Professional Documents

Culture Documents

SEO Rotary Encoders

Uploaded by

shyhuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEO Rotary Encoders

Uploaded by

shyhuCopyright:

Available Formats

179

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

Product Line

Horizontal

Vertical

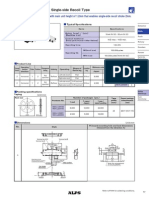

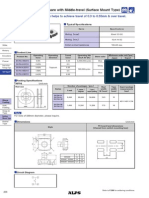

12 12 1.6 1.3

4.5

EC05E1220202

EC05E1220203

EC05E1220401

1

2

3

Product No.

Drawing

No.

4,000 8,000

8,000 16,000

Minimum order unitpcs.

Japan Export

Number of

detent

Number of

pulse

Mount height

mm

Operating

direction

Detent torque

mNm

Packing Specications

Taping

Reel size

Unit:mm

Operating

direction

16

8,000 4,000 1,000 Horizontal

Number of packagespcs.

Tape

width

mm

410 485 246

16,000 8,000 2,000 Vertical

Export package

measurements

mm

1 reel

1 case /

Japan

1 case /

export packing

Refer to P.193 for soldering conditions.

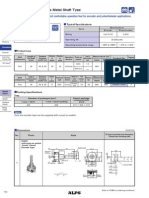

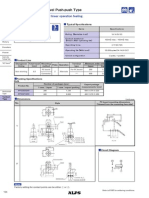

EC05E

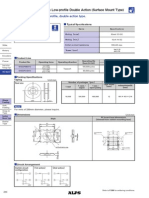

5mm Size Hollow Shaft Type

Compact type employing Alps' DRUMCODE technology

Typical Specifications

Items Specifications

Rating 0.55mA 5V DC

Operating life 100,000cycles

Operating temperature range 30 to 85

Dimensions Unit:mm

Photo Style No.

Horizontal type

1

PC board mounting hole dimensions

(Viewed from mounting side)

F

$ $

B A

B

A

[|/)

]/])J

|(,(}J.'q

P.W.B.Mounting detail (Reference)

Viewed from mounting side

Hatched area shows soldering land

2-1.25

8.5

2

2

1

.

5

2

.

7

0

.

8

4

0

.

1

7

3-1

2 holes

R0.15 max.

F

B C A Terminal No.

Shaded areas are solder lands.

180

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

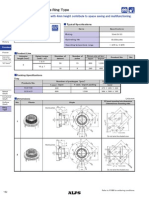

Dimensions Unit:mm

Photo Style No.

2

3

Horizontal type

Vertical type

PC board mounting hole dimensions

(Viewed from mounting side)

$ $

B A

F

B

A

$

B

A

$

B

A

[|/)

]/])J

|(,(}J.'q

P.W.B.Mounting detail (Reference)

Viewed from mounting side

Hatched area shows soldering land

2-1.25

8.5

2

2

1

.

5

2

.

7

0

.

8

4

0

.

1

7

3-1

2 holes

R0.15 max.

F

B C A Terminal No.

2

.

6

3

3

.

6

1

.

3

2

.

7

2

.

1

3

1.7 1.7 5.9

4.0

2.4

3-1.5 Hole

A C B Terminal No.

2

-

0

.

6

2

h

o

l

e

s

2

-R

0

.5

4

-R

0

.3

m

a

x

.

[|/)

]/])J

|(,(}J.'q

P.W.B.Mounting detail (Reference)

Viewed from mounting side

Hatched area shows soldering land

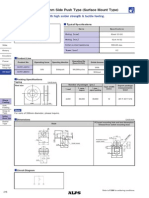

Output Wave Sliding Noise

V

1

=V

2

=2.5V max.

At R = 10k

Chattering : 6ms max. Bounce : 6ms max.

A signal

B signal ON

ON OFF

OFF

Detent position

CW direction

EC05E 5mm Size Hollow Shaft Type

5V DC

R R

Terminal B Terminal A

Terminal C

Encoder

Test circuit

t t

V1

V2

5

V

ON ON OFF

Output waveform

Sliding direction

t : Masking time to avoid chattering Measurement conditionRotation speed 360/s

Shaded areas are solder lands.

Shaded areas are solder lands.

*Signal A and signal B output at detent

positions cannot be specified.

Encoders Encoders Encoders

157

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

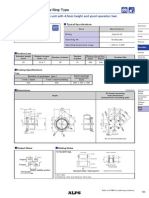

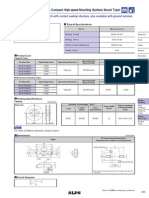

Type

Insulated Shaft Type Hollow Shaft Type

12mm size 18mm size 5mm size 10mm size

Series EC12E EC12D EC18A EC05E EC10E

Photo

Output IncrementalTwo phase A and B Absolute type IncrementalTwo phase A and B

Shaft types Single-shaft Hollow shaft

Operating direction Vertical Vertical Horizontal Horizontal

Number of pulse /

Number of detent

12 / 12

24 / 24

24 / Without

15 / 30

12 positions

16 positions

12 / 12

12 / 24

12 / 12

Features - With push-on switch

Water Resisting

Performance IPX7

Surface

Mount Type

-

Dimensions

mm

W 12.4 12.5 20 5.7 7.5 9.8

D 13.2 11.7 18 6 3.3 4.4

H 5 8.75 2.7 7.25 10.6 / 12.6 / 14.6

Operating temperature range 10 to 70 40 to 85 20 to 60 30 to + 85

5 to + 45

30 to + 85For Automotive

Operating life

15,000 cycles

30,000 cycles

30,000 cycles 100,000 cycles

Automotive use - - -

Life cycle (availability)

Electrical

performance

Rating 0.5mA 5V DC 1mA 5V DC 1mA 10V DC 0.55mA 5.5V DC 1mA 5V DC

Max./min. operating current

Resistive load

5mA / 0.5mA 10mA / 1mA - 0.55mA / -

Insulation

resistance

10M min.

50V DC

100M min. 250V DC 10M min. 250V DC 50M min. 50V DC

Voltage proof 50V AC for 1 minute

300V AC for 1 minute

or 360V AC for 1s

50V AC for 1 minute or

60V AC for 2s

50V AC for 1 minute

Mechanical

performance

Rotational torque

Without detent

10mNm max.

2515mNm

4015mNm

- - - -

Detent torque

3 2mNm

3 to 20mNm

5 3mNm

10 5mNm

60 20mNm 1.6 1.3mNm

5 3mNm

6 3mNm

Push-pull

strength

80N 100N

Push 100N /

pull 50N

-

Shaft configuration Flat, Hollow Shaft Flat Hollow shaft

Terminal type Insertion Reflow Insertion

Switch

Specications

Switch type - Push-on switch - - -

Contact

arrangement

-

Single pole and

single throwPush-on

- - -

Travel mm - 0.5 0.3 - - -

Operating

force N

-

3

1.5

1 6

2.5

2

- - -

Rating - 1mA 5V DC - - -

Contact

resistance

-

100m max. for initial period;

200m max. after operating life.

- - -

Operating life - 30,000times min. - - -

Page 174 177 179 181

Encoders Soldering Conditions 193

Encoders Cautions 194

Notes

1. The operating temperature range for automotive applications can be raised upon request. Please contact us for details.

2. indicates applicability to all products in the series, while indicates applicability to some products in the series.

List of Varieties

193

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

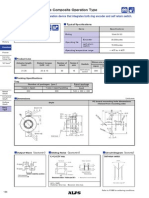

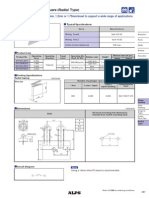

Encoders Soldering Conditions

Soldering surfacetemperature Soldering temperature Heating time Soldering time

No. of solders

3 s EC11J

EC10E, EC12D, EC12E

EC45A, EC60A

EC40A

EM20B

EC05E, EC09E, EC10E, EC111, EC11B,

EC11E, EC11G, EC11K, EC12D, EC12E,

EC18A, EC20A, EC21A, EC28A, EC35A,

EC35AH, EC35B, EC40A, EC45A, EC50A,

EC60A, EM20B

EC09E, EC11B, EC111, EC11E, EC11G,

EC11K, EC18A, EC20A, EC21A, EC28A,

EC35A, EC35AH, EC35B, EC50A

Series

Series

350 max. 3s max. 1 time

100 max. 2605 2 min. max. 51s 2 time max.

35010 2 time

100 max.

100 max.

110 max.

80 max.

2605

260 max.

260 max.

260 max.

1 min. max.

2 min. max.

1 min. max.

1 min. max.

31s

5s max.

10s max.

3s max.

2 time max.

2 time max.

1 time

2 time max.

Tip temperature Soldering time No. of solders

Preheating Dip soldering

Reference for Dip Soldering

Condition for Refow

Reference for Hand Soldering

EC05E

EC11J

Series

260 230 180 150 2 min.max. 3s 40s 4 min. max 2 time max.

250 min. 230 min. 180 150 60s to 120s 30s to 40s 2 time max.

A B C D E F G H No. of reows

Temperature profle

1

0

1.When using an infrared reow oven, solder may sometimes not be applied. Be sure to use a hot air reow oven or a

type that uses infrared rays in combination with hot air.

2.The temperatures given above are the maximum temperatures at the terminals of the potentiometer when

employing a hot air reow method. The temperature of the PC board and the surface temperature of the

potentiometer may vary greatly depending on the PC board material, its size and thickness. Ensure that the surface

temperature of the potentiometer does not rise to 250C or greater.

3.Conditions vary to some extent depending on the type of reow bath used. Be sure to give due consideration to this

prior to use.

Notes

300

200

100

A

B

C

Time (s)

G max.

F max.

H max.

E max.

Room

temperature

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Pre-heating

D

You might also like

- 20mm Metal Shaft Encoder & Potentiometer GuideDocument4 pages20mm Metal Shaft Encoder & Potentiometer GuideshyhuNo ratings yet

- 21mm Ring Encoder Guide with Specs & Soldering TipsDocument4 pages21mm Ring Encoder Guide with Specs & Soldering TipsshyhuNo ratings yet

- INSULATED SHAFT TYPEDocument5 pagesINSULATED SHAFT TYPEshyhuNo ratings yet

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDocument3 pages10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuNo ratings yet

- 20mm Size Metal Shaft Magnetic TypeDocument4 pages20mm Size Metal Shaft Magnetic TypeshyhuNo ratings yet

- EC35AH: 35mm Size ABC Switch TypeDocument4 pagesEC35AH: 35mm Size ABC Switch TypeshyhuNo ratings yet

- 35mm Ring Encoder GuideDocument3 pages35mm Ring Encoder GuideshyhuNo ratings yet

- Insulated Shaft Rotary EncodersDocument3 pagesInsulated Shaft Rotary EncodersshyhuNo ratings yet

- EC18A 18mm Insulated Shaft EncoderDocument4 pagesEC18A 18mm Insulated Shaft EncodershyhuNo ratings yet

- 35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchDocument3 pages35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchshyhuNo ratings yet

- 50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDDocument3 pages50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCDshyhuNo ratings yet

- 9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceDocument3 pages9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceshyhuNo ratings yet

- Rotary Encoder GuideDocument3 pagesRotary Encoder GuideshyhuNo ratings yet

- 45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignDocument3 pages45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignshyhuNo ratings yet

- 1.2 (H) MM, Single-Side Recoil TypeDocument4 pages1.2 (H) MM, Single-Side Recoil TypeshyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- Recoil Type For Single-Side and Both SidesDocument5 pagesRecoil Type For Single-Side and Both SidesshyhuNo ratings yet

- 60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningDocument3 pages60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningshyhuNo ratings yet

- SSSS7Document5 pagesSSSS7shyhuNo ratings yet

- 12mm Size Insulated Shaft TypeDocument4 pages12mm Size Insulated Shaft TypeZoltán Halász100% (2)

- TACT Switch GuideDocument3 pagesTACT Switch GuideshyhuNo ratings yet

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Document3 pagesHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- SKEGDocument4 pagesSKEGshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- SKHH 6mm Square Tact Switch Product GuideDocument6 pagesSKHH 6mm Square Tact Switch Product GuideshyhuNo ratings yet

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDocument3 pages7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNo ratings yet

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDocument5 pages6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNo ratings yet

- Snap-in Tact Switch Specs and Soldering GuideDocument3 pagesSnap-in Tact Switch Specs and Soldering GuideshyhuNo ratings yet

- 6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationDocument4 pages6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationshyhuNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- 10mm Square Water-proof Tact Switch SpecificationsDocument5 pages10mm Square Water-proof Tact Switch SpecificationsshyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDocument4 pages12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuNo ratings yet

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- Quiet Surface Mount Switch SpecificationsDocument3 pagesQuiet Surface Mount Switch SpecificationsshyhuNo ratings yet

- Spvqa: Water-Proof TypeDocument4 pagesSpvqa: Water-Proof Typeshyhu100% (1)

- 12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsDocument4 pages12mm Square Long-Life (Snap-In Type) : Long-Life Type With Unique Dust-Proof Structure and Highly Reliable Metal ContactsshyhuNo ratings yet

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocument3 pages6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNo ratings yet

- Low-Profile Tri-Directional Operation TypeDocument3 pagesLow-Profile Tri-Directional Operation TypeshyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

- Snap-in switch documentDocument3 pagesSnap-in switch documentshyhuNo ratings yet

- SPED2 Push Switch SpecsDocument3 pagesSPED2 Push Switch SpecsshyhuNo ratings yet

- SKQM 6 × 3.5mm Compact (Surface Mount TypeDocument3 pagesSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- AlpsDocument4 pagesAlpsciohaniNo ratings yet

- Low-Profile, 1.2mm Height, Long Travel TypeDocument3 pagesLow-Profile, 1.2mm Height, Long Travel TypeshyhuNo ratings yet

- Trigear Brochure - 2121 PDFDocument5 pagesTrigear Brochure - 2121 PDFDeep PatelNo ratings yet

- List of Varieties: Top Push Side PushDocument5 pagesList of Varieties: Top Push Side PushshyhuNo ratings yet

- Power Detector Slide Push Rotary Encoders Dual-in-line Package Type TACT SwitchDocument4 pagesPower Detector Slide Push Rotary Encoders Dual-in-line Package Type TACT SwitchshyhuNo ratings yet

- 265 6.1×3.7mm Compact Switch SpecsDocument3 pages265 6.1×3.7mm Compact Switch SpecsshyhuNo ratings yet

- Encoder S Short FormDocument2 pagesEncoder S Short FormelecompinnNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- Spvq5: Micro Switch Type With Female Connector TerminalDocument3 pagesSpvq5: Micro Switch Type With Female Connector TerminalshyhuNo ratings yet

- 40-character for detector switch documentDocument3 pages40-character for detector switch documentshyhuNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Medijski linč Gorana JevtićaDocument64 pagesMedijski linč Gorana JevtićashyhuNo ratings yet

- WM 00013Document127 pagesWM 00013shyhuNo ratings yet

- List of Varieties: Resistive Position SensorsDocument1 pageList of Varieties: Resistive Position SensorsshyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDocument3 pages4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNo ratings yet

- RDC40 RDC50 RDC90: Rotary TypeDocument6 pagesRDC40 RDC50 RDC90: Rotary TypeshyhuNo ratings yet

- Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputDocument4 pagesHollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputshyhuNo ratings yet

- List of Varieties: Detector Slide Push RotaryDocument5 pagesList of Varieties: Detector Slide Push RotaryshyhuNo ratings yet

- Resistive Position Sensors Specifications and Testing MethodsDocument4 pagesResistive Position Sensors Specifications and Testing MethodsshyhuNo ratings yet

- Resistive Position Sensors Linear Type Specifications and VarietiesDocument5 pagesResistive Position Sensors Linear Type Specifications and VarietiesshyhuNo ratings yet

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDocument5 pagesLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuNo ratings yet

- TACT Switch GuideDocument3 pagesTACT Switch GuideshyhuNo ratings yet

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDocument3 pages6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNo ratings yet

- SKQM 6 × 3.5mm Compact (Surface Mount TypeDocument3 pagesSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuNo ratings yet

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Document3 pages3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- 5.2mm Square Low-Profile (Surface Mount Type)Document4 pages5.2mm Square Low-Profile (Surface Mount Type)shyhuNo ratings yet

- 265 6.1×3.7mm Compact Switch SpecsDocument3 pages265 6.1×3.7mm Compact Switch SpecsshyhuNo ratings yet

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Document3 pagesSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNo ratings yet

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Document3 pagesQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNo ratings yet

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDocument3 pagesTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNo ratings yet

- Quiet Surface Mount Switch SpecificationsDocument3 pagesQuiet Surface Mount Switch SpecificationsshyhuNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Document3 pagesSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNo ratings yet

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDocument4 pages6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNo ratings yet

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDocument3 pages4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNo ratings yet

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDocument3 pagesSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNo ratings yet

- List of Varieties: Top Push Side PushDocument5 pagesList of Varieties: Top Push Side PushshyhuNo ratings yet

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDocument3 pages1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNo ratings yet

- Measuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsDocument1 pageMeasuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsshyhuNo ratings yet

- Interview@InfosysDocument13 pagesInterview@InfosysSudheer KumarNo ratings yet

- PBL62 1 30M3Document1 pagePBL62 1 30M3Hai Tran HongNo ratings yet

- 臺灣傳統木工鉋刀種類及其變異性Document12 pages臺灣傳統木工鉋刀種類及其變異性CiouZih-YanNo ratings yet

- Resilience Advantage Guidebook HMLLC2014Document32 pagesResilience Advantage Guidebook HMLLC2014Alfred Schweizer100% (3)

- Cambridge International Examinations: Additional Mathematics 4037/12 May/June 2017Document11 pagesCambridge International Examinations: Additional Mathematics 4037/12 May/June 2017Ms jennyNo ratings yet

- Advanced View of Projects Raspberry Pi List - Raspberry PI ProjectsDocument186 pagesAdvanced View of Projects Raspberry Pi List - Raspberry PI ProjectsBilal AfzalNo ratings yet

- Lexmark™ X950de, X952dte and X954dhe (7558-xxx) - Service ManualDocument1,178 pagesLexmark™ X950de, X952dte and X954dhe (7558-xxx) - Service ManualNikkiSpencerNo ratings yet

- Cummins KTA19-G4 Genset Spec SheetDocument6 pagesCummins KTA19-G4 Genset Spec SheetRonald BoocNo ratings yet

- Genbio 2 Module 1 Genetic Engineering ProcessDocument26 pagesGenbio 2 Module 1 Genetic Engineering Processeaishlil07No ratings yet

- Rutherford Gate Condominiums BLDG C Feature SheetDocument2 pagesRutherford Gate Condominiums BLDG C Feature SheetCarringtonNo ratings yet

- Nordstrom Physical Security ManualDocument13 pagesNordstrom Physical Security ManualBopanna BolliandaNo ratings yet

- Ashrae Ashraejournal 2020.12Document135 pagesAshrae Ashraejournal 2020.12Joao MoreiraNo ratings yet

- W3 Deep FoundationDocument42 pagesW3 Deep FoundationTeoh Zhi TongNo ratings yet

- Creep Behavior of GPDocument310 pagesCreep Behavior of GPYoukhanna ZayiaNo ratings yet

- Calculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEDocument4 pagesCalculating Ampacity in Small-Gauge, Electrical Cables: Greig S. Latham, Member, IEEEAlaa RamadanNo ratings yet

- Analisis Penggunaan Strategi Generik Terhadap Kinerja Pada Lembaga Pendidikan Luar Sekolah Di Kota MalangDocument24 pagesAnalisis Penggunaan Strategi Generik Terhadap Kinerja Pada Lembaga Pendidikan Luar Sekolah Di Kota MalangLeon SumargoNo ratings yet

- Sustainable Urban Transport Index for Bhopal, IndiaDocument43 pagesSustainable Urban Transport Index for Bhopal, IndiaSayani MandalNo ratings yet

- List of Intel MicroprocessorsDocument46 pagesList of Intel MicroprocessorsnirajbluelotusNo ratings yet

- Last Service ReportDocument4 pagesLast Service ReportSandeep NikhilNo ratings yet

- MGEC61 - LEC 01 & LEC 02 International Economics: Finance Summer 2021Document8 pagesMGEC61 - LEC 01 & LEC 02 International Economics: Finance Summer 2021Yutong WangNo ratings yet

- TLEN 5830-AWL Lecture-05Document31 pagesTLEN 5830-AWL Lecture-05Prasanna KoratlaNo ratings yet

- Positronic Industries Inc. FC4012D: SK2415 ECO B 23033 TK Yk Cole ECO C 52574 Cole CM ColeDocument1 pagePositronic Industries Inc. FC4012D: SK2415 ECO B 23033 TK Yk Cole ECO C 52574 Cole CM ColekamaveriyanNo ratings yet

- Leadership Styles - Types of Leadership Styles - BBA - MantraDocument5 pagesLeadership Styles - Types of Leadership Styles - BBA - Mantrakarthik sarangNo ratings yet

- SH BSC Hons Pre Registration Nursing PDFDocument104 pagesSH BSC Hons Pre Registration Nursing PDFJogendra Singh PatelNo ratings yet

- CMS 332D Digital Ethics Syllabus UndergrDocument7 pagesCMS 332D Digital Ethics Syllabus UndergrRaúl VillarroelNo ratings yet

- Design of Hydroelectric Power PlantsDocument6 pagesDesign of Hydroelectric Power PlantsPDN PRGNo ratings yet

- Sine and Cosine Functions WorksheetDocument6 pagesSine and Cosine Functions WorksheetManya MNo ratings yet

- Chapter 1 PPT (Compressibility and Consolidation)Document65 pagesChapter 1 PPT (Compressibility and Consolidation)Eba GetachewNo ratings yet

- Egerton Genetics eLearning MaterialsDocument213 pagesEgerton Genetics eLearning MaterialsAringo ArumNo ratings yet

- Shs Environmental AttitudeDocument19 pagesShs Environmental AttitudeProfTeng DePano RecenteNo ratings yet