Professional Documents

Culture Documents

Important dimensions and tolerances for metric threads

Uploaded by

manish_chaturvedi_6Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Important dimensions and tolerances for metric threads

Uploaded by

manish_chaturvedi_6Copyright:

Available Formats

1.

01 2012/1

THE IMPORTANT DIMENSIONS ON A THREAD

D Major diameter for an internal thread

D2 Pitch diameter for an internal thread

D1 Minor diameter for an internal thread

d Major diameter for an external thread

d2 Pitch diameter for an external thread

d1 Minor diameter for an exernal thread

P Pitch

Pitch is the distance a single start thread moves when

turned a single rotation. The correct definition is the axial

distance between one point on a flank and the same point

on the following and corresponding flank.

On a metric thread the number given (i.e. M16x2) after the

thread diameter is the pitch whereas in a thread with TPI it

is the number of threads (n) per inch (TPI) divided into 1.

1/n.

Flank angle

Metric (M) and American (UN) threads are 60

O

, Whitworth

55

O

, Metric trapezoidal 30

O

and Acme 29

O

Other flank angles can be used for special threads

Tolerances

Unless otherwise specified the tolerance on a standard metric (M) nut is 6H and on a screw 6g

Unless otherwise specified the tolerance on a standard American (UNC) nut is 2B and on a screw 2A

The following information is for a standard ISO metric thread M16x2 - 6H/6g ref. ISO 965-3

Standard

M16x2

NUT (6H)

D

16,000

Standard

M16x2

SCREW

(6g)

d

16,000

- 0,038

- 0,318

Measuring an external thread is usually easier than measuring

an internal thread. This is the one reason why internal screw

threads often have larger tolerances than internal threads.

Note the pitch diameter size

the nut 0,212mm and the screw 0,160mm

As threads are usually measured within 0,01mm, it is practical

to round the measurement result up or down to the nearest

0,01mm.

If the measurement result is deemed necessary to 0,001mm

then the flank angle and pitch should also be measured.

The pitch diameter D2 for an internal thread must never be less

than the nominal pitch diameter. The pitch diameter d

2

for an

external thread should never be larger than the nominal pitch

diameter.

D2

14,701

+

0,212

- 0

d2

14,701

- 0,038

- 0,198

D1

13,835

+

0,375

- 0

d1

13,546

- 0,038

- 0,327

P 2,000 0,005 up to and including a length of 32 mm

60

O

0,5

O

r 0,25 minimum radius on D og d1

If the tolerance on d2 (- 0,042 / - 0,212 giving 0,17mm) is set to 100 then the tolerances

for D2, D1 and d respectively are 132, 264 and 197. Measuring an external thread is usually easier than an internal

thread. This is probably one reason why internal screw threads often have larger tolerances than external threads.

WWW.F-M-S.DK

You might also like

- Gel Electrophoresis Lab ReportDocument10 pagesGel Electrophoresis Lab Reportapi-31150900783% (6)

- Bolt Pretension AnsysDocument2 pagesBolt Pretension Ansys001tabNo ratings yet

- Thread Cutting FundamentalsDocument56 pagesThread Cutting Fundamentalsjaydip2410chhatrala100% (1)

- Beginners Python Cheat Sheet PCC AllDocument14 pagesBeginners Python Cheat Sheet PCC AllTelmo Joao Magalhaes OliveiraNo ratings yet

- ANSYS ACT Developers Guide PDFDocument410 pagesANSYS ACT Developers Guide PDFJames0% (1)

- ScrewsDocument35 pagesScrewsRodel Marata100% (2)

- Full Design of Flange CouplingDocument41 pagesFull Design of Flange CouplingAasawari Mahagaonkar0% (1)

- Mechanical Spring Design GuideDocument8 pagesMechanical Spring Design GuideJosafatNo ratings yet

- Practical On CouplingDocument13 pagesPractical On Couplingfaham khanNo ratings yet

- A PresentationDocument57 pagesA Presentationmadan023No ratings yet

- Perfect Day Formula PDFDocument6 pagesPerfect Day Formula PDFjeffNo ratings yet

- 14 CWO Marcrau Memo To Commanding General Army Air Forces, 12 August 1947Document2 pages14 CWO Marcrau Memo To Commanding General Army Air Forces, 12 August 1947oztronixNo ratings yet

- Baroque MusicDocument15 pagesBaroque Musicthot777100% (2)

- Meshing in ANSYS WorkbenchDocument5 pagesMeshing in ANSYS Workbenchfr129834No ratings yet

- Compliment To Entire PDFDocument159 pagesCompliment To Entire PDFEzequiel Ezequiel100% (1)

- Shell 99Document13 pagesShell 99001tabNo ratings yet

- Shortcut Keys For MS OfficeDocument5 pagesShortcut Keys For MS OfficesokkanlingamNo ratings yet

- Studies: Air Force Regulation 200-2Document3 pagesStudies: Air Force Regulation 200-2Claudiu StanculescuNo ratings yet

- Final Exam Review: Spring 2010Document18 pagesFinal Exam Review: Spring 2010Eric E CastroNo ratings yet

- Simple StressDocument28 pagesSimple StressRaven ShadeNo ratings yet

- Mentally Strong People Hold The PowerDocument8 pagesMentally Strong People Hold The PowerReaz ReazNo ratings yet

- Consciousness SummaryDocument9 pagesConsciousness SummaryLaura ToronNo ratings yet

- Talent Is OverratedDocument6 pagesTalent Is OverratedjeffNo ratings yet

- David Williams: ContributorDocument4 pagesDavid Williams: ContributorCzarina Jasmine MadrigalNo ratings yet

- Majestic 12 committee exposed in UFO docsDocument2 pagesMajestic 12 committee exposed in UFO docsAndrés Garza0% (1)

- Philosophy & Neuroscience - Understanding Conscious ExperienceDocument3 pagesPhilosophy & Neuroscience - Understanding Conscious ExperienceAldo PrietoNo ratings yet

- Thread Gauge ISO1502 PDFDocument5 pagesThread Gauge ISO1502 PDFBaldev SinghNo ratings yet

- The Roswell Mystery...Document8 pagesThe Roswell Mystery...sithusoemoeNo ratings yet

- Graham and AlfordDocument32 pagesGraham and AlfordUSAHMNo ratings yet

- Din 8140-1Document5 pagesDin 8140-1main46prairieNo ratings yet

- Metric STD ThreadDocument4 pagesMetric STD ThreadmayurNo ratings yet

- Spline DesignDocument5 pagesSpline DesignRuchira Chanda Indu100% (2)

- Three Laws of RoboticsDocument2 pagesThree Laws of RoboticsBav VAansoqnuaetzNo ratings yet

- Ufo Advanced TechnologyDocument2 pagesUfo Advanced TechnologyTommy BJNo ratings yet

- Power SystemsDocument47 pagesPower Systemsmanish_chaturvedi_6No ratings yet

- Interference Fits and PressureDocument21 pagesInterference Fits and PressurerwmingisNo ratings yet

- ME6603 Finite Element Analysis Important QuestionsDocument8 pagesME6603 Finite Element Analysis Important QuestionsAnirudhan Ravi100% (1)

- MoitvationDocument66 pagesMoitvationDiane Jayne Justo RiveraNo ratings yet

- Bolt design: Screw thread fundamentals and terminologyDocument3 pagesBolt design: Screw thread fundamentals and terminologyAlla EddineNo ratings yet

- Crop CircleDocument11 pagesCrop CircleMKostyakovNo ratings yet

- Guide to Understanding FEA Stress and Fatigue MechanicsDocument18 pagesGuide to Understanding FEA Stress and Fatigue MechanicsMagesh BNo ratings yet

- Mechanical Intro 17.0 M05 Mesh ControlDocument59 pagesMechanical Intro 17.0 M05 Mesh ControlSamedŠkuljNo ratings yet

- Shortcut KeysDocument2 pagesShortcut KeysAnil KumarNo ratings yet

- Funny FactsDocument3 pagesFunny FactsArpit KachaliaNo ratings yet

- John KotterDocument3 pagesJohn KotterSyedAshirBukhariNo ratings yet

- Fonzi's Last Investigation of JFK AssassinationDocument11 pagesFonzi's Last Investigation of JFK AssassinationThames ChaseNo ratings yet

- 27 Mental ToughnessDocument3 pages27 Mental ToughnessBoris0% (1)

- Horton Wingless Patent ApplicationDocument4 pagesHorton Wingless Patent ApplicationMystery WireNo ratings yet

- Motivation & LearningDocument21 pagesMotivation & Learningrm53No ratings yet

- Screw ThreadsDocument2 pagesScrew ThreadsN.PalaniappanNo ratings yet

- Tapping Drill Sizes and Thread Pitch DiametersDocument3 pagesTapping Drill Sizes and Thread Pitch DiametersMukesh GuptaNo ratings yet

- Pin Bush Coupling DesignDocument15 pagesPin Bush Coupling Designyogwani79No ratings yet

- Stud ExplanationDocument1 pageStud ExplanationJamal Mohamed100% (1)

- Product and Dimensional Standards For FastenersDocument7 pagesProduct and Dimensional Standards For Fastenersmech_abhiNo ratings yet

- BSP ThreadsDocument6 pagesBSP ThreadsVinod YbNo ratings yet

- Threaded FastenersDocument49 pagesThreaded Fastenersmuhammed sahilNo ratings yet

- Unified Thread StandardDocument3 pagesUnified Thread Standardeogus9021No ratings yet

- Flange CouplingDocument18 pagesFlange Coupling58-Sanket TupkarNo ratings yet

- Design of Guiding Mechanism: I.E. A Bolt and Nut. The Screwed Joints Are Widely Used Where The MachineDocument7 pagesDesign of Guiding Mechanism: I.E. A Bolt and Nut. The Screwed Joints Are Widely Used Where The MachineHAIMANOTNo ratings yet

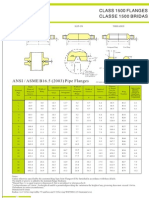

- Flanges 2Document15 pagesFlanges 2chicotonyxdNo ratings yet

- Din 13-9Document5 pagesDin 13-9rajeskumarNo ratings yet

- UTS - Unified Thread Standard Definition & SpecificationsDocument4 pagesUTS - Unified Thread Standard Definition & SpecificationsskluxNo ratings yet

- Bts3902e Quick GuideDocument20 pagesBts3902e Quick GuideAlexander TyshchenkoNo ratings yet

- The Essential Guide To Spring Technology: WWW - Springs.co - UkDocument32 pagesThe Essential Guide To Spring Technology: WWW - Springs.co - UkFurqan ShabbirNo ratings yet

- Electrical Power System Fault Analysis PDFDocument60 pagesElectrical Power System Fault Analysis PDFKumardeep MukhopadhyayNo ratings yet

- Switchgear Notes PDFDocument134 pagesSwitchgear Notes PDFGorla RamuNo ratings yet

- Syllabus I YearDocument25 pagesSyllabus I YearDipesh PatelNo ratings yet

- Electrical Power System Fault Analysis PDFDocument60 pagesElectrical Power System Fault Analysis PDFKumardeep MukhopadhyayNo ratings yet

- Switchgear Notes PDFDocument134 pagesSwitchgear Notes PDFGorla RamuNo ratings yet

- PS Lab ManualDocument25 pagesPS Lab ManualPhani PhaniNo ratings yet

- PHD Thesis Format and GuidelinesDocument15 pagesPHD Thesis Format and GuidelinesPranayNo ratings yet

- PHD Thesis Evaluation FormDocument2 pagesPHD Thesis Evaluation Formmanish_chaturvedi_6No ratings yet

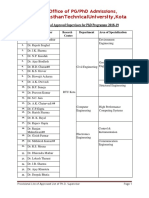

- Supervisor 2018 19Document8 pagesSupervisor 2018 19manish_chaturvedi_6No ratings yet

- Syllabus I Year 2019 20 Onwards PDFDocument24 pagesSyllabus I Year 2019 20 Onwards PDFRitik KalwarNo ratings yet

- PHD Thesis Format and GuidelinesDocument15 pagesPHD Thesis Format and GuidelinesPranayNo ratings yet

- Ph.D. Pre Synopsis Seminar Examination ReportDocument4 pagesPh.D. Pre Synopsis Seminar Examination Reportmanish_chaturvedi_6No ratings yet

- Provisional List of Research Centers For The Session 2018 191Document4 pagesProvisional List of Research Centers For The Session 2018 191manish_chaturvedi_6No ratings yet

- PHD Oral Defence Evaluation FormDocument2 pagesPHD Oral Defence Evaluation Formmanish_chaturvedi_6No ratings yet

- Half Yearly Exam General Science Class 3Document3 pagesHalf Yearly Exam General Science Class 3manish_chaturvedi_6No ratings yet

- PHD Thesis Evaluation FormDocument2 pagesPHD Thesis Evaluation Formmanish_chaturvedi_6No ratings yet

- PHD Oral Defence Evaluation FormDocument2 pagesPHD Oral Defence Evaluation Formmanish_chaturvedi_6No ratings yet

- Counselor For Ist Year StudentsDocument1 pageCounselor For Ist Year Studentsmanish_chaturvedi_6No ratings yet

- Ph.D. Pre Synopsis Seminar Examination ReportDocument4 pagesPh.D. Pre Synopsis Seminar Examination Reportmanish_chaturvedi_6No ratings yet

- Half Yearly Exam - Class3 - ComputerDocument5 pagesHalf Yearly Exam - Class3 - Computermanish_chaturvedi_6No ratings yet

- Ist Year Branchwise Batch AllottmentDocument1 pageIst Year Branchwise Batch Allottmentmanish_chaturvedi_6No ratings yet

- Half Yearly Exam English - IDocument2 pagesHalf Yearly Exam English - Imanish_chaturvedi_6No ratings yet

- Half Yearly Exam - Class 3 - English 1Document3 pagesHalf Yearly Exam - Class 3 - English 1manish_chaturvedi_6No ratings yet

- Final Year Exam MATHS1Document2 pagesFinal Year Exam MATHS1manish_chaturvedi_6No ratings yet

- Half Yearly Exam - Deepta - Evs - 1Document3 pagesHalf Yearly Exam - Deepta - Evs - 1manish_chaturvedi_6No ratings yet

- Half Yearly Exam English - IDocument2 pagesHalf Yearly Exam English - Imanish_chaturvedi_6No ratings yet

- List of Officials of UTDDocument1 pageList of Officials of UTDmanish_chaturvedi_6No ratings yet

- Ist Year Branchwise Batch AllottmentDocument1 pageIst Year Branchwise Batch Allottmentmanish_chaturvedi_6No ratings yet

- Mba Brochure1 PDFDocument17 pagesMba Brochure1 PDFMadhusudan DadhichNo ratings yet

- Nodal Officer Wise Student ListDocument48 pagesNodal Officer Wise Student ListguerellaNo ratings yet

- Useful List of Responsive Navigation and Menu Patterns - UI Patterns - GibbonDocument16 pagesUseful List of Responsive Navigation and Menu Patterns - UI Patterns - Gibbonevandrix0% (1)

- And Others - ScriptDocument32 pagesAnd Others - ScriptLisaNo ratings yet

- ST Biology Nervous System IEP TestDocument3 pagesST Biology Nervous System IEP TestDanielle WilsonNo ratings yet

- Life and Works or Rizal - EssayDocument2 pagesLife and Works or Rizal - EssayQuince CunananNo ratings yet

- Ozone Layer EssayDocument7 pagesOzone Layer Essayb71bpjha100% (2)

- Burning Arduino Bootloader With AVR USBASP PDFDocument6 pagesBurning Arduino Bootloader With AVR USBASP PDFxem3No ratings yet

- 1st Activity in ACCA104Document11 pages1st Activity in ACCA104John Rey BonitNo ratings yet

- Odoo Video Conference User GuidesDocument12 pagesOdoo Video Conference User GuidesZeus TitanNo ratings yet

- Justification: Justification: Doctrine of Council of TrentDocument4 pagesJustification: Justification: Doctrine of Council of TrentMihai SarbuNo ratings yet

- Performance of Filler Material in GabionsDocument4 pagesPerformance of Filler Material in GabionsPreetham N KumarNo ratings yet

- Nestle CompanyDocument5 pagesNestle CompanymehakNo ratings yet

- Data Sheet 6EP1457-3BA00: InputDocument4 pagesData Sheet 6EP1457-3BA00: InputSeyyed Amir MohmmadiNo ratings yet

- Tie Technology DK SKDocument32 pagesTie Technology DK SKVladimir PleșcaNo ratings yet

- Renold Transmission Chain Catalogue ENG 0112Document94 pagesRenold Transmission Chain Catalogue ENG 0112nataliaNo ratings yet

- ADTHEORENT SOTI Programmatic 102722Document20 pagesADTHEORENT SOTI Programmatic 102722chinmayNo ratings yet

- Sidney W A Dekker From Threat and Error Management To ResilienceDocument11 pagesSidney W A Dekker From Threat and Error Management To ResilienceDaniel fabian Sánchez henaoNo ratings yet

- ICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseDocument8 pagesICJ Judgment on Philippines' Bid to Intervene in Indonesia-Malaysia Maritime Boundary CaseZayd Iskandar Dzolkarnain Al-Hadrami100% (1)

- 4.6.6 Lab View Wired and Wireless Nic InformationDocument4 pages4.6.6 Lab View Wired and Wireless Nic InformationThắng NguyễnNo ratings yet

- Urea CycleDocument2 pagesUrea CycleyoungdandareNo ratings yet

- Key concepts in biology examDocument19 pagesKey concepts in biology examAditya RaiNo ratings yet

- FMS 1Document27 pagesFMS 1bishal dattaNo ratings yet

- Bangladesh Red Crescent Society First Aid Kit SpecificationDocument1 pageBangladesh Red Crescent Society First Aid Kit SpecificationWORLDWIDE TRANSLATIONNo ratings yet

- CM105 18to19Document30 pagesCM105 18to19api-3849444100% (2)

- Red Lion MP Sensor Product Manual PDFDocument2 pagesRed Lion MP Sensor Product Manual PDFJigneshNo ratings yet

- Symbolic Calculus Sage ReferenceDocument25 pagesSymbolic Calculus Sage ReferenceLn Amitav BiswasNo ratings yet

- Mahabharata Book 9 Shalya ParvaDocument413 pagesMahabharata Book 9 Shalya Parvaavacdis1969No ratings yet