Professional Documents

Culture Documents

Steel Ohtl Poles Characteristic and Advantages

Uploaded by

Ahmed TahaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Ohtl Poles Characteristic and Advantages

Uploaded by

Ahmed TahaCopyright:

Available Formats

REN Conference 15.10-16.

10 Oslo

STEEL OHTL POLES

CHARACTERISTIC

AND

ADVANTAGES

Tadeusz Turzanski

Jean Christophe Andre

Einar Karsten

VALMONTs HISTORY

1946

1954

1959

1960 1990

1981 2000

2001

Presence 1970

1980 1968

founded 1946 in Valley

(Nebraska, USA)

started with irrigation

2011: Valmont is listed at

the NY stock exchange

with 90 locations and

appr. 10.000 employees

worddwide

Valmont Industries

3

Coatings

Irygtion

Our Markets

Lighting

Sygnaling &Transport

UTILITY

Telecommunikcation

Irigation Systems

What we do

Tubing

Coatings

Telecomm

Masts &Poles

Madrid, Spain

Creuzier-le-Neuf, France

Gelsenkirchen, Germany

Maarheeze, The Netherlands

Rive-de-Gier, France

Bay Minette, Alabama

Uberaba, Brazil

Jebel Ali, Dubai

Johannesburg, South Africa

St. Julie, Quebec,

Chicago, Illinois

Elkhart, Indiana

Minneapolis, Minnesota

Salem, Oregon

Tualatin, Oregon

Albany, Oregon

Los Angeles, California

Long Beach, California

McCook, Nebraska

Omaha, Nebraska

Sioux City, Iowa

Waverly, Nebraska

West Point, Nebraska

Plymouth, Indiana

Canada

Berrechid, Morocco

Valley, Nebraska

Brenham, Texas

Monterrey, Mexico

Tulsa, Oklahoma

Jasper, Tennessee

Siedlce, Poland

Charmeil, France

Shanghai, China

Stainton, United Kingdom

Commerce, City, Colorado

Barstow, California

Bellville, Texas

Mansfield, Texas

Tuscaloosa, Alabama

Claxton, Georgia

Bartow, Florida

Farmington, Minnesota El Dorado, Kansas

Selbyville, Delaware

Heshan, China

Kangasniemi, Finland

Kiiu, Estonia

Qingdao, China

VALMONT Poland

ESTABLISHED 1994 as joint

venture VALMONT 70% and

MOSTOSTAL 30%

- Lighting

- High Masts

- Utility

- Telecommunication

- Tramway Poles

TELECOM

Self Supported

TRAMWAYS

Utility Poles

Different Geometry Poles

Steel Pole Basic Features

Tapered tubular shaft and arms

Shaft consists of multiple

sections (typical 9-15m long)

High strength alloy steel

Used in 20kv to 750kv lines

Smaller foundation, less

components and better

appearance than lattice tower

Steel Pole Variety of Options

Type - tangent, angle, dead-end

Circuit - single, double, multiple

Steel Pole Variety of Options

Configuration - single pole, H-frame, Y-frame,

X-frame, 3-pole structure

Steel Pole Variety of Options

Support - self supporting, guyed

Steel Pole Variety of Options

Sections connections: Slip joints, flange joints,

and butt weld joints.

Steel Pole Variety of Options

Foundations types concrete foundations

with anchor bolts, direct embedded, and

caisson foundations

Steel Pole Variety of Options

Surface protection galvanizing, weathering

steel, powder coating

Less Right-of-way

Smaller foundation takes less land

Efficiently placed along highways, roads, rail tracks

Can be installed at locations with very limited space

Better Appearance

Trend of city beautification

Remove visual pollution

Need structure compatible with environment

Bulky clutter lattice tower visually unpleasant

76% public prefer poles over lattice towers

Fast Installation

Typical steel pole only has 15 or less components

Whole structure can be assembled before erection

Multiple structures can be installed in one day

Flexibility in Design

Various structure configuration pole and frame

Different voltage circuits on same pole

Distribution under-built

Multiple circuit in different orientation

Adding lines for telephone, cable TV

Lower Total Installed Cost

Less land and right-of-way cost

Less installation time and cost

Structure cost pole maybe slightly more than tower

Pole has lower total installed cost

Reliable Performance Over Time

Effective corrosion protection

Engineered product

Controlled fabrication process and tolerance

Structural integrity maintained through service life

Full Scale Test

Better Reliability under Extreme Condition

Steel monopole more flexible

than lattice tower, concrete or

wood pole under heavy loads

In broken conductor case,

bigger deflection of steel pole

reduces tension in intact span

and induces smaller bending

moment at base

Round or multi-side profile

induces less wind load

In past cases where lattice

towers and wood poles failed in

hurricane and tornado, no steel

poles were damaged

.

.

Height under

lower cross-

arm

Utilisation Lattice ref

Dimension

atGL

Land

occupancy

(m)

Monopole

ref

Dimension

atGL

Land

occupancy

(m)

Land

occupancy

suspension and

small angle

H92 KN T4

H15

2.79m x

2.79m

8.6

S3 F10-16-

25 T4 R1

dia 0.97 0.94 11%

tension

medium angle

H92 TA T4

H15

3m x

3m

9.9

S3 F40-52-

67 T4 R1

dia 1.41 2.0 20%

tension large

angle

H92 SS1 T4

H15

4m x

4m

17.6

S3 F90-

G15T4 R1

dia 1.68 2.8 16%

suspension and

small angle

H92 KN T4

H24

3.92m x

3.92m

16.9

S3 F10-16-

25 T4 Y

dia 1.21 1.5 9%

tension

medium angle

H92 TA T4

H24

4.26m x

4.26m

20

S3 F40-52-

67 T4 Y

dia 1.62 2.6 13%

tension large

angle

H92 SS1 T4

H24

5.8m x

5.8m

37

S3 F90-

G15T4 Y

dia 1.92 3.7 10%

12% 109.9 13.5

24m

90kV Single Circuit

Lattice tower Monopole

Monopol e vs

l atti ce i n %

15m

Monopoles & Towers land occupancy

Monopol e vs

l atti ce i n %

Height under

lower cross-

arm

Utilisation Lattice ref

Dimension

atGL

Land

occupancy

(m)

Monopole

ref

Dimension

atGL

Land

occupancy

(m)

Land

occupancy

suspension and

small angle

G4 NT B3 X

6.63m x

6.63m

48.4

S2 KNT

H6 Y

dia 1.95 3.80 8%

tension

medium angle

G4 AS B3 X

7.13m x

7.13m

55.921

S2 AS H6

Y

dia 2.98 8.9 16%

tension large

angle

G4 S0S1 B3

X

7.13m x

7.13m

55.921

S2 S1 H6

Y

dia 3.66 13.4 24%

16%

30m

160.2 26.1

225kV Double Circuit

Lattice tower Monopole

European & US standards

EN 50341 1 Overhead electrical lines exceeding AC 45 kV;

Part 1:General requirements - Common specifications; a

new standard being introduced + NNA (national normative

aspects for 20 European countries)

Old national standards still valid = NNAs

Currently most common standard for international projects -

ASCE Manual No. 72, "Design of Steel Transmission Pole

Structures", Second Edition, 1990 then called ASCE-SEI

48-05

Structural Welding Code - Steel, EN1011; ANSI/AWS D1.1-

92, American Welding Society

Material EN 10025; ASTM A36/A36M Specification for

Structural Steel;;

Galvanizing, EN 1461; ASTM A123 Specification for Zinc

(Hot-Dip Galvanized) Coatings on Iron and Steel

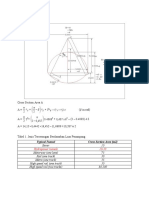

Assembly of tapered shafts by slip

joints

Assembly by slip joints

Slip length

Slip joint force

kN

Maxi

816

Mini

408

Mini

1670

Nominal

1820

Maxi

1970

mm

OK if values within this

area

Steel Materials

ASTM A572 Grade 65 Ksi (450 Mpa) material for pole shaft.

Special silicon controlled steel (0.06% maximum).

ASTM A572 Grade 50 Ksi (345 Mpa) material for base-plate.

European SS400 and St-52 (355 Mpa) steel.

Major steel suppliers Nucor, Arcelor, Baoshan Steel and Wuhan

Steel

Manufacturing

State-of-the-art facilities

Workforce has more than 35 years experience in

transmission pole fabrication

Biggest equipment capability for pole making

Shared global technology and best practice

July 2008 47

Other solutions

Pre-cambering and raking

For strong angle poles and for EDS , not for tangent poles

In the cross-arms plan

Steel Transmission Pole Examples

Steel Transmission Pole Examples

Steel Transmission Pole

Steel Transmission Pole Examples

Steel Transmission Pole Examples

Steel Transmission Pole Examples

Steel Transmission Pole Examples

Steel Transmission Pole Examples

Steel Transmission Pole Examples

Steel Transmission Pole Examples

Substation A-frame, H-frame

Substation Structure

Summery

Unlimited possibility to design the pole

Less elements much quicker erection

Small area of foot print

Beter resistance to extrem loads.

Vandalism protection

Long service life

Less visual pollution - aesthetic design

Thank you

THANK YOU

REN Conference 15.10-16.10 2013 Oslo

You might also like

- Applsci 13 01463 v4Document22 pagesApplsci 13 01463 v4Ahmed TahaNo ratings yet

- Design Optimization of GFRP Pole Structures Using Finite Element Analysis PDFDocument8 pagesDesign Optimization of GFRP Pole Structures Using Finite Element Analysis PDFAhmed TahaNo ratings yet

- Hardware Catalog No Prices (PTHW0208.1C) PDFDocument11 pagesHardware Catalog No Prices (PTHW0208.1C) PDFAhmed TahaNo ratings yet

- RUS Adds 9 More PUPI Crossarms to Accepted Materials ListDocument1 pageRUS Adds 9 More PUPI Crossarms to Accepted Materials ListAhmed TahaNo ratings yet

- Only. This File Is Illegal.: Design of Four-Axis Winding Machine For Tapered Composite Pole Using Heated-Mandrel CuringDocument8 pagesOnly. This File Is Illegal.: Design of Four-Axis Winding Machine For Tapered Composite Pole Using Heated-Mandrel CuringAhmed TahaNo ratings yet

- Comparison of Loads Timber Vs Jerol - Signature PDFDocument1 pageComparison of Loads Timber Vs Jerol - Signature PDFAhmed TahaNo ratings yet

- PL010 PUPI Technical Information REV01.2016 PDFDocument16 pagesPL010 PUPI Technical Information REV01.2016 PDFAhmed TahaNo ratings yet

- Structural Assessment of Fiber-Reinforced Polymer Composite Electric PolesDocument8 pagesStructural Assessment of Fiber-Reinforced Polymer Composite Electric PolesAhmed TahaNo ratings yet

- Durable Fiberglass Cross Arms for UtilitiesDocument3 pagesDurable Fiberglass Cross Arms for UtilitiesAhmed TahaNo ratings yet

- 5th Percentile Strength Development Values R1 PDFDocument12 pages5th Percentile Strength Development Values R1 PDFAhmed TahaNo ratings yet

- Only. This File Is Illegal.: Design of Four-Axis Winding Machine For Tapered Composite Pole Using Heated-Mandrel CuringDocument8 pagesOnly. This File Is Illegal.: Design of Four-Axis Winding Machine For Tapered Composite Pole Using Heated-Mandrel CuringAhmed TahaNo ratings yet

- Case Study: Composite Power Pole Benefits Out-Weigh Those of Wood and ConcreteDocument1 pageCase Study: Composite Power Pole Benefits Out-Weigh Those of Wood and ConcreteAhmed TahaNo ratings yet

- 2016 Seismic Assessment of Guyed Towers A Casestudy Combining Eld Measurements and Pushover Analysis PDFDocument7 pages2016 Seismic Assessment of Guyed Towers A Casestudy Combining Eld Measurements and Pushover Analysis PDFAhmed TahaNo ratings yet

- 494-13-09 Composite Fiberglass Reinforced Polymer Utility Poles PDFDocument4 pages494-13-09 Composite Fiberglass Reinforced Polymer Utility Poles PDFAhmed TahaNo ratings yet

- 5th Percentile Strength Development Values R1 PDFDocument12 pages5th Percentile Strength Development Values R1 PDFAhmed TahaNo ratings yet

- Assessing Structural Capacity of Power Towers Under WindDocument4 pagesAssessing Structural Capacity of Power Towers Under WindAhmed TahaNo ratings yet

- Structural Assessment of Fiber-Reinforced Polymer Composite Electric PolesDocument8 pagesStructural Assessment of Fiber-Reinforced Polymer Composite Electric PolesAhmed TahaNo ratings yet

- RUS Adds 9 More PUPI Crossarms to Accepted Materials ListDocument1 pageRUS Adds 9 More PUPI Crossarms to Accepted Materials ListAhmed TahaNo ratings yet

- Analysis and Design of Four Legged Transmission Tower: Archana R, Aswathy S KumarDocument5 pagesAnalysis and Design of Four Legged Transmission Tower: Archana R, Aswathy S Kumaranon_108261563No ratings yet

- 2013 Capacity - Assessment - of - A - Transmission - Tower - Under - Wind - Loading PDFDocument192 pages2013 Capacity - Assessment - of - A - Transmission - Tower - Under - Wind - Loading PDFAhmed TahaNo ratings yet

- Pushover Analysis For Seismic Assessment and Design of StructuresDocument287 pagesPushover Analysis For Seismic Assessment and Design of Structuresapirakq100% (2)

- 2014 In-Plane Buckling and Semi-Rigid Joints of Tubular High Strength Steel Trusses PDFDocument169 pages2014 In-Plane Buckling and Semi-Rigid Joints of Tubular High Strength Steel Trusses PDFAhmed TahaNo ratings yet

- Joint Slippage Effects On Mechanical Behavior of A New Anti-Icing TowerDocument5 pagesJoint Slippage Effects On Mechanical Behavior of A New Anti-Icing TowerAhmed TahaNo ratings yet

- Assessing Structural Capacity of Power Towers Under WindDocument4 pagesAssessing Structural Capacity of Power Towers Under WindAhmed TahaNo ratings yet

- 2016 Cigre Iec 068 PDFDocument9 pages2016 Cigre Iec 068 PDFAhmed TahaNo ratings yet

- X-Tech DeckCoat CP Top Coat PDFDocument2 pagesX-Tech DeckCoat CP Top Coat PDFAhmed TahaNo ratings yet

- 2012 Pushover Analysis For Cold Formed Storage Rack Structures PDFDocument12 pages2012 Pushover Analysis For Cold Formed Storage Rack Structures PDFAhmed TahaNo ratings yet

- X-Tech DeckCoat CP (Anti Skid Coat) PDFDocument2 pagesX-Tech DeckCoat CP (Anti Skid Coat) PDFAhmed TahaNo ratings yet

- X-Tech DeckCoat CP - Method Statment PDFDocument4 pagesX-Tech DeckCoat CP - Method Statment PDFAhmed TahaNo ratings yet

- X-Shield SF Primer PDFDocument2 pagesX-Shield SF Primer PDFAhmed TahaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- List of Contracts AwardedDocument21 pagesList of Contracts AwardedShailesh GangNo ratings yet

- Full Download Excellence in Business Communication Canadian 6th Edition Thill Test BankDocument36 pagesFull Download Excellence in Business Communication Canadian 6th Edition Thill Test Banksatleundukenn0l597% (35)

- Published PPP PaperDocument15 pagesPublished PPP Paperliza shoor100% (1)

- Bollards Catalogue en A4 Metric v.2.0 WebDocument20 pagesBollards Catalogue en A4 Metric v.2.0 WebspasmNo ratings yet

- CollocationsDocument93 pagesCollocationsBreggae91% (23)

- English Stage 4 Sample Paper 1 Insert - tcm142-594884Document4 pagesEnglish Stage 4 Sample Paper 1 Insert - tcm142-594884gordon50% (2)

- Tapal Kuda & Circular - Raynold Frinata Makuku - 11.2014.1.00466Document4 pagesTapal Kuda & Circular - Raynold Frinata Makuku - 11.2014.1.00466Aprilia Dwi AstutiNo ratings yet

- DC Traction ConnectionDocument25 pagesDC Traction ConnectionBrajesh SharmaNo ratings yet

- 1906 Afghanistan by Hamilton S PDFDocument580 pages1906 Afghanistan by Hamilton S PDFBilal Afridi100% (1)

- Library1v14-8-Cbj Visual GuideDocument34 pagesLibrary1v14-8-Cbj Visual GuideAlbert PriyambadhaNo ratings yet

- 1477640352901-GE Governor ALCODocument19 pages1477640352901-GE Governor ALCOManikanta ReddyNo ratings yet

- (1905) Report (Volume 1)Document112 pages(1905) Report (Volume 1)Herbert Hillary Booker 2nd100% (1)

- Express 1B (FWS)Document199 pagesExpress 1B (FWS)yusdi afandi100% (2)

- Question Paper HJS 2024Document15 pagesQuestion Paper HJS 2024shruti shikhaNo ratings yet

- Railtrack GuesstimateDocument5 pagesRailtrack GuesstimateAkhil DNo ratings yet

- Proposed Appendix F M-1002-1 Form 4-2 CleanDocument7 pagesProposed Appendix F M-1002-1 Form 4-2 CleanlomelindanielNo ratings yet

- Civil 3D Road Design BasicsDocument22 pagesCivil 3D Road Design BasicsthescubataterNo ratings yet

- SSI Basic System Notes PDFDocument8 pagesSSI Basic System Notes PDFBambang Soegeng0% (1)

- Geoinformatics 2012 Vol06Document68 pagesGeoinformatics 2012 Vol06protogeografoNo ratings yet

- Hyrib User Guide PDFDocument35 pagesHyrib User Guide PDFYoong Lai YeeNo ratings yet

- VDZ-Onlinecourse 2 2 en PDFDocument22 pagesVDZ-Onlinecourse 2 2 en PDFAnonymous iI88LtNo ratings yet

- Bridge ManualDocument360 pagesBridge ManualsunilNo ratings yet

- Iron Horse Terminals - Construction Begins at Beaumont Rail FacilityDocument2 pagesIron Horse Terminals - Construction Begins at Beaumont Rail FacilityPR.comNo ratings yet

- Finding the Third LevelDocument2 pagesFinding the Third LevelLini DasanNo ratings yet

- Road its development and Geometric design of highwaysDocument104 pagesRoad its development and Geometric design of highwayskesharinareshNo ratings yet

- El Libro de Bolsillo de Mecánica e Ingeniería de Nystrom PDFDocument708 pagesEl Libro de Bolsillo de Mecánica e Ingeniería de Nystrom PDFpieroap21100% (1)

- Bridges: Structure Span Body of Water Valley RoadDocument19 pagesBridges: Structure Span Body of Water Valley RoadpandiyanNo ratings yet

- LATsol SMAN 57Document10 pagesLATsol SMAN 57NAYLA NURRIZKYNo ratings yet

- Manukau Bus Station Project Information Boards Low Res Oct 15Document10 pagesManukau Bus Station Project Information Boards Low Res Oct 15Ben RossNo ratings yet

- Diesel and Electric Locomotive SpecificationsDocument5 pagesDiesel and Electric Locomotive SpecificationsSurendra KumarNo ratings yet