Professional Documents

Culture Documents

Steel Quiz

Uploaded by

jakeer7Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Quiz

Uploaded by

jakeer7Copyright:

Available Formats

MODERN STEEL CONSTRUCTION JULY 2010

steel quiz

LOOKING FOR A CHALLENGE? Modern Steel Constructions monthly Steel Quiz tests your knowledge of steel design and

construction. The answers to this months Steel Quiz can be found in the 2005 Specification for Structural Steel Buildings

(available as a free download at www.aisc.org/freepubs) and AISC Steel Design Guide 19, Fire Resistance of Structural Steel

Framing, also a free download for AISC members at www.aisc.org/epubs.

1

Which ASTM standards covering

bars are referenced in the AISC

Specification?

2

True/False: The AISC Specification

cannot be used to design steel

castings and forgings.

3

According to the 2005 AISC

Specification, when should the

contract documents require that

shapes be supplied with Charpy

V-Notch (CVN) toughness of 20

ft-lbs absorbed energy at +70 F?

4

True/False: Heavy W-shapes

(those with flanges that exceed

2 in. in thickness) require special

material, design, and fabrication/

erection considerations because

the perimeter of the heavy cross

section is a zone of coarse grain

structure and reduced toughness.

5 What is the maximum permitted

temperature for heating operations

per the AISC Specification?

a) 800 F

b) 1,000 F

c) 1,100 F

d) 1,200 F

6

True/False: Steel stud shear con-

nectors shall conform to the

requirements of AWS D1.1.

7

Which methods of design for fire

conditions are recognized by the

AISC Specification?

8

True/Fal se: The f i re perf or-

mance of concrete-filled HSS

col umns can be adver sel y

affected if vent holes are not

provided in the steel section.

9

What are two commonly used

r ef er ences t o det er mi ne

proprietary assembly ratings when

designing for fire conditions using

Qualification Testing?

a) IBC and the UL Fire Resistance

Directory

b) IBC and ASCE 7

c) ASCE/SFPE 29 and IBC

d) ASCE/SFPE 29 and the UL Fire

Resistance Directory

10

Is it permissible to use shapes in

assemblies that are different from

the shape that was rated by test-

ing such as that shown in the UL

Fire Resistance Directory?

MODERN STEEL CONSTRUCTION JULY 2010

steel quiz ANSWERS

1

According to Section A3 of the

2005 AISC Specification bars

conform to ASTM A36, A529,

A572, and A709 are referenced.

2

False. Cast steel that conforms

to ASTM A216 Grade WCB

with Supplement S11, and steel

forgings that conform to ASTM

A668, fall within the scope of the

AISC Specification.

3

The supplemental CVN require-

ment of 20 ft-l bs absorbed

energy at +70 F is required for

plates and shapes with flanges

that exceed 2 in. in thickness,

used as members subject to pri-

mary tensile forces due to ten-

sion or flexure and spliced using

CJP groove welds.

4

False. It is the core area of these

shapes, not the perimeter, that

can have a coarse grain structure

and reduced level of toughness.

For more information on this sub-

ject, download the NASCC con-

ference proceedings for session

E13, presented by Duane Miller,

available for no charge at www.

aisc.org/2010nascconline.

5

Trick question, sorry. Both (c) and

(d) are correct depending upon

the steel grade. According to

Section M2.1 of the 2005 AISC

Specification temperatures of

heated areas shall not exceed

1,100 F for A514 and A852 steel

or 1,200 F for other steel.

6

True. According to Section A3.6

of the 2005 AISC Specification

steel stud shear connectors shall

conform to the requirements of

AWS D1.1.

7

Two methods of design for fire

conditions are recognized in

Appendix 4 of the 2005 AISC

Specification: Qualification Test-

ing and Engineering Analysis.

8

True. The fire performance of

a concrete-filled HSS column

improves when heat absorption

occurs as the moisture in the

concrete is converted to steam.

The resulting steam must be

released through vent holes in

the steel section. See Section VI

of AISC Steel Design Guide 19

for additional information.

9

(d) ASCE/SFPE 29 and the UL

Fire Resistance Directory are two

commonly used references when

fire-resistant designs are based

upon qualification testing. See

Section IV of AISC Steel Design

Guide 19 at www.aisc.org/

epubs for more information.

10

Yes. All test assemblies are based

upon a specific member size with

spray-on thickness adjustment

formulas to account for use of

other shapes.

Anyone is welcome to submit questions and

answers for Steel Quiz. If you are interested

in submitting one question or an entire quiz,

contact AISCs Steel Solutions Center at

866.ASK.AISC or at solutions@aisc.org.

MODERN STEEL CONSTRUCTION JULY 2010

You might also like

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- SDI-C-2011 Standard for Composite Steel Floor Deck-SlabsDocument36 pagesSDI-C-2011 Standard for Composite Steel Floor Deck-SlabsDiego Torres100% (1)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Metallurgy & WeldingDocument10 pagesMetallurgy & WeldingMominé VeNo ratings yet

- Steel Quiz AnswersDocument2 pagesSteel Quiz AnswerspmjoshirNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Structural Steel Framing Specs - AISCDocument5 pagesStructural Steel Framing Specs - AISCSteve HuppertNo ratings yet

- 2006v07 Si WebDocument2 pages2006v07 Si WebLuciano Alves CavalcantiNo ratings yet

- Astm A992Document2 pagesAstm A992Harley Ilave IlaveNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Metallurgy and Welding PDFDocument18 pagesMetallurgy and Welding PDFPatrick DominguezNo ratings yet

- Sdi Ansi NC 2010 XDocument15 pagesSdi Ansi NC 2010 XNyein ZawNo ratings yet

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesRating: 4.5 out of 5 stars4.5/5 (16)

- Si 10 2013 PDFDocument2 pagesSi 10 2013 PDFhector diazNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Structural Steel Framing SpecificationDocument11 pagesStructural Steel Framing SpecificationsivaNo ratings yet

- Sdi Ansi0 C 2011 (Deck)Document37 pagesSdi Ansi0 C 2011 (Deck)Ricardo MontachanaNo ratings yet

- Sdi Ansi NC 2010Document15 pagesSdi Ansi NC 2010Vitelio PinzonNo ratings yet

- Structural Steel Spec. and ConstructionDocument12 pagesStructural Steel Spec. and ConstructionAshwani DograNo ratings yet

- Composite Steel Floor Deck - Slabs: C - 2011 Standard ForDocument37 pagesComposite Steel Floor Deck - Slabs: C - 2011 Standard ForArnel DodongNo ratings yet

- ANSI SDI RD-2010 Standard Steel Roof DeckDocument11 pagesANSI SDI RD-2010 Standard Steel Roof DeckruayoNo ratings yet

- Composite Steel Floor Deck SlabsDocument37 pagesComposite Steel Floor Deck SlabsFelipe CantillanoNo ratings yet

- Steel Stairs, Ladders and Platforms - MSTDocument13 pagesSteel Stairs, Ladders and Platforms - MSTwafikmh4No ratings yet

- Steel QuizDocument2 pagesSteel QuizCebeiller Sdn BhdNo ratings yet

- Are You Properly Specifying Materials - Part 3 PDFDocument3 pagesAre You Properly Specifying Materials - Part 3 PDFasmasm123No ratings yet

- Project I.D. ( - ) Structural Metal Framing (Rev. 10, April 11, 2018) 05 1000-1Document29 pagesProject I.D. ( - ) Structural Metal Framing (Rev. 10, April 11, 2018) 05 1000-1081382991318No ratings yet

- SECTION 05 21 00 Steel Joist FramingDocument5 pagesSECTION 05 21 00 Steel Joist FramingJuanPaoloYbañezNo ratings yet

- Monthly Steel Quiz Tests Your KnowledgeDocument2 pagesMonthly Steel Quiz Tests Your KnowledgeRajed MaglinteNo ratings yet

- Steel Quiz: Manual (Document2 pagesSteel Quiz: Manual (Seismotec EngineersNo ratings yet

- AISC 13th - Material GradesDocument5 pagesAISC 13th - Material GradesUpadrasta HarishNo ratings yet

- Design Mega Columns-N-M ImperialDocument27 pagesDesign Mega Columns-N-M Imperialtuanna2000No ratings yet

- H Proc Notices Notices 030 K Notice Doc 29803 883010837Document165 pagesH Proc Notices Notices 030 K Notice Doc 29803 883010837XTINCT Mobile LegendsNo ratings yet

- ASTM A6 - What Recent Changes Mean For Designers and FabricatorsDocument2 pagesASTM A6 - What Recent Changes Mean For Designers and FabricatorsAngel Arturo Castellanos SantamariaNo ratings yet

- SDI Technical Note No 5Document4 pagesSDI Technical Note No 5phil brownNo ratings yet

- STEEL INTERCHANGE: GALVANIZING PROTECTION AND SEISMIC DOUBLER PLATESDocument2 pagesSTEEL INTERCHANGE: GALVANIZING PROTECTION AND SEISMIC DOUBLER PLATESMohanNo ratings yet

- General Provisions: Chapeer ADocument9 pagesGeneral Provisions: Chapeer AJerry M. Davila MartelNo ratings yet

- Steel Joist Specification for Libyan Infrastructure ProjectDocument7 pagesSteel Joist Specification for Libyan Infrastructure Projectwafikmh4No ratings yet

- A 1018 - A 1018M - 04Document6 pagesA 1018 - A 1018M - 04Khin Aung ShweNo ratings yet

- Reinforcing Bar Specifications - tcm45-340903Document3 pagesReinforcing Bar Specifications - tcm45-340903Anonymous vGKYNSPNo ratings yet

- Steel Interchange: Code of Standard Practice Hss Connections in OmfsDocument2 pagesSteel Interchange: Code of Standard Practice Hss Connections in Omfshector diazNo ratings yet

- Pocs. Also Please Contact The Pocs WithDocument65 pagesPocs. Also Please Contact The Pocs Withrize1159100% (1)

- Steel QuizDocument2 pagesSteel Quizmuh2006No ratings yet

- ASTM A36-A36M-2008 Standard Specification For Carbon Structural Steel PDFDocument3 pagesASTM A36-A36M-2008 Standard Specification For Carbon Structural Steel PDFmasv792512100% (2)

- Cold Formed SteelDocument42 pagesCold Formed SteelGabyBravoNo ratings yet

- Is2062 E350Document12 pagesIs2062 E350Sowmen ChakrobortyNo ratings yet

- New Specification for the Design of Structural Stainless Steel_Structure Mag_Dec 2022Document3 pagesNew Specification for the Design of Structural Stainless Steel_Structure Mag_Dec 2022Thomas ManderNo ratings yet

- Vigas Apoyadask SeriesDocument36 pagesVigas Apoyadask SeriesdevitgNo ratings yet

- SECTION 05 12 00 Structural Steel FramingDocument6 pagesSECTION 05 12 00 Structural Steel FramingmiteshsuneriyaNo ratings yet

- A 1011 - A 1011M - 03 Qtewmtetmdm - PDFDocument7 pagesA 1011 - A 1011M - 03 Qtewmtetmdm - PDFTiến Lượng NguyễnNo ratings yet

- Astm A217-A217m 2010Document4 pagesAstm A217-A217m 2010rcfrcf279No ratings yet

- 03 20 00 - Concrete ReinforcingDocument6 pages03 20 00 - Concrete Reinforcingahmad ibrahinNo ratings yet

- Design and Construction Standards For Steel Connections in Seismic FramesDocument8 pagesDesign and Construction Standards For Steel Connections in Seismic FramesDuong TranNo ratings yet

- Carbon Structural Steel: Standard Specification ForDocument3 pagesCarbon Structural Steel: Standard Specification Foralejandro_marín_15100% (1)

- Norma AstmDocument8 pagesNorma AstmmaryconejoNo ratings yet

- Comparison of Ansi Aisc 360-05 To 1989 Asd SpecificationDocument32 pagesComparison of Ansi Aisc 360-05 To 1989 Asd SpecificationRicardo MGNo ratings yet

- STEEL INDUSTRY EMBRACES A992Document6 pagesSTEEL INDUSTRY EMBRACES A992Jagadeesh Nandam100% (1)

- American steel grades A36, A572, A588, A709, A913, A992 propertiesDocument1 pageAmerican steel grades A36, A572, A588, A709, A913, A992 propertiesRaymondLeungNo ratings yet

- Seismic Analysis of Multistoried BuildingDocument8 pagesSeismic Analysis of Multistoried Buildingjakeer7No ratings yet

- Response Spectrum Analysis For Regular Multistory Structure in Seismic Zone IIIDocument6 pagesResponse Spectrum Analysis For Regular Multistory Structure in Seismic Zone IIIjakeer7No ratings yet

- Seismic Design Load Distribution in Steel FrameDocument8 pagesSeismic Design Load Distribution in Steel Framejakeer7No ratings yet

- Day 29 Dynamic Analysis Using Response Spectrum MethodDocument9 pagesDay 29 Dynamic Analysis Using Response Spectrum Methodjakeer7No ratings yet

- American steel grades A36, A572, A588, A709, A913, A992 propertiesDocument1 pageAmerican steel grades A36, A572, A588, A709, A913, A992 propertiesRaymondLeungNo ratings yet

- Dynamic Analysis of Machine Foundation-INFODocument8 pagesDynamic Analysis of Machine Foundation-INFOjakeer7No ratings yet

- A Comparative Analysis On Absolute and SRSSDocument4 pagesA Comparative Analysis On Absolute and SRSSjakeer7No ratings yet

- Foundations For Industrial Machines and Earthquake Effects-InfoDocument17 pagesFoundations For Industrial Machines and Earthquake Effects-Infojakeer7No ratings yet

- Analysis of Structural Member Systems - Jerome J. Connor PDFDocument617 pagesAnalysis of Structural Member Systems - Jerome J. Connor PDFDiego Leonel Suárez Vásquez100% (1)

- American steel grades A36, A572, A588, A709, A913, A992 propertiesDocument1 pageAmerican steel grades A36, A572, A588, A709, A913, A992 propertiesRaymondLeungNo ratings yet

- Structural Forces in Beams and Frames (38chDocument42 pagesStructural Forces in Beams and Frames (38chjakeer7No ratings yet

- Machine TypesDocument25 pagesMachine TypesAnonymous xcFcOgMiNo ratings yet

- Aci 351 3R PDFDocument26 pagesAci 351 3R PDFLakshmi PrabhaNo ratings yet

- PIP STE03350 Vertical Vessel Foundation Design Guide 12-2008 (Last Upd) PDFDocument33 pagesPIP STE03350 Vertical Vessel Foundation Design Guide 12-2008 (Last Upd) PDFbute79100% (3)

- Aci 351 3R PDFDocument26 pagesAci 351 3R PDFLakshmi PrabhaNo ratings yet

- Analysis and Design of Vertical Vessel FoundationDocument46 pagesAnalysis and Design of Vertical Vessel Foundationjakeer7No ratings yet

- Typical Mat Foundation Design ProcedureDocument7 pagesTypical Mat Foundation Design Procedurejakeer7No ratings yet

- Plastic vs Elastic Section Modulus: Zp and Ze ExplainedDocument1 pagePlastic vs Elastic Section Modulus: Zp and Ze Explainedjakeer7No ratings yet

- Process Industry Practices Civil: PIP CVC01015 Civil Design CriteriaDocument17 pagesProcess Industry Practices Civil: PIP CVC01015 Civil Design Criteriajakeer7No ratings yet

- Offshore Structural Analysis MethodsDocument10 pagesOffshore Structural Analysis Methodsjakeer7No ratings yet

- Offshore Structural Analysis MethodsDocument10 pagesOffshore Structural Analysis Methodsjakeer7No ratings yet

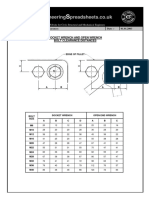

- Bolt Load Capacity Tables for EngineersDocument1 pageBolt Load Capacity Tables for Engineersjakeer7No ratings yet

- Ngineering Preadsheets - Co.uk: Analysis of Equal Span Continuous Beams With Uniformly Distributed LoadsDocument1 pageNgineering Preadsheets - Co.uk: Analysis of Equal Span Continuous Beams With Uniformly Distributed Loadsjakeer7No ratings yet

- Bolt Capacity Diagrams To BS5950 01.01.03 PDFDocument1 pageBolt Capacity Diagrams To BS5950 01.01.03 PDFjakeer7No ratings yet

- Mat Foundation 2Document355 pagesMat Foundation 2Wondwosen BelayNo ratings yet

- Bolt Clearances 01.01.03Document1 pageBolt Clearances 01.01.03jakeer7No ratings yet

- Mat Foundation 2Document355 pagesMat Foundation 2Wondwosen BelayNo ratings yet

- Design and Manufacturing Guideline For Aerospace CompositesDocument11 pagesDesign and Manufacturing Guideline For Aerospace CompositesBrice_ParmentierNo ratings yet

- CPVC - Cat VIKING Conexiones UL FM BlazemasterDocument28 pagesCPVC - Cat VIKING Conexiones UL FM BlazemasterpvaldezmtzNo ratings yet

- Precision Folding Guard Rail BrochureDocument2 pagesPrecision Folding Guard Rail BrochuregunterivNo ratings yet

- CLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFDocument1 pageCLP Regulation (EC) No. 1272-2008 On The Classification, Labelling and Packaging of Substances and Mixtures PDFCan YıldırımNo ratings yet

- Lab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Document20 pagesLab 4-Measurement of Plastic Viscosity of Different Mud Samples by Viscometer.Sunny BbaNo ratings yet

- DEGASSING AGENT AF 100 - Ind1 - AngDocument1 pageDEGASSING AGENT AF 100 - Ind1 - AngFrench Corvette50% (2)

- Balancing Chemical Equations: For Advanced Chemistry Special Science High School in Grade 10 Quarter 3/ Week 2Document9 pagesBalancing Chemical Equations: For Advanced Chemistry Special Science High School in Grade 10 Quarter 3/ Week 2Venice Gwyn ChavezNo ratings yet

- Lec 3Document14 pagesLec 3anuda09No ratings yet

- Items To Review at Hostel CHC ZAMKODocument1 pageItems To Review at Hostel CHC ZAMKOHumphrey OnyejegbuNo ratings yet

- Ionic Bond of LoveDocument1 pageIonic Bond of LoveMohd FarisNo ratings yet

- Dyeing Process of Cotton Fabric With Reactive DyesDocument6 pagesDyeing Process of Cotton Fabric With Reactive DyesMianAbrarAnjumNo ratings yet

- Astm A-6 PDFDocument1 pageAstm A-6 PDFFrank Berrios GarcesNo ratings yet

- Injection Molding Defects Causes RemediesDocument60 pagesInjection Molding Defects Causes RemediesMada PopescuNo ratings yet

- Taller de GasesDocument20 pagesTaller de GasesAle Cruz DNo ratings yet

- Stabilo Ink Compliance StatementDocument2 pagesStabilo Ink Compliance StatementNurul HaziqahNo ratings yet

- Hapter: Occurrence of Noble GasesDocument10 pagesHapter: Occurrence of Noble GasesSandipan SahaNo ratings yet

- Department of Materials Science and Engineering (MSE)Document11 pagesDepartment of Materials Science and Engineering (MSE)shouvikNo ratings yet

- Route 34 PlansDocument1 pageRoute 34 PlansThe Valley IndyNo ratings yet

- Master Emaco P210Document2 pagesMaster Emaco P210Gavriel NgNo ratings yet

- WG 101Document1 pageWG 101'Lampa'No ratings yet

- Impact of Source Drain DopingDocument6 pagesImpact of Source Drain DopingjjNo ratings yet

- White Powder GoldDocument28 pagesWhite Powder GoldSpiredon Kayyal57% (7)

- WRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionDocument5 pagesWRC 107 Stress Calculation For Sustained Loads:: Dimensionless Loads For Cylindrical Shells at Attachment JunctionmsmrizhwanNo ratings yet

- Parker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016Document370 pagesParker Autoclave Engineers: Fluid Componets Product Catalog Feb. 2016mds9185No ratings yet

- Brick Industry Project - Production and Operation ManagementDocument16 pagesBrick Industry Project - Production and Operation ManagementSundar Pro RiderNo ratings yet

- Load Testing Bridges - 3.6MBDocument43 pagesLoad Testing Bridges - 3.6MBscribbey123No ratings yet

- Formula Mass WorksheetDocument21 pagesFormula Mass WorksheetEsther ParNo ratings yet

- Neil Dominic C. Mahusay Bsme-3 Module 1 Assignment: Military Body ArmorDocument4 pagesNeil Dominic C. Mahusay Bsme-3 Module 1 Assignment: Military Body ArmorMahusay Neil DominicNo ratings yet

- Vinyl Fabric Specification - Upholstery Vinyl Fabric Monaco HoneydewDocument2 pagesVinyl Fabric Specification - Upholstery Vinyl Fabric Monaco HoneydewRehman LatifNo ratings yet

- VERITAS PHARMACEUTICALS LIMITED MICROCRYSTALLINE CELLULOSE SPECIFICATIONDocument1 pageVERITAS PHARMACEUTICALS LIMITED MICROCRYSTALLINE CELLULOSE SPECIFICATIONShagorShagorNo ratings yet

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (115)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceFrom EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceRating: 5 out of 5 stars5/5 (9)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkFrom EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkRating: 5 out of 5 stars5/5 (1)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Dark Aeon: Transhumanism and the War Against HumanityFrom EverandDark Aeon: Transhumanism and the War Against HumanityRating: 5 out of 5 stars5/5 (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessFrom EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNo ratings yet

- Artificial Intelligence: From Medieval Robots to Neural NetworksFrom EverandArtificial Intelligence: From Medieval Robots to Neural NetworksRating: 4 out of 5 stars4/5 (3)

- Shallow Foundations: Discussions and Problem SolvingFrom EverandShallow Foundations: Discussions and Problem SolvingRating: 5 out of 5 stars5/5 (1)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- Artificial You: AI and the Future of Your MindFrom EverandArtificial You: AI and the Future of Your MindRating: 4 out of 5 stars4/5 (3)

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet