Professional Documents

Culture Documents

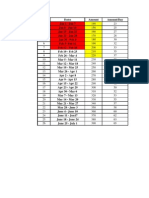

Equipment Used in Crystallization Group 2

Uploaded by

eliyaht05Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment Used in Crystallization Group 2

Uploaded by

eliyaht05Copyright:

Available Formats

Equipment Used in Crystallization

1. Tank Crystallizers

This is probably the oldest and most basic method of crystallization. In fact, the "pot

of salt water" is a good example of tank crystallization. Hot, saturated solutions are

allowed to cool in open tanks. fter crystallization, the mother li!uor is drained and the

crystals are collected. "ontrolling nucleation and the size of the crystals is difficult. The

crystallization is essentially #ust "allowed to happen". Heat transfer coils and agitation

can be used. $abor costs are high, thus this type of crystallization is typically used only

in the fine chemical or pharmaceutical industries where the product %alue and

preser%ation can #ustify the high operating costs.

&. Scraped Surface Crystallizers

n example may be the 'wenson()alker crystallizer consisting of a trough about &

feet wide with a semi(circular bottom. The outside is #acketed with cooling coils and an

agitator blade gently passes close to the trough wall remo%ing crystals that grow on the

%essel wall.

*. Forced Circulating Liquid Evaporator-Crystallizer

+ust as the name implies, these crystallizers combine crystallization and e%aporation,

thus the dri%ing forces toward supersaturation. The circulating li!uid is forced through

the tubeside of a steam heater. The heated li!uid flows into the %apor space of the

crystallization %essel. Here, flash e%aporation occurs, reducing the amount of sol%ent in

the solution ,increasing solute concentration-, thus dri%ing the mother li!uor towards

supersaturation. The supersaturated li!uor flows down through a tube, then up through a

fluidized area of crystals and li!uor where crystallization takes place %ia secondary

nucleation. $arger product crystals are withdrawn while the li!uor is recycled, mixed

with the feed, and reheated.

.. Circulating agma !acuum Crystallizer

In this type of crystallizer, the crystal/solution mixture ,magma- is circulated out of

the %essel body. The magma is heated gently and mixed back into the %essel. %acuum

in the %apor space causes boiling at the surface of the li!uid. The e%aporation causes

crystallization and the crystals are drawn off near the bottom of the %essel body.

"eferences:

0rice, "hris +., "Take 'ome 'olid 'teps to Impro%e "rystallization", Chemical

Engineering Progress, 'eptember 1112, p. *..

3eankoplis, "hristie +., Transport 0rocesses and 4nit 5perations, *rd 6d., 0rentice Hall,

7ew +ersey, 111*, I'879 :(1*(1*:.*1(;

8rown, Theodore $., "hemistry9 The "entral 'cience, <th 6d., 0rentice Hall, 7ew +ersey,

1111,

I'879 :(1*(1&=&:&(<

You might also like

- Continuous CrystallizersDocument22 pagesContinuous CrystallizersAravind Vicky0% (1)

- Project ReportDocument3 pagesProject ReportNaveen Singh50% (2)

- Crystallization (Latest)Document31 pagesCrystallization (Latest)Lin Xian XingNo ratings yet

- CRYSTALLIZATION YIELD AND HEAT REMOVALDocument29 pagesCRYSTALLIZATION YIELD AND HEAT REMOVALRA Memije33% (3)

- Crystallization ReactorsDocument20 pagesCrystallization ReactorsMelisa JuradoNo ratings yet

- CrystallizationDocument13 pagesCrystallizationnilay100% (1)

- Description of Process - Nbsm-1Document10 pagesDescription of Process - Nbsm-1avisheklochunNo ratings yet

- CrystallizationDocument6 pagesCrystallizationJemar Lim100% (1)

- CrystallizerDocument31 pagesCrystallizersivsyadavNo ratings yet

- Scraped Surface Crystallizer Process and DesignDocument2 pagesScraped Surface Crystallizer Process and Designnas_101303No ratings yet

- CrystallizationDocument11 pagesCrystallizationjinNo ratings yet

- MSG CrystallizerDocument22 pagesMSG CrystallizerRonel MendozaNo ratings yet

- Engineering College Sugar Industry Waste Water ReportDocument20 pagesEngineering College Sugar Industry Waste Water ReportAditi SharmaNo ratings yet

- The Production of Acetylsalicylic Acid Project - Barbra Dozier's BlogDocument43 pagesThe Production of Acetylsalicylic Acid Project - Barbra Dozier's BlogAnonymous 4EWKYOzJeNo ratings yet

- The Production of Sugar From Sugar CaneDocument9 pagesThe Production of Sugar From Sugar CaneNeiliah Jackson50% (2)

- Chapter#8 CrystallizationDocument49 pagesChapter#8 Crystallization07216738950% (1)

- Crystallizers and Their ControlDocument34 pagesCrystallizers and Their ControlVinitaVartakNo ratings yet

- Crystallization in FoodsDocument63 pagesCrystallization in Foodsprofkarim100% (1)

- CIRCULAR CLARIFIERDocument3 pagesCIRCULAR CLARIFIERChristine FernandezNo ratings yet

- Caustic EvaporationDocument2 pagesCaustic EvaporationSihanu Subasingha100% (1)

- AELCS Lab Manual JntuhDocument50 pagesAELCS Lab Manual JntuhKomal Joshi100% (1)

- CRYSTALLIZATIONDocument53 pagesCRYSTALLIZATIONKshitiz KumarNo ratings yet

- Sugar ReportDocument7 pagesSugar ReportJustineMarieSegoviaBuenaflorNo ratings yet

- Filtration FinalDocument42 pagesFiltration FinalUsha gowdaNo ratings yet

- The People: Behind SugarDocument58 pagesThe People: Behind SugarGhazouani AymenNo ratings yet

- Centrifuge: (January 2009)Document11 pagesCentrifuge: (January 2009)hamadadodo7No ratings yet

- LeachingDocument10 pagesLeachingnhalieza1067No ratings yet

- Centrifuge: Separate substances by centrifugal forceDocument5 pagesCentrifuge: Separate substances by centrifugal forcesiva1974No ratings yet

- Leaching Equipment - Pharm Eng I - 2nd YrDocument28 pagesLeaching Equipment - Pharm Eng I - 2nd YrRutens NdreaNo ratings yet

- Sedimentation PDFDocument33 pagesSedimentation PDFniezajanepatnaNo ratings yet

- CHE572 Chapter 2 Particle Size Characterization PDFDocument18 pagesCHE572 Chapter 2 Particle Size Characterization PDFMuhd FahmiNo ratings yet

- Mamufacturing of Potassium ChlorideDocument16 pagesMamufacturing of Potassium Chloriderajesh100% (1)

- FILTRATION PROCESS GUIDE: FACTORS, TYPES, MEDIADocument41 pagesFILTRATION PROCESS GUIDE: FACTORS, TYPES, MEDIAKonesi RonaldNo ratings yet

- Crystallization: Mass Transfer 2Document77 pagesCrystallization: Mass Transfer 2rishikeshmandawadNo ratings yet

- Rachel Adams Jana Dengler Megan Macleod Kyla Sask Rachel Adams Jana Dengler Megan Macleod Kyla SaskDocument31 pagesRachel Adams Jana Dengler Megan Macleod Kyla Sask Rachel Adams Jana Dengler Megan Macleod Kyla Saskbetengaan2100% (1)

- Production: Santosh Kr. Paswan Roll No 138510 ME3 YearDocument21 pagesProduction: Santosh Kr. Paswan Roll No 138510 ME3 YearEricMargateNo ratings yet

- DistillationDocument22 pagesDistillationAhmed Omar Amine100% (1)

- Insulin Crystallization Process OptimizationDocument21 pagesInsulin Crystallization Process OptimizationDo Bui100% (1)

- CrystallizationDocument29 pagesCrystallizationYawar QureshiNo ratings yet

- SRS (Sulphate Removal System) - Brine Electrolysis - ThyssenKrupp Uhde Chlorine Engineers (Japan) LTDDocument2 pagesSRS (Sulphate Removal System) - Brine Electrolysis - ThyssenKrupp Uhde Chlorine Engineers (Japan) LTDpetros222No ratings yet

- Diffusion Vs MillingDocument4 pagesDiffusion Vs MillingcbqucbquNo ratings yet

- Sugar Processing StepsDocument17 pagesSugar Processing StepsTehreem_2000No ratings yet

- Mass Transfer Operation 1 (2150501) : Crystallization Concept, Techniques and ProcessesDocument18 pagesMass Transfer Operation 1 (2150501) : Crystallization Concept, Techniques and Processesvashu patelNo ratings yet

- Liquid Liquid ExtractionDocument25 pagesLiquid Liquid ExtractionsyafiqNo ratings yet

- Crystallization Concepts & Manufacturing StrategiesDocument31 pagesCrystallization Concepts & Manufacturing StrategieschaitanyavuraNo ratings yet

- Leaching: Diagram 1: Example of Making Green Tea To Illustrate LeachingDocument4 pagesLeaching: Diagram 1: Example of Making Green Tea To Illustrate LeachingMiracle Chibuike OdiNo ratings yet

- Ep 201 Industrial Chemistry Laboratory ReportDocument9 pagesEp 201 Industrial Chemistry Laboratory ReportThobashinni ManimaranNo ratings yet

- CCB2053 Leaching Part 1Document22 pagesCCB2053 Leaching Part 1yassinroslanNo ratings yet

- Operating ConditionsDocument3 pagesOperating ConditionsMariAntonetteChangNo ratings yet

- Softening FinalDocument23 pagesSoftening FinalSonali Jahagirdar100% (1)

- 02 Affination Mingling Centrifugation MeltingDocument2 pages02 Affination Mingling Centrifugation MeltingjantskieNo ratings yet

- Extraction MethodsDocument3 pagesExtraction MethodsMuhammadRafiqNo ratings yet

- High Pressure Homogenizer ManualDocument5 pagesHigh Pressure Homogenizer ManualAhmed AlakhliNo ratings yet

- KCLDocument3 pagesKCLrahulkotadiya97No ratings yet

- Brine Recovery in Sugar Refinery Using Poresep Membrane SolutionDocument3 pagesBrine Recovery in Sugar Refinery Using Poresep Membrane SolutionLalit VashistaNo ratings yet

- Liquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentFrom EverandLiquid Membranes: Principles and Applications in Chemical Separations and Wastewater TreatmentNo ratings yet

- Crystallization Lecture 15Document25 pagesCrystallization Lecture 15Syed Zawar ShahNo ratings yet

- Equipment For CrystallizationDocument7 pagesEquipment For CrystallizationjY-renNo ratings yet

- Crystallization EquipmentsDocument1 pageCrystallization EquipmentsKumar AmitNo ratings yet

- Antioxidant Potential of Polyphenols and TanninsDocument11 pagesAntioxidant Potential of Polyphenols and TanninsFarshad TasaodianNo ratings yet

- MGP Chapter5 Solids Thickening Dewatering Jan 2005Document22 pagesMGP Chapter5 Solids Thickening Dewatering Jan 2005Dito KristaNo ratings yet

- 52 Week ChallengeDocument3 pages52 Week Challengeeliyaht05No ratings yet

- Perry's Side Labels ContinuationDocument1 pagePerry's Side Labels Continuationeliyaht05No ratings yet

- Perry's LabelDocument1 pagePerry's Labeleliyaht05No ratings yet

- Side Labels ContinuationDocument1 pageSide Labels Continuationeliyaht05No ratings yet

- Perry's Side Labels ContiDocument1 pagePerry's Side Labels Contieliyaht05No ratings yet

- Preventive MeasureDocument4 pagesPreventive Measureeliyaht05No ratings yet

- Wind Energy PhilippinesDocument7 pagesWind Energy Philippineseliyaht05No ratings yet

- Preventive MeasureDocument4 pagesPreventive Measureeliyaht05No ratings yet

- Criteria (Group)Document2 pagesCriteria (Group)eliyaht05100% (1)

- Low Cost or Free Dental Services 1Document1 pageLow Cost or Free Dental Services 1probativeinfoNo ratings yet

- Physics Reference TableDocument4 pagesPhysics Reference Tablegoncstate93No ratings yet

- ROW 1502 BrochureDocument2 pagesROW 1502 BrochureahmedkhlNo ratings yet

- NOE-Notice of Escape-Boeing 2090 3-19-12Document1 pageNOE-Notice of Escape-Boeing 2090 3-19-12initiative1972No ratings yet

- Types of Heat Sinks: by Vijayakumar KDocument17 pagesTypes of Heat Sinks: by Vijayakumar KMervin RodrigoNo ratings yet

- SP3D CursoDocument10 pagesSP3D Cursodhaval20110% (1)

- Gas Cyl Rule3Document1 pageGas Cyl Rule3rudrakrNo ratings yet

- Calculating The Time Weighted Average (TWA) Noise Level and Noise Dose Levels PDFDocument1 pageCalculating The Time Weighted Average (TWA) Noise Level and Noise Dose Levels PDFwfng77No ratings yet

- Business Process ReDocument2 pagesBusiness Process ReSyed AyazNo ratings yet

- Feasibility Study OutlineDocument4 pagesFeasibility Study OutlineKim GosengNo ratings yet

- SRM University School of Mechanical Engineering Lesson Plan Course Code: Me0353Document2 pagesSRM University School of Mechanical Engineering Lesson Plan Course Code: Me0353PradeepvenugopalNo ratings yet

- Simple Dual Axis Solar Tracker PDFDocument28 pagesSimple Dual Axis Solar Tracker PDFIndiver MbNo ratings yet

- GNLD Carotenoid Complex Studio ClinicoDocument1 pageGNLD Carotenoid Complex Studio ClinicoAndrea CampiNo ratings yet

- Marcohly Fire 1Document1 pageMarcohly Fire 1Jesus Olandria DequenaNo ratings yet

- RR-170 ChaffDocument2 pagesRR-170 Chaffcover72No ratings yet

- Longterm Deflection Comparison With EtabsDocument6 pagesLongterm Deflection Comparison With EtabsArnel Dodong100% (1)

- Goljan High Yield Cell Injury USMLE 1Document2 pagesGoljan High Yield Cell Injury USMLE 1habdulhye100% (1)

- S 2Document2 pagesS 2UniQuNo ratings yet

- Teenage Risky BehaviorsDocument18 pagesTeenage Risky BehaviorsrebekkyahNo ratings yet

- Water Treatment StartupsDocument2 pagesWater Treatment StartupsDinyar MehtaNo ratings yet

- ADocument9 pagesALakshay Jindal LJNo ratings yet

- Welding DefectsDocument22 pagesWelding DefectsAnil KumarNo ratings yet

- ER420-130328-5003-CV-ULT - Method Statement of Box Culvert ConstructionDocument3 pagesER420-130328-5003-CV-ULT - Method Statement of Box Culvert ConstructionWr ArNo ratings yet

- Genu ValgumDocument2 pagesGenu ValgumPurohit_R0% (1)

- Hydra Jar Accelerator AP CsDocument1 pageHydra Jar Accelerator AP Csice_PLNo ratings yet

- Calculate Area and Volume Using Survey DataDocument3 pagesCalculate Area and Volume Using Survey Dataaogu100% (2)

- Case Study HousingDocument14 pagesCase Study HousingYamini Bhargava82% (11)

- Introduction To ROBOTICS: ControlDocument15 pagesIntroduction To ROBOTICS: ControlMANOJ MNo ratings yet

- Passive Sentences Change Active to PassiveDocument2 pagesPassive Sentences Change Active to PassivegranjerillaNo ratings yet

- Damodaran ValuationDocument2 pagesDamodaran ValuationDmitriy SuleshkoNo ratings yet