Professional Documents

Culture Documents

Back To Basics - Water Heaters

Uploaded by

miniongsky0 ratings0% found this document useful (0 votes)

21 views5 pagesplumbing

Original Title

Back to Basics_ Water Heaters

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentplumbing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views5 pagesBack To Basics - Water Heaters

Uploaded by

miniongskyplumbing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Home

November 10, 2003

These commercial water heaters are designed to work together in a system to provide domestic hot

water during peak period applications for short stay hotels. (Courtesy of A.O. Smith.)

Issue: 11/03

Editor's Note: "Back to Basics" is a column that will run periodically in PME reviewing the basic

principles of plumbing engineering.

As frequent business travelers know, there can be many frustrations to being on the road, including

cancelled flights, long lines for rental cars, and indigestion from constantly being on the run, attending

meeting after meeting. There is nothing more frustrating than jumping into the shower for a

much-needed morning wake-up, only to discover that the water is ice cold--no hot water to be had

anywhere!

We're sure this is just as frustrating for the hotel manager, who has to deal with calls from angry guests

on mornings when occupancy exceeds the capacity of the building's undersized domestic water heating

system. The fact is that with the right water heaters that are properly sized, a hotel should never run out

of hot water. Standard efficiency atmospheric water heaters or high efficiency sealed combustion water

heaters can both handle the load equally well, but there is a significant difference between the two in

operating and installation costs. Let's look at a "real world" example, based on one of the trends in the

hotel business.

Back to Basics: Water Heaters http://www.pmengineer.com/articles/print/88925-back-to-basics-water-he...

1 of 5 8/16/2014 1:15 AM

Commercial water heaters like this A.O. Smith Cyclone model place the down-fired burner on top of

the unit, so condensation and resulting corrosion do not affect the burner.

You see it more and more often--a "hotel park," with three or more "inns" clustered together. They're

usually right off the interstate, close to an industrial park or airport, with a Cracker Barrel, Denny's or

other chain restaurant nearby. These mid-sized "short stay" hotel chains include LaQuinta Inns,

Fairfield Inns, Comfort Inns, Wingate Inns and Baymont Inns. All cater to the business traveler who

really only needs a comfortable bed, a TV set, a telephone, a cup of coffee in the mornings, and of

course, a hot shower. They typically have no more than 60 guestrooms and no restaurant, since their

guests can head over to Cracker Barrel if they need breakfast or a quick snack. Because they offer little

in the way of frills, they also offer discount rates, so they need to keep their overhead as low as possible

to make a profit.

Domestic hot water for this type of lodging can represent up to 30% of the hotel's energy operating

cost. That's a significant percentage, so investing in a high efficiency water heating system will pay big

dividends down the road. Here's how it works.

The first and most important step in commercial water heater sizing for hotels is determining the hot

water demand for a specific timeframe, referred to as the peak period. In a hotel, there will normally be

Back to Basics: Water Heaters http://www.pmengineer.com/articles/print/88925-back-to-basics-water-he...

2 of 5 8/16/2014 1:15 AM

two peak periods, one in the morning and a second in the early evening. Sizing for these periods should

not include requirements for the hotel's laundry facilities. All hot water during peak periods should be

devoted to serving the guestrooms. Laundry should only be done during "off-peak" hours.

The key to proper sizing for the specific model water heater is to achieve the proper balance between

usable stored water in the tank and the recovery rate. The recovery rate represents the amount of water

the system can heat (to a specific "temperature rise") in one hour. In the case of our "short stay" 60-unit

hotel, we're going to base our calculations on a one-hour peak demand period in the morning and a

one-hour peak demand period in the evening. We normally calculate hotel sizing based on two-hour

peak demand, but the nature of these "short stay" facilities is that the guests get up and out faster than

normal, so the peak can be compressed to one hour.

With 60 rooms, each with 3 gpm shower heads, and factoring in 100F temperature rise requirement

(water heaters must be able to provide sufficient hot water supply even in the coldest months), our

sizing tables tell us we'll need to be able to provide 740 gallons of hot water to satisfy our one-hour

peak demand. (The A.O. Smith Accu-Size Guide was used for these calculations. The current defaults

are set to assure the minimum required hot water with a minimum amount of information.)

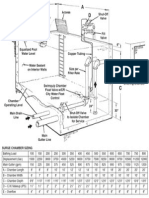

To achieve this objective, the sizing tables recommend a system with 240 gallons of total storage. Bear

in mind, that the tank can only provide 70% to 80% of its stored water as useable water in one hour. So,

we'll get a portion of the hot water demand from storage during our peak period, leaving the balance

needed to come from the system's recovery capacity. Finally, after the peak period is over, we'll have to

reheat the gallons drawn from storage to restore the unit to full capacity (Figures 1 and 2).

(Btu input =gph x 8.25 x temp rise x 1.0) divided by % efficiency

Having determined our hotel's peak demand, plus the storage and recovery capacity needed to meet it,

here are two gas-fired options that satisfy the requirements:

Option One: Three standard tank-type heaters:

80% thermal efficiency

100-gallon storage capacity per unit, 70% tank draw efficiency, and

199,000 Btuh maximum input per unit produces 193 gph recovery

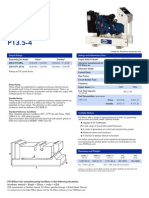

Option Two: Three tank-type heaters:

94% thermal efficiency

100-gallon storage capacity per unit, 80% tank draw efficiency, and

Back to Basics: Water Heaters http://www.pmengineer.com/articles/print/88925-back-to-basics-water-he...

3 of 5 8/16/2014 1:15 AM

150,000 Btuh maximum input produces 171 gph recovery

Both of these systems produce an adequate supply of hot water, but their operating costs are

significantly different. Let's compare the impact the 94% efficient model has on the actual fuel

consumption required to meet the one-hour peak demand at our 60-unit "short stay" hotel.

80% thermal efficiency: 763,125 Btu

94% thermal efficiency: -649,468 Btu

Difference: 113, 657 Btu

This burner design mixes incoming blower-driven air with incoming gas. When the mixture is ignited by

the hot surface igniter, a flame shoots downward into the submerged central combustion chamber. The

resulting hot fuel gases are then forced for high velocity through a helical heat exchanger coil. The

spiral shape of the coil keeps the hot gases swirling against the heat exchanger walls, producing a high

rate of heat transfer. (Courtesy of A.O. Smith.)

As the numbers show, by using three 94% efficient water heaters instead of three 80% efficient models,

we can reduce our hotel's energy consumption during that critical peak period by nearly 15%. Figure 3

illustrates how that translates into dollar savings on water heating costs, as extended over a full year.

Bear in mind, the $737 estimated savings covers the hotel's two daily peak periods. Obviously, there

will be off-peak hot water use by guests, as well as hotel laundry and other maintenance requirements.

We can conservatively estimate that savings during off-peak hours will increase the total by 50%,

bringing total one-year savings to just over $1,100. Extend that over the three-year warranty period,

Back to Basics: Water Heaters http://www.pmengineer.com/articles/print/88925-back-to-basics-water-he...

4 of 5 8/16/2014 1:15 AM

and the comparative savings exceed $3,000. It's not unreasonable to expect this rate of savings to

continue throughout the life of the heater.

The key to proper sizing for the specific model water heater is to achieve the proper balance between

usable stored water in the tank and the recovery rate.

As we've shown, operating costs savings can be substantial, but there are other good reasons to choose

a high efficiency commercial water heater. Certain high efficiency models offer multiple venting

options, including sealed power direct venting, in which all combustion air is drawn from outside the

structure. This takes indoor ventilation out of the equation, and prevents performance problems caused

by negative indoor air pressure.

In addition, such a design permits intake and exhaust runs up to 120 feet using four-inch PVC pipe, or

50 feet using three-inch PVC pipe. Use of inexpensive PVC pipe, along with a model's flexibility to use

either vertical or horizontal vent runs, can produce significant savings on installation labor and material

costs compared to standard water heaters.

To summarize, the first priority in sizing a water heater system for a hotel must be making sure the

system can keep up with the application's peak demand to ensure their guests are not met with cold

showers in the morning or at any other time.

Cost efficiency is an important consideration, but it's certainly a distant second on the priority list. Who

cares how cost-effective a water heating system is if it doesn't do its job? Having no water heaters at all

would be cost-effective in the short run, but long term, depriving guests of hot water will put any hotel

out of business. Adequate hot water is always the most important consideration.

Once the need is met, new efficiency technologies have also created new possibilities for significant

savings. Such models may have a higher initial product cost difference, but then provide lower

installation and operating costs.

We could go on and on, because commercial water heating system sizing is unique to each water heater

model and each application. Maybe next time you spring into the hotel shower, you will give a

moment's thought to the contractor or engineer who sized the application.

Back to Basics: Water Heaters http://www.pmengineer.com/articles/print/88925-back-to-basics-water-he...

5 of 5 8/16/2014 1:15 AM

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- NADCA-Introduction To Die Casting PDFDocument116 pagesNADCA-Introduction To Die Casting PDFMichael Naím Dévora Quintanar100% (6)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Technical Bid For Electric Heat Tracing SystemDocument27 pagesTechnical Bid For Electric Heat Tracing SystemNaveed Ahmed MirNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- RT-flex-Introduction May13 Rev1Document96 pagesRT-flex-Introduction May13 Rev1NAGENDRA KUMAR D100% (1)

- History of MechatronicsDocument20 pagesHistory of MechatronicsManoj DhageNo ratings yet

- Combining DOAS and VRF, Part 1 of 2Document8 pagesCombining DOAS and VRF, Part 1 of 2miniongskyNo ratings yet

- "Solutions For The Plastics Industry": Co. IncDocument4 pages"Solutions For The Plastics Industry": Co. IncminiongskyNo ratings yet

- Jad Schenk Eddy Current DynamometerDocument34 pagesJad Schenk Eddy Current DynamometerAchmad PraptijantoNo ratings yet

- Air King Ventilation Ashrae 62Document5 pagesAir King Ventilation Ashrae 62miniongskyNo ratings yet

- Product LoadDocument6 pagesProduct LoadDave Harrison Flores100% (1)

- 16 Ways To Reduce HVAC Energy in Supermarkets and RetailDocument4 pages16 Ways To Reduce HVAC Energy in Supermarkets and RetailminiongskyNo ratings yet

- Combining DOAS and VRF, Part 2 of 2Document9 pagesCombining DOAS and VRF, Part 2 of 2miniongskyNo ratings yet

- Design of Isolated Footing with Moment CalculationsDocument28 pagesDesign of Isolated Footing with Moment CalculationsmeenuNo ratings yet

- 36 PneumaticDocument50 pages36 PneumaticduythienddtNo ratings yet

- Renault Magnum 400 - 440 - 480 Service ManualDocument251 pagesRenault Magnum 400 - 440 - 480 Service ManualMihai CostasNo ratings yet

- Tender Document For Construction of Ghorasal 300-450 MW ... - BPDBDocument315 pagesTender Document For Construction of Ghorasal 300-450 MW ... - BPDBhumayan kabir100% (1)

- CIH Taco7aExpansionTankAirSepDocument16 pagesCIH Taco7aExpansionTankAirSepminiongskyNo ratings yet

- Bolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceDocument6 pagesBolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceminiongskyNo ratings yet

- Types and efficiencies of fuel-fired boilersDocument4 pagesTypes and efficiencies of fuel-fired boilersminiongskyNo ratings yet

- Glossary - Education - CAGI - Compressed Air and Gas InstituteDocument6 pagesGlossary - Education - CAGI - Compressed Air and Gas InstituteminiongskyNo ratings yet

- Selecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerDocument5 pagesSelecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerminiongskyNo ratings yet

- Application & Design of Energy Recovery Wheels - Airxchange, Inc PDFDocument8 pagesApplication & Design of Energy Recovery Wheels - Airxchange, Inc PDFminiongskyNo ratings yet

- Cooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringDocument3 pagesCooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- Sugar - Fluid Flow VelocitiesDocument4 pagesSugar - Fluid Flow VelocitiesminiongskyNo ratings yet

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDocument7 pagesImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyNo ratings yet

- Expert Cooling Tower Repair, LLC - 303.790Document4 pagesExpert Cooling Tower Repair, LLC - 303.790eimrehNo ratings yet

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocument13 pagesFM Global Property Loss Prevention Data Sheets: List of FiguresminiongskyNo ratings yet

- FMDS 1-35 Green Roof SystemsDocument27 pagesFMDS 1-35 Green Roof SystemsminiongskyNo ratings yet

- ACH Recommended air changes per hourDocument2 pagesACH Recommended air changes per hourminiongskyNo ratings yet

- Characteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncDocument2 pagesCharacteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncminiongskyNo ratings yet

- Table - First Hour RatingDocument1 pageTable - First Hour RatingminiongskyNo ratings yet

- APEC Building Codes, Regulations and StandardsDocument227 pagesAPEC Building Codes, Regulations and StandardsminiongskyNo ratings yet

- Table 1MDocument2 pagesTable 1MminiongskyNo ratings yet

- Back To Basics - Water Pipe SizingDocument5 pagesBack To Basics - Water Pipe Sizingminiongsky100% (1)

- Table 6 - Demographic2Document1 pageTable 6 - Demographic2miniongskyNo ratings yet

- Table - Hot Water Temperatures NHSDocument1 pageTable - Hot Water Temperatures NHSminiongskyNo ratings yet

- Surge ChamberDocument1 pageSurge ChamberminiongskyNo ratings yet

- Table - Hot Water Temperatures22Document2 pagesTable - Hot Water Temperatures22miniongskyNo ratings yet

- Evaporative Pool DehumidificationDocument9 pagesEvaporative Pool DehumidificationminiongskyNo ratings yet

- Design Considerations of Water FeaturesDocument102 pagesDesign Considerations of Water Featuresminiongsky100% (1)

- BWT 7000 SCDocument1 pageBWT 7000 SCMehdi AcilNo ratings yet

- Motor effect concepts and applicationsDocument2 pagesMotor effect concepts and applicationsIntiser RahmanNo ratings yet

- Choosing the Right Sanitary Rupture DiskDocument35 pagesChoosing the Right Sanitary Rupture DiskAnonymous bHh1L1No ratings yet

- Long Haul / Highway and Regional Drive: Solid Shoulder Drive Tire Stone EjectorsDocument1 pageLong Haul / Highway and Regional Drive: Solid Shoulder Drive Tire Stone EjectorsDionicio ChavezNo ratings yet

- FG Wilson P13.5-4 Generating Set Ratings and SpecsDocument4 pagesFG Wilson P13.5-4 Generating Set Ratings and Specsscribdledee100% (1)

- Tank DesignDocument2 pagesTank DesignkamleshyadavmoneyNo ratings yet

- Mann Tek CouplingsDocument16 pagesMann Tek CouplingsBerniceNo ratings yet

- 04-Samss-055 - 2020Document34 pages04-Samss-055 - 2020MEHBOOB19786No ratings yet

- Technical Description: 1 Demag Wall Mounted Slewing Jib Crane 1000 KG X 4000 MM JC-W-270-KBK-BR-M-1000-4000Document3 pagesTechnical Description: 1 Demag Wall Mounted Slewing Jib Crane 1000 KG X 4000 MM JC-W-270-KBK-BR-M-1000-4000nasif andriantoNo ratings yet

- Title: Idler ASSY (320J/323J) Model Number: 320 Serial Number: 224511001 & Above, 562411001 & AboveDocument11 pagesTitle: Idler ASSY (320J/323J) Model Number: 320 Serial Number: 224511001 & Above, 562411001 & AboveJustin FoleyNo ratings yet

- TURNING FIX (04-005) - Sheet - 1Document1 pageTURNING FIX (04-005) - Sheet - 1daryosh hassanyNo ratings yet

- Haider Ali: Field Service Technician (Level 3)Document3 pagesHaider Ali: Field Service Technician (Level 3)Junaid Ahmed SattiNo ratings yet

- Ambuja Cement LTD C/o Wartsila India LTD., (Unit-Rawan)Document4 pagesAmbuja Cement LTD C/o Wartsila India LTD., (Unit-Rawan)rajsekharkvNo ratings yet

- Soldier Pile and Lagging Caltan 1990 Tedds CalcDocument2 pagesSoldier Pile and Lagging Caltan 1990 Tedds CalcRJSQNo ratings yet

- An Introduction To Marine Composites: Paul H. MillerDocument36 pagesAn Introduction To Marine Composites: Paul H. MillerGregory ChuaNo ratings yet

- Motion Along A Straight LineDocument16 pagesMotion Along A Straight LineNorhapidah Mohd SaadNo ratings yet

- Welding Machine Repairing Service in Rajkot Gujarat IndiaDocument127 pagesWelding Machine Repairing Service in Rajkot Gujarat IndiaSpandan MishraNo ratings yet

- Ab-522 Standard Pneumatic Test Procedure Requirements PDFDocument17 pagesAb-522 Standard Pneumatic Test Procedure Requirements PDFMarizta Perdani PutriNo ratings yet

- "2020" Seminar Information: FORD 6R140W - 6R80Document4 pages"2020" Seminar Information: FORD 6R140W - 6R80Gina LópezNo ratings yet

- Application of Pump: CentrifugalDocument8 pagesApplication of Pump: CentrifugalLipika GayenNo ratings yet