Professional Documents

Culture Documents

Stud Bolt Specification

Uploaded by

santoshblonkar0 ratings0% found this document useful (0 votes)

1K views8 pagesf

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentf

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views8 pagesStud Bolt Specification

Uploaded by

santoshblonkarf

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 8

STUD BOLT SPECIFICATION

High Tensile Hex Bolts/Screws

Metric Series - Dimensions

Note:

1. The bolts and screws will

generally confirm to

IS:1364

2. Threads will generally

confirm to class 6G of

IS:4218

3. Material High grade

carbon / alloy steel

4. Heat Treatment

: Property class 8.8 or

10.9

5. Thread Length : Bolts

shall be half threaded.

Screws

shall be fully threaded.

6. All dimensions are in

millimeters.

Specifications Diameter Range Length Range Property Grade

IS 1364 M 16 - M 64 30 mm - 450 mm IS 1367 Gr. 8.8 / 10.9

High Tensile Hex Head Nuts

Note:

1. The nuts will generally

confirm to IS:1364

2. Threads will generally

confirm to class 6H of

IS:4218

3. Material : High

grade carbon/alloy steel

4. Heat Treatment : As per

property class 8 or 10.

5. In Bolt/Nut assembly,

tightening should be

done by rotation of nut.

6. All dimensions are in

millimeters.

Specifications Diameter Range Grade

IS 1364 M 16 - M 64 IS 1367 Gr. 8 / 10

It is obvious from the following chart that high tensile bolt of property class 8.8 is approximately

four times stronger than an ordinary mild steel bolt of property class 4.6. This extra strength of

high tensile bolts can be used to upgrade an assembled joint from a low tensile one to high

tensile one to gain all the advantage described.

Advantage :

Reduced number of bolts. * Reduced bolt size. *Less numbers of holes.

Reduced size of holes. *Reduced assembly cost. *Reduced maintenance cost.

Strength Grade Tensile Grade Yield Grade

Yield Index

(4.6=100)

4.6 400 Mpa 240 Mpa 100

8.8 800 Mpa 640 Mpa 266

10.9 1000 Mpa 900 Mpa 375

Heavy Structural Friction Grip Bolts-IS 3757

Metric Series - Dimensions

Note:

1. The bolts and screws will generally

confirm to IS:3757-Metric Heavy

Structural Bolts.

2. Threads will confirm to class 6G of

IS:4218

3. Material : High grade carbon / alloy

steel

4. Heat Treatment : As per Property

class 8S or 10S

5. Thread Length

LT for < 100

LT for > 100

6. All dimensions are in millimeters.

Specifications Diameter Range Length Range Property Grade

IS 3757 M 16 - M 36 30 mm - 300 mm IS 1367 Gr. 8.5 / 10.5

Heavy Structural Friction Grip Nuts - IS 6623

Note:

1. The nuts will generally confirm to IS:6623

Metric Heavy Structural nuts.

2. Threads will generally confirm to class 6H of

IS:4218

3. Material : High grade carbon/alloy steel

4. Heat Treatment : As per property class 8 to

10.

5. In Bolt/Nut assembly, tightening should be

done by rotation of nut.

6. All dimensions are in millimeters.

Specifications Diameter Range Grade

IS 6623 M 16 - M 36 IS 1367 Gr. 8 / 10

In expanding use of constructional steel, particularly in bridges and other structures where the

weight of the structure itself is extremely important initiated to use a bolt with higher strength and

heavy hex than those of normal high tensile bolts.

Higher value for your money

Cost of fasteners is disproportionate with their utility. Consequently, the reliability of 95%

cost, of the project resets on 5% cost of the fastners giving them high value responsibility

in structural joints.

The IPC cost (In Place Coast), for a given joint, can be reduced be using lesser bolts or

smaller diameter bolts. This can only be done through smaller fasteners with tensile

strength.

= = = = = = == = = = =

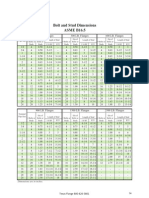

Stud Bolts ASTM A 193

Inch Series, UNC/UN - Dimensions

Note:

1. The stud bolts will generally confirm to

ASTM A 193 Gr:B7

2. Threads will confirm to class 2A of

unified coarse threads as per ANSI B1.1

3. Material : Medium Carbon Chromium

Molybdenum Steel. CR-MO Alloy Steel

(Cr-Mo).

4. Heat Treatment : As per Grade 'B7'

5. All dimensions are in inches.

Specifications Diameter Range Length Range Property Grade

ASTM A 193 1/2" - 3.3/4" 3.1/2" - 40" GR.B7

Hexagon Nuts ASTM A 194

Note:

1. The nuts will generally confirm to ANSI /

ASME B 18.22 Heavy Hex Nuts.

2. Threads will confirm to class 2B of ANSI

B1.1

3. Material and Heat Treatment : As per

Grade '2H'

4. In Bolt/Nut assembly, tightening should

be done by rotation of nut.

5. All dimensions are in inches.

Specifications Diameter Range Grade

ASTM A 194 1/2" - 3.3/4" GR.2H

Stud bolts grade B7 and associated hexagon nuts grade 2H are the most popular grades for

pressure vessels, valves and fittings for High-Temprature / High - Pressure services.

Temperature range : from min -46C to max +538C (for Guidance)

= = = = == = = == = = =

THREAD SIZE COMPARISON

Metric Products

Unified Inch

Products

B.S. Inch Products

Size

Thread Pitch & T.P.I.

Major Dia

Size

T.P.I

Majo

r Dia

Inch

Size

T.P.I

Major

Dia

Inch

T.P.

I

Majo

r Dia

Inch

Coarse Fine

BSW

BS

F

Pitc

h

mm

T.P.I.

Pitc

h

mm

T.P.I

.

mm Inch

UN

C

UN

F

BA

M3 0.50 51 - - 3.00

0.11

8

#5 40 44

0.12

5

1/8 40 - 0.125

#6 32 40

0.13

8

5

BA

4

BA

43.1

38.5

0.12

6

0.14

2

M4

M5

0.70

0.80

36

32

-

-

-

-

4.00

5.00

0.15

7

0.19

7

#8

#10

32

24

36

32

0.16

4

0.19

0

3

BA

3/16

24

32

0.187

34.8

0.16

1

2

BA

1

BA

31.3

28.2

0.18

5

0.20

7

M6 1.0 25 - - 6.00

0.23

6

1/4 20 28

0.25

0

1/4

0BA

20 26 0.250

25.4

0.23

6

M8

M10

1.25

1.50

20

17

1.00

1.25

25

20

8.00

10.0

0

0.31

5

0.39

4

5/16

3/8

18

16

24

24

0.31

3

0.37

5

5/16

3/8

18

16

22

20

0.313

0.375

M12

(M14

)

1.75

2.00

14.5

0

12.5

0

1.25

1.50

20

17

12.0

0

14.0

0

0.47

2

0.55

1

7/16

1/2

14

13

20

20

0.50

0

7/16

1/2

14

12

18

16

0.438

0.500

M16

(M18)

2.00

2.50

12.5

0

10

1.50

1.50

17

17

16.0

0

18.0

0

0.63

0

0.70

9

9/16

5/8

12

11

18

18

0.62

5

9/16

5/8

12

11

16

14

0.500

M20

(M22)

M24

2.50

2.50

3.00

10

10

8.5

1.50

1.50

2.00

17

17

13

20.0

0

22.0

0

24.0

0

0.78

7

0.86

6

0.94

5

3/4

7/8

1

10

9

8

16

14

12

0.75

0

0.87

5

1.00

0

3/4

7/8

1

10

9

8

12

11

10

0.75

0

0.875

1.000

(M27)

3.00

8.5

2.00

13

27.0

0

1.06

3

M30 3.50 7.25 2.00 13

30.0

0

1.18

1

1.1/

8

7 12 1.12

5

1.1/

8

7 9 1.125

(M33)

M36

3.50

4.00

7.25

6.40

2.00

3.00

13

8.5

33.0

0

36.0

0

1.29

9

1.41

7

1.1/

4

7

12

1.25

0

1.1/

4

7

9

1.250

(M39)

M42

4.00

4.50

6.40

5.60

3.00

3.00

8.5

8.5

39.0

0

42.0

0

1.53

5

1.65

3

1.1/

2

6

12

1.50

0

1.1/

2

6

8

1.500

Note : Sizes in brackets are non-preferred standards

= = == = = = = = = =

COMPARISON OF DIFFERENT STRENGTH GRADES

SEA B.S.

IS

I.S.D.

DIN

Ultimate Tensile Strength Hardness

Tonnes/in

2

(kgf/mm

2

)

Newtons/in

2

Min.

(kgf/mm

2

)

Pounds/in

2

Min.

(kgf/mm

2

)

BHN HRd HRc

4.6

400

(40.8)

114

209

67

95

Grade

2

60.000

(42.3)

(121)

(241)

70

100

4.8

420

(408)

124

209

71

95

500

(51.0)

147

209

79

95

Grade

2

74.000

(52.1)

(154)

(241)

80

100

5.8

52.0

(53.0)

152

207

P

35/45

55.2/71.0

152

209

82

95

6.8

600

(61.2)

181

238

89

99

R

45/55

(71.0/86.8)

201

285

(20/33)

S

50/60

(78.9/94.7)

223

310

8.8

800<M16

830>M16

(81.6)

(84.6)

219/285

243/319

20/30

23/34

Grade 1,20,000 (266) 25/34

5 (84.6) (318)

T

55/65

(86.8/102.6)

248

335

(24/36)

U

60/70

(94.7/110.5)

269

331

(28/36)

V

65/75

(120.6/118.4)

293

370

(31/40)

Grade

8

1,50,000

(1.5.7)

(311)

(362)

33/39

10.9

1,040

(106.0)

295

362

31/39

W

70/80

(110.5/126.3)

311

375

(33/41)

X

78/85

(118.4/134.2)

341

410

(37/44)

12.9

1,220

(124.4)

353

412

38/44

Y

80/90

(126.33/142.0)

363

429

39/46

Z

100 Min.

(157.8)

444

(47)

Note: 1.1 kgf=9.81 Newtons kgf/mm

2

= 1421.7 Psi 2) Values in brackets are approximate

conversions.

= = = = = = = =

Grade 8.8 means , Approx. 800 MPa TS and 640 MPa yield strength( you will arrive at the YS by

multiplying the both the numbers times 10. That is 8x8x10=640)

Similarly , 10.9 means approx.1000 MPa TS and 900 MPa yield strength. I have given below the

exact details.

Proper

ty

Class

Tensile

strength,

Mpa

Hardne

ss Material

heat

treatment tempering

4.6 400

B67-

B87

low or medium carbon steel

witth max limits for C 0.55,

P0.048, S0.058 no

4.8 420

B71-

B87

5.8 520

B82-

B95

8.8 830

C23-

C34

medium carbon steel with

max limits for C0.28- 0.55,

P0.048, S0.058

oil

quenched

min 425

deg C

9.8 900

C27-

C36

min 410

deg C

10.9 1040

C33-

C39

min425 de

g C

12.9 1220

C38-

C44

medium carbon steel with

max limits for C0.31- 0.65,

P 0.045 MAX, S 0.045MAX

oil

quenched min 380de

= = = == = = == =

You might also like

- All Materials DocumentsDocument1 pageAll Materials DocumentsHarnish BariaNo ratings yet

- SU Blind Plate ThicknessDocument2 pagesSU Blind Plate Thicknessmanoj19801226100% (1)

- PIPE DIMENSIONS AND SPECIFICATIONSDocument13 pagesPIPE DIMENSIONS AND SPECIFICATIONSChristopher Bodys100% (1)

- 19013 MTC【CY】 PDFDocument1 page19013 MTC【CY】 PDFConstruction ProjectsNo ratings yet

- Pipe SpecDocument84 pagesPipe SpecAbdullahNo ratings yet

- Code Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Document4 pagesCode Construction: ASME B16.49 (Induction Bend) Outside Diameter O.D. (MM) Angle Bending Ø Tangent Length at Each End Wall Thickness (MM)Edwardhutauruk100% (1)

- Make $50 A Day Autopilot MethodDocument4 pagesMake $50 A Day Autopilot MethodJadon BoytonNo ratings yet

- Pipes. Pressure and Wall Thickness Equations and Data For A Straight Pipe. ASME B31.1 and B31.3.odsDocument100 pagesPipes. Pressure and Wall Thickness Equations and Data For A Straight Pipe. ASME B31.1 and B31.3.odsNaufal FirmansyahNo ratings yet

- PROTON Preve 2012 On 4 DR Sal 1.6 Premium (CFE) AUTO 138Bhp (A) (04/12-)Document12 pagesPROTON Preve 2012 On 4 DR Sal 1.6 Premium (CFE) AUTO 138Bhp (A) (04/12-)bluhound1No ratings yet

- Asme Flange RatingsDocument4 pagesAsme Flange RatingsvaliullahNo ratings yet

- Stored Energy CalculationDocument4 pagesStored Energy Calculationaauppal0% (1)

- MATERIAL Comp - Chart China GB Stand. Vis A Vis ASME Stand.Document1 pageMATERIAL Comp - Chart China GB Stand. Vis A Vis ASME Stand.S.KAMBAN100% (1)

- Cast Basalt Information SheetDocument4 pagesCast Basalt Information SheetVijayakumar AtthuluriNo ratings yet

- Approvals Management Responsibilities and Setups in AME.BDocument20 pagesApprovals Management Responsibilities and Setups in AME.BAli LoganNo ratings yet

- Forged Flanges Pressure RatingsDocument1 pageForged Flanges Pressure RatingsEswara Rao BodduNo ratings yet

- TC-ST52 MSLDocument1 pageTC-ST52 MSLVijay BhureNo ratings yet

- Material Specifications Tradename Astm Specification UNS Werkstoff DIN Barstock Forging Casting Diversity Rpa Key Pipe Fittings Number NumberDocument3 pagesMaterial Specifications Tradename Astm Specification UNS Werkstoff DIN Barstock Forging Casting Diversity Rpa Key Pipe Fittings Number NumberErcan YilmazNo ratings yet

- Bolting Information Pertaining To ASTM A193Document25 pagesBolting Information Pertaining To ASTM A193dirtylsu100% (2)

- Flanges - Hydrostatic Test Pressure PDFDocument8 pagesFlanges - Hydrostatic Test Pressure PDFnoha azamaliNo ratings yet

- MTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Document3 pagesMTC-SML (1) - 4500528257 I - Ii - Tubos GB - SCH 6MT - 210251 - 210291 - 210377Saul Omar Fernandez RojasNo ratings yet

- List of Useful Materials StandardDocument6 pagesList of Useful Materials StandardStephen MontelepreNo ratings yet

- S.NO. Description Unit QTY Remarks 1.0 Pipe: 1.1 A B: Total (Usd) Rate (USD /unit)Document6 pagesS.NO. Description Unit QTY Remarks 1.0 Pipe: 1.1 A B: Total (Usd) Rate (USD /unit)Mavia KhanNo ratings yet

- Alco ValvesDocument56 pagesAlco ValvesGuillermo de la Fuente SantiagoNo ratings yet

- IS-3757 HT BoltDocument6 pagesIS-3757 HT BoltRam Balak RoyNo ratings yet

- 03CA2SAE: Specification Piping Material ClassDocument7 pages03CA2SAE: Specification Piping Material Classabhishek186186No ratings yet

- 91 SOC Interview Question BankDocument3 pages91 SOC Interview Question Bankeswar kumarNo ratings yet

- Flanges Table: ANSI B16.5 #150Document17 pagesFlanges Table: ANSI B16.5 #150Gaurav SalujaNo ratings yet

- API602 Forged Steel Gate & Globe ValvesDocument4 pagesAPI602 Forged Steel Gate & Globe ValvesThomasFrenchNo ratings yet

- Sau - MTC 0001-002163 - Acc.aºcºDocument24 pagesSau - MTC 0001-002163 - Acc.aºcºrosa aurora montesano somarribaNo ratings yet

- PSC Single SpanDocument99 pagesPSC Single SpanRaden Budi HermawanNo ratings yet

- Carbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingDocument9 pagesCarbon Steel ASME B36.10M Stainless Steel ASME B36.19M Cu-Ni Brass Bronze Thermoplastic ThermosettingkaviramanNo ratings yet

- Pipe Dimensions Imperial/Metric Pipe Chart: Nominal Pipe Size MM OD MM Wall Thickness MM KG/MDocument6 pagesPipe Dimensions Imperial/Metric Pipe Chart: Nominal Pipe Size MM OD MM Wall Thickness MM KG/MAmlan SahaNo ratings yet

- 6 Acop v. OmbudsmanDocument1 page6 Acop v. OmbudsmanChester Santos SoniegaNo ratings yet

- MA5616 V800R311C01 Configuration Guide 02Document741 pagesMA5616 V800R311C01 Configuration Guide 02Mário Sapucaia NetoNo ratings yet

- EIL Technical Notes For Pipe FittingsDocument9 pagesEIL Technical Notes For Pipe FittingsMurli ramchandranNo ratings yet

- Bolt and Stud DimentionDocument1 pageBolt and Stud DimentionwhngomjNo ratings yet

- API 5L Line Pipe 24 Inch SCH 40 ERW PipeDocument14 pagesAPI 5L Line Pipe 24 Inch SCH 40 ERW PipeJuan CilloNo ratings yet

- Flanges & Pipe Fittings SpecificationsDocument3 pagesFlanges & Pipe Fittings Specificationsmcoswald83No ratings yet

- Catalogo Niple Swage 03Document1 pageCatalogo Niple Swage 03BuenDíaNo ratings yet

- Instrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard RatingDocument5 pagesInstrumentation Pipe & Weld Fittings: 6000psig, 10000psig and Standard Ratinggohjh80No ratings yet

- Metal Chemical CompositionDocument1 pageMetal Chemical CompositionprathmeshNo ratings yet

- Denso Quantity Estimate Sheet PDFDocument2 pagesDenso Quantity Estimate Sheet PDFIvan RocoNo ratings yet

- Tube and Pipe Material Comparison ChartDocument2 pagesTube and Pipe Material Comparison Chartvalli rajuNo ratings yet

- Boq For AS BoilerDocument1 pageBoq For AS BoilerGayan ChathurangaNo ratings yet

- Nomial Carbon & Alloy Steel Pipe Table (Size-Weight)Document1 pageNomial Carbon & Alloy Steel Pipe Table (Size-Weight)Mostafa ShipishlyNo ratings yet

- 5D Bends Combine RFQDocument376 pages5D Bends Combine RFQMuhammad Ghufran KhanNo ratings yet

- Asme Section Ii A-2 Sa-815 Sa-815mDocument10 pagesAsme Section Ii A-2 Sa-815 Sa-815mdavid perezNo ratings yet

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISDocument50 pagesSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediNo ratings yet

- Flange Dim EN1092 1 BS4504Document13 pagesFlange Dim EN1092 1 BS4504rcpretoriusNo ratings yet

- Is 3589Document22 pagesIs 3589Otavio123100% (1)

- Welding of P91Document37 pagesWelding of P91Shyam Sundar GayenNo ratings yet

- ASTM A53 Vs A500 EquivalenceDocument6 pagesASTM A53 Vs A500 Equivalenceemmanuilmoulos6339No ratings yet

- G12MF TypeDocument1 pageG12MF Typeosto72No ratings yet

- b2020-Tdc-Fas-004 Fasteners r3Document2 pagesb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranNo ratings yet

- ANSI B 16.48 Flange Dimensions for Class 150, 300 and 600Document3 pagesANSI B 16.48 Flange Dimensions for Class 150, 300 and 600l kishoreNo ratings yet

- FRP Piping SystemDocument15 pagesFRP Piping Systemindia100% (1)

- Sample MTCDocument1 pageSample MTCheavens indiaNo ratings yet

- Induction BendingDocument2 pagesInduction BendingshaonaaNo ratings yet

- Hyundai Pipe CatalogueDocument36 pagesHyundai Pipe Cataloguefelram100% (2)

- 60 MM SA 516 GR 70 MTCDocument21 pages60 MM SA 516 GR 70 MTCgeoanburajaNo ratings yet

- Tube Bundle DrawingDocument1 pageTube Bundle DrawingVeera ManiNo ratings yet

- Material Specification for Forged Bar and Ring in ASTM A182-F51Document2 pagesMaterial Specification for Forged Bar and Ring in ASTM A182-F51Amjath PallasNo ratings yet

- Bolts ReferencesDocument8 pagesBolts ReferencesvinnuzNo ratings yet

- P.F. High Strength Structural Fasteners Dimensions & SpecificationsDocument4 pagesP.F. High Strength Structural Fasteners Dimensions & SpecificationspajipitarNo ratings yet

- RITZ Screw SpecificationDocument12 pagesRITZ Screw Specificationmx100sanookNo ratings yet

- Fastenr GradesDocument5 pagesFastenr GradesVipul ShereNo ratings yet

- Crane Engineering Data2Document40 pagesCrane Engineering Data2jerry666aNo ratings yet

- Develop Project Team Manage Project TeamDocument1 pageDevelop Project Team Manage Project TeamsantoshblonkarNo ratings yet

- 1 Torque SpedDocument1 page1 Torque SpedsantoshblonkarNo ratings yet

- Cost Estimating Cost Budgeting Cost ControlDocument1 pageCost Estimating Cost Budgeting Cost ControlsantoshblonkarNo ratings yet

- 1 AmeterDocument1 page1 AmetersantoshblonkarNo ratings yet

- Scope Planning Scope Definition Create WBS Scope Verification Scope ControlDocument1 pageScope Planning Scope Definition Create WBS Scope Verification Scope ControlsantoshblonkarNo ratings yet

- 1 System Used For Bonding TheDocument1 page1 System Used For Bonding ThesantoshblonkarNo ratings yet

- 2 Force CoefficientsDocument1 page2 Force CoefficientssantoshblonkarNo ratings yet

- 1 Develop Project CharterDocument1 page1 Develop Project ChartersantoshblonkarNo ratings yet

- 4 It Shall Be The Responsibility of The ApplicatorDocument1 page4 It Shall Be The Responsibility of The ApplicatorsantoshblonkarNo ratings yet

- Project planning and scheduling guideDocument1 pageProject planning and scheduling guidesantoshblonkarNo ratings yet

- 1 Overlap Scarf JointDocument1 page1 Overlap Scarf JointsantoshblonkarNo ratings yet

- 1 Peak Gust Velocity Averaged Over A ShortDocument1 page1 Peak Gust Velocity Averaged Over A ShortsantoshblonkarNo ratings yet

- 3 All Holes Left After Removal of Ties To Secure andDocument1 page3 All Holes Left After Removal of Ties To Secure andsantoshblonkarNo ratings yet

- 1.6.2 What Does A Hydrostatic or Pneumatic Pressure Test Do?Document1 page1.6.2 What Does A Hydrostatic or Pneumatic Pressure Test Do?santoshblonkarNo ratings yet

- 1 Weld Surfaces Shall Be SmoothDocument1 page1 Weld Surfaces Shall Be SmoothsantoshblonkarNo ratings yet

- 5 of A Hydrostatic TestDocument1 page5 of A Hydrostatic TestsantoshblonkarNo ratings yet

- 7 Physics of SolidsDocument1 page7 Physics of SolidssantoshblonkarNo ratings yet

- 2 Proper Curing of The Concrete Shall Be EnsuredDocument1 page2 Proper Curing of The Concrete Shall Be EnsuredsantoshblonkarNo ratings yet

- 1 Rubberlining Contractor Shall Inspect EquipmentDocument1 page1 Rubberlining Contractor Shall Inspect EquipmentsantoshblonkarNo ratings yet

- Example 1.5 Problem SolutionDocument1 pageExample 1.5 Problem SolutionsantoshblonkarNo ratings yet

- 1.6,1 Asme Code Requirements: Completed Asmeboiler and PressureDocument1 page1.6,1 Asme Code Requirements: Completed Asmeboiler and PressuresantoshblonkarNo ratings yet

- 8 Relationship Between Load and Induced StressDocument1 page8 Relationship Between Load and Induced StresssantoshblonkarNo ratings yet

- 6 Design of Tall Pressure Vessels Subject To Wind andDocument1 page6 Design of Tall Pressure Vessels Subject To Wind andsantoshblonkarNo ratings yet

- 2 The Rubberlining ManufacturerDocument1 page2 The Rubberlining ManufacturersantoshblonkarNo ratings yet

- 1 It Is Listed As The Official or CoDocument1 page1 It Is Listed As The Official or CosantoshblonkarNo ratings yet

- 9 Membrane Theory of Pressure Vessel DesignDocument1 page9 Membrane Theory of Pressure Vessel DesignsantoshblonkarNo ratings yet

- 10 English Is A Germanic Language of The IndoDocument1 page10 English Is A Germanic Language of The IndosantoshblonkarNo ratings yet

- 5 Design Tolerances and Safety FactorsDocument1 page5 Design Tolerances and Safety FactorssantoshblonkarNo ratings yet

- 3 Weather DataDocument1 page3 Weather DatasantoshblonkarNo ratings yet

- 4 The Final Acceptance Shall Be Effective Only After The Submission of TheDocument1 page4 The Final Acceptance Shall Be Effective Only After The Submission of ThesantoshblonkarNo ratings yet

- Lab Equipment Catalog Research Concept LabDocument40 pagesLab Equipment Catalog Research Concept LabSeetanshu AwasthiNo ratings yet

- Investigations in Environmental Science: A Case-Based Approach To The Study of Environmental Systems (Cases)Document16 pagesInvestigations in Environmental Science: A Case-Based Approach To The Study of Environmental Systems (Cases)geodeNo ratings yet

- Infineon ICE3BXX65J DS v02 - 09 en PDFDocument28 pagesInfineon ICE3BXX65J DS v02 - 09 en PDFcadizmabNo ratings yet

- Educ 3 ReviewerDocument21 pagesEduc 3 ReviewerMa.Lourdes CamporidondoNo ratings yet

- Maximum Yield USA 2013 December PDFDocument190 pagesMaximum Yield USA 2013 December PDFmushroomman88No ratings yet

- Converted File d7206cc0Document15 pagesConverted File d7206cc0warzarwNo ratings yet

- CS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationDocument28 pagesCS221 - Artificial Intelligence - Machine Learning - 3 Linear ClassificationArdiansyah Mochamad NugrahaNo ratings yet

- Lunakleen: Standard Type Hepa FilterDocument1 pageLunakleen: Standard Type Hepa FilterRyan Au YongNo ratings yet

- Operations Management For Competitive Advantage 11Th Edition Solutions Manual PDFDocument2 pagesOperations Management For Competitive Advantage 11Th Edition Solutions Manual PDFLouis DodsonNo ratings yet

- A Survey of The Advancing Use and Development of Machine Learning in Smart ManufacturingDocument32 pagesA Survey of The Advancing Use and Development of Machine Learning in Smart Manufacturingbeben_19No ratings yet

- Accor vs Airbnb: Business Models in Digital EconomyDocument4 pagesAccor vs Airbnb: Business Models in Digital EconomyAkash PayunNo ratings yet

- SQL DBA Mod 1 IntroDocument27 pagesSQL DBA Mod 1 IntroDivyaNo ratings yet

- Chilled Beam SystemsDocument3 pagesChilled Beam SystemsIppiNo ratings yet

- Modicon Quantum - 140DDI85300Document5 pagesModicon Quantum - 140DDI85300Samdan NamhaisurenNo ratings yet

- Rodriguez, Joseph Lorenz Ceit-08-402ADocument7 pagesRodriguez, Joseph Lorenz Ceit-08-402AJOSEPH LORENZ RODRIGUEZNo ratings yet

- Unit 4 Probability AssignmentsDocument8 pagesUnit 4 Probability AssignmentsSumycheen BhusalNo ratings yet

- Flex VPNDocument3 pagesFlex VPNAnonymous nFOywQZNo ratings yet

- 60 Years of Cannes Lions Infographics: The 50sDocument9 pages60 Years of Cannes Lions Infographics: The 50sSapientNitroNo ratings yet

- Questions For ReviewDocument2 pagesQuestions For ReviewJoemar JavierNo ratings yet

- Practice Questions & Answers: Made With by SawzeeyyDocument141 pagesPractice Questions & Answers: Made With by SawzeeyyPhake CodedNo ratings yet

- Term Paper Mec 208Document20 pagesTerm Paper Mec 208lksingh1987No ratings yet

- Cambridge IGCSE: GEOGRAPHY 0460/13Document32 pagesCambridge IGCSE: GEOGRAPHY 0460/13Desire KandawasvikaNo ratings yet

- Presenting India's Biggest NYE 2023 Destination PartyDocument14 pagesPresenting India's Biggest NYE 2023 Destination PartyJadhav RamakanthNo ratings yet