Professional Documents

Culture Documents

Scaffolding Guide Book - Literature

Uploaded by

Jogi Oscar SinagaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scaffolding Guide Book - Literature

Uploaded by

Jogi Oscar SinagaCopyright:

Available Formats

Welcome to the Welcome to the Welcome to the Welcome to the

Scaffold Guide Scaffold Guide Scaffold Guide Scaffold Guide B BB Book. ook. ook. ook.

This booklet contains information on how to This booklet contains information on how to This booklet contains information on how to This booklet contains information on how to

erect, stabilize, dismantle and maintain your erect, stabilize, dismantle and maintain your erect, stabilize, dismantle and maintain your erect, stabilize, dismantle and maintain your

EQUIPTEC aluminium scaffolding. EQUIPTEC aluminium scaffolding. EQUIPTEC aluminium scaffolding. EQUIPTEC aluminium scaffolding.

Mobile Scaffolds Mobile Scaffolds Mobile Scaffolds Mobile Scaffolds

WORK FASTER AND SAFER BY FOLLOWING THESE SEVEN

ESSENTIAL RULES:

1. Never move scaffold when someone is on it.

2. Always re-level the scaffold after moving.

3. Always apply brakes on all four wheels before using the scaffold.

4. Make sure the scaffold is used on a firm surface, which will support the

loaded scaffold weight.

5. Do not overload the scaffold weight limits are clearly shown on the

side of the platforms.

6. Do not allow scaffold to come within 4 metres of overhead power lines.

7. Make sure the area of operations is free of floor penetrations and other

hazards.

Page 1 Page 1 Page 1 Page 1

Attention: Attention: Attention: Attention:- -- - Safety Directive Safety Directive Safety Directive Safety Directive

Attention all EQUIPTEC Aluminium Scaffolding Customers: Attention all EQUIPTEC Aluminium Scaffolding Customers: Attention all EQUIPTEC Aluminium Scaffolding Customers: Attention all EQUIPTEC Aluminium Scaffolding Customers:

Please note that when horizontals are clipped to standards (vertical member) they are designed for sideways

deflection only and are not load supporting.

Do Do Do Do not not not not step step step step on these horizontals when climbing into the scaffold.

Please do do do do not not not not stand stand stand stand on midrails or handrails.

Misuse by dropping from height or throwing onto the back of vehicles for example can damage the ends of

graspers. Fittings should be regularly inspected and any damaged fitting should be replaced.

Further, if the grasper becomes closed or extended in any way for any reason it is to be discarded.

Transportation Transportation Transportation Transportation

All loads must be securely fastened as slippage occurs with aluminium components.

Storage Storage Storage Storage

Equipment is best stacked away from corrosive materials. If stored indoors stack one on top of each other and

outdoors store upright to allow moisture to run off.

Page 2 Page 2 Page 2 Page 2

Maximum height Maximum height Maximum height Maximum height

All scaffolds with a platform height of 5.0m or greater must be constructed/dismantled only under the supervision

of a suitably qualified and certificated scaffolder.

The maximum height of the working platform of a mobile scaffold should not exceed three (3) times the smallest

base dimension e.g. 3.0m long x 1.3m wide scaffolds should not exceed 3 x 1.3m = 3.9m.

While using standard width gear (1.3m wide) to achieve a platform height greater than 3 x the smallest base

dimension, extra wide bases or outrigger props are acceptable. Some of the recommended configurations are

depicted at the back of this book. (If the height you require is not included, please contact EQUIPTEC.)

However, due to the lightweight nature of aluminium scaffolding, additional outriggers may be necessary for some

configurations to comply strictly with AS/NZS 1576.1 clause 2.7. Please contact EQUIPTEC for advice.

The actual centre measurement of the scaffold frames are as follows:

(Remember to add 48.4mm to find the actual frame width)

0.7m wide = 679mm 1.3m wide = 1,286mm 2.0m wide = 1,913mm

2.5m wide = 2,493mm 3.0m wide = 3,049mm

Scaffold lengths are exactly the same i.e. 2.5m long x 2.5m wide scaffold is 2,493mm centres both ways. This can

be a big advantage on awkward jobs e.g. when steel pipe work passes through a scaffold, the direction of frames

and braces can be reversed partway up.

All transom centres on all frames are 465mm apart. This means two transom spaces (930mm) exceeds the

Australian Standard minimum hand rail height, of 900mm. (AS 1576.1).

Standard base frames with castors installed = 2,110mm actual height.

1.9m high frames have 4 rungs = 1,860mm actual height.

1.4m high frames have 3 rungs = 1,395mm actual height.

0.9m high frames have 2 rungs = 930mm actual height.

Extra width base frames with castors installed = 1,450mm actual height.

Screwjacks have 350mm of threaded adjustment available for uneven surfaces.

For higher mobile scaffolds obtain EQUIPTECS recommendations.

Equiptec scaffolds may also be used in static situations and utilising walk-through frames for multi-bay link-up

scaffolds. These applications may require the scaffold to be built well beyond the ratios/requirements mentioned.

This is allowable provided it is constructed/dismantled only under the supervision of a suitably qualified and

certified scaffolder. It must be built on base plates (not castors) and tied to a suitably strong structure using

methods complying with AS/NZS 4576:1995. Contact EQUIPTEC for load capacity information.

Page 3 Page 3 Page 3 Page 3

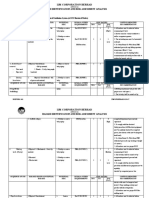

Erection of EQUIPTEC Mobile Scaffolding Erection of EQUIPTEC Mobile Scaffolding Erection of EQUIPTEC Mobile Scaffolding Erection of EQUIPTEC Mobile Scaffolding

Carry out risk assessment and check for potential hazards before erecting scaffold.

Please note that when horizontals are clipped to standards (vertical member) they were designed for sideways

deflection only and are not load supporting. Therefore do no step on these horizontals when climbing onto the

scaffold. Do not stand on midrails or handrails.

Instruction:

Step 1 Step 1 Step 1 Step 1

Lock brakes on castors and attach 2 horizontal braces (yellow) to inside of standards (vertical member) above

bottom transom (horizontal member)

Always ensure you understand and can comply with the regulations that apply to the erection and use of

scaffolding in the area that you intend using this equipment.

Page 4 Page 4 Page 4 Page 4

Step 2 Step 2 Step 2 Step 2

Lock brakes on castors of second base frame and attach horizontal braces to INSIDE of standards, use screwjacks

to approximately level scaffold.

Step 3 Step 3 Step 3 Step 3

Attach plan brace (red) to diagonally opposite standards. The suggested position is just above the castor.

Plan bracing should be incorporated at the base of a mobile scaffold to provide stability, to the base of

the scaffold. Alternatively the base of the mobile may be fully decked out.

Page 5 Page 5 Page 5 Page 5

Step 4 Step 4 Step 4 Step 4

Install 4 diagonal braces (silver) from bottom transom, to third transom up (2 spaces). These should be as close as

practical to the outside. Level scaffold in each direction using height adjustable screwjacks.

NB NB NB NB 0.7m wide scaffolds require only 2 diagonal braces running in opposite directions.

Step 5 Step 5 Step 5 Step 5

Add upper frames 1.9m high, 1.4m high and 0.9m high as required, installing 4 diagonal braces per lift in 1.3m

wide gear and 2 diagonal opposing braces per lift in 0.7m wide gear. Each brace should be attached to the top

transom of the frame below.

For a scaffold that requires intermediate platforms to aid erection, clip horizontal braces as handrails while adding

height.

Carefulness commonsense and caution are factors that cannot be built into scaffolding. These must be Carefulness commonsense and caution are factors that cannot be built into scaffolding. These must be Carefulness commonsense and caution are factors that cannot be built into scaffolding. These must be Carefulness commonsense and caution are factors that cannot be built into scaffolding. These must be

provided by pers provided by pers provided by pers provided by person(s) erec on(s) erec on(s) erec on(s) erecting, using, dismantling and mainta ting, using, dismantling and mainta ting, using, dismantling and mainta ting, using, dismantling and maintain in in inin in in ing equipment. g equipment. g equipment. g equipment.

Page 6 Page 6 Page 6 Page 6

Step 6 Step 6 Step 6 Step 6

When the required platform height is reached, ensure 2 transom spaces extend above for handrails. Install

platform, internal access ladders and toe boards.

The ladder can extend up to 2 rungs above the platform levelbut must at least, be up to the same level as the

platform.

Attach 4 horizontal (yellow) braces to standards as handrails and midrails. Please note that when horizontals Please note that when horizontals Please note that when horizontals Please note that when horizontals

are clipped to standards (vertical member) are clipped to standards (vertical member) are clipped to standards (vertical member) are clipped to standards (vertical member) they are designed for sideways deflection only and are not load they are designed for sideways deflection only and are not load they are designed for sideways deflection only and are not load they are designed for sideways deflection only and are not load

supporting. Therefore do not step on these horizontals when climbing into the scaffold. Do not stand on supporting. Therefore do not step on these horizontals when climbing into the scaffold. Do not stand on supporting. Therefore do not step on these horizontals when climbing into the scaffold. Do not stand on supporting. Therefore do not step on these horizontals when climbing into the scaffold. Do not stand on

midrails and handrails. midrails and handrails. midrails and handrails. midrails and handrails.

Dismantle is the reverse of the above Dismantle is the reverse of the above Dismantle is the reverse of the above Dismantle is the reverse of the above

Pa Pa Pa Page 7 ge 7 ge 7 ge 7

Outrigger Props Outrigger Props Outrigger Props Outrigger Props

Adjustable Outrigger Props are normally used to increase the base size of a scaffold when space or obstruction do

not permit the use of Extra Wide Base Frames.

Two outrigger props may be used when scaffold is against a wall or solid structure and the scaffold platform

height, does not exceed the wall height. At all other times four outrigger props should be used (two on each side).

The normal industry accepted rule of platform height not exceeding 3 times the smallest base dimension applies

e.g. 1.3m wide scaffold with outrigger props adjusted outwards by 0.7m (can then be erected to 6.0m platform

height. However due to the lightweight nature of Aluminium scaffolding additional outriggers may be necessary

for some configurations to comply strictly with AS/NZS 1576.1 clause 2.7. Contact EQUIPTEC for advice.

The supporting surface for the outrigger props must give adequate support. Outriggers must then be adjusted to

provide firm pressure on the supporting surface.

Sole plates must be used on soft ground.

When moving mobile scaffolds with outriggers fitted, it is good practice to lift Outriggers feet / the minimum

required space to achieve mobility. Care is needed because of the reduced base size when feet are clear of the

supporting surface.

Page 8 Page 8 Page 8 Page 8

EXTRA WIDE BASE FRAME EXTRA WIDE BASE FRAME EXTRA WIDE BASE FRAME EXTRA WIDE BASE FRAME

Carry out risk assessment and check for potential hazards before erecting scaffold. Please note that when Carry out risk assessment and check for potential hazards before erecting scaffold. Please note that when Carry out risk assessment and check for potential hazards before erecting scaffold. Please note that when Carry out risk assessment and check for potential hazards before erecting scaffold. Please note that when

horizontals are clipped to standards (vertical member) they are designed for sideways deflection onl horizontals are clipped to standards (vertical member) they are designed for sideways deflection onl horizontals are clipped to standards (vertical member) they are designed for sideways deflection onl horizontals are clipped to standards (vertical member) they are designed for sideways deflection only and y and y and y and

are not load supporting. Therefore do not step on these horizontals when climbing into the scaffold. Do are not load supporting. Therefore do not step on these horizontals when climbing into the scaffold. Do are not load supporting. Therefore do not step on these horizontals when climbing into the scaffold. Do are not load supporting. Therefore do not step on these horizontals when climbing into the scaffold. Do

not stand on midrails or handrails. not stand on midrails or handrails. not stand on midrails or handrails. not stand on midrails or handrails.

Follow steps 1,2,3,4 as set out on pp 4-6. Ensure frames are orientated in the same direction and 1 plan brace

(red) is installed directly under where 1.3m wide tower will be. Level scaffold in each direction using height

adjustable screwjacks. Your scaffold should now look like this:

Page 9 Page 9 Page 9 Page 9

Step 5 Step 5 Step 5 Step 5

Add upper frames 1.9m high, 1.4m high and 0.9m high as required, installing 4 diagonal braces per lift in 1.3m

wide gear. Each brace should be attached to the top transom of the frame below.

For a scaffold that requires intermediate platforms to aid erection, clip horizontal braces as handrails while adding

height. Install spur braces (as shown) as soon as possible and intermediate landing platform with access ladder.

Hand and mid rails need to be provided for intermediate work level/s.

Page 10 Page 10 Page 10 Page 10

Step 6 Step 6 Step 6 Step 6

When the required platform height is reached, ensure 2 transom spaces extend above for handrails. Install

platforms, internal access ladders and toe boards. Attach 4 horizontal (yellow) braces to standards as handrails

and midrails.

Please note that when hor Please note that when hor Please note that when hor Please note that when horizontals are clipped to standards (vertical member) they are designed for izontals are clipped to standards (vertical member) they are designed for izontals are clipped to standards (vertical member) they are designed for izontals are clipped to standards (vertical member) they are designed for

sideways deflection only and are not load supporting. Therefore do no step on these horizontals when sideways deflection only and are not load supporting. Therefore do no step on these horizontals when sideways deflection only and are not load supporting. Therefore do no step on these horizontals when sideways deflection only and are not load supporting. Therefore do no step on these horizontals when

climbing into the scaffold climbing into the scaffold climbing into the scaffold climbing into the scaffold do not do not do not do not stand on midrails or handrails. stand on midrails or handrails. stand on midrails or handrails. stand on midrails or handrails.

Fully decked work levels can vary according to work requirements.

Ladder access platforms may vary to suit the length of the ladder being used. If intermediate working levels are

required these must be fully decked.

Dismantle is the reverse of the above Dismantle is the reverse of the above Dismantle is the reverse of the above Dismantle is the reverse of the above

Intermediate working platforms may vary according to the work requirements. (However, ensure ladder access

and hand and midrails are installed as per erection procedure given.)

Only suitably qualified personnel should erect and dismantle scaffolding Only suitably qualified personnel should erect and dismantle scaffolding Only suitably qualified personnel should erect and dismantle scaffolding Only suitably qualified personnel should erect and dismantle scaffolding

Page 11 Page 11 Page 11 Page 11

Maintenance (and when to discard component!) Maintenance (and when to discard component!) Maintenance (and when to discard component!) Maintenance (and when to discard component!)

When to discard component:

If grasper becomes closed or extended in any way for any reason it is to be discarded.

If a coupler is cracked it should be discarded.

Whilst mid denting or bowing of tube components may be straightened, if the component is creased it should

be discarded. Contact EQUIPTEC for clarification if in doubt.

Transtex purpose built non-slip plywood will withstand many years of outdoor use without any protection.

For those castors with a grease nipple fitted

Twice per year (more frequently under dirty conditions) pump a small amount of grease in until it comes out

through the top pintol bearing. None will come out the bottom bearing as it has a seal to the outside.

Screwjacks should be fully wound out occasionally, brushed clean and lightly oiled. (We suggest kerosene and

engine oil mixed 50:50.)

Brace grasper pins and springs should also be given a few drops of light oil, particularly if stored in the weather.

All base frames are fitted with plastic plugs internally on the standards to exclude dirt, plaster etc from interfering

with the free turning of the jacks. Base frames should be turned upside down and tapped on the ground whenever

a build up of foreign material occurs.

If plugs should ever be damaged please call EQUIPTEC, we will be glad to post replacements to you.

Any cracks in welds should be ground out and repaired by a certified welder or returned to be repaired by certified

EQUIPTEC welding staff.

Couplers and accessories should be maintained so that they can be used as intended, for example, nuts should be

free running and swivels should turn freely.

Avoid excessive oil, grease or paint, which can cause a coupler or accessory to slip.

Do not apply heat to couplers and accessories.

A bent plate of an adjustable base plate should be straightened. If straightening is not possible, the base plate

should be replaced.

Page 12 Page 12 Page 12 Page 12

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Myer Contractor Safety Policies SummaryDocument17 pagesMyer Contractor Safety Policies Summaryvhlactaotao0% (1)

- Guidelines for Marine Lifting OperationsDocument32 pagesGuidelines for Marine Lifting OperationsFoxg98924No ratings yet

- Hsse Slide (Contractor) PDFDocument25 pagesHsse Slide (Contractor) PDFelyasNo ratings yet

- 41953Document18 pages41953Jogi Oscar SinagaNo ratings yet

- MSC in Lift Engineering, University of NorthamptonDocument6 pagesMSC in Lift Engineering, University of NorthamptonJogi Oscar Sinaga100% (1)

- Ufc 3 430 07Document84 pagesUfc 3 430 07Jogi Oscar SinagaNo ratings yet

- WLL Veification of Lifting Set Base On BS en 12079Document3 pagesWLL Veification of Lifting Set Base On BS en 12079JogiNo ratings yet

- Spreader BarDocument1 pageSpreader BarJogi Oscar SinagaNo ratings yet

- Hydrogen Embrittlement: Causes, Effects & Prevention: Sidheshwar Kumar 107MM024Document24 pagesHydrogen Embrittlement: Causes, Effects & Prevention: Sidheshwar Kumar 107MM024Jogi Oscar SinagaNo ratings yet

- TNT 02-2Document8 pagesTNT 02-2Jogi Oscar SinagaNo ratings yet

- AB-012 Pressure Vessel Inspection ReportDocument1 pageAB-012 Pressure Vessel Inspection ReportJogi Oscar SinagaNo ratings yet

- 1 IntroductionToArtificialLiftMethodsDocument29 pages1 IntroductionToArtificialLiftMethodsMahesh MahajanNo ratings yet

- Threadprotrusion 110731084506 Phpapp02 PDFDocument163 pagesThreadprotrusion 110731084506 Phpapp02 PDFJogi Oscar SinagaNo ratings yet

- Spreader BarDocument1 pageSpreader BarJogi Oscar SinagaNo ratings yet

- Tank 182Document2 pagesTank 182Jogi Oscar SinagaNo ratings yet

- Hoisting in House Training Providers Guidelines For Registration 1Document4 pagesHoisting in House Training Providers Guidelines For Registration 1Jogi Oscar SinagaNo ratings yet

- RC Build FlyDocument46 pagesRC Build FlyBlashko GjorgjievNo ratings yet

- Extra Heavy Wire Rope ThimblesDocument1 pageExtra Heavy Wire Rope ThimblesJogi Oscar SinagaNo ratings yet

- FerrulesDocument22 pagesFerrulesJogi Oscar Sinaga100% (1)

- Forklift Truck 3T, Logistic Forklift, China Lifting Equipment ManufacturerDocument2 pagesForklift Truck 3T, Logistic Forklift, China Lifting Equipment ManufacturerJogi Oscar SinagaNo ratings yet

- Budgit Hvy Duty Rigid MNT IBeam and Pat Track Trolley 113534 99Document12 pagesBudgit Hvy Duty Rigid MNT IBeam and Pat Track Trolley 113534 99Jogi Oscar SinagaNo ratings yet

- Longer Load Lifting Made Easy with Quality Fork ExtensionsDocument13 pagesLonger Load Lifting Made Easy with Quality Fork ExtensionsJogi Oscar SinagaNo ratings yet

- Sub Button2Document2 pagesSub Button2Jogi Oscar SinagaNo ratings yet

- 1Document1 page1Jogi Oscar SinagaNo ratings yet

- PpeDocument16 pagesPpeJogi Oscar SinagaNo ratings yet

- Budgit® Push and Hand-Geared TrolleysDocument2 pagesBudgit® Push and Hand-Geared TrolleysJogi Oscar SinagaNo ratings yet

- PVAR Catalog PDFDocument16 pagesPVAR Catalog PDFrodriguez.gaytanNo ratings yet

- BUDGIT Electric Hoists and Trolley BrochureDocument16 pagesBUDGIT Electric Hoists and Trolley BrochureJogi Oscar SinagaNo ratings yet

- NSL Loler MatrixDocument1 pageNSL Loler MatrixJogi Oscar SinagaNo ratings yet

- FerrulesDocument22 pagesFerrulesJogi Oscar Sinaga100% (1)

- Wire Rope TerminationsDocument16 pagesWire Rope TerminationschinphengNo ratings yet

- JDN Air Hoists Profi 3 Ti / 6 Ti: The JDN Solution For Subsea HoistingDocument2 pagesJDN Air Hoists Profi 3 Ti / 6 Ti: The JDN Solution For Subsea HoistingJogi Oscar SinagaNo ratings yet

- T11M408 I1 Takraf 03910 Vdcme02 P1me01 004Document42 pagesT11M408 I1 Takraf 03910 Vdcme02 P1me01 004manuelarranoNo ratings yet

- ToolHire 2005Document76 pagesToolHire 2005treazer_jetaimeNo ratings yet

- Falsework-Formwork FailuresDocument57 pagesFalsework-Formwork Failuresronelyn bernal100% (1)

- Scaffold Erection, Dismantling and Maintenance Safety ProcedureDocument27 pagesScaffold Erection, Dismantling and Maintenance Safety ProcedureGeorge OgbecheNo ratings yet

- Appendix 22 - Atpac Technical SpecifcationDocument34 pagesAppendix 22 - Atpac Technical SpecifcationJose MedinaNo ratings yet

- MCHE EXE HCSB MLNG 000 CVS JMS 0001 Job Method Statement For Site PreparationDocument8 pagesMCHE EXE HCSB MLNG 000 CVS JMS 0001 Job Method Statement For Site PreparationSaldan Mohammad HadoumiNo ratings yet

- Culvert Construction (Boq)Document3 pagesCulvert Construction (Boq)Siddiqur RahmanNo ratings yet

- As 1576.4 Scaffolding Suspended Scaf PDFDocument17 pagesAs 1576.4 Scaffolding Suspended Scaf PDFtheNo ratings yet

- HIP-Aramco-Yanpet Sales Gas BI-21-00008Document9 pagesHIP-Aramco-Yanpet Sales Gas BI-21-00008Darius DsouzaNo ratings yet

- (EDIT) F-SAF-0046.12 Hydraulic Nut Splliting Risk Assessment (Generic)Document8 pages(EDIT) F-SAF-0046.12 Hydraulic Nut Splliting Risk Assessment (Generic)ainun mardiahNo ratings yet

- HariomCatalogue 2019Document12 pagesHariomCatalogue 2019Crazy SansNo ratings yet

- Bracing For Wall FormworkDocument4 pagesBracing For Wall FormworkKrm ChariNo ratings yet

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- MS For Installation of Drainage PipesDocument20 pagesMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- Working at Height Safety RequirementsDocument7 pagesWorking at Height Safety RequirementsRicky Stormbringer ChristianNo ratings yet

- Scaffold Fittings: Fixed Coupler Heavy DutyDocument4 pagesScaffold Fittings: Fixed Coupler Heavy DutyBoy BangusNo ratings yet

- DLP-TLE (Carpentry 10) Parts of Wooden ScaffoldingDocument9 pagesDLP-TLE (Carpentry 10) Parts of Wooden Scaffoldingcolleen100% (2)

- Risk Assessment of Installation of Chilled Water PipesDocument20 pagesRisk Assessment of Installation of Chilled Water PipesJomy JohnyNo ratings yet

- Sec 25Document12 pagesSec 25pukhrajNo ratings yet

- Temporary Structures-B4Document43 pagesTemporary Structures-B440 BishalNo ratings yet

- ARES ScaffoldingDocument7 pagesARES ScaffoldingaresscaffoldingNo ratings yet

- Scaffolding PPT EditedDocument28 pagesScaffolding PPT EditedKhiZra ShahZad50% (2)

- Implementation of Eurocodes in Malaysia - A View Point From Consulting Engineer (Iem)Document45 pagesImplementation of Eurocodes in Malaysia - A View Point From Consulting Engineer (Iem)raritylimNo ratings yet

- Support Frame Instruction ManualDocument24 pagesSupport Frame Instruction ManualMae FalcunitinNo ratings yet

- Air Conditioning and Mechanical Ventilation System (ACMV Electrical Works)Document5 pagesAir Conditioning and Mechanical Ventilation System (ACMV Electrical Works)haidil abd hamidNo ratings yet

- PERI UP Rosett For The Use On The Constr. Jobsite.Document28 pagesPERI UP Rosett For The Use On The Constr. Jobsite.YUSAK ABDILLAHNo ratings yet

- Scaff TrainingDocument29 pagesScaff TrainingrakeshNo ratings yet

- Scaffolding Price ListDocument11 pagesScaffolding Price ListJerry BitongNo ratings yet