Professional Documents

Culture Documents

Determination of Fuel Filter Blocking Potential of Biodiesel (B100) Blend Stock by Cold Soak Filtration Test (CSFT)

Uploaded by

Leny Porto0 ratings0% found this document useful (0 votes)

194 views6 pagesThis standard covers the determination by filtration time after cold soak of the suitability for a biodiesel (B100) Blend Stock. The formal precision of this test method is included in 13. On precision. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Original Description:

Original Title

D7501.1207483-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis standard covers the determination by filtration time after cold soak of the suitability for a biodiesel (B100) Blend Stock. The formal precision of this test method is included in 13. On precision. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

194 views6 pagesDetermination of Fuel Filter Blocking Potential of Biodiesel (B100) Blend Stock by Cold Soak Filtration Test (CSFT)

Uploaded by

Leny PortoThis standard covers the determination by filtration time after cold soak of the suitability for a biodiesel (B100) Blend Stock. The formal precision of this test method is included in 13. On precision. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Designation: D7501 09b

Standard Test Method for

Determination of Fuel Filter Blocking Potential of Biodiesel

(B100) Blend Stock by Cold Soak Filtration Test (CSFT)

1

This standard is issued under the xed designation D7501; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon () indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination by ltration

time after cold soak of the suitability for a biodiesel (B100)

blend stock that meets all other requirements of Specication

D6751 and has a cloud point below 68F (20C) to provide

adequate low temperature operability performance to at least

the cloud point of the nished blend.

1.2 The formal precision of this test method is included in

13.1 on Precision.

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

and are not considered standard.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

2

D4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

D5452 Test Method for Particulate Contamination in Avia-

tion Fuels by Laboratory Filtration

D6300 Practice for Determination of Precision and Bias

Data for Use in Test Methods for Petroleum Products and

Lubricants

D6751 Specication for Biodiesel Fuel Blend Stock (B100)

for Middle Distillate Fuels

3. Terminology

3.1 Denitions:

3.1.1 biodiesel, nfuel comprised of mono-alkyl esters of

long chain fatty acids derived from vegetable oils or animal

fats, designated as B100.

3.1.2 bond, vto connect two parts of a system electrically

by means of a conductive wire to eliminate voltage differences.

3.1.3 BXX blend, nfuel blend consisting of up to 20

volume percent biodiesel designated as up to B20 conforming

to the requirements of Specication D6751 with the remainder

being a light middle or middle distillate grade diesel fuel and

meeting the requirements of this test method.

3.1.3.1 DiscussionThe abbreviation BXX represents a

specic blend concentration in the range B2 to B20, where XX

is the percent volume of biodiesel in the fuel blend.

3.1.4 ground, vto connect electrically with earth.

3.2 Denitions of Terms Specic to This Standard:

3.2.1 air chamber, nunit to control temperature of sample

for cooling with maximum 0.5C variation from set point. The

unit shall use a microprocessor temperature controller with

digital set point and readout. Afood-grade refrigerator does not

provide adequate temperature stability for this test method.

3.2.2 minor component, nmaterial present in B100, typi-

cally at concentrations well below 1% by mass.

3.2.3 thermal history, nrange of temperatures that a batch

or sample of B100 has experienced which can result in

separation or precipitation of minor components.

3.2.3.1 DiscussionCooling some biodiesel fuels can result

in precipitation or separation of minor components that have

limited solubility in B100. Heating these biodiesel fuels above

40C is believed to redissolve most of these minor components

and thus erase the thermal history of the sample.

3.3 Abbreviations:

3.3.1 CSFTCold Soak Filtration Test

4. Summary of Test Method

4.1 In this test method, 300 mL of biodiesel (B100) is stored

at 40 6 1F (4.5 6 0.5C) for 16 h, allowed to warm to 77 6

2F (25 6 1C), and vacuum ltered through a single 0.7 m

glass ber lter at controlled vacuum levels of 2125 in. of Hg.

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved Oct. 1, 2009. Published November 2009. Originally

approved in 2009. Last previous edition approved in 2009 as D750109a. DOI:

10.1520/D7501-09B.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

the ASTM website.

1

Copyright. ASTM International. 100 Barr Harbour Dr. PO Box C700 West Conshohocken, Pennsylvania 19428-2959, United States

Copyright by ASTM Int'l (all rights reserved); Thu Jul 26 14:51:27 EDT 2012

Downloaded/printed by

Universidade Federal do Rio de Janeiro pursuant to License Agreement. No further reproductions authorized.

4.2 The ltration time is reported in seconds.

5. Signicance and Use

5.1 Some substances that are soluble or appear to be soluble

in biodiesel (B100) at room temperature will, upon cooling to

temperatures above the cloud point or standing at room

temperature for extended periods, come out of solution. This

phenomenon has been observed in both B100 and BXX blends.

These substances can cause lter plugging. This method

provides an accelerated means of assessing the presence of

these substances in B100 and their propensity to plug lters.

5.1.1 B100 biodiesel fuels that give short ltration times are

expected to give satisfactory operation of BXX blends at least

down to the cloud point of the biodiesel blends.

5.2 The test method can be used in specications as a means

of controlling levels of minor lter plugging components in

biodiesel and biodiesel blends.

6. Apparatus

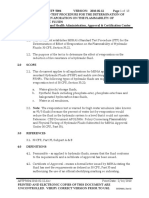

6.1 Filtration SystemArrange the following components

as shown in Fig. 1.

6.1.1 Funnel and Funnel Base, with a stainless steel lter

support for a 47-mm diameter glass ber lter, and locking ring

or spring action clip, capable of receiving 300 mL.

NOTE 1Sintered glass supports were found to give much higher

ltration times during initial studies and are not recommended to be used.

6.1.2 Ground/Bond Wire, 0.912-2.59-mm (No. 10 through

No. 19) bare stranded exible, stainless steel or copper

installed in the asks and grounded as shown in Fig. 1.

6.1.3 Electrical Bonding Apparatus, as described in Test

Method D5452 or by using other suitable means of electrical

grounding that ensure safe operation of the ltration apparatus

and ask.

6.1.4 Receiving Flask, 1-L borosilicate glass vacuum lter

ask, into which the ltration apparatus ts, and equipped with

a sidearm to connect to the safety ask.

6.1.5 Safety Flask, 1-L borosilicate glass vacuum lter ask

equipped with a sidearm to connect the vacuum system. A fuel

and solvent resistant rubber hose, through which the grounding

wire is connected to the sidearm of the receiving ask to the

tube, passes through the rubber stopper in the top of the safety

ask.

6.1.6 Vacuum System, capable of producing a vacuum of 70

to 100 kPa below atmospheric pressure when measured at the

safety ask. A mechanical vacuum pump may be used if it has

this capability.

NOTE 2Water aspirated vacuum will not provide relative vacuum

within the prescribed range.

6.1.7 Chilling Apparatus, either 6.1.7.1 or 6.1.7.2 may be

used.

6.1.7.1 Circulating Water Bath, capable of sustaining a

temperature of 40 6 1F (4.5 6 0.5C).

6.1.7.2 Air Chamber, capable of sustaining a temperature of

40 6 1F (4.5 6 0.5C). The unit shall use microprocessor

temperature control and have a digital temperature control/

display.

6.1.8 Circulating Water Bath, capable of sustaining a tem-

perature of 77 6 1F (25 6 0.5C).

FIG. 1 Schematic of Filtration System

D7501 09b

2

Copyright by ASTM Int'l (all rights reserved); Thu Jul 26 14:51:27 EDT 2012

Downloaded/printed by

Universidade Federal do Rio de Janeiro pursuant to License Agreement. No further reproductions authorized.

6.1.9 Whatman Glass Fiber Filters (GF/F),

3

plain, 47-mm

diameter, nominal pore size 0.7-m. Acid treated low metal

TCLP lters are not suitable for this purpose.

6.2 Other Apparatus:

6.2.1 Forceps, approximately 12-cm long, at-bladed, with

non-serrated, non-pointed tips.

6.2.2 Graduated Cylinders, to contain at least 0.5 L of uid

and marked at 10-mL intervals. Samples that lter slowly may

require 100-mL graduated cylinders.

6.2.3 Petri Dishes, approximately 12.5 cm in diameter, with

removable glass supports for glass ber lters.

6.2.3.1 Small Watch Glasses, approximately 5 to 7 cm in

diameter, have been found suitable to support the glass ber

lters.

NOTE 3B100 will dissolve some plastics. This can cause the lters to

adhere to the plastic.

6.2.4 Protective Cover, polyethylene lm or clean alumi-

num foil.

6.2.5 Timer, capable of displaying elapsed times of at least

900 s to the nearest 0.1 s.

6.2.6 Thermometer or RTD Sensor, for measuring sample

temperature, should be capable of measurement 61F

(60.5C).

7. Reagents and Materials

7.1 Purity of ReagentsReagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specications of the Commit-

tee on Analytical Reagents of the American Chemical Society,

where such specications are available. Other grades may be

used, provided it is rst ascertained that the reagent is of

sufficient purity to permit its use without lessening the accu-

racy of the determination.

7.2 Flushing FluidsFlushing uids are not required for

the test as the lter is not weighed. However, heptane or

isooctane may be used to wash the apparatus after ltration to

remove any residue.

7.2.1 Heptane, (WarningFlammable.)

7.2.2 2,2,4-trimethylpentane (isooctane), (Warning

Flammable.)

7.3 Liquid or Powder Detergent, water-soluble, for cleaning

glassware.

8. Sampling

8.1 A separate representative sample shall be collected for

this test method. Samples may preferentially be obtained

dynamically from a sampling loop in a distribution line or from

the ushing line of a eld sampling kit. Ensure that the line to

be sampled is ushed with fuel before collecting the sample.

Alternatively, circulate or agitate the contents of the tank in

order to collect a representative sample that includes any

precipitates that might have settled in the tank. One option is to

sample the tank immediately after lling, before the contents

have time to settle.

8.1.1 Where it is necessary to obtain samples from static

storage using a sampling container or intermediate containers,

follow the procedures given in Practice D4057 or equivalent,

taking precautions for cleanliness of all equipment used. This

is interpreted to mean a representative sample in accordance

with Practice D4057, and refers to an all-levels sample.

(WarningSamples obtained from static storage can give

results which are not representative of the bulk contents of the

tank because of particulate matter settling.)

8.2 Precautionsto avoid sample contamination include:

8.2.1 Selection of an appropriate sampling point.

8.2.2 Use of clean sample containers. Visually inspect the

sample container before taking the samples to verify that there

are no visible particles present inside the container.

8.2.3 Keeping a clean protective cover over the top of the

sample container until the cap is replaced after lling.

8.2.4 If the primary sample container cannot be selected

such that it is suitable for this test procedure, the sample shall

pass through only a minimum number of intermediate contain-

ers prior to placement in the nal container.

8.2.5 After lling the sample container with 300 mL of

sample, protect the fuel sample from prolonged exposure to

light by wrapping the container in aluminum foil or storing it

in the dark to reduce the possibility of particulate formation by

light-promoted reactions.

8.3 If 300 mL of sample is not received in a 500-mL bottle

or the sample has been received in a container not suitable for

this test, follow the sampling condition procedure in 8.4.

8.4 Sample Conditioningfor samples received that might

have been cooled to temperatures below 68F (20C):

8.4.1 Upon receipt of a biodiesel blend stock (B100)

sample, the entire sample is to be heated to 104F (40C) for

at least 3 h under an inert atmosphere to erase any thermal

history and to dissolve any solids that might have precipitated

during transit. After heating for the required time, allow the

sample to sit for 24 h at a temperature no lower than 68F

(20C).

8.4.2 This sample conditioning step may be omitted if the

sample was collected from a heated tank at a production

facility. In this case, proceed directly to 8.5.

8.4.3 If there is any doubt about the thermal history of the

sample, the sample conditioning step shall be performed.

8.5 Analyze fuel samples as soon as possible after sampling.

8.6 Shake the sample vigorously for 1 min. If the sample is

not already in a 500-mL bottle suitable for this test procedure,

transfer 300 mL to a clean, fresh 500 6 15-mL bottle. If a

300-mL sample was received is already in such a bottle,

proceed with the test procedure in Section 11.

9. Preparation of Apparatus and Sample Containers

9.1 Clean all components of the ltration apparatus using

the reagents described in 7.2 and 7.3.

9.1.1 Filtration apparatus shall be clean and dry prior to use.

9.1.2 Remove any labels, tags, and so forth.

10. Preparation of Glass Fiber Filter

10.1 Each ltration uses one lter as specied in 6.1.9. The

glass ber lter used for each individual test may be identied

by marking the petri dish used to hold and transport the lter.

10.2 Clean all glassware used in preparation of glass ber

lter as described in 9.1.

3

Whatman lters were used in the ILS. See Section 13.

D7501 09b

3

Copyright by ASTM Int'l (all rights reserved); Thu Jul 26 14:51:27 EDT 2012

Downloaded/printed by

Universidade Federal do Rio de Janeiro pursuant to License Agreement. No further reproductions authorized.

10.3 Using forceps, place the lter on clean glass support

rods or watch glasses in petri dish.

10.4 Place the petri dish, with its lid slightly ajar, in a drying

oven at 194F (90 6 2C and leave it for 30 min.

10.5 Remove the petri dish from the drying oven. Keep the

petri dish cover ajar, such that the lter is protected from

contamination from the atmosphere. Allow 30 min for the lter

to come to equilibrium with room air temperature and humid-

ity.

10.6 Using clean forceps, place the lter centrally on the

lter support of the ltration apparatus (see Fig. 1). Install the

funnel and secure with locking ring or spring clip.

10.7 Protect the funnel opening of the assembled ltration

apparatus with a clean protective cover until ready for use.

11. Procedure

11.1 Place 300 mL of sample in a 500 mL glass bottle and

set in a liquid or air chamber at 40 6 1F (4.5 6 0.5C) for 16

6 0.25 h. A refrigerator is not suitable for this procedure.

11.2 After the 16-h cold soak at 40 6 2F (4.5 6 1.1C) is

completed, remove sample from bath and place in a circulating

water bath with the temperature set to 77 6 1F (25 6 0.5C)

according to 11.2.1 or 11.2.2. The sample shall be completely

liquid before ltration.

11.2.1 If the sample is completely liquid after the 16-h cold

soak, heat the sample at 77 6 1F (25 6 0.5C) for 2 6 0.25

h. Otherwise follow 11.2.2.

11.2.2 If the sample is solid or contains any solids or haze

after the 16-h cold soak, heat the sample at 77 6 1F (25 6

0.5C) for 4 6 0.25 h.

11.2.3 Verify that the sample is at 77 6 1F (25 6 0.5C) by

dipping without stirring or agitating the sample with an RTD

sensor or thermometer.

11.3 Filter the samples as quickly as possible upon removal

from the warming bath once the desired warming time has

elapsed according to 11.2.1 or 11.2.2, whichever applies.

11.4 Complete assembly of the receiving ask, 0.7 m glass

ber lter and funnel as a unit (see Fig. 1) before swirling the

sample. To minimize operator exposure to fumes, the ltering

procedure may be performed in a fume hood.

11.5 Start the vacuum system. Record the pressure in the

system after 1 min of ltration. The pressure shall be between

71.1 and 84.7 kPa (21 and 25 in. of Hg) below atmospheric. If

the vacuum is not within the specied range, make adjustments

to the vacuum system.

11.6 Thoroughly clean the outside of the sample container

in the region of the cap by wiping it with a damp, lint-free

cloth. Swirl the container for about 2-3 s to dislodge any

particles that might have adhered to the walls of the container.

11.6.1 Take care not to shake the sample vigorously after

the cold soak as this could cause some of the solids to go back

into solution.

11.7 Immediately after swirling, remove cap and pour the

entire contents of the sample container into the ltration funnel

and simultaneously start the timer. The entire contents of the

sample container shall be ltered through the glass ber lter

to ensure a correct measure of the contamination in the sample.

11.7.1 The entire contents of the sample container is dened

as everything that will ow out of the sample container when

it is poured into the ltration funnel and held for 10 s after the

bulk of the sample has been poured out.

11.8 When ltration is complete, as evidenced by no sample

remaining on the lter, immediately turn off the vacuum

system and record the duration of the ltration, rounding to the

nearest second.

11.9 If the ltration is not complete when 720 s (12 min) has

elapsed, turn off the vacuum system and record the duration of

the ltration to the nearest second. Record the pressure in the

system and the volume ltered just before the termination of

the ltration.

12. Report

12.1 Report the time for the 300 mL B100 to be completely

ltered as B100 CSFT time by ASTM D7501 in seconds to the

nearest second.

12.2 If the ltration of the 300 mL failed to be completed

after 720 s, report the result as B100 CSFT time greater than

720 s by ASTM D7501, and report the volume which was

ltered in 720 s in mL to the nearest mL.

13. Precision and Bias

4

13.1 PrecisionThe formal precision of this test method

for B100 ltration is given below. The 2009 ILS on which this

precision is based included samples with mean CSFT results

from 77.5 to 188.6.

13.1.1 RepeatabilityThe difference between successive

test results, obtained by the same operator using the same

apparatus under constant operating conditions on identical test

material, would in the long run, in the normal and correct

operation of this test method, exceed 0.2959(X - 4.5000E+01)

time(s) only in one case in twenty. The degrees of freedom for

this estimate are 55. Repeatability for samples falling outside

the range of the ILS samples may be estimated with the above

equation, but will represent an extrapolation of the repeatabil-

ity relationship. The actual repeatability may deviate from

these estimates.

13.1.2 ReproducibilityThe difference between the two

single and independent results obtained by different operators

working in different laboratories on identical test material for

B100 ltration would, in the long run, in normal and correct

operation of this test method, exceed 0.5387(X - 4.5000E+01)

time(s) only in one case in twenty. Reproducibility for samples

falling outside the range of the ILS samples may be estimated

with the above equation, but will represent an extrapolation of

the reproducibility relationship. The actual reproducibility may

deviate from these estimates. The degrees of freedom for this

estimate are 28.

13.1.2.1 The degrees of freedom associated with the repro-

ducibility estimate from this round robin study are 28. Since

the minimum requirement of 30 (in accordance with Practice

D6300) is not met, users are cautioned that the actual repro-

ducibility may be signicantly different than this estimate.

13.1.2.2 Based on the above, the precision estimates from

the 2009 CSFT ILS for the specication limits from the ranges

4

Supporting data have been led at ASTM International Headquarters and may

be obtained by requesting Research Report RR:D02-1672.

D7501 09b

4

Copyright by ASTM Int'l (all rights reserved); Thu Jul 26 14:51:27 EDT 2012

Downloaded/printed by

Universidade Federal do Rio de Janeiro pursuant to License Agreement. No further reproductions authorized.

of 120 to 400 s would be as shown in Table 1. This Table is

provided as a convenience for the user of the test method. Both

r and R above 200 seconds are estimates that do not conform

to the requirements of Practice D6300.

13.2 BiasThe procedure given for the determination of

B100 ltration time has no bias because the value of the

ltration time is dened in terms of this test method.

14. Keywords

14.1 biodiesel; biodiesel blend; diesel fuel; lter blocking

potential; glass ber lter; laboratory ltration; low tempera-

ture operability; middle distillate fuel

APPENDIX

(Nonmandatory Information)

X1. PRECISION AND BIAS FROM THE 2007 COLD SOAK FILTRATION TEST (CSFT) RESEARCH REPORT (ILS0328)

X1.1 Precision

5

X1.1.1 The reproducibility for this test method for B100

ltration has not yet been determined.

X1.1.2 RepeatabilityThe difference between successive

test results, obtained by the same operator using the same

apparatus under constant operating conditions on identical test

material, would in the long run, in the normal and correct

operation of this test method, exceed 0.1689(X + 1.2018)

time(s) only in one case in twenty.

X1.1.3 ReproducibilityThe difference between the two

single and independent results obtained by different operators

working in different laboratories on identical test material for

B100 ltration has not yet been determined.

X1.1.4 Interim PrecisionRepeatability and reproducibil-

ity determinations were made using data from the ASTM

Biodiesel Low Temperature Operability Task Force (see Table

X1.1.) The analysis of this data from ILS0328 is the subject of

Research Report RR:D02-1649.

5

The report is an attempt to

supply such an analysis based on well-established methodolo-

gies. Subsequent to test method publication a more thorough

round robin is planned.

NOTE X1.1Interim precision repeatability and reproducibility deter-

minations were made using data from the ASTM Operability Task Force.

The degree of freedom associated with the repeatability/reproducibility

estimate from this round robin study is 25 for repeatability and 10 for

reproducibility. Since the minimum requirement of 30 (in accordance with

Practice D6300) is not met, users are cautioned that the actual

repeatability/reproducibility may be signicantly different than these

estimates.

5

Supporting data have been led at ASTM International Headquarters and may

be obtained by requesting Research Report RR:D02-1649.

TABLE 1 Precision Range from 2009 CSFT ILS

TABLE 1A

from ILS data in accordance with Practice D6300

Time, s 80 120 160 200

Repeatability, r 10 22 34 46

Reproducibility, R 19 40 62 83

TABLE 1B

extrapolated, not compliant with Practice D6300

Time, s 240 280 320 360 400

Repeatability, r 58 70 81 93 105

Reproducibility, R 105 127 148 170 191

D7501 09b

5

Copyright by ASTM Int'l (all rights reserved); Thu Jul 26 14:51:27 EDT 2012

Downloaded/printed by

Universidade Federal do Rio de Janeiro pursuant to License Agreement. No further reproductions authorized.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

TABLE X1.1 Precision Range from 2007 Operability TF Data

160 s 200 s 240 s 280 s 320 s 360 s

Repeatability 27 34 41 47 54 61

Reproducibility 93 116 139 162 185 208

D7501 09b

6

Copyright by ASTM Int'l (all rights reserved); Thu Jul 26 14:51:27 EDT 2012

Downloaded/printed by

Universidade Federal do Rio de Janeiro pursuant to License Agreement. No further reproductions authorized.

You might also like

- Biobor JF PdsDocument19 pagesBiobor JF PdsHozifa Krar100% (1)

- Astm D-664-09Document3 pagesAstm D-664-09kaminaljuyuNo ratings yet

- Chrome-Extension Mhjfbmdgcfjbbpaeojofohoefgiehjai IndexDocument7 pagesChrome-Extension Mhjfbmdgcfjbbpaeojofohoefgiehjai Indexjangri10980% (1)

- E2193 02Document3 pagesE2193 02Luz Ma R CNo ratings yet

- Operating Manual: Ac Oxytracer Analyzer On 7890 GCDocument49 pagesOperating Manual: Ac Oxytracer Analyzer On 7890 GCstemman95No ratings yet

- D2784Document7 pagesD2784rimi7alNo ratings yet

- Iso 3425 1975Document4 pagesIso 3425 1975sarahNo ratings yet

- Apha 9050 Media B.inggrisDocument2 pagesApha 9050 Media B.inggrisItaNo ratings yet

- Astm d1319 2003 PDFDocument10 pagesAstm d1319 2003 PDFJeffreyCheleNo ratings yet

- Astm D5600Document4 pagesAstm D5600Abu WildanNo ratings yet

- PDFDocument502 pagesPDFRiandi SaputraNo ratings yet

- Trace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyDocument12 pagesTrace Hydrocarbons in Hydrogen or LPG by Gas ChromatographyDavinNo ratings yet

- 585M Parr 6200 Calorimeter Operating Instructions Post Oct 2010Document89 pages585M Parr 6200 Calorimeter Operating Instructions Post Oct 2010Eleni AsimakopoulouNo ratings yet

- D3427Document5 pagesD3427Fabian Antonio RoldanNo ratings yet

- ASTM D7321 Standard Test Method For Particulate Contamination of Biodiesel by Laboratory Filtration PDFDocument6 pagesASTM D7321 Standard Test Method For Particulate Contamination of Biodiesel by Laboratory Filtration PDFEdgar Fabian Diaz ArceNo ratings yet

- Astm D1160.2012Document19 pagesAstm D1160.2012Leny PortoNo ratings yet

- Astm D721Document7 pagesAstm D721ebalideNo ratings yet

- Low-Temperature Viscosity of Automotive Fluid Lubricants Measured by Brookfield ViscometerDocument9 pagesLow-Temperature Viscosity of Automotive Fluid Lubricants Measured by Brookfield ViscometerPhạm Hoàng Ái LệNo ratings yet

- D1160Document18 pagesD1160guadalupegomezperezNo ratings yet

- D 2983 - 04 Low ViscozityDocument13 pagesD 2983 - 04 Low ViscozityCorina StanculescuNo ratings yet

- Punto de Fluidez - ASTM D5853-11 PDFDocument8 pagesPunto de Fluidez - ASTM D5853-11 PDFgregorio2407No ratings yet

- Pour Point of Crude Oils: Standard Test Method ForDocument7 pagesPour Point of Crude Oils: Standard Test Method ForSteven ErzhanNo ratings yet

- Method 25E - Determination of Vapor Phase Organic Concentration in Waste SamplesDocument14 pagesMethod 25E - Determination of Vapor Phase Organic Concentration in Waste SamplesĐàm QuânNo ratings yet

- Residuo de Evaporacion GLP Astm D 2158-05Document5 pagesResiduo de Evaporacion GLP Astm D 2158-05Cecilia Cruz ToribioNo ratings yet

- Punto de Fluidez - ASTM D97-11Document5 pagesPunto de Fluidez - ASTM D97-11Chäz XdNo ratings yet

- D 2983 - 87 R93Document9 pagesD 2983 - 87 R93David CazorlaNo ratings yet

- Metodo ASTM D402Document5 pagesMetodo ASTM D402Roberto ChamorroNo ratings yet

- Measurement of Hexane Extractable Content of Polyolefins: Standard Test Method ForDocument6 pagesMeasurement of Hexane Extractable Content of Polyolefins: Standard Test Method ForManuel IbarraNo ratings yet

- Astm 2196Document5 pagesAstm 2196Alexandre LiraNo ratings yet

- D 2235 - 96 RdiymzutukveDocument7 pagesD 2235 - 96 RdiymzutukveHumberto GutierrezNo ratings yet

- Atm D5773Document7 pagesAtm D5773Ennio PalumboNo ratings yet

- Iso 3675 1998Document9 pagesIso 3675 1998hossam alebrahimNo ratings yet

- Wax Appearance Point of Distillate Fuels: Standard Test Method ForDocument4 pagesWax Appearance Point of Distillate Fuels: Standard Test Method ForCristian Alberto CidNo ratings yet

- ASTM D 2741 - 95 (Reapproved 2001) Susceptibility of Polyethylene Bottles To Soot AccumulationDocument5 pagesASTM D 2741 - 95 (Reapproved 2001) Susceptibility of Polyethylene Bottles To Soot Accumulationalin2005No ratings yet

- BS 812-117-1988 PDFDocument14 pagesBS 812-117-1988 PDFMohammad Twaha Jaumbocus0% (1)

- Astm D2041M-11Document4 pagesAstm D2041M-11kinlaychengNo ratings yet

- D130-12 Corrosiveness To Copper From Petroleum Products PDFDocument10 pagesD130-12 Corrosiveness To Copper From Petroleum Products PDFL Ayquipa MerinoNo ratings yet

- D1795Document6 pagesD1795Ненад Кнежевић100% (2)

- Flash Point and Fire Point of Liquids by Tag Open-Cup ApparatusDocument8 pagesFlash Point and Fire Point of Liquids by Tag Open-Cup Apparatusmanox007No ratings yet

- Astm D1092-20Document9 pagesAstm D1092-20imad qaissouniNo ratings yet

- CCS D5293Document9 pagesCCS D5293Sofia Fasolo CunhaNo ratings yet

- D4629Document5 pagesD4629Aditya Kafi Berkahsmgshop100% (1)

- M 24-D V M C, W C, D, V S, W S S C: 1.0 Scope and ApplicationDocument8 pagesM 24-D V M C, W C, D, V S, W S S C: 1.0 Scope and ApplicationSameehu TVNo ratings yet

- D402 PDFDocument5 pagesD402 PDFArnold RojasNo ratings yet

- ISO3675Document14 pagesISO3675thanhhuyen100% (1)

- Astmd4530 2003Document7 pagesAstmd4530 2003सचिन उरुणकर100% (1)

- Standard Test Method For Oxidation Stability of GasolineDocument7 pagesStandard Test Method For Oxidation Stability of Gasolinejohn tanNo ratings yet

- D 1078 - 01 Rdewnzgtukve PDFDocument10 pagesD 1078 - 01 Rdewnzgtukve PDFmiguel perezNo ratings yet

- ASTM D 2041 - 03 - RdiwndetukveDocument5 pagesASTM D 2041 - 03 - RdiwndetukveharisahamedNo ratings yet

- D2603Document3 pagesD2603rimi7alNo ratings yet

- Mechanically Tapped Density of Activated Carbon (Powdered and Fine Mesh)Document3 pagesMechanically Tapped Density of Activated Carbon (Powdered and Fine Mesh)omar TahaNo ratings yet

- Joint Treatment Materials For Gypsum Board Construction: Standard Test Methods ForDocument14 pagesJoint Treatment Materials For Gypsum Board Construction: Standard Test Methods ForJoseph Marriott AndersonNo ratings yet

- D1480Document6 pagesD1480rpajaro75No ratings yet

- ASTP5004Document13 pagesASTP5004Hang NguyenNo ratings yet

- Determining Silicone Volatiles in Silicone Rubber For Transportation ApplicationsDocument3 pagesDetermining Silicone Volatiles in Silicone Rubber For Transportation ApplicationsAMUL VEKARIANo ratings yet

- Astm D4052-11Document8 pagesAstm D4052-11Jose Miguel Bautista Figueroa100% (1)

- D4870 22-5-02 Standard Test Method For Determination of Total SedimentDocument8 pagesD4870 22-5-02 Standard Test Method For Determination of Total SedimentHamidreza AraghianNo ratings yet

- Freezing Point of Aviation Fuels: Standard Test Method ForDocument4 pagesFreezing Point of Aviation Fuels: Standard Test Method ForJorgeTunNo ratings yet

- ASTM D 7172-06 Standard Test Method For Determining The Relative Density (Specific Gravity) and Absoption of Fine Aggregates Using InfraredDocument4 pagesASTM D 7172-06 Standard Test Method For Determining The Relative Density (Specific Gravity) and Absoption of Fine Aggregates Using InfraredPablo Antonio Valcárcel VargasNo ratings yet

- Catalog 2010 RetailDocument13 pagesCatalog 2010 RetailmonibroNo ratings yet

- 03 Jaer V2N2 PDFDocument6 pages03 Jaer V2N2 PDFAnonymous KzJcjGCJbNo ratings yet

- GE Frame 5002 Power Crystal PDFDocument4 pagesGE Frame 5002 Power Crystal PDFatfrost4638100% (2)

- FoamDocument23 pagesFoamSam JoseNo ratings yet

- Fire ExtinguisherDocument22 pagesFire ExtinguisherKamal Mirza100% (3)

- ASTM D6751 - Specification For Biodiesel PDFDocument8 pagesASTM D6751 - Specification For Biodiesel PDFDwi Wahyu Ramadhan100% (1)

- CHERY QQ 465 Mechanical System PDFDocument55 pagesCHERY QQ 465 Mechanical System PDFAnonymous OArHcompmc100% (1)

- Hinomoto OEM 2020Document68 pagesHinomoto OEM 2020Piesemasini MasinieuNo ratings yet

- MHEV Architectures Guide - P0 Belt Starter Generator ConfigurationDocument9 pagesMHEV Architectures Guide - P0 Belt Starter Generator ConfigurationRui MendesNo ratings yet

- Engine Mechanical (D6A, D8A)Document168 pagesEngine Mechanical (D6A, D8A)Manuales De Maquinaria JersoncatNo ratings yet

- Vegetable Oil StandardDocument4 pagesVegetable Oil StandardIbrahim SyaharuddinNo ratings yet

- Windstar 2000-2001 3.8 v6Document77 pagesWindstar 2000-2001 3.8 v6Juan RiveraNo ratings yet

- Powertech: 6068Tf220 - 120 KW at 1500 RPM 6068Tf250 - 142 KW at 1800 RPM Specifications For Gen Set ApplicationsDocument2 pagesPowertech: 6068Tf220 - 120 KW at 1500 RPM 6068Tf250 - 142 KW at 1800 RPM Specifications For Gen Set ApplicationsJulio0% (1)

- Trooper ManualDocument3,573 pagesTrooper ManualRick Malik100% (13)

- Corvette C4 Conversions - Intake To Carb 1984-1991Document5 pagesCorvette C4 Conversions - Intake To Carb 1984-1991Corvettecraft100% (1)

- L23 30HDocument814 pagesL23 30HBăng Phong100% (1)

- ER BST PL VentRequirementsDocument3 pagesER BST PL VentRequirementsMichael WagnerNo ratings yet

- Octane Rating Systems: Electronic Systems Design, Inc Palatine, Illinois Usa N, NosusDocument56 pagesOctane Rating Systems: Electronic Systems Design, Inc Palatine, Illinois Usa N, NosusjhossielmartineauNo ratings yet

- PpeDocument7 pagesPpeChristopher YsitNo ratings yet

- Bendix D-2 GovernorDocument4 pagesBendix D-2 GovernormarcrunnerNo ratings yet

- 1 - Catalog 2019 PDFDocument33 pages1 - Catalog 2019 PDFAndres VargasNo ratings yet

- Fuel Metering For Diesel Engines: Mixture RequirementsDocument6 pagesFuel Metering For Diesel Engines: Mixture Requirementsallan lariosaNo ratings yet

- Service Manual Trucks: Electrical Schematic Illustration Index VN, VHD Version2, VTDocument84 pagesService Manual Trucks: Electrical Schematic Illustration Index VN, VHD Version2, VTRegistr RegistrNo ratings yet

- HMDocument2 pagesHMapi-279049687No ratings yet

- Every Load.: Cummins Euro 4 Engines 280-400PsDocument6 pagesEvery Load.: Cummins Euro 4 Engines 280-400PsFernando BatistaNo ratings yet

- Diesel Locomotive RosterDocument11 pagesDiesel Locomotive RosterAgnivesh SharmaNo ratings yet

- Heavy Equipment - Spek PC5500Document8 pagesHeavy Equipment - Spek PC5500David HalomoanNo ratings yet

- 09-014 Oil in Turbocharger and Air PipingDocument6 pages09-014 Oil in Turbocharger and Air PipingVictor MontesdeocaNo ratings yet

- Sanden Compressor ListDocument28 pagesSanden Compressor ListSIVARAMANJAGANATHANNo ratings yet

- Chevron Taro XL SeriesDocument1 pageChevron Taro XL SerieswfjerrNo ratings yet