Professional Documents

Culture Documents

Design Methodology

Uploaded by

Girish KalsaitCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design Methodology

Uploaded by

Girish KalsaitCopyright:

Available Formats

Parametric Design Methods for car body design

Luca Avallone

1

, Gennaro Monacelli

1

, Federico Pasetti

2

, Fabrizio Giardina

2

1

Elasis S.C.p.A.

2

Fiat Auto S.p.A.

Abstract

This work describes a new design methodology for car development process based

on the archetype concept, modular systems and parametric and associative CAD. An

archetype is defined by a parametric model of a component or system configuration. Car

body archetypes can be developed using a parametric and associative CAD.

The archetype models contain geometric constraints and design rules. The

methodology contains the representation of the car body design process based on the use of

these parametric models.

Using this methodology, engineers can define the frame of a new car body,

respecting the company standards. The principal benefit is the reduction of the design

development time as the modification process is optimised. Furthermore the design history

is recorded and the same parametric models can be re-used for several vehicle projects.

1. INTRODUCTION

Elasis and FIAT Auto started to test parametric and associative (P/A) techniques at

least 6 years ago [1], in order to create some archetypes of an entire Fiat vehicle. Fiat was

one of the first automotive companies to test P/A features in the development of a new car.

Car body design is a very critical and time-consuming activity because it is deeply

linked to body style. The most frequent design modifications during car development

process, in fact, depend on style changes.

For this purpose P/A design seems to be very attractive for designers because it

enables to speed up the process of geometric features updating, according to the new style

changes. In this way, designers dont waste time in boring and repetitive activities without

adding value. The project goal was to develop a new P/A design methodology in order to:

reduce modification time during the development of a new car body;

reuse the same parametric models for future platforms.

The methodology was based, not only on P/A design, but also on the concept of

archetype and modular platform. The archetype is a set of logical and parametric features

of an object or system. With these archetypes it is possible to build the model of a single

component or a whole system. The modular platform is a platform that can be used for

several types of vehicles with specific modifications. A car body, in fact, has usually made

for only one vehicle with its specific platform, while a modular platform can be used for

several cars (usually in the same car segments) and can be adapted to the current style.

A4-17

XII ADM International Conference - Grand Hotel - Rimini Italy - Sept. 5

th

-7

th

, 2001

The developed methodology is able to manage modular platform and style modifications.

2. STATE OF THE ART OF CAD SYSTEMS

Nowadays the most advanced CAD systems are based on features, parametric

modelling and associative environment concepts. These types of systems are called

generally parametric and associative CAD (P/A CAD) or feature based CAD (FB CAD),

even if we have not found on the market a product that implement all these capabilities at

the same level [2], [3], [4]. In this paragraph we will examine the meaning of these

concepts: feature, parametric and associative.

Features are physical o logical elements of an object that an engineer can use

during the definition of the geometrical model of the component. Examples of feature are

through hole, slot, pocket, chamfer and so on. Therefore features can be seen like a

sequence of geometric operations (building blocks) that has an engineering meaning for

product definition. Engineers usually look at the feature like a physical constituent of a

part. Therefore the feature model is a data structure that represents a part or an assembly

mainly in terms of its own features [5].

In a parametric environment, user can completely define a geometric feature with

some parameters, so he will be able to modify it changing the parameter values instead of

deleting geometric entities (for example, a surface offset could be modified acting on the

offset parameter).

In an associative environment, user can catch the relationships between objects,

features (i.e. the tangency between a segment and a circle could be kept also if the circles

radius is varying or if a designer replaces the circle) and different process phases (i.e. CAD

Model, FEM model an Drawing). User can define relationships between systems and

components in large file assembly (multimodel associativity).

Another important property of these systems is the capability to store in their

database all the operations made to define the product model: this is called design history.

In some case it is possible to re-update parts of the product model, just re-executing the

relative design history steps.

The last concept regards the variational systems. A variational CAD allows user to

create geometry not fully constrained, therefore user can fix some parameters that are

useful, leaving the other parameters unconstrained.

The main expected benefits from these systems are the optimisation of the user

productivity in modeling and the reduction of the modification time.

Our design methodology has been developed using these CAD characteristics and

the implementation of car archetype systems that will be explained in the following

paragraph.

3. CAR BODY DESIGN METHODS

The methodology was based on P/A CAD but also on the concept of archetype. An

archetype is a set of logical and parametric features of an object or system that can be used

to build the relative CAD model [5]. In figure 1 is illustrated the building process of an

anterior pillar using its archetype design. Each rectangle represents a feature and each

arrow represents an operation made on features. The generated CAD model can be

modified in flexible way and sometimes with an automatic procedure.

A4-18

XII ADM International Conference - Grand Hotel - Rimini Italy - Sept. 5

th

-7

th

, 2001

Archetype design

Archetype Tree

Figure 1. Anterior pillar archetype.

Instead of building a unique model file with a whole set of features, we usually split

the feature relationships into more files, for better manage the archetypes. In figure 2 it is

shown that an archetype might be composed by three files:

the first file gives only a set of surfaces and construction features;

the second file uses these features to build a primary model;

the third file allows to obtain the complete part.

1

st

STEP

2

nd

STEP

3

th

STEP

Figure 2. Example of an archetype split in three models.

A4-19

XII ADM International Conference - Grand Hotel - Rimini Italy - Sept. 5

th

-7

th

, 2001

A designer starting from an archetype can generate different components, simply

changing its parameter values. This is another advantage of the archetype design.

The example reported in figure 2 shows the archetype anterior pillar construction.

In order to develop the design methodology and the relative archetypes it was set up

a development team composed by engineers coming from different departments of Elasis

and FIAT Auto. The phases of design methodology were the following:

a) Define the vehicle reference model (developed with explicit CAD systems and

procedure)

b) Build the design development history (list of modifications)

c) P/A modeling of new vehicle model (archetypes definition and implementation)

d) Optimisation phase

e) Models update during vehicle development

f) Design method implementation

The first step was to analyse the explicit CAD model of a car body design, in order

to understand its design history, in particular the most common and frequent design

modifications. After this analysis, we tried to understand the logical constraints and the

most appropriate parameters for every model and the definition of reference archetypes.

The result of this step was a tree, in which there were macro logical constraints among

different archetypes and the relative updating sequence. Next phase consisted in

developing P/A archetypes of components and systems. The archetypes were tested in

order to evaluate their reliability: this was the optimisation phase concerning the parameter

modifications and the feature links of each archetype.

The last phase consisted in the implementation of the single steps of car body

design method.

It is to underline that this P/A method doesn't limit the creativity designer, but

augments his productivity respecting company procedures and standards [6].

The design methodology is mainly based on the top down approach focused on two

different levels:

Vehicle level

Component level

There were two different teams in order to manage the different levels:

a) The vehicle level is managed by the project manager that, with reference to the car

decomposition (see i.e. figure 3), assigns the single vehicle systems to each system

team leader (TL). Then TLs assign the component areas to each engineer and define

the rules to manage the interfaced components (master-slave strategies). Furthermore

TL defines the system assembly, the carry over components and the feasibility studies.

At this level, we can say that the main activity consists in defining the car body

decomposition in beams and nodes, as shown in figure 3.

A4-20

XII ADM International Conference - Grand Hotel - Rimini Italy - Sept. 5

th

-7

th

, 2001

Nodes

Beams

Figure 3. Car body decomposition of into nodes and beams.

b) The component level is managed by engineer that has the responsibility to develop the

relative group of nodes and beams, with specific archetypes.

In figure 4 is reported the general schema that contains the relationships among explicit

and P/A environment and the parametric hierarchy of vehicle systems and components.

Figure 4. Top down organisation of vehicle systems model generation.

A4-21

XII ADM International Conference - Grand Hotel - Rimini Italy - Sept. 5

th

-7

th

, 2001

The Style is a set of explicit entities as well as the carry over parts or components.

The assembly is managed by a TL who is responsible for the updating of documents of the

whole vehicle design.

The mating structure is the gateway between the explicit entities and the P/A

environment.

In figure 4 are represented all the relationships for car door systems.

An example of general updating tree has shown in the figure 5. Note that every

part is made by a sequence of different files that are the archetypes.

STYLING SURF. CARRY-OVER

MATING

Model 1.1 Model 2.1 Model 3.1

Model 3.2

Model 1.2

Model 4.1

Model 3.3

Model 3.1

Explicit Env.

P/A Env.

Trim surf.

Mold planes

FEASIBILITY

Figure 5. The updating tree.

The explicit entities are style surfaces and carry over components. The mating

structure allows us to link explicit geometry with the P/A environment.

The feasibility contains mainly beam, production constraints and section

archetypes. The hierarchy of the P/A models is a cascade, without loops that could cause

problems during the model regeneration process.

The updating tree could be managed in the future by a software system that builds

automatically the design tree.

4. BENEFITS OF METHODOLOGY

In this paragraph are shown some results obtained by the application of the

methodology in body design context. In the figure 6 is shown the so-called 'A-Node' model

of car body.

A4-22

XII ADM International Conference - Grand Hotel - Rimini Italy - Sept. 5

th

-7

th

, 2001

Figure 6. Sub-assembly of car body.

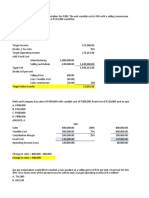

In the figure 7 are compared, in qualitative manner, the traditional process of

modeling an A-node and the new method based on P/A approach. As we can see, the

development time of A-node model is longer for P/A method, because it is necessary to

build P/A library archetypes. When a style change occurs, the P/A library enables to reduce

design time because it is reduced the modifying phase. On the other hand the explicit

design take always the same time for every style change.

ASSEMBLY/MATING

STYLE

LIBRARY

ARCHETYPES

CARRY OVER

A NODE MODELING

MODELING

REFERENCES

STYLE

FEASIBILITY

CARRY OVER

MATING ZONES

NEW STYLE

NEW STYLE

1ST EXPLICIT

MODEL

2NDEXPLICIT

MODEL

P/A MODELS

REGENERATED

A NODE MODELING

Time

MODELING

REFERENCES

A NODE MODELING

MATING ZONES

ASSEMBLY/MATING

MODELS REGENERATION

CHECK INTERFERENCE

A NODE REGENERATION

P/A

Design

Explicit

Design

MATING ZONES

DOOR FEASIBILITY

SIDE FEASIBILITY

1ST P/A

MODEL

Figure 7. Explicit and P/A method comparison

For these reasons we can say that P/A approach seems to be robust enough to

manage several style modifications, saving time and costs. In order to cover different

system typologies we are developing an archetype library of beam and nodes shared for the

same car segments.

A4-23

XII ADM International Conference - Grand Hotel - Rimini Italy - Sept. 5

th

-7

th

, 2001

Furthermore, it is necessary to build the documentation for each archetype, so that a

new designer is soon able to modify the archetype.

Other vehicle systems seem to be good candidates to use the same methodologies:

for example, the car platform design and the electrical cabling design.

5. CONCLUSIONS

The developed P/A CAD methodology seems to be a useful tool in order to apply

the best company practices and component standardisation, without limit the designers

creativity.

Company emphasis is focused on modifications management because it affects on

product development time and, consequently, on the process flexibility related to styling

modifications, continuous refinement and new concepts implementation. In that way, each

modification can be executed in a short time, respecting all the product and process

constraints.

On the other hand, the use of P/A CAD has a great impact on the traditional process

and on the job designer: more skills are necessary. It also needs a more powerful hardware

installed to satisfy feature-based design. For this reasons the P/A CAD has to be justified

with accurate return of productivity and product quality improvement.

A4-24

XII ADM International Conference - Grand Hotel - Rimini Italy - Sept. 5

th

-7

th

, 2001

6. REFERENCES

[1] G. Monacelli, A. Quaglione, Limpatto delle nuove tecnologie CAD nellambito

della progettazione automobilistica: una metodologia di analisi, ADM, Caserta,

Settembre 1995.

[2] CATIA Reference Manual, Dassault Systemes, 1996, 1997,1998,1999,2000.

[3] Unigraphics Reference Manual, UGS, 2000.

[4] Pro/Engineer Reference Manual, PTC, 1995, 1996, 1997, 1998, 1999, 2000.

[5] J.J. Shah, M. Mantila, Parametric and Feature-Based CAD/CAM, John Wiley and

Sons Inc., 1995.

[6] L. Morello, F. DAprile, Associative CAD in Vehicle Development through

Simultaneous Engineering, ATA, Firenze, Febbraio 1997.

[7] C. Floyd, A comparative evaluation of system development methods, IFIP, 1986

[8] U. Cugini, D. Ferretti, G. Colombo, How to Represent Design Rules in a

Parametric CAD System, International Symposium of Advanced Geometric

Modeling fir Engineering Applications, 1989, F.L. Krause & H. Jansen eds.

[9] C. D. Potter, Utilizzare al meglio la Modellazione Solida, CG Computer Gazette,

N1, 1996, pp. 26-33

[10] L. Brooke, Creating the best CAD/CAM System, Automotive Industries, December

1996.

[11] J. Hoschek, D. Lasser, Computer Aided Geometric Design, AK Peters Wellesley,

Massachussets, 1993.

[12] G. Farin, Curves and Surfaces for CAGD: A pratical guide, Academic Press, 1997.

[13] K. Lee, Principles of CAD/CAM/CAE Systems, Addison Wesley Longman Inc.,

1999.

A4-25

XII ADM International Conference - Grand Hotel - Rimini Italy - Sept. 5

th

-7

th

, 2001

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- GE Design GuideDocument53 pagesGE Design GuideGuido Kats100% (1)

- DFM DFA Guidelines Manufacturing AssemblyDocument44 pagesDFM DFA Guidelines Manufacturing AssemblyOmer TokhNo ratings yet

- Design Guide For Reaction Injection Molded Plastic PartsDocument26 pagesDesign Guide For Reaction Injection Molded Plastic Partsxeron7126No ratings yet

- Aerodynamics Stability and ControlDocument134 pagesAerodynamics Stability and ControlmordorceteNo ratings yet

- Variable M Differential LockDocument1 pageVariable M Differential LockGirish KalsaitNo ratings yet

- Automotive Application Sensors Details..Document4 pagesAutomotive Application Sensors Details..Girish KalsaitNo ratings yet

- Variable Twin Turbo DieselDocument1 pageVariable Twin Turbo DieselGirish KalsaitNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- All Wheel Steer Electric Sports CarssDocument1 pageAll Wheel Steer Electric Sports CarssGirish KalsaitNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 20220720-MODIG-Supply Chain Manager (ENG)Document2 pages20220720-MODIG-Supply Chain Manager (ENG)abhilNo ratings yet

- December 2018: Russian Journal of Agricultural and Socio-Economic SciencesDocument339 pagesDecember 2018: Russian Journal of Agricultural and Socio-Economic Sciencesnahla saviraNo ratings yet

- Borneo United Sawmills SDN BHD V Mui Continental Insurance Berhad (2006) 1 LNS 372Document6 pagesBorneo United Sawmills SDN BHD V Mui Continental Insurance Berhad (2006) 1 LNS 372Cheng LeongNo ratings yet

- Activate Adobe Photoshop CS5 Free Using Serial KeyDocument3 pagesActivate Adobe Photoshop CS5 Free Using Serial KeyLukmanto68% (28)

- CLC Customer Info Update Form v3Document1 pageCLC Customer Info Update Form v3John Philip Repol LoberianoNo ratings yet

- HetNet Solution Helps Telcos Improve User Experience & RevenueDocument60 pagesHetNet Solution Helps Telcos Improve User Experience & RevenuefarrukhmohammedNo ratings yet

- WSM 0000410 01Document64 pagesWSM 0000410 01Viktor Sebastian Morales CabreraNo ratings yet

- The Punjab Commission On The Status of Women Act 2014 PDFDocument7 pagesThe Punjab Commission On The Status of Women Act 2014 PDFPhdf MultanNo ratings yet

- Parasim CADENCEDocument166 pagesParasim CADENCEvpsampathNo ratings yet

- Design of Shear Walls Using ETABSDocument97 pagesDesign of Shear Walls Using ETABSYeraldo Tejada Mendoza88% (8)

- Afar Partnerships Ms. Ellery D. de Leon: True or FalseDocument6 pagesAfar Partnerships Ms. Ellery D. de Leon: True or FalsePat DrezaNo ratings yet

- C - Official Coast HandbookDocument15 pagesC - Official Coast HandbookSofia FreundNo ratings yet

- Technical Skills:: Surabhi SrivastavaDocument3 pagesTechnical Skills:: Surabhi SrivastavaPrasad JoshiNo ratings yet

- FZ16 9B 1KD2 (Patada) PDFDocument62 pagesFZ16 9B 1KD2 (Patada) PDFPanthukalathil Ram100% (1)

- 16 BPI V FernandezDocument1 page16 BPI V FernandezAngelica Joyce BelenNo ratings yet

- 10 Appendix RS Means Assemblies Cost EstimationDocument12 pages10 Appendix RS Means Assemblies Cost Estimationshahbazi.amir15No ratings yet

- Machine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILUREDocument5 pagesMachine Design - LESSON 4. DESIGN FOR COMBINED LOADING & THEORIES OF FAILURE9965399367No ratings yet

- Best Homeopathic Doctor in SydneyDocument8 pagesBest Homeopathic Doctor in SydneyRC homeopathyNo ratings yet

- Scenemaster3 ManualDocument79 pagesScenemaster3 ManualSeba Gomez LNo ratings yet

- STS Chapter 5Document2 pagesSTS Chapter 5Cristine Laluna92% (38)

- Central BankDocument65 pagesCentral BankFarazNaseer100% (1)

- Factors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawatDocument26 pagesFactors Affecting Employee Turnover and Job Satisfaction A Case Study of Amari Hotels and Resorts Boondarig Ronra and Assoc. Prof. Manat ChaisawathumeragillNo ratings yet

- Safety interlock switches principlesDocument11 pagesSafety interlock switches principlesChristopher L. AlldrittNo ratings yet

- SABIC Ethanolamines RDS Global enDocument10 pagesSABIC Ethanolamines RDS Global enmohamedmaher4ever2No ratings yet

- cp2021 Inf03p02Document242 pagescp2021 Inf03p02bahbaguruNo ratings yet

- Memento Mori: March/April 2020Document109 pagesMemento Mori: March/April 2020ICCFA StaffNo ratings yet

- Pyramix V9.1 User Manual PDFDocument770 pagesPyramix V9.1 User Manual PDFhhyjNo ratings yet

- Admission Checklist (Pre-) Master September 2021Document7 pagesAdmission Checklist (Pre-) Master September 2021Máté HirschNo ratings yet

- CVP Solution (Quiz)Document9 pagesCVP Solution (Quiz)Angela Miles DizonNo ratings yet

- 11 Dole Philippines vs. Maritime Co., G.R. No. L-61352 PDFDocument8 pages11 Dole Philippines vs. Maritime Co., G.R. No. L-61352 PDFpa0l0sNo ratings yet