesia,

MS Company realizes that the companys

business process needs changes to effectively

and efficiently support the decision making

process as well as to increase the

competitiveness of the business and the

company. Business process re-engineering

(BPR) is not just the program of business

process improvement, but more than that, it

can improve the operations of the business

process as a whole. Improvement priorities of

the company are on the improvement in the

operation division which includes the

administration, customer service and

operations. Improvement of the system is done

by changing the system from being manually

run into a computerized system that runs with

an emphasis on the achievement of

improvements in the effectiveness of the

speed of processing time, cost efficiency and

human resources as well as an increase in

level of customer service. Change of the

system and program on MS Company were

conducted by implementing four main phases:

1) Building vision and objective, 2)

Identification of existing process, 3)

Identifying process improvements, and 4)

Building of a prototype. This paper explains

the phases in more detail and presents the

conceptual model for MS Companys BPR

model.

KEYWORDS

Business process reengineering, Conceptual

model, SME.

1 INTRODUCTION

Nowadays the business environment has

become so fiercely competitive that it needs

strong relationships between the customers

and leading production, manufacturing, and

service companies. Unfortunately, many such

companies are still experiencing various

problems for their competitiveness in the

world market and fulfilling customers

demands. This phenomenon occurs because of

several reasons. The first reason is when the

companies are not well prepared to face

rapidly changing technologies and the high

pace of product development. The second

reason arises when companies cannot control

resource utilization, inventory level, and

system performance. The third reason is that

error rates of customer order fulfillment are

high and their inquiries are ignored for long

time. These management problems can lead to

high turnover of the staff and loss of money. It

can be observed that this critical situation

threatens the survival of the companies despite

restructuring and downsizing. It reflects the

fact that the traditional methodology of

improvement programs, such as restructuring,

36

downsizing, rationalization, and automation,

have not been able to solve the system

performance problems in the companies

concerned.

According [1] stated that the main

objective of business process re-engineering

(BPR) is to radically redesign business

organizations to achieve dramatic

improvements in order to make more efficient

business processes, improve quality and

shorten the time for making decisions.

According to [2] business process re-

engineering is defined as a radical re-design of

processes in order to gain significant

improvements in cost, quality, and service.

Firms have been re-engineering various

business functions for years, ranging from

customer relationship management to order

fulfillment, and from assembly lines to

logistics.

Why do we need to do re-engineering?

Some argue that the purpose of business

process re-engineering is to make all

processes within the organization to be the

best in its class [3]. According to Andrews and

[4] the purposes of business process re-

engineering, as mentioned by [5], are to:

1. Enhance the organization's ability to

produce a particular good or service and

maintain mass production.

2. Improve satisfaction with the goods or

services so that customers will choose the

goods or services over competitors.

3. Make it easier and enjoyable for customers

to do business with the company.

4. Decide organizational boundaries,

bringing customers to channel information

through communication, networking and

computer technology.

5. Speed up response time to customers,

eliminate errors and dissatisfaction, and

reduce the development of goods or

services in factory cycle time.

6. Raise customer demand for more

processing and increasing the volume of

each customer and to determine the price

of "value-driven" to the customer without

reducing profitability.

7. Improve the quality of work and the

individual's ability to contribute to the

company.

8. Improve the usability of knowledge

sharing and organization so the

organization does not depend on the

expertise of several people.

BPR could also be at risk when a large

enterprise acquires small fast-growing

companies to power its own growth engine

[6]. Integration of business processes across

disparate organizations with different cultures

requires careful planning and involves process

automation, globalization, system selection,

downsizing, and information security. It is

important to streamline and automate

processes in order to improve efficiency and

reduce operating cycle times. According to [6]

ideally, during re-engineering, processes

should be built from scratch based on evolving

business needs, changing market conditions,

as well as innovations in technology. This

helps avoid disruption of organizational

operations and allows for more flexible time

constraints during implementation. Several

compromises must be made during this re-

design. This paper presents a framework for

BPR using a structured analytic approach to

make business decisions

2 LITERATURE REVIEW

2.1 Business Process Engineering in the face

of competition

BPR is known as a way to achieve

competitive advantage in business. This

approach was experienced by Wrigley, an

American company, to re-engineer their IT

infrastructure. This company made the

improvements in boarding arrangements,

customer service, and productivity. By

implementing the BPR, the company managed

to achieve the advantages of Wrigley's

37

competitiveness. This has been proved by the

fact that an excess of competitiveness in

boarding, handling customer service, qualities

and productivity achieved a minimum low

score [7].

2.2 An airline's cargo handling process

A previous project involving airline cargo at

an international airport was studied and

reviewed. The company was improved by

taking up a BPR technique with a view to

achieve the following objectives:

1. To improve the cargo services;

2. To shift to the automatic or semi-

automatic system from the manual system

if it exists;

3. To re-think on adopting modern or

updated concepts and methods of air cargo

handling processes used in freight

services;

4. To reduce clerical assignments as much as

possible;

5. To re-design and develop elective methods

to exchange required information and data

as fast as possible;

6. To reduce total time taken for completing

export shipment operations starting from

the truck unloading point on the ground to

loading into the aircraft.

There are several ways to improve

processes and make them better, faster and

cheaper. Efforts to improve processes must be

fact-based. It means process improvements

should be based on systematic observation and

collection of quantitative data which will

allow first a focus on major problems and then

on steps taken to eliminate waste. In other

words, a standard method is needed to identify

the areas that need to be broken, reduced and

fixed-refixed. A seven-step process

improvement can be summarized as follows:

1) Definition of process boundary, 2)

Observation of process steps, 3) Collection of

process-related data, 4) Analysis of collected

data, 5) Identification of improvement area, 6)

Development of improvements and 7)

Implementation and monitoring of

improvements [8].

2.3 The Distribution Theory of Innovation

in BPR

This study presents a case study at the

University of Turku which describes the

process re-engineering human resource

management related to organizing the teaching

and other duties in the Applied Science

Degree Program at the University of Turku

using the diffusion of innovation theory [9]. It

also uses a three-phase re-engineering process,

starting with the natural process and end

process re-engineering.

2.4 Workflow Management Technology

for Business Process Re-engineering

American companies and government

agencies alike are striving to improve,

streamline, and automate their business

practices to adjust to the rigorous demands of

a highly volatile marketplace, austere financial

resources and manpower reductions. Research

was conducted by using workflow data

gathered from the Port Hueneme Division of

the Naval Surface Warfare Center (PHD

NSWC). The proposed methodology consists

of five phases and 32 component steps with

associated data collection forms. The purpose

of this research was to conduct a thorough

study into structured methodologies available

for enabling business process re-engineering

(BPR) through the use of workflow

management automation. The proposed

Workflow Re-engineering Methodology

promises to be a methodology that can be used

with supporting workflow automation to

improve an organization's business processes.

Using this methodology, the researcher could

achieve the following: Increased Productivity,

heightened Competitive Advantage, Reduced

Costs, Increased Communications, Improved

Process Control, Reduced Manpower, and

Support for Process Re-engineering [10].

38

The methodology used in the above

research by Bitzer was not applicable to all

domains and predicted size. Of 32 steps, there

are only 19 steps which are appropriate for

small and medium enterprises in particular for

MS Cargo. This step will be explained in the

next section.

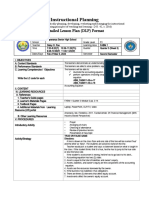

3 RESEARCH APPROACH

This research was conducted based on the

methodology used by [11], [9], [12]. The

methodologies mentioned from the previous

researchers above are summarized into four

main phases as follows:

Phase 1: Building of vision and objective

Phase 2: Identification of existing process

Phase 3: Identification of process

improvements

Phase 4: Building of prototype

For each phase there are steps and associated

activities that can be referred to in Figure 1.

Figure 1. Workflow Re-engineering Methodology

4 CASE STUDY

This research was carried out in a case study

which involved a cargo company in Malaysia

(which will be named as MS Company). MS

Company is engaged in serving delivery of

goods from Malaysia to Indonesia. This

company was established in 2001 with the

motto "Your Package Our Responsibility".

It is operated and supported by several

sections involving the treasury, customer

service, operation, administration, marketing,

human resource, warehouse and information

technology divisions. These various

divisions have to work together

collaboratively to produce a good business

processes. Business processes that are

operating now in MS Company is a business

process that is less impressive because it runs

manually, resulting in business processes

which are less effective and inefficient. This

research project aims to help this company to

analyse and improve its existing business

processes to produce enhanced and integrated

processes befitting a competitive enterprise

company. This case study focuses on 3 main

divisions: customer service, operation and

administration.

The case study was implemented based on

the approach discussed earlier in section 3.

The following sections will explain the steps

and activity carried out in each phase.

4.1 PHASE 1: BUILDING OF VISION

AND OBJECTIVE

In this phase, a need for improvement in the

way business operations is identified and

recognized. The business cycles of the

organization are identified, and a vision for

the organizations future is established. The

project environment is defined and a business

39

cycle is selected for improvement. A proactive

change management program is employed

throughout the organization to prepare all

employees for modifications to business

operations and to train them on how to operate

the workflow management tool. In this phase

six steps were conducted.

Step 4.1.1: Identification of a Need for

Process Improvement

MS Company ensures that customer

requirements are determined from the time of

service assurance and ensures that customer

requirements are prescribed and filled with the

aim of enhancing customer satisfaction.

To ensure that the BPR model developed

meets the perfect integration of the system and

services, the top management should be

involved. The requirements were obtained by

means of interviews. Interviews with the

stakeholders are also conducted in order to

ensure business processes are consistent with

the strategy planning of MS Company. In

addition the answers from the respondents via

interviews served as the inputs to the new

BPR model and prototype which will be

developed in this research. In the interview

sessions, staff involved in each division is

aware of all activities and information related

to their tasks and responsibility as well as the

requirements of this research project. At first

the researcher presented the Project

Management Plan to all staff to provide better

understanding to all the people involved in

this exercise. The interview sessions were

conducted with three senior officers of the

company. In the interview sessions the

respondents gave good response and feedback

collaboratively.

Step 4.1.2: Establishing Change of

Leadership Roles

The organization must establish key

leadership roles to support and assist the

change team. These roles include a re-

engineering leader, and an executive level re-

engineering steering committee. The leader is

an executive-level manager who creates a

corporate vision, motivates, oversees the re-

engineering effort, and ensures that the

program has continuing financial and

managerial support. The steering committee is

a group of senior managers who define the

organizations re-engineering strategy. The re-

engineering leader is often the chairperson of

this committee. The committee determines

project priority, controls resource allocations,

and provides problem resolution assistance to

re-engineering teams.

The General Manager is personally, as is a

general manager's function, solely responsible

for all operational activities to support

activities of MS Company deliveries "door to

door" to reach the destination. The General

Managers responsibilities include

implementation, maintenance, and

improvement of management systems,

classification of events, and initiation of

preventive action to minimize aberrations.

The Operations Manager is responsible for

organizing, specifying, and controlling the

intake of ordering items from the list based on

customer service.

The Customer Service Manager is the

person directly responsible for dealing with

customers and serves the customer if there are

complaints.

The Administration Manager is the person

responsible for container booking, applying

for Malaysian and Indonesian customs

clearance, liaison with the Indonesian

embassy and process and approval of

payment.

Step 4.1.3: Introduction of Automated

Workflow Management Technology

Each unit in an organization needs strong

coordination with each other. However, the

problem is that each unit usually has different

working technologies. Each unit is still

necessary in coordination so that

40

organizational goals can be achieved.

Information technology infrastructure is

needed to support the connectivity throughout

the organization. Members in this team

provide information on the necessity of IT

support. IT services will need to identify,

acquire, and install the necessary

infrastructure support to provide connectivity

throughout the organization.

Step 4.1.4: Briefing, Educating, and

Training of a Change Team

In this step, the selected staff will be collected

to perform workflow modeling and system

improvements. The staff consisted of an

individual from the financial division, and

one person from the warehouse division.

Analyzing and re-designing should be

completed within a limited time, as at least a

certain level of commitment is required for

this project be successful [13]. The staff

involved will be briefed, and educated on

workflow management.

Step 4.1.5: Identification of the Business

Cycle

Next, the organization of the business cycle

must be identified and recorded. To determine

the organization of the business cycle, and

changes to be made, the team should identify

the mission and goals of the organization to

gather and review any regulations or

instructions governing the operation. They

also need to consult with the executive

director for clarification and confirmation of

business objectives. This would explain the

current work on the Administration division

(Table 1). Prior to this step the flowcharts of

all services in this case study will be

produced.

Step 4.1.6: Creation of an Organizational

Vision

The Mission and Vision need to be defined

initially as they will determine strategic

management. But they are not something that

should be fixed, because the Vision and

Mission of a company will change after seeing

the new realities that may should be fixed,

because the new realities that may become

obvious after analyzing the external and

internal environments.

The Vision of MS Company is to be a

company capable of operating in line with

international companies in the field of

shipping goods to the destinations of Malaysia

and Indonesia through optimization of its own

strength and sensitivity to the market

environment.

The Mission of MS Company is to be a

freight forwarding company that can compete

with international companies through the

optimal delivery of services at a minimal price

and be able to play a role in the creation of

jobs.

4.2 PHASE 2: IDENTIFICATION OF

EXISTING PROCESS

During the second phase of this research, the

business products of the business cycles are

reviewed and identified. The component

processes of the cycle are distinguished and

selected for improvement. There are 5 steps

involved in this phase and these are explained

in the following sections.

Step 4.2.1: Catalog Business Products

The change team identifies the products that

result from the completion of the chosen

business cycle. Using the Business Process

Identification Form, shown in Table 1, each

products form (physical or electronic) are

identified and recorded. Table 2 shows the

Business Process Identification Form for

Administration, Table 3 shows the Business

Process Identification Form for Customer

Services and Table 4 shows the Business

Process Identification Form for Operational

Division

41

Table 1.Flowchart of Administration Division

Flow Diagram Explanation

Make forecast for procuremant of

container -1

Making manifest of goods into the

warehouse -2

Information prepare for

loading from warehouse to

container -4

Reservation container -3

Match

Procedur Car/

Par -5

Proses Loading to

coaintainer -6

Send data for draft Bill

of Lading (shiping

Intruction) -7 Send Manifest to

Indonesia -9

Send Manifest to Embassy for

confirmation -10

Send document to

customs -11

Bill of Lading

Indonesia -8

Match

No

Yes

yes No

Distribution of goods in

Indonesia -13

Last Report

Distributor -14

Match

Customer -16

Finish

Indonesia

customs -12

Report to CS

-15

No

Yes

1. The administration makes predictions based on

previous years data and provides the container to

implement the forwarding

2. Make manifest according to receipts from the

operation and data entry of goods in warehouse

3. If the goods in the warehouse are suitable,

prediction or at least able for loading goods into

containers then make sure to return to prepare for

the arrival of containers

4. Ensure the warehouse for loading goods into

containers where the goods are suitable for

container loading and ready

5. If the goods are in accordance with the manifest

the receipts are then directly inserted into

container; when it is not done the reporting in the

form of car/ par, to be followed up, and the goods

will be separated first.

6. Carry out the process of loading into the container

while a record of the suitability of goods with the

documents in the manifest/ receipt is made.

7. Perform data transmission draft Bill of Lading

8. Bill of Lading was obtained in Indonesia

9. Do the delivery manifest to Indonesia

10. Do the delivery manifest to the Embassy to be

confirmed

11. Perform transmission of documents to customs

12. if it does not match/have a problem, coordination

with Indonesian customs

13. if it matches do distribution goods in Indonesia

14. Admin gets the final report of the delivery status

15. If there are problems they will be reported to the

customer service

16. If appropriate then, that data kept by the admin.

42

Table 2. Business Process Identification Form for

Administration

BUSINESS PROCESS IDENTIFICATION

FORM for Business Cycle, Administration

No Form Business Process Priority

1 Loading

Forms used for the

admin and the

warehouse for a list

of data items into the

container.

Important

2

Shipping

instructi

on

Details of shipping

containers used for

Malaysian customs

with a copy of

passport of one of the

representatives on

behalf of the sender

to be given to the

forwarding agent

after loading the

goods.

Important

3

Bill of

Lading

Receipt and is signed

by the Malaysian

customs, the goods

are received in good

condition, clear and

ready to depart.

Important

4 Manifest

Detail of data items

in the container, its

data is sent to the

Embassy and

distributor in

Indonesia

Important

5

BSTK /

additiona

l items

Form of Indonesian

distributor about

container receiving

report

Important

Table 3. Business Process Identification Form for

Customer service

BUSINESS PROCESS IDENTIFICATION

FORM for Business Cycle Customer Service

No Form Business Process Priority

1

DO

(delivery

order)

List of addresses and

telephone numbers

of customers and

agents who want to

order a box or a

Important

request goods to be

taken to send to

Indonesia.

2

CB

(checking

goods)

Report of the

customer or agent

that the goods have

not been sent to the

recipient, and the

goods have not

arrived for less than

one month.

Important

3

SLP

(shipmen

t through

the

period)

Report of the

customer or agent

that the goods have

not been sent to the

recipient, and the

goods have not

arrived for more than

a month.

Important

4

RPA

(request

exchange

address

or phone

number)

Reports from

customers that the

phone number or

address of the

recipient in Indonesia

have been exchanged

for new ones. Or

distributor to the

ministry asking

customer service to

look for a new phone

number because the

numbers in the

receipt could not be

reached

Important

5

TDC

(technica

l

distributi

on case)

Reports from

customers that the

goods are delivered

to Indonesia down

the road (not to

home) or the

Indonesian side

requested the

distribution of goods

delivery.

Important

6

OPR

(open

report)

Reports from

customers that the

goods sent there are

missing or damaged.

Important

43

Table 4. The Operation of the business cycle

component

BUSINESS PROCESS IDENTIFICATION

FORM for Business Cycle Operational

No Form Business Process Priority

1

SPJ

(Permit)

Warrant the path

given by the

operations

manager or

assistant manager

of operations for

drivers who run to

take the goods

Important

2

DO

(delivery

order)

List of customer

addresses of each

area prepared by

the customer

service to pick-up

Important

3 Resit

Proof that the

customer has

delivered the

goods to the

officer to be sent

to the destination

and the customer

pays shipping

costs.

Important

4

STBA

(receipt of

goods

dealer)

The driver takes

the goods to the

agent and then

writes handover

of goods agent

accreditation

forms.

Important

5

LDO (

delivery

order

report)

Form to enter

details of items

taken from the

customer or agent.

Important

6

Daily

Report

Daily report that

contains the

number of

incoming goods

and the carrying

box to the

customer and

agent.

Important

Step 4.2.2: Identification of Business

Processes

During this step, the business cycle is

decomposed into its component processes by

identifying how each business cycle product is

created. Using the Business Process

Identification Form, the change team records

the process name and the priority assigned to

the tasks: low, routine, high, urgent. The

priority of the tasks is assigned by the offices

in the divisions. The priority of the process

will be used to determine work assignment

and precedence. Table 5, Table 6 and Table 7

show the results of the business processes and

the time of completion.

Table 5. The administration of the business cycle

component

Task Priority Time

Completion

make a forecast routine 1 day

Loading routine 3 days

Delivery shipping instruction urgent 1 day

Bill of lading urgent 2 days

Make manifest routine 4 days

Send documents to the

Embassy

urgent

1 day

Send documents to the

customs Jakarta

urgent

1 day

Distribution of goods to

Indonesia

routine

4 days

Table 6. The Customer service of the business cycle

component

Task Priority Time

Completion

Pick-list High 1 day

CB (checking goods) Low 1 day

SLP (shipment through the

period)

High

7 days

RPA (request exchange

address or phone number)

High

2 days

TDC (technical distribution High 2 days

44

case)

OPR (open report) High 7 days

replacement of the goods High 4 days

Table 7. The Operation of the business cycle

component

Task Priority Time

Completion

For pick-zoning High 1day

Take the empty boxes from

the warehouse

Routine 30 minutes

Take the goods to the

customer and agent

High 9 hours

Writing of receipt High 15 minutes

Make the LDO High 30 minutes

Submit receipt to the admin High 5 minutes

Deposit money into

Finance

High 15 minutes

Creating a Daily Report Routine 1 Hour

Step 4.2.3: Selection of a Process for

Implementation and Improvement

Once all the processes of a business cycle are

identified and recorded, the team selects a

single business process for implementation

based on a set of factors. A Weighted

Selection Approach to rate each process on a

scale of one to five on the factors of

changeability, performance, and business and

customer impact [14].

To determine the value for each element,

the change team must answer the following

questions:

Changeability: How easily can the process

be fixed? (1 = Cannot be changed; 5 =

Easily changed)

Performance: How does the process

presently function? (1 = Well; 5 = Badly)

Business Impact: How important is the

process and its product to the success of

the company? (1 =Unimportant; 5 =

Critical)

Customer Impact: To what extent is the

customer concerned with or affected by

the present state of the process or its

product? (1 = Unconcerned; 5 = Highly

concerned)

The process with the highest total score is

the process that is in the greatest need of

improvement. Therefore, the change team

selects this process for automation and

improvement. The ranking of each process is

recorded, in order of their re-engineering

priority on the Business Process Identification

Form. These rankings are used to schedule the

remaining processes for future improvement

projects.

The change team committee must identify

the owner of the selected process. The process

owner is the senior manager responsible for

the effective and efficient functioning of that

particular process. He/She should understand

the tasks involved in the entire process and be

able to predict how any proposed changes

might affect both the process and the overall

business cycle.

Step 4.2.4: Construction of a Work

Breakdown Structure

The change team act together to build a work

breakdown structure. Description from the

business cycle is then composed into several

parts. Composed goal is to make a more easily

understood and modeled. The process is

divided into sub-components of the process,

further subdivided into steps of the actual

work of the process.

4.3 PHASE 3: IDENTIFYING PROCESS

IMPROVEMENTS

Business process improvement is the third

phase in this research approach. This phase

was carried out in four main activities or steps.

Step 4.3.1: Considering the Customers'

Requirements

Because the company's customers know

about what they want from the business

45

processes and products, their requirements

must be considered in determining the goals of

new processes. The change team had meetings

with customers representatives to discuss and

record their needs, ideas of improvement, and

performance objectives. A survey was then

created and posted to gather broad customer

base needs. Direct contact, however, should be

used whenever possible to demonstrate a

strong commitment to customer needs and to

foster a better relationship.

Step 4.3.2: Benchmarking against Industry

Competitors

In the recent years, the increasing number of

actors has created a tight market competition

in businesses. Even now this is a competition

among entrepreneurs with other business

actors and is getting more complex. It is

necessary for a company to know their

competitors in their business environment to

stay competitive and maintain its presence in

the business.

Without new innovations from the

company, customers will quickly get bored

and the business would sink in the midst of

much competition. That is why the

competitors would work towards both

innovation in the internal affairs of the

company as well as enhancing the

competitiveness of their products. To achieve

this goal, the team must be aware of changes

and adapt to any new methods and

technologies employed in the industry.

These information sources may include

the publishing industry, academic research,

consulting firms, and visits to other companies

inside and outside the circle of their

competitiveness. For this case study, we have

identified nine competitors with similar effort

and services provided. In response to these

competitors, MS Company has undertaken a

number of strategies such as providing an

appropriate price, having its service profile

published in the magazine of the Embassy of

the Republic of Indonesia-Malaysia, serving

the customers door to door, and giving 1 free

shipping for customers who have sent goods a

total of 5 times.

Step 4.3.3: Specifying of Performance Goals

Using data collected from customers and

benchmarks, processes and objectives stated

in the vision statement of the organization, the

team determines the whole process of

performance goals (in terms that can be

measured) for each key performance indicator

implemented in the workflow. Each of these

goals is recorded in order of priority in the

process of performance form. This amount is

then divided into each component task process

and the task performance recorded in each

form.

Step 4.3.4: Construction of New Workflow

Models

Based on previous activities and inputs the

new workflow model which consists of

integrated processes and components for MS

Company will be produced in this step. Figure

2 shows the general and conceptual model of

BPR with four main components. The

components are people, input, output and the

technical component. The new model is the

process integrated model proposed by this

research and will be evaluated by this case

study.

The components have links inter connected

with each other, and each component has a

very important role for MS Cargo.

The Distributor is a person who is given

responsibility for delivery of goods after

the container lands up in Indonesia.

The Customer is someone who repeatedly

comes to a similar place to gratify his

desire to have a product or a service by

paying for the product or service.

The Agent is someone who helps MS

Company in finding and selling services to

customers. Agents are also able to explain

46

the distribution of goods to reach the

receiver.

The Database is a collection of data items

inter-related to each other, organized

based on a schema or a particular

structure, stored in computer hardware and

software to do the manipulation for

specific purposes.

The System is a group element / elements

that are interconnected and affect each

other in doing the activities together to

achieve the goal.

The Input is a process that is running in

MS Company. Processes are those such as

the ordering of items, sending the box and

taking the goods, and serving customers'

complaints. All processes were done

manually, so often delay and errors occur

in input data.

The Output is a new process that will be

developed, integrating the three divisions

into a single system. The new process will

run automatically and are expected to

reduce errors and deficiencies that have

occurred over the years.

BUSINESS PROCESS

REENGINEERING

Customer

People

TECHNICAL SOFTWARE/ SYSTEM

Distributor /

vendor

Agent

Database System

Staff

OUTPUT

INTEGRASI NEW

MODEL

INPUT

1. Prosess of ordering goods

2. Process of delivery and

pick-up box

3. Serve and resolve customer

complaints

4. Input data resit

Figure 2. The Conceptual Model of BPR

5 CONCLUSION

The case study showed that WRM (Workflow

Reengineering Methodology) promises to be a

methodology that can be used successfully to

improve an organizations business processes.

The data collection and process identification

forms significantly streamlined the process

definition effort, ensuring that all relevant

information was gathered from workflow

participants.

WRM is comprehensive, covering the

process improvement effort from the

identification of a need for change to the final

implementation and maintenance of the

improved workflow. The method can be

applied to different processes and is designed

to be easy for all personnel to learn and

understand. Simple forms and detailed

guidance are provided for all phases and steps.

Our research has proposed a new enhanced

methodology of WRM to suit small and

medium-sized companies. A conceptual model

of BPR for SME has been proposed in this

paper and currently is at the stage of being

evaluated.

47

This study is at the stage of developing

an integrated BPR model for MS Company.

The model will be validated by a prototype.

6 REFERENCES

1. James D.M., Heather A.S.: Managing IS-User coes

in conflict. Management challenges in IS :

Successful strategies and appropriate action.

England: John Wiley & Son West Sussex (1996).

2. Ozcelik Y.: Do business process re-engineering

project payoff? Evidence from the united state.

International Journal of Project Management 28

(2010), pp. 713 (2010).

3. Soumitra, D.: Software Engineering in Europe: A

Study of Best Practices. IEEE Software 16(3), pp.

82-90 (1999).

4. Andrews and Stalick.: Organizational change; Re-

engineering (Management); Management. Yourdon

Press (Englewood Cliffs, NJ) (1994).

5. Sitorus Iskandar.: Fenomenologi Manajemen

Rumah Sakit., Suara pembaruan daily. 10 March

2007. (2007).

6. Goel S and Chen V.: Integrating the global

enterprise using Six Sigma: Business process re-

engineering at General Electric Wind Energy., Int.

J. Production Economics 113 (2008), pp. 914927.

(2008).

7. Mumford, E., Beekma, G.J.: Tools for Change and

Progress: A Socio-technical Approach to Business

Process Re-engineering. CG Publications, UK

(1994).

8. M.R. Rotab Khan.: Business process re-

engineering of an air cargo handling process. Int.

J. Production Economics 63 (2000), pp. 99-108

(1999)

9. Juha Kontio.: Business Process Re-engineering: A

Case Study At Turku University Of Applied

Sciences, Proc. of European and Mediterranean

Conference on Information Systems 2007

(EMCIS2007) June 24-26 2007, Polytechnic

University of Valencia, Spain www.emcis.org

(2007).

10. M. Bitzer.: Workflow Re-engineering: A

Methodology for Business Process Re-engineering

with Workflow Management Technology, Masters

Thesis, Naval Postgraduate School, September

1995. (1995).

11. LT Sharon M. Bitzer & Magdi N. Kamel.:

Workflow Re-engineering: A Methodology for

Business Process Re-engineering Using Workflow

Management Technology. (1997).

12. Arun Kumar and Linet Ozdamar.: Business

Process Re-engineering At The Hospitals: A Case

Study At Singapore Hospital, Proc. 18th European

Simulation Multi conference Graham Horton (c)

SCS Europe, (2004)

13. M. Hammer and J. Champy.: Re-engineering the

Corporation, New York: Harper Business. (1993).

14. H. J. Harrington,: Business Process Improvement,

New York: McGraw-Hill, (1991).

48

You might also like

- Introduction To Internal AuditsDocument27 pagesIntroduction To Internal AuditsqidohsNo ratings yet

- InternalauditreportDocument6 pagesInternalauditreportqidohsNo ratings yet

- InternalauditreportDocument6 pagesInternalauditreportqidohsNo ratings yet

- InternalauditreportDocument6 pagesInternalauditreportqidohsNo ratings yet

- ISO 9001 Operational Procedure QOP-56-01 Management Review PT ASADocument5 pagesISO 9001 Operational Procedure QOP-56-01 Management Review PT ASAqidohsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Dabba WalaDocument16 pagesDabba Walarobin70929No ratings yet

- Traffic Growth Rate EstimationDocument6 pagesTraffic Growth Rate Estimationmanu1357No ratings yet

- Form 26AS Annual Tax StatementDocument4 pagesForm 26AS Annual Tax StatementAnish SamantaNo ratings yet

- Urban Liveability in The Context of Sustainable Development: A Perspective From Coastal Region of West BengalDocument15 pagesUrban Liveability in The Context of Sustainable Development: A Perspective From Coastal Region of West BengalPremier PublishersNo ratings yet

- Foreign Exchange Manual (March 2020)Document561 pagesForeign Exchange Manual (March 2020)Mehmood Ul HassanNo ratings yet

- The Customer and Car Rental Service RelationshipDocument3 pagesThe Customer and Car Rental Service RelationshipAbhimanyu GuptaNo ratings yet

- AmazonianDocument19 pagesAmazonianbapt100% (1)

- The Phuket Beach CaseDocument4 pagesThe Phuket Beach Casepeilin tongNo ratings yet

- Unit 2 Income From SalariesDocument21 pagesUnit 2 Income From SalariesShreya SilNo ratings yet

- Income From SalariesDocument24 pagesIncome From SalariesvnbanjanNo ratings yet

- SERVICE QUALITY AND MEASUREMENT SEM 6 CH 1-Ilovepdf-CompressedDocument16 pagesSERVICE QUALITY AND MEASUREMENT SEM 6 CH 1-Ilovepdf-CompressedDj kakaNo ratings yet

- E-TAX: A Solution to Nigeria's Tax System ChallengesDocument102 pagesE-TAX: A Solution to Nigeria's Tax System ChallengesKENNETH EPPENo ratings yet

- IBT - Lesson 1Document18 pagesIBT - Lesson 1Melvin Ray M. MarisgaNo ratings yet

- Ds 3 ZJG PFA8 VV 0 Uhb Itzm K2 ARl EGBc 82 SQB 9 ZHC 4 PDocument1 pageDs 3 ZJG PFA8 VV 0 Uhb Itzm K2 ARl EGBc 82 SQB 9 ZHC 4 PprabindraNo ratings yet

- Social Entrepreneurship Success Story of Project SukanyaDocument4 pagesSocial Entrepreneurship Success Story of Project SukanyaHimanshu sahuNo ratings yet

- Changhong Zhu’s PARS IV fund earned 61 percent for Bill Gross’s PimcoDocument11 pagesChanghong Zhu’s PARS IV fund earned 61 percent for Bill Gross’s PimcoMichael BenzingerNo ratings yet

- ENTR510 Final Assignment KeyDocument5 pagesENTR510 Final Assignment Keystar nightNo ratings yet

- LCG LCPharma EN 160421Document11 pagesLCG LCPharma EN 160421Patrick MontegrandiNo ratings yet

- Supply Chain Management of Zara: End Term ProjectDocument32 pagesSupply Chain Management of Zara: End Term ProjectMukund Verma100% (1)

- Financial Accessibility of Women Entrepreneurs: (W S R T W P W E)Document5 pagesFinancial Accessibility of Women Entrepreneurs: (W S R T W P W E)Vivi OktaviaNo ratings yet

- DLP Fundamentals of Accounting 1 - Q3 - W3Document5 pagesDLP Fundamentals of Accounting 1 - Q3 - W3Daisy PaoNo ratings yet

- BBA(IB) Semester 1 SyllabusDocument14 pagesBBA(IB) Semester 1 SyllabusArsheen WaseemNo ratings yet

- Chapter 2 - Consumer BehaviourDocument95 pagesChapter 2 - Consumer BehaviourRt NeemaNo ratings yet

- Ottoman Bow - Burgundy - MetbowsDocument1 pageOttoman Bow - Burgundy - MetbowsfazalNo ratings yet

- Abercrombie & Fitch Co.: Investment ThesisDocument17 pagesAbercrombie & Fitch Co.: Investment ThesisFan SijingNo ratings yet

- Assignment 1: Course Name & Code: Assignment Title: Student Name: Student ID: Submitted To: Date of SubmissionDocument7 pagesAssignment 1: Course Name & Code: Assignment Title: Student Name: Student ID: Submitted To: Date of Submission4basilalhasaniNo ratings yet

- Varun MotorsDocument81 pagesVarun MotorsRohit Yadav86% (7)

- Consolidated Balance Sheet of Steel Authority of India (In Rs. Crores) Mar-17 Mar-16 Mar-15 Equity and Liabilities Shareholder'S FundDocument4 pagesConsolidated Balance Sheet of Steel Authority of India (In Rs. Crores) Mar-17 Mar-16 Mar-15 Equity and Liabilities Shareholder'S FundPuneet GeraNo ratings yet

- Information Sheet For Real Estate Client Template-68109Document3 pagesInformation Sheet For Real Estate Client Template-68109Oscar Forradellas CasabonNo ratings yet

- HR SopDocument7 pagesHR SopDen PamatianNo ratings yet