Professional Documents

Culture Documents

C Power Manual

Uploaded by

Arun KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

C Power Manual

Uploaded by

Arun KumarCopyright:

Available Formats

Instruction Manual

For Range of

Air Circuit Breakers

Switchgear Factory at Powai, Mumbai

The L&T switchgear Advantage

Suitable for tropical climate

Stands up the Indian summer

Withstands wide voltage fluctuations

Accommodates Aluminum terminations

Easy to maintain

Easy spares availability through a wide

network of authorised stockists

Switchgear Testing Laboratory (STL) at

Powai Works:

STL is NABL accredited laboratory, fully

equipped for all the type tests and routine

tests.

STL has dedicated 85 kA short- circuit testing

laboratory to ensure that the air circuit

breakers meet the high design standards of

quality and reliability.

Switchgear Testing Laboratories at Powai, Mumbai.

Larsen and Toubro is Indias largest

manufacturer of low tension switchgear,

offering the widest range of products

from push buttons to circuit breakers.

L&T invests continually in upgrading

its design, manufacturing and testing

facilities to ensure that the products

offer every feature and every advantage

that state-of-the-art technology can offer.

A proven performance record in tropical

conditions has established that L&T

switchgear is ideal for adverse conditions.

INTRODUCTION

L&Ts range of Air Circuit Breakers are manufactured and tested at one

of Indias most modern switchgear factories. Proper installation and maintenance

according to the instructions given in this manual will ensure that the breakers

render long years of trouble-free service.

These breakers are designed for normal industrial environment. It is important that

the circuit breakers subjected to hostile environment e.g. dust, caustic vapour,

corrosive gases etc. are appropriately enclosed.

CONTENTS

Storage.............................................................................................................

Unpacking........................................................................................................

Handling...........................................................................................................

Identification.....................................................................................................

Operation.......................................................................................................

Racking............................................................................................................

Installation........................................................................................................

Protection.........................................................................................................

Accessories......................................................................................................

Maintenance....................................................................................................

Spare Parts......................................................................................................

Overall dimensions..........................................................................................

Wiring diagrams..............................................................................................

Special applications........................................................................................ 14

13

12

11

10

8

7

6

5

4

3

1

2

9

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

9-1

10-1

11-1

12-1

13-1

14-1

1. STORAGE

1-1

P TRI

O F F

Do not store the breaker

uncovered even for a short

period. Always keep it covered

with polyethylene bag.

1. If the ACB is not going to be

used for a long time then place

the carton back on it.

2.

3. Store the breaker in a cool and

well-ventilated place protected

from dusty, corrosive, salt laden

or wet atmosphere.

Only same frame breakers should

be stacked one above another.

5.

4. Please do not drop or roll the

ACB carton while storing or

transporting. Use proper

material handling equipment for

stacking of breakers.

Do not stack more than four

breakers one above another.

6.

2. UNPACKING

FOR DRAWOUT ACBs (up to 3200A & except 4 pole version of 2000A / 2500A / 3200A)

Follow the first 2 steps of fixed ACB unpacking.

2-1

FOR FIXED ACBs

Lift the carton/wooden case. Cut and

remove any accessories taped to

breaker or kept loose on the pallet.

Open the polyethylene bag.

2.

1. Cut the straps and remove the nails.

3. Remove breaker mounting hardware, arc-chute holding bracket,

Remove the locking plate & Rack

out the breaker.

1.

Pull the breaker out. Remove breaker

mounting hardware & lift the breaker.

2.

5. Remove cradle clamping hardware. Lift the cradle.

FOR DRAWOUT ACBS (4 pole version of 2000A / 2500A / 3200A & above)

There are separate packing cases for packing of breaker & cradle.

1. For breaker unpacking follow procedure mentioned for fixed ACB unpacking.

2. For cradle unpacking, follow 1 & 5 steps mentioned in drawout ACB unpacking.

3.

(Arc chute holding bracket

Remove arc-chute holding bracket,

padding fixed to the breaker over arc-chute.

4.

Case packing

Carton packing

Nails

Nails

padding fixed to the breaker over arc chutes & lift the breaker.

(Arc chute holding bracket and padding)

*: For 3P/4P 3200D/4000C breaker, arc chute should be unpacked and mounted on the breaker.

*

and padding)

*

(If any)

3. HANDLING

3-1

Move the packing with fork lift. Do

not drop or roll the packing case.

1.

Caution:

1. Before handling remove breaker from cradle (for drawout ACBS).

2. Do not lift / handle the breaker or cradle by holding its front facia / operating handle / breaker

3. Keep the breaker on a flat, firm surface in its normal position. Do not

keep it on sides or in up side down position.

Note : Refer the table as per clause 3.1 for weights of different

ratings of breaker.

2. Pictures showing attachment of ropes to breaker & cradle for handling.

or cradle terminal / jaw contacts.

3-2

3.1 Weight of manually operated breaker (kg):

For electrical breaker add 7 kg to the above mentioned breaker weight.

CN-CS...C

Rating

800/1000C

1250/1600C

2000/2500C

5000/6300C

38

38

50

105

54

55

77

207

44

44

65

137

Breaker 3P Breaker 4P Cradle 3P Cradle 4P

50

51

72

153

51

51

72

76

76

CN-CS...H

Rating

800/1000H

1250/1600H

2000/2500H

3200H0/3200H1

4000H0/4000H

Breaker 3P Breaker 4P Cradle 3P Cradle 4P

38

38

50

53

53

55

55

77

86

86

44

44

65

57

57

Special orders

Rating

3200D

4000C

3200C

Breaker 3P Breaker 4P Cradle 3P Cradle 4P

113

115

73

75

75

50 86

154

156

57

101

101

CN-CS...S1

Rating

630/800/1000/1250S1

1600S1

2000S1

2500S1

3200S1

Breaker 3P Breaker 4P Cradle 3P Cradle 4P

50

51

62

72

73

38

38

38

50

50

54

55

71

85

86

44

44

44

57

57

4. IDENTIFICATION

I : ......... A

n

U : .........V ~ 50/60 Hz

e

I : .........kA I : .....kA

cu cs

I : .........kA for 1 sec

cw

Utilization Category : B

1

2

3

4

5

IS 13947-2

IEC 60947-2

BS EN 60947-2

8

9

10

CN-CS 2000C

METAL LABEL OF

4-1

Rated current

Rated operational voltage

Rated ultimate short-circuit breaking capacity

Rated short time withstand capacity

Utilization category

Range of rated frequency

6

5

4

3

2

1

6

7

APPLICABLE

STANDARDS

ACB RATING

TYPE DESIGNATION

RATED CURRENT

RATED OPERATIONAL

VOLTAGE

RATED ULTIMATE SHORT-

CIRCUIT BREAKING CAPACITY

RATED SHORT TIME

CURRENT WITHSTAND

CAPACITY

SUITABILITY FOR ISOLATION

UTILIZATION CATEGORY

SERIAL NUMBER

RATED SERVICE SHORT-

CIRCUIT BREAKING CAPACITY

CN-CS 2000C

FR167177 I

n

: 415 V ~ 50/60 Hz

I : 55 kA I : 55 kA

cu cs

I : 55 kA for 1 sec

cw

Utlization Category : B

Standard : IS 13947-2 IEC 60947-2

: 2000 A Sr. No.

U

e

X

11

13

12

12

13

11

10

9

8

7 Rated service short-circuit breaking capacity

Standard compliance

Standard compliance

Standard compliance

Suitability for isolation

Type designation

marking

LARSEN & TOUBRO LIMITED

C-POWER

MAIN FACIA LABEL

4-4 4-2

** Should not be removed while removing ACB from packing case.

* Overcurrent releases type DN1/ SR18/ SR18G / SR71 etc.,when provided is mounted at

the same location.

Rating label

2 Top cover

3 Arc chutes

4 Lifting lug **

5 Breaker (Draw-out part)

6 Cradle (Fixed part)

7 ON / OFF indication

8 Spring Charged / Discharged indication

9 Operating handle

10 Door interlock

1 11

12 Position indication

13 Lock in - Isolated position / Any position

14 Racking handle

15 Bezel (to be mounted on panel door)

16 Overcurrent release type SR21i *

17 Sealable sliding shutters for push buttons

18 Close push button

19 Trip push button

Racking interlock

11 12 14

1 2 3

4

5

6

7

8

9

10

13

15

16

17

19

18

Fig. 4-1 DRAWOUT ELECTRICAL ACB

Current

transformer

(for protection)

Scraping

earth (moving)

Moving

isolating contacts (SIC)

Secondary

Contact jaws

Safety

shutter

Microswitch

for position

indication

Racking

screw

Door

interlock

Racking

interlock

Fixed

isolating contacts (SIC)

Secondary

Earthing terminal

at rear

Scrapping

earth (fixed)

Telescopic rail

Interlock support

Cradle facia

4-3

Door interlock pin

Lock in isolated /

any position

Voltmetric

release termination

Cradle

terminal

Arc chute

clamps

Fig. 4-2 DRAWOUT ACB - REAR VIEW

Fig. 4-3 CRADLE - FRONT VIEW

Note : Please do not place the breaker on its rear side.

Racking

handle

Mounting bracket

4-4

* Please consult us for application at dc voltages & higher operational voltage upto

** Icw values are indicated based on thermal considerations. While selecting a breaker please ensure that Icw requirement for the application is not more than

Ics / Icu at the point of installation.

690V AC.

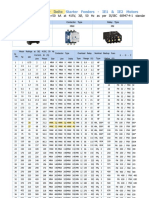

Technical Data Sheet

E

3

50

-

50

-

50

50

-

105

-

S1

50

-

50

-

50

50

-

105

-

C

3/4

50

35

50

35

50

50

35

105

73.5

H

65

50

65

50

65

65

50

143

105

1000

1000

415

1000

394

326

414

431

Rating (A)

Type Designation

Rated current (A) at 50C

Rated operational voltage (V), 50/60Hz

Rated insulation voltage (V), 50/60Hz

No. of poles

380/415/500V

690V

380/415/500V

690V

0.5 sec

1 sec

3 sec

380/415/500V

690V

Fixed

Draw out

400

E

400

415

1000

3

50

-

50

-

50

50

-

105

-

E

3

50

-

50

-

50

50

-

105

-

S1

3/4

50

-

50

-

50

50

-

105

-

S1

50

-

50

-

50

50

-

105

-

E

3

50

-

50

-

50

50

-

105

-

I

n

*

U

e

U

i

I

cu

I

cs

**

I

cw

I

cm

630

630

415

1000

800

800

415

1000

C

3/4

50

35

50

35

50

50

35

105

73.5

H

65

50

65

50

65

65

50

143

105

394

326

414

431

3 Pole

4 Pole

3 Pole

4 Pole

H

W

D

H

W

D

4 4 4

40

60

B

?

40

60

B

?

40

60

B

?

Rated impulse withstand voltage

of main circuit (kV)

Rated making capacity

50/60Hz (kA peak)

40

60

B

x

x

15000

6000

385

316

-

423.5

-

-

-

-

?

?

?

?

?

x

x

15000

6000

385

316

-

423.5

-

-

-

-

?

?

?

?

8000

?

?

x

x

15000

6000

385

316

-

423.5

-

-

-

-

?

?

?

?

8000

?

?

?

?

20000

8000

468

399

487

587

Rated impulse withstand voltage

of aux. circuit (kV)

U

imp 4

?

?

?

?

8000

?

x

?

x

15000

6000

385

316

-

423.5

-

-

-

-

?

?

?

?

8000

?

?

?

?

20000

8000

468

399

487

587

U

imp

?

?

?

?

8000

Typical opening time (ms)

Typical closing time (ms)

Utilization category

Suitability for isolation

Fixed

Draw out

Manual

Electrical

Electrical & Mechanical life (operating cycles)

Electrical life without maintenance

Dimensions (in mm)

8 8 8 8 12 12 12

20000

Rated short time

withstand capacity

50/60Hz (kA rms)

Rated service short circuit breaking

capacity 50/60Hz (kA rms)

Rated ultimate short circuit breaking

capacity 50/60Hz (kA rms)

394

326

414

431

468

399

487

587

Electrical life = Mechanical life. However, arcing contacts need to be replaced depending upon wear & tear.

4-5

S1

50

-

50

-

50

50

-

105

-

C

3/4

50

35

50

35

50

50

35

105

73.5

H

65

50

65

50

65

65

50

143

105

E

3

50

-

50

-

50

50

-

105

-

S1

50

-

50

-

50

50

-

105

-

C

3/4

50

35

50

35

50

50

35

105

73.5

H

65

50

65

50

65

65

50

143

105

E

3

50

-

50

-

50

50

-

105

-

C

3/4

55

40

55

40

55

55

50

121

84

20000

394

482

628

431

468

555

701

587

S1

50

-

50

-

50

50

-

105

-

2000

2000

415

1000

1250

1250

415

1000

394

326

414

431

20000

394

326

414

431

20000

H

75

65

75

65

75

75

65

165

143

1600

1600

415

1000

4 4 4

40

60

B

?

40

60

B

?

40

60

B

?

?

?

?

?

7000

?

?

?

?

7000

468

399

487

587

?

?

?

?

7000

?

x

?

x

6000

385

316

-

423.5

-

-

-

-

?

?

?

?

7000

?

?

?

?

7000

?

?

?

?

7000

?

x

?

x

4500

385

316

-

423.5

-

-

-

-

x

?

?

?

5000

-

-

-

-

468

399

487

587

?

?

?

?

5000

?

?

?

?

5000

8 8 12 12 12

Technical Data Sheet

Rating (A)

Type Designation

Rated current (A) at 50C

Rated operational voltage (V), 50/60Hz

Rated insulation voltage (V), 50/60Hz

No. of poles

380/415/500V

690V

380/415/500V

690V

0.5 sec

1 sec

3 sec

380/415/500V

690V

Fixed

Draw out

I

n

*

U

e

U

i

I

cu

I

cs

**

I

cw

I

cm

3 Pole

4 Pole

3 Pole

4 Pole

H

W

D

H

W

D

Rated impulse withstand voltage

of main circuit (kV)

Rated making capacity

50/60Hz (kA peak)

Rated impulse withstand voltage

of aux. circuit (kV)

U

imp

U

imp

Typical opening time (ms)

Typical closing time (ms)

Utilization category

Suitability for isolation

Fixed

Draw out

Manual

Electrical

Electrical & Mechanical life (operating cycles)

Electrical life without maintenance

Dimensions (in mm)

Rated short time

withstand capacity

50/60Hz (kA rms)

Rated service short circuit breaking

capacity 50/60Hz (kA rms)

Rated ultimate short circuit breaking

capacity 50/60Hz (kA rms)

468

399

487

587

* Please consult us for application at dc voltages & higher operational voltage upto

** Icw values are indicated based on thermal considerations. While selecting a breaker please ensure that Icw requirement for the application is not more than

Ics / Icu at the point of installation.

690V AC.

Electrical life = Mechanical life. However, arcing contacts need to be replaced depending upon wear & tear.

E

50

-

50

-

50

50

-

105

-

?

?

6000

-

-

-

385

316

423.5

3

8

x

x

4-6

2500

C

2500

415

1000

3/4

60

40

60

40

60

60

55

132

84

S1

60

-

60

-

60

60

-

132

-

H

75

65

75

65

75

75

65

165

143

3200

H0

3200

415

1000

3/4

75

65

75

65

75

75

70

165

143

S1

60

-

60

-

60

60

-

132

-

H1

100

85

100

85

100

100

85

220

187

H0

75

65

75

65

75

75

70

165

143

H

100

85

100

85

100

100

85

220

187

5000

C

5000

415

1000

3/4

95

?

95

?

95

95

?

209

?

6300

C

6300

415

1000

3/4

95

?

95

?

95

95

?

209

?

4000

4000

415

1000

3/4

394

482

628

431

?

?

?

?

468

701

909

587

10000

?

?

?

?

468

701

909

587

4

12

40

60

B

?

40

60

B

?

40

60

B

?

x

?

?

?

5000

-

-

-

-

?

?

?

?

20000

5000

468

555

701

587

?

?

?

?

5000

x

?

?

?

5000

-

-

-

-

468

555

701

587

x

?

?

?

x

?

?

?

5000

x

?

?

?

5000

x

?

?

?

5000 2500

-

-

-

-

583

913

1182

691

x

?

?

?

?

x

?

?

?

2500

-

-

-

-

583

913

1182

691

40

60

B

4

12

4

12 12 12

4 4

40

60

B

?

10000

5000

5000 5000

Technical Data Sheet

Rating (A)

Type Designation

Rated current (A) at 50C

Rated operational voltage (V), 50/60Hz

Rated insulation voltage (V), 50/60Hz

No. of poles

380/415/500V

690V

380/415/500V

690V

0.5 sec

1 sec

3 sec

380/415/500V

690V

Fixed

Draw out

I

n

*

U

e

U

i

I

cu

I

cs

**

I

cw

I

cm

3 Pole

4 Pole

3 Pole

4 Pole

H

W

D

H

W

D

Rated impulse withstand voltage

of main circuit (kV)

Rated making capacity

50/60Hz (kA peak)

Rated impulse withstand voltage

of aux. circuit (kV)

U

imp

U

imp

Typical opening time (ms)

Typical closing time (ms)

Utilization category

Suitability for isolation

Fixed

Draw out

Manual

Electrical

Electrical & Mechanical life (operating cycles)

Electrical life without maintenance

Dimensions (in mm)

Rated short time

withstand capacity

50/60Hz (kA rms)

Rated service short circuit breaking

capacity 50/60Hz (kA rms)

Rated ultimate short circuit breaking

capacity 50/60Hz (kA rms)

* Please consult us for application at dc voltages & higher operational voltage upto 690V AC.

** Icw values are indicated based on thermal considerations. While selecting a breaker please ensure that Icw requirement for the application is not more than

Ics / Icu at the point of installation.

Electrical life = Mechanical life. However, arcing contacts need to be replaced depending upon wear & tear.

??Please consult us.

4-7

Breaking capacities:

CN-CS : S1

CN-CS : E

50kA 50kA 50kA

50kA 50kA

50kA 50kA

630A 400A

CN-CS : C

CN-CS : H

CN-CS : H0

CN-CS : H/H1

Frame-1

50kA 50kA 50kA 50kA

65kA 65kA 65kA 65kA

800A 1000A 1250A 1600A

50kA

Icu = Ics = Icw

Frame-1 Frame-2

50kA

50kA 50kA 50kA 50kA

60kA 60kA

Frame-3 Frame-2

55kA 60kA

75kA 75kA

75kA

100kA

2000A 2500A 3200A

75kA

100kA

95kA 95kA

4000A 5000A 6300A

Frame-4

Rated Current

50kA

Frame-1

Range

4-8

CAUTION

SPRING UNDER TENSION.

PERSONAL INJURY

MAY BE CAUSED

ELECTRICAL HAZARD

BEWARE OF

ELECTRICAL SHOCK,

PERSONAL INJURY OR

SCALDING BURN

MAY BE CAUSED

WEAR PERSONAL

PROTECTIVE EQUIPMENT

WHILE CONNECTING

OR DISCONNECTING

CAUTION

OPERATION

5-1

TRIP / RESET Push Button

ON - OFF Indicator

P

T

R

I

-

R

E

S

T

E

C

lose

Front View Side View

2

1

5

3

4

Fig. 5-1

OFF

Fig. 5-2

N O

Fig. 5-3

(Except 5000/6300-4P version)

Speed of closing is independent of the speed

of handle movement.

Initially breaker is OFF.

1. For carrying out any operation, the

breaker-operating handle has to be

pulled out fully by holding its top portion.

2. For extra leverage, the handle can be

telescoped lengthwise (recommended).

RESETTING:

0

3. Rotate the operating handle by 90 in

anti-clockwise direction (till it becomes

horizontal). The breaker will trip at the

beginning of the resetting operation, if it

is in closed condition.

CLOSING :

0

4. Rotate the operating handle by 90 in

clockwise direction (till it becomes

vertical to close the ACB).

5. After completing the operation ensure

that the handle is placed back in the

cavity on the front facia.

The sequence of operation is

RESET ?CLOSE ?OPEN

Caution :

Resetting the ACB in ON condition will

cause the ACB to trip.

Precaution :

Ensure presence of supply voltage to

undervoltage release (if fitted) before

closing the ACB.

In case of manual reset type ACB actuation

of TRIP push button / key of lockable trip

push button, resets the tripping

mechanism of ACB.

5. OPERATION

5.1.1 OPERATION FOR C/S1/H/D - RANGE BREAKER

5.1 MANUALLY OPERATED BREAKERS:

Operating sequence of manual breakers:-

Operating Handle (refer Fig. 5-2) can occupy either of the two

distinct position spaced 90 apart.

- Horizontal Position : OPEN- RESET

- Vertical Position : CLOSED or TRIPPED

An indicator provided on front facia (refer

Fig. 5-1) shows the

- RED / ON : CLOSED

- GREEN / OFF : OPEN

position of the main contacts.

0

ACB closes in single stroke operation of the

handle.

5-2

OFF

Fig. 5-4

Fig. 5-5

Fig. 5-6

OPENING THE CIRCUIT BREAKER :

The breaker can be opened by the following

means :

LOCALLY (Manually) :

1. Press the TRIP push button.

OR

2. Press key of lockable trip push button

(when provided).

3. Rotate key of racking interlock for draw

out breakers (if provided) when the

breaker is in any position between

Service and Test.

4. Operate handle anti-clockwise.

REMOTELY (Electrically) :

1. Through shunt release.

2. Through under voltage release.

(Refer section 9: Accessories)

Indicate with key

OFF

T P RI

ON

Note: For operation of 5000/6300-4P version of manual ACB refer manual charging (clause 5.2 in page 5-4)

and for closing & opening the circuit breaker (page no. 5-5).

OPERATION

5-3

Operating sequence of manual breakers:-

TRIP / RESET Push Button

ON - OFF Indicator

P

T

R

I

-

R

E

S

T

E

C

lose

Front View

3

4

Fig. 5-7

Speed of closing is independent of the speed

of handle movement.

Initially breaker is OFF.

RESETTING :

0

CLOSING :

The sequence of operation is

RESET ?CLOSE ?OPEN

Caution :

5.1.2 OPERATION FOR E - RANGE BREAKER

Operating Handle (refer Fig. 5-7) can occupy either of the two distinct position spaced 90 apart.

- Horizontal Position : OPEN - RESET

- Vertical Position : CLOSED or TRIPPED

An indicator provided on control box (refer Fig. 5-7) shows the position of the main contacts.

- RED / ON : CLOSED

- GREEN / OFF : OPEN

Rotate the operating handle by 90 in anti-clockwise direction (till it becomes horizontal).

The breaker will trip at the beginning of the resetting operation, if it is in closed condition.

0

Rotate the operating handle by 90 in clockwise direction (till it becomes vertical to close the ACB).

Presence of supply voltage is essential to close a breaker fitted with under voltage release.

0

The breaker can be tripped by the following means:

Local : a) By pressing the red TRIP button (refer Fig. 5-7)

b) Key of lockable trip push button (when provided)

Remote : Through Voltmetric release (refer Section 9 )

The tripping push button also serves to reset the over-current and short circuit release if the breaker

is fitted with local resetting feature. Resetting of the manual breaker by handle will not reset O/L-S/C

release in such case.

: Accessories

OPENING :

Resetting the ACB in ON condition will cause the ACB to trip.

ACB closes in single stroke operation of the handle.

5-4

ON

TRIP / RESET Push Button

CLOSING Push Button

Front View

Side View

ON - OFF Indicator

Spring Charged / Discharged Indicator

Charging Handle

0

5

2

Fig. 5-8

Fig. 5-9

5.2 ELECTRICALLY OPERATED CIRCUIT BREAKER :

Initially breaker is OFF and spring is

discharged.

Spring condition is indicated by a

mechanical indicator visible through a

transparent window on the front facia.

Indicator display Spring condition

YELLOW

BLACK

CHARGED

DISCHARGED

The spring in the circuit breaker operating

mechanism must be charged to store the

energy required to close the main contacts.

The spring may be charged manually using

the charging handle or automatically by the

motor.

Electrical Charging :

The spring is automatically charged &

automatically recharged after each closing

operation. (Provided there is a continuous

supply to the motor)

Manual Charging :

In case of power failure, charge the main

spring through multiple strokes of charging

handle. The handle has to pulled outward by

gripping its top portion.

0

Charge by giving small strokes (25 ) as shown in Fig. 5-8 in the clockwise direction till indicator display

shows a spring charged condition (yellow colour).

Now the breaker is OFF and spring is charged.

OPERATION FOR C/S1/H/D - RANGE BREAKER

5-5

ON

CLOSING THE CIRCUIT BREAKER :

(Ensure precautions before closing same as

manual ACBs.)

Breaker is OFF and spring is charged.

LOCALLY (Manually):

Press ON push button.

REMOTELY (Electrically):

The closing electromagnet, when actuated,

discharges the spring and closes the

breaker.

OPENING :

The methods of opening are the same as those for manually operated breakers (except method 4 of

local opening).

5.3 OPERATIONAL FEATURES

5.3.1 ANTI-PUMPING :

After a close - open cycle, it is not possible to reclose the breaker (for electrically operated breakers) if

the closing command is maintained. This feature known as anti-pumping, is assured mechanically,

both in local and remote control operation. This feature prevents auto reclosure of breaker on fault. For

reclosing the breaker, the permanent closing command should be momentarily interrupted. For Electrical

5.3.2 TRIP FREE MECHANICAL SWITCHING :

(Both for manually and electrically operated breakers)

The moving contacts of the breaker return and remain in open position, when the opening operation is

initiated after initiation of closing command. In this case the closing command is overruled by the

tripping command.

Fig. 5-10

anti-pumping refer page no.8-19.

6. RACKING

SERVICE

Panel door

TEST

Panel door

ISOLATED

ON

6-1

OFF

OFF

Panel door

Fig. 6-1

Fig. 6-2

Fig. 6-3

Circuit breaker positions

The indicator on the front, shows the position of the circuit breaker in the cradle.

Service position : In service position both power and control circuits are connected.

Isolated position : In isolated position both power and control circuits are disconnected from

supply to ensure complete isolation.

Test position : In test position power circuit is open ensuring full safety, while control circuit is

connected for checking accessories as well as breaker operation.

Panel door facia have to be aligned

6-2

Racking OUT / IN

1

2

SERVICE

Fig. 6-4 (i)

Rack out

Rack in

3

5

4

SERVICE

Fig. 6-4 (ii)

Fig. 6-4 (iii)

PROCEDURE :

1. Racking operation must be done with the

aid of racking handle, provided in racking

handle storage location.

2. Insert the racking handle in the racking

slot.

3. Rotate the racking handle in clockwise

direction to rack in and in anti clockwise

direction to rack out.

4.

emove the racking handle from the

racking slot.

5. After completion of racking operation

ensure that the racking handle is kept in

its correct storage location.

Note :

I. If the panel door is open, keep the door

interlock pin pressed during racking.

II. If racking interlock is provided press the

key inwards and turn it clockwise before

racking.

Ensure the breaker is in SERVICE position

and r

Caution :

Open the circuit breaker before racking

IN / OUT.

Note: If the breaker is inserted or withdrawn with its main contacts in closed position, then a device

automatically trips the breaker before separation of the main isolating contacts(during withdrawal)

or before they come into contact (during insertion). The same device prevents the closing of the

breaker at one particular location between the position Test and Service.

When racking interlock provided, the key of the lock has to be pressed and turned anti-clockwise (this

will trips the breaker if it is in closed condition at any location between the positions Test and Service)

before initiation of the racking operation, otherwise it will not be possible to rack the breaker in or out.

If the cradle is provided with door interlock, ensure that either the door is closed or interlock is defeated

while attempting racking.

7. INSTALLATION

7-1

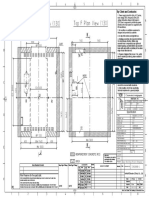

Fig. 7-1 FIXED ACB - METHOD OF MOUNTING

7.1 INSTALLATION AMBIENT

Install the ACB in dry, dust free, non-corrosive ambience without subjecting it to abnormal shocks /

vibrations. If the above is not possible, provide adequate degree of protection.

Refer to Section 12 for the following information.

- Overall dimensions

- Mounting details

- Panel door cut-out and bezel fixing

- Terminal connections

- Fixing of door interlock components on the panel door (provided in a polyethylene bag)

For fixing the door interlock components on the cradle (provided in another polyethylene bag) Please refer to

Section 9.

7.2 INSTALLING A FIXED BREAKER

7.2.1 MOUNTING

Mount the breaker on the side brackets with the aid of 4 bolts of M8 or M10 (Refer to item No. in

Fig. 7-1). For further details refer the section 12.

1

Insert spacers, if necessary, to prevent deformation during tightening.

To facilitate normal maintenance, following clearances are required to be maintained

- 140 mm above the breaker to replace arc chutes.

- 200 mm above the breaker to replace arcing contacts.

- 200 mm below the breaker to replace voltmetric releases.

- 50 mm on either side of the breaker (150 mm on left side in case of breaker with mechanical

interlock).

Clearance distance - a safety requirement :

- It is essential to maintain a minimum clearance of 100 mm above the breaker for permitting

expansion/dispersion of the gases emanating from the arc chutes.

- The metallic components, if exist, should be placed at a minimum distance of 200 mm above the

arc chutes.

- If there are metallic components between 100 mm and 200 mm, then an insulating screen should

be placed at a distance of 100 mm minimum above the arc chutes.

Panel Structure

Metalic components (if exist)

2

0

0

m

i

n

1

0

0

First fixed Support

Insulating Screen

100

min

m

i

n

2

0

0

m

i

n

1

NOTE: Dimensions are in mm

Metalic components (if exist)

2

0

0

m

i

n

1

0

0

First fixed Support

Insulating Screen

100

min

m

i

n

2

0

0

m

i

n

E-Range breaker

C/H/S1/D-Range breaker

7-2

Bolt size

Torque (kgf-m)

High-tensile

M8

M10

M12

Standard

0.85

1.88

3.2

2.5

4.7

7.8

Bolt dia (mm)

8

10

12

7.2.2 CONNECTIONS

7.2.2.1 MAIN CIRCUIT

Use links as per the recommendations given in IS/IEC: 60947 (Part 1).

Support these links to guard against electrodynamic forces during short circuit.

Ensure that the first set of fixed supports (fixing the conductor rigidly through an insulating support to

panel structure) is fixed at a distance 100 mm (as shown in fig. 7-1) so that stresses induced during

short circuit do not exceed elastic limit of the link material.

Ensure that the links are terminated with right size of bolts, tightened to appropriate torque by using

proper plain and spring washers.

Refer clause 12.4 for additional information on good termination practices.

Clean the terminals and links by using cheese cloth. Do not damage plating.

7.2.2.2

Rated for 16A at 500 V.

7.2.2.3

7.2.3

AUXILIARY CIRCUIT

Auxiliary terminals for control circuit connections are located on the rear top cross-piece of the

Breaker.

Max. 24 nos.

2

Accommodates flexible cable upto 2.5 mm .

2

Unless otherwise specified by the customer, connections are to be made with PVC insulated 1.5 mm

copper wire conforming to IS: 694.

Refer to Sec. 13 for internal wiring.

The fuse ratings to be provided for the protection of accessories (voltmetric releases, charging motor

and the closing electromagnet) must be based on their power consumption (indicated in Sec. 9 -

Accessories).

EARTHING

The earthing location is in the rear bottom corner of the right side plate of the breaker marked with

symbol. (Please refer drawing in section 12)

Clean and degrease the unpainted surface of the earthing connection.

Use M6 screw for connecting earth bar.

ARRANGEMENT OF CUBICLE DOOR

Provide a cut-out in the cubicle door for breaker front facia projection

Refer to Sec. 12 for location of the door cut-out with respect to door hinges (right or left) and fixing the

bezel on the door.

7-3

7.3 INSTALLING A DRAWOUT BREAKER

7.3.1 MOUNTING

Holes are provided on horizontal surface for mounting the cradle

Insert spacers, if necessary, to prevent deformation of the cradle during tightening. To ensure proper

dust proofing, maintain the distance of 8.9 mm between the inner side of the cubicle door and the

outer surface of the interlock support .

No extra space is required to be provided in the cubicle for maintenance. The breaker can be

maintained fully by drawing it out to a Maintenance position (telescopic rails fully stretched)

In case of breaker with mechanical interlocking leave minimum of 150 mm space on the left side of

the ACB for clutch cable routing.

Clearance distance - a safety requirement :

Follow the same instructions as mentioned for Installing a fixed breaker (clause 7.2.1)

(for mounting refer the clause 12.2.1

& 12.2.2 in Section 12).

7.3.2

7.3.2.1 MAIN CIRCUIT

Remove the nut plates fixed to the terminals.

Use the nut plates for making connection to the terminals.

Follow the same instructions as mentioned for Installing a fixed breaker.

7.3.2.2 AUXILIARY CIRCUIT

Secondary Isolating contacts (SICs) meant for control circuit connections are located on cradle &

breaker (Refer to Sec. 4 - Identification)

Maximum 24 SICs are available for Electrical D/O and 18 SICs for Manual D/O (standard ACBs).

2

Each SIC terminal can accommodate two lugs suitable for crimping with 1.5 mm flexible cable.

Rated for 16A at 500 V.

Unless otherwise specified by the customer, internal connections are made with PVC insulated

2

1.5 mm copper wire conforming to IS: 694.

The SIC terminals on the breaker and the cradle are arranged in a precise order (refer. to wiring

diagrams in Sec. 13) to facilitate interchangeability between breaker of same specification.

Different electrical connection for Test & Service position of the breakers are possible by adopting

the procedure mentioned as follows.

CONNECTIONS

7-4

Procedure for having different electrical connections in Test and Service positions.

Remove fixed SIC block by removing fixing

screws

Decrimp the terminal which needs to be

removed

Break at neck of the terminal

The standard secondary isolating contact block comprising totally 6 sets of terminals, has two through

terminals. These through terminals are necessary for electrical breakers to give electric supply to the

charging motor in (terminals C and D on wiring diagram in Section 13).

Please do not forget to wire the microswitch C6 in position (refer to Section 13) for electrical

breakers.

The microswitches in Service, Test or Isolated position are designed to take wires with snap on

cable lugs.

Two covers are provided on the cradle at SIC outgoing side. These covers protect the auxiliary

circuit wire from accidental trapping with the moving part while the breaker is being racked in or

racked out.

The wiring of the position microswitches should pass between

the rear-end of telescopic rail and the cradle terminal mounting

plate of the cradle before joining the bunch of wires leaving the

secondary isolating contact blocks (as shown in fig. 7-2).

The rating of the fuses to be used for the protection of the accessories (voltmetric releases ,charging

motor and the closing electromagnet) should be based on their power consumption (indicated in Section 9

- Accessories).

EARTHING

The earthing location is on rear bottom right side of the cradle marked with symbol

Clean and degrease the unpainted surface for the earthing connection.

Connect earthbar of the switchboard / panel to the M10 earthing screw on the cradle.

Test and Service positions

Service

7.3.2.3

Terminal

Connection

Fig. 7-2

1

2

Point for Adjustment of

Overload Current Setting.

Mechanical Trip Actuator.

1

2

Fig. 8-1

8-1

In case of breakers with local reset feature, tripping through release leaves the latch of the mechanism

open & hence resetting with the help of the local TRIP/RESET or TRIP/LOCK/RESET push button is

necessary prior to subsequent closing operation.

The release is provided with a Strip (refer to item no. 1 in Fig. 8-1) for manual tripping. Pressing the strip

downwards will release the mechanical latch of the release and trip the breaker.

The DN1 release incorporates a definite minimum impulsion time of 25 ms on magnetic trip. Trip time is

independent of the magnitude of short circuit current and is achieved by the aid of a fly wheel. This release

has inverse thermal time-current characteristics on overload.

The magnetic threshold of the release depends on the tap of the current transformer chosen. A label is

pasted on the top of the release to indicate the magnetic threshold of the protection system at various CT

taps.

8.1 THERMOMAGNETIC RELEASE TYPE DN1

8.1.1 FEATURE

Air circuit breakers are available with multi-tap CT fed over current release system type DN1.

The rated secondary current of the CT is 8.75A.

Mechanism of protection is as under :

(I) Three electro-magnets provide protection against short-circuit current. Each electromagnet is

provided with two taps M1 and M2 for selecting operating threshold.

(II)Three bimetallic strips give protection against overloads. These are individually adjustable from

0.75 In to 1.0 In by means of a pointer (2) on the front face of the release (refer to Fig. 8-1).

The release operates through its striker on the main trip latch of the mechanism and is reset by the main

8. PROTECTION

Fig. 8-2

8-2

0.1

1

10

100

1000

10000

0.01

1 2 6 10 20

Multiples of Current

T

r

i

p

t

i

m

e

i

n

s

e

c

o

n

d

s

0.2

0.4

0.3

0.7 3 4 5 7 8 9 30 40 50 100 400 1000

M1

M2

1.05

1.2

OPERATING LIMITS THERMAL

DN 1

25 ms

ZONE OF SHORT CIRCUIT OPERATION (M1/M2)

TOTAL OPERATING TIME

MIN. IMPULSION TIME

8.1.2 TIME-CURRENT CHARACTERISTICES OF DN1 RELEASE

NOTE : Only one CT per pole can be fitted on the breaker. Request you to choose correct CT

to be mounted in breaker, in case more than one CTs are available for a particular rating.

8-3

8.1.3 RELEASE SETTING FOR CN-CS C/E/S1/H/D ACBs

TYPE

DESIGNATION

CT CT

Tap

(A)

Setting of Magnetic

release

(A)

Thermal Current

Setting

(A)

CN-CS 4000 C/H/H0

CN-CS 630 S1/E

CN-CS 800 C/H/S1/E

CN-CS 1000 C/H/S1/E

CN-CS 1250 C/H/S1/E

CN-CS 1600 C/H/S1/E

CN-CS 1600D

CN-CS 2000 C/H/S1/E

CN-CS 2500 C/H/S1

CN-CS 3200 H0/H1/S1

CN-CS 3200D

630

500

800

1000

1250

1600

1600

1250

2000

2500

3200

2000

3200

4000

400

500

630

400

500

640

800

800

1000

1000

1200

1250

1600

800

1000

1250

1600

1000

1250

1600

2000

2000

2500

2500

3200

1600

2000

2000

2500

3200

2000

2500

3200

4000

2500

3000

3600

2700

3200

3900

4700

4700

5700

5700

7000

7000

8800

4700

5700

7000

8800

5700

7000

8800

11000

11000

13500

14000

17500

8500

11500

12500

14000

17000

12500

14000

17000

22000

*

3700

4500

*

3900

4900

6000

6000

7200

7200

8900

8900

11500

6000

7200

8900

11500

7200

8900

11500

14000

14000

17000

17500

22000

11500

16000

16500

18000

23000

16500

18000

23000

29000

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

to

300

375

472

300

375

480

600

600

750

750

940

940

1200

600

750

940

1200

750

940

1200

1500

1500

1875

1875

2400

1200

1500

1500

1875

2400

1500

1875

2400

3000

400

500

630

400

500

640

800

800

1000

1000

1250

1250

1600

800

1000

1250

1600

1000

1250

1600

2000

2000

2500

2500

3200

1600

2000

2000

2500

3200

2000

2500

3200

4000

Operating Limits 0.8 to 1.2 of setting 1.05 to 1.2 of setting

* Not recommended.

CN-CS 400 E

400

320 1800

400 2300

*

*

240 to 300

300 to 400

8-4

8.1.4 TYPES OF PROTECTIONS

Following types of protections can be provided using DN1 release:

Only overcurrent protection

Only magnetic protection

Overcurrent and magnetic protection

8.1.4.1 ONLY OVERCURRENT PROTECTION

When wired as per Fig. 8-3 with points A & C shorted only overcurrent protection (this includes

protection against both over load & short circuit conditions) is provided.

8.1.4.2 PROCEDURE FOR INCORPORATING ONLY MAGNETIC PROTECTION

Connect the current transformer between terminal M1 or M2 and star point S (refer to Fig. 8-4).

The system provides only magnetic protection.

T1 M1 T2 M2 T1 M1 T2 M2 T1 M1 T2 M2 S

R Y B

A

C

CTs

Fig. 8-3

T1 M1 T2 M2 T1 M1 T2 M2 T1 M1 T2 M2 S

R Y B

C

A

Fig. 8-4

1

2

3

4

5

Current Setting BCD switches.

Power ON LED.

ON/OFF Switch for Thermal

Memory.(Instantaneous ON/OFF,

Button to test the SR18G release.

Time Delay Setting BCD switches.

6&12 In)

6

7

8

9

Button to clear previous

Connector for External Testing through

SRT-2 Kit.

Query button - for indicating the last

fault.

LEDS for fault Indication.

fault indication.

In : Nominal current

Ir : Rated current

LTP : Long Time pick-up

GFP: Ground Fault pick-up

LTD : Long Time delay

STD : Short Time delay

GFD : Ground Fault delay

LT : Long Time Trip Indicator

ST : Short Time Trip Indicator

GF : Ground Fault Trip Indicator

The complete list of abbreviations used is given below.

8-5

*Available in SR18G release only.

8.2.1 FEATURES

Current Transformer

8.2 MICROPROCESSOR BASED RELEASE TYPE SR18 / SR18G

The release SR18/SR18G is a micro-processor based over-current and earth-fault release designed

specifically for breakers. It has three zones of protection in a single unit. The release monitors

and operates on the secondary currents of the current transformer (CT) mounted on the breaker. The

suitable knobs on the facia enable the release to provide a wide range of protection for various applications.

Ir-0.5 to 1.00 times In

Steps : 0.50, 0.60, 0.65, 0.70,

0.75, 0.80, 0.85, 0.90, 0.95, 1.00

Operating Limit: 1.05 to 1.2 times Ir

2.5 Sec at 6 times Ir

Long Time

2 to 10 times In

Steps : 2, 3, 4, 5, 6, 7, 8, 9, 10

20 ms to 600 ms.

Steps : 20, 60,100,160, 200,

260, 300, 400, 500, 600 ms.

0.2 to 0.6 times In

Steps: 0.2, 0.3, 0.4, 0.5, 0.6

100 to 400 ms.

Steps : 100, 200, 300, 400 ms & OFF

Tolerance: 10% or 20 ms. (whichever is higher)

Ground

Fault*

6 and 12 In

Tolerance: 15% of fault current

Instantaneous

Short Time

Type of

Protection

SETTING RANGE OF SR18/SR18G

PICK-UP CURRENT TIME DELAY

6 7 3 4 5 2 1 8 9

The release is fed by three single tap current transformers of same

rating as that of the circuit breaker. This current is referred to as

the nominal current (In) throughout this manual. The CT rating on

the secondary side is 750 mA.

Tolerance: 10% of current.

Tolerance: 10% or 20 ms. (whichever is higher)

8-6

Fig. 8-5

Rotary BCD switches are used to adjust setting. Red knob for pick-up currents and blue knobs for

time delays.

Factory Settings are as follows

LTP =1.0, LTD-2.5s., STP=6, STD=60ms., IP=12, GFP=0.3, GFD=100ms., Thermal Memory = OFF

Short time pick-up, Ground fault pick-up and Ground fault delay have nine, five and five position of

settings respectively. BCD switch arrow placed in between two setting is invalid.

Note : Please change release setting as per your system protection requirement to ensure

effective protection.

Multiples of Rated Current

T

r

i

p

T

i

m

e

i

n

S

e

c

0.1

1

10

100

1000

1 10

1 1.2 1.5 2 3 4 5 6 7 8 9 10 20

CURRENT MULTIPLE

0.1

1

10

100

1000

OVERLOAD CHARACTERISTICS SR 18 / 18G

T

R

I

P

T

I

M

E

1. Long Time protection zone

2. Short Time protection zone

3. Instantaneous protection zone

4. Ground Fault protection zone

5. Asymptote for Long Time

protection

8.2.2 CHARACTERISTIC CURVE

A Typical four zone time-current curve provided by the release is shown in Fig. 8-6

8-7

Fig. 8-6

5

1

2

3

4

Current

Trip time

0.01

0.1

1

0.1 1 10 100

T

R

I

P

T

I

M

E

(

s

)

CURRENTMULTIPLES

GROUND FAULT CHARACTERISTICS SR 18 / 18 G

CURRENT MULTIPLE

R

I

P

T

I

E

T

M

0.01

0.1

1

1 10 100

100

SHORT CIRCUIT CHARACTERISTICS SR 18 / 18G

10 20

CURRENT MULTIPLE

4 5 6 7 8 9 2 3 1

0.01

0.02

0.06

0.1

0.16

0.2

0.26

0.3

0.4

0.5

0.6

T

R

P

I

M

E

I

T

Three LEDs are used for displaying the type of fault under which the breaker trips. No external

power supply is required for these indicators. The LED corresponding to the fault shows 'red' when

Query button is pressed showing the type of fault, which has caused the tripping of the breaker.

This lasts for 72 hrs. max and remains so till it is cleared by 'clear' pushbutton.

8.2.5 TRIP INDICATORS

8-8

8.2.6

The test button is used to verify the validation of

the software internally, checking whether the

controller is healthy or not. When it is pressed the

Power-On LED changes from blinking green (ON

state) to steady red. However, during the time when

the Test button is pressed all the protections are still

alive and none are affected/defeated.

TEST BUTTON

Sw1

Sw3

Sw5

Sw4

Sw6

Overload

Short

Circuit

G.F

Test Clear Query

POWER Sw9

Inst.

Sw2

8.2.3 CHANGING OF SETTINGS

The settings can be done by changing the knob positions using a suitable screwdriver. Red knobs are used

for setting the pick-up currents, whereas blue knobs are meant for time-delay setting. Settings are on line

changeable but if any of the fault is active than new setting will not be accepted. The position of the knobs is

indicated by the arrow as shown in the figure below. The following examples further clarify this.

EXAMPLE 1 :

Changing long time pick-up (LTP) from 0.95 to 0.5 times In

0.50

1.00

0.95

0.90

0.85

0.80

0.70

0.65

0.50

1.00

0.95

0.90

0.85

0.80

0.70

0.65

Set at 0.95 X In Set at 0.5 X In

8.2.4

When the breaker trips under long-time protection, the cooling time allowed affects the subsequent

trip-time when the breaker is re-energized under fault condition. This feature can be switched off by the

ON/OFF dip switch, provided on the release facia. It is advisable to use a screwdriver to change the switch

position.

THERMAL MEMORY

0.75

0.60

0.75

0.60

8-9

8.3.1 FEATURES OF THE RELEASE

Current Transformer

The release is fed by three single tap current transformers of same rating as that of the circuit

breaker. This current is referred to as the nominal current (In) throughout this manual. The CT

rating on the secondary side is 750 mA.

The release SR21i is a micro-processor based over-current and earth-fault release designed

specifically for C-POWER breakers. It has four zones of protection in a single unit. The release

monitors and operates on the secondary currents of the current transformer (CT)

mounted on the breaker. The setable knobs on the facia enable the release to provide a wide

range of protection for various applications.

1 6 77 3 4 5 2 8 9

1

2

3

4

5

Current setting BCD Switches.

Power ON LED.

ON/OFF Switch for Thermal Memory.

Button to test the SR21i release.

Time Delay Setting BCD Switches.

6

7

8

9

Button to clear previous fault indication.

Connector for External Testing through

SRT-2 Kit.

Query button - for indicating the last

fault.

LEDS for fault indication.

8.3 MICROPROCESSOR BASED RELEASE TYPE SR21i

The release provides the four zones of protection by an electronic circuit with a micro-processor as the

central processing unit.

The four zones of protection are

1) Protection against overload : In Long time zone

2) Protection against short circuit : In Short time zone

Instantaneous zone

4) Protection against earth fault : In Ground fault zone

It trips the breaker through a Flux Shift Device (FSD) which is mounted on the rear bottom side of the

release. The Flux Shift performs the tripping operation through a link connected to the trip rod of the

breaker. The release is reset by the main shaft of the breaker at the end of the opening operation for

auto-reset type ACBs. For ACBs with local reset feature, resetting is done with the help of the local

TRIP/RESET or TRIP/LOCK/RESET Push button.

3) Protection against short circuit : In

The complete list of abbreviation used is given below

In : Nominal current STD : Short Time delay

Ir : Rated current GFD : Ground Fault delay

LTP : Long Time Pick-up LT : Long Time Trip

STP : Short Time Pick-up ST : Short Time Trip

Ip : Instantaneous pick-up INS : Instantaneous Trip

GFP : Ground Fault pick-up GF : Ground Fault Trip

LTD : Long Time delay ZSI : Zone Selective Interlocking

Table1 lists the setting range in all four zones of protection. The settings at the time of shipping are

given at the end of the table.

* Inst. max. = Inst. OFF . So Positioning the knob to max position will suppress the corresponding

protection.

Setting for all are done by rotary BCD switches having red knob for pick-up currents and blue knobs

for time delays.

Factory Settings:

LTP =1.0, LTD-2s., STP=6, STD=60 ms., Ip=8, GFP=0.3, GFD=100 ms., Thermal Memory = OFF.

Note : Please change release setting as per your system protection requirement to ensure effective

protection.

8-10

PICK-UP CURRENT

Ir = 0.5 to 1.00 times In

Steps: 0.50, 0.60, 0.65, 0.70, 0.75

0.80, 0.85, 0.90, 0.95, 1.00

Operating Limit: 1.05 to 1.2 times Ir

SETTING RANGE OF SR21i

2 to 10 times In

Steps: 2, 3, 4, 5, 6, 7, 8, 9 and 10

Ip = 2 to 16 times In

Steps: 2, 3, 4, 6, 8, 10, 12, 14, 16

One position as max

Tolerance: 15% of fault current

0.2 to 0.6 times In

Steps: 0.2, 0.3, 0.4, 0.5, 0.6

TIME DELAY

0.2 to 30 sec. at 6 Ir

Steps: 0.2, 0.5, 1, 1.5, 2, 3.5, 6, 12, 17

and 30 sec

Tolerance: 10% of current.

20 ms to 600 ms.

Steps: 20, 60, 100, 160, 200, 260, 300,

400, 500 and 600 ms.

Tolerance: 10% or 20 ms. (whichever is higher)

100 ms to 400 ms.

Steps: 100, 200, 300, 400 ms. & OFF

Tolerance: 10% or 20 ms. (whichever is higher)

Type of

Protection

Long Time

Short Time

Instantaneous

Ground

Fault

-

*

1

8-11

8.3.2 CHARACTERISTIC CURVE

A typical four zone time-current curve provided by the release is shown

1. Long Time protection zone

2. Short Time protection zone

3. Instantaneous protection zone

4. Ground Fault protection zone

5. Asymptote for Long Time protection

The required characteristic curve can be chosen by selecting proper settings. The settings can be

changed as described below.

Fig. 8-7

Facia Cut-out cover

has to be removed

to change knob

positions.

Red knobs are used for

setting the pick-up currents,

whereas the knobs for

time-delay setting are blue.

The settings can be made by

changing the knob positions

using screw-driver.

OFF

TRIP

OFF

TRIP

8.3.3 CHANGING OF SETTINGS

The position of the knobs is indicated by the arrow.

5

1

2

3

4

Current

Trip time

Set at 0.5 x In

0.95

1.00

0.50

0.60

0.65

0.70

0.75

0.80

0.85

0.90

Set at 0.95 x In

0.95

1.00

0.50

0.60

0.65

0.70

0.75

0.80

0.85

0.90

8-12

TABLE II : LONG TIME PICK-UP CURRENT (Ir) FOR VARIOUS SETTINGS (A)

8.3.3.2 LONG TIME DELAY

One out of ten possible inverse time-current

characteristics can be selected by choosing

the delay at six times the rated current (Ir).

Fig. 8-8

8.3.3.1 RANGE OF PROTECTION

LONG TIME PICK-UP : The release rating (Ir) can be selected by the LTP switch from 0.5 times

(50%) to 1.0 times (100%) the rating of the breaker. Table II gives the selected rated current (Ir)

for different positions of the LTP switch for the entire range of breakers.

In

800 1000 1250 1600 2000 2500 3200 4000

400

480

520

560

600

640

680

720

760

800

0.5

0.6

0.65

0.7

0.75

0.8

0.85

0.9

0.95

1

500

600

650

700

750

800

850

900

950

1000

625

750

812

875

937

1000

1062

1125

1187

1250

800

960

1040

1120

1200

1280

1360

1440

1520

1600

1000

1200

1300

1400

1500

1600

1700

1800

1900

2000

1250

1500

1625

1750

1875

2000

2125

2250

2375

2500

1600

1920

2080

2240

2400

2560

2720

2880

3040

3200

2000

2400

2600

2800

3000

3200

3400

3600

3800

4000

LTP

5000

2500

3000

3200

3500

3250

4000

4250

4500

4750

5000

6300

3150

3780

4095

4410

4725

5040

5355

5670

5985

6300

0.1

1

10

100

1000

10000

1 1.2 1.5 2 6 10 14 20

0.01

T

r

i

p

t

i

m

e

i

n

s

e

c

Multiples of Set Current

8.3.3.4 INSTANTANEOUS

The release provides instantaneous (with no intentional time delay) protection against short-circuit

in this zone. The instantaneous pick-up current (IP) can be varied from 2 to 16 times In. The

characteristic curve changes with change in I setting, as shown below in Fig. 8-10. Table III lists

instantaneous pick-up currents for all I settings for all ratings of breaker.

P

P

The Characteristics curve changes with change in I setting.

P

Instantaneous can be switched off by putting the I switch to the position marked MAX. P

8-13

8.3.3.3 SHORT TIME

The release provides time-delayed protection against short circuit in short protection zone. The

short time pick-up current (STP) can be varied from 2 to 10 times In and the definite delay (STD)

can be set from 20 to 600 ms.

The characteristic curve changes as per Fig. 8-9 given below, as STP & STD are changed.

In

800

1600

2400

3200

4800

6400

8000

9600

11200

12800

2

3

4

6

8

10

12

14

16

1000

2000

3000

4000

6000

8000

10000

12000

14000

16000

1250

2500

3750

5000

7500

10000

12500

15000

17500

20000

1600

3200

4800

6400

9600

12800

16000

19200

22400

25600

2000

4000

6000

8000

12000

16000

20000

24000

28000

32000

2500

5000

7500

10000

15000

20000

25000

30000

35000

40000

3200

6400

9600

12800

19200

25600

32000

38400

44800

51200

4000

8000

12000

16000

24000

32000

40000

48000

56000

64000

Ip

5000

10000

15000

20000

30000

40000

50000

60000

70000

80000

6300

12600

18900

25200

37800

50400

63000

75600

88200

100800

Fig. 8-9

STD

Trip

time

STP Current

CHARACTERISTIC CURVE

In this zone, the release provides time delayed protection against earth fault. The ground fault

pick-up (GFP) can be set from 0.2 to 0.6 time In. The delay (GFD) is settable from 100 to 400 ms

in four equal steps. Table IV lists the ground fault pick-up currents for all ratings of ACB for various

settings of GFP.

8.3.3.5 GROUND FAULT

The ground fault protection can be switched off by putting the GFD switch to the position marked

OFF.

Knob setting position for ground fault

protection switched off

Trip

time

IP Current

8-14

In

800

160

240

320

400

480

0.2

0.3

0.4

0.5

0.6

1000

200

300

400

500

600

1250

250

375

500

625

750

1600

320

480

640

800

960

2000

400

600

800

1000

1200

2500

500

750

1000

1250

1500

3200

640

960

1280

1600

1920

4000

800

1200

1600

2000

2400

GFP

5000

1000

1500

2000

2500

3000

6300

1260

1890

2520

3150

3780

2

3

4

6

8

10

12

14

16

MAX

Ground Fault Protection

Ground Fault

The characteristic curve change in GFP & GFD, as shown below in Fig. 8-11

Knob setting position for ground

fault protection switched off

Trip

time

GRD

GFP

Current

8.3.4 THERMAL MEMORY (For SR18/SR18G/SR21i/SR71)

Every time electrical power system is overloaded, there are thermal stresses induced in the

system. Thermal stresses caused by repetitive overload faults,can damage the insulation material used in

power system, if the threshold temperature is exceeded (Threshold temperature is the maximum operating

t emper at ur e) . The t her mal memor y f eat ur e r el eases r ecor d t he t her mal

stresses induced in the system. This thermal memory ensures reduced tripping time in case of subsequent

overload faults. Hot/Cold curves take into account integrated heating effects to offer closer protection to the

system.

8-15

Intelligent Microprocessor Based Release

Threshold

Temperature

of insulation

T

e

m

p

e

r

a

t

u

r

e

Temperature at subsequent

fault (incase of release

without Thermal memory)

2nd Fault 1st Fault Normal

Normal

operating temperature

Temperature at 1st fault

X sec <X sec

0

95 C

0

105 C

0

120 C

0

60 C

Temperature

At Subsequent fault

(in case of release)

Fig. 8-12

Fig. 8-11

10

1

0.1

0.01

0.2 0.1 06 X In

Multiples of Rated Current

T

r

i

p

t

i

m

e

i

n

s

e

c

400 300

200 OFF

100

8-16

A, B, C, D and E are ACBs with intelligent releases having zone selective interlocking & are connected in

cascade as shown by dotted line. Short time delays are as indicated to achieve time based discrimination

between upstream & downstream breakers.

When a fault occurs in zone Z, breaker E trips after a delay of 100ms*, and breaker C and A follow

delays of 200ms* and 300ms*, respectively, if required. But in case of a fault at Y, breaker C trips after a

delay of 60ms* (a default value), instead of 200ms*. Thus saving your system of seeing the fault for another

140ms. Similarly a fault in zone X results in breaker A tripping after a delay of 60ms*, thus achieving

intelligent discrimination.

Z

Y

X

A 300 ms

C 200 ms B 200 ms

D 100 ms E 100 ms

*Breaker opening

time additional

Single line diagram for ZSI

Fig. 8-13

If time delay for overload protection is set at x sec, then a release without thermal memory trips the ACB in

x sec each time an overload fault occurs, even if it is of a repetitive nature. Line for threshold temperature

of insulation depicts such a case, where temperature overshoots threshold temperature, causing damage

to the insulation.

However, protection releases in ACBs are intelligent to detect a repetitive fault. Here, thermal

memory takes into account the stresses caused due to the previous thermal fault resulting in faster

tripping (< x sec in this case) of the release, and hence temperature rise is limited to a lower and safer

level.

ZONE SELECTIVE INTERLOCKING (ZSI)

Zone selective interlocking enables faster clearance of faults thereby reducing the thermal and

dynamic stresses produced. This minimizes the damage to the system, thus enhancing the useful

life available to the users.

8.3.5

TEST KIT SRT-2

The test-kit simulates setable phase (Long time, short and

Instantaneous) and ground fault conditions which can be injected

to the release through the TEST connector provided on the front

facia of the release. The release can be tested for its characteristics

by applying this input.

Test-Kit can simulate the following fault currents,

For phase fault : 2.5, 4.5, 6.5, 9.5, 11 and 13 times In.

For ground fault : 0.25, 0.35, 0.45, 0.55 times In.

8-17

8.3.6 TESTING

Release SR18/SR18G/SR21i can be tested for its functions using test-kit type SRT-2. The release

should be tested with the breaker in isolated or test position. The releases should never be tested when

the breaker is carrying current.

8.3.6.1 PHASE FAULT TEST PROCEDURE

The release can be tested for Long time, Short time and

Instantaneous zone of protection in the following manner,

I. Connect the 9-pin D-sub connecter in the test-kit to

TEST socket on the release.

II. Connect the power supply of the kit to 240 V, 50 Hz

supply. Ignore the reading shown on the LED time

indicator of the test-kit.

III. Select a suitable test-current from the left-side current

setting knob of the test-kit.

EXAMPLE :

If the release is set for LTP = 0.5, STP = 6, IP = 8 then, test

current 2.5 x In will trip the release in Long time. However

for test current of 4.5 or 6.5 x In, the release will trip in short

time, and for all other current it will trip instantaneously.

IV. Start test by setting the 3-postion TEST switch on the test-kit to PHASE FAULT side. The display on

the kit will reset to zero and start counting till tripping takes place. After tripping the input to the release

is automatically cut-off and display shows the trip time.

V. Test-current can be changed and the release can be re-tested be changing the TEST switch position

to OFF position and then setting it back to PHASE fault.

8-18

CAUTION :

No or loose connection will result in CT secondary remaining open, which creates very high

voltage when the breaker carries current, possibly damaging the CT and the release.

8.3.6.2.GROUND FAULT

The release can be tested for ground fault in a similar way by first selecting the appropriate ground fault

test current and setting the 3-POSITION test switch to GROUND FAULT position.

Power supply unit test need not be conducted if the POWER LED on the release facia keeps on blinking

when the breaker is carrying more than 15-20% of the nominal current.

TEST PROCEDURE

I. Disconnect the D-Sub connecter from the release TEST socket.

II. Remove the CT connector from the rear side of the release. (MUST BE PUT BACK TIGHTLY

AFTER THE TEST IS OVER)

III. Connect the 9-pin shrouded connecter of the test-kit at the CT connector of the release.

IV. Set the 3-way sliding switch (given at the back-side of the kit) to any of the R, Y, or B phase.

V. Set the Ground Fault pick-up value of the release to 0.4 x In and delay as 400ms.

VI. Pass single phase current by pressing the TEST switch of the kit given at the back. The time

display goes blank when current is passed. The release will reset the status indicators to black

position and will trip in Ground Fault. This test can be repeated for the other phases by changing

the slide-switch position.

VII.Remove the shrouded connector from the release and put the CT connector firmly in its place.

8.3.7 SALIENT POINT

1. The release operates from CT currents only. It uses special CTs which have 750mA secondary

current.

2. In normal operating mode,

a) None of the LEDs will glow, when current is carried by the breaker.