Professional Documents

Culture Documents

Goods Receipt

Uploaded by

jhsagasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Goods Receipt

Uploaded by

jhsagasCopyright:

Available Formats

Goods Receipt

http://help.sap.com/saphelp_45b/helpdata/en/c6/f83f084afa11d182b90000e829fbfe/frameset.htm

Purpose

A goods receipt is the physical inbound movement of goods or materials into the warehouse. It is a goods

movement that is used to post goods received from external vendors or from in-plant production. All goods receipts

result in an increase of stock in the warehouse.

The following kinds of goods receipts are considered in the SAP System:

Goods receipt with reference to a purchase order

Goods receipt with reference to a production order

Goods receipt with reference to a delivery

Other goods receipts (without reference)

The Goods Receipt Process

When goods are received in the warehouse, the processes that take place in the Warehouse Management (WM)

System are generally automatic and transparent to the user. From the time a dock worker scans a bar code on the

container slip until the goods are placed into a storage slot within the warehouse, WM keeps a record of all the

transactions that take place that are associated with each piece of stock. Each of the steps that are concerned

from posting the receipt of the goods in the Inventory Management (IM) component to confirming that the

movement has taken place can be carried out automatically by the system. Since they can also be carried out

manually if desired, the following description explains each of these steps in detail.

To initiate the receipt of goods into WM, you generally post a goods receipt in IM.

With the IM posting, the system assigns a quantity of material to a storage bin in an interim storage area for

goods receipts and creates a transfer requirement in WM.

Subsequently a transfer order is created, usually automatically by the system, based on the information in

the transfer requirement.

Using a predetermined search strategy, the system determines where in the warehouse the goods should

be placed and palletizes the goods.

The transfer order is used to transfer the goods from the interim storage bin in the receiving zone to one or

several storage bins in the warehouse.

The warehouse worker confirms that the goods have been transferred. This can be entered manually into

the system or automatically by using RF equipment to scan a bar code on a container.

Any discrepancies between the quantity requested and the quantity transferred into the warehouse are recorded in

WM. These differences must be cleared later in the IM component.

At this point, the goods receipt process is completed.

What happens in WM when goods are received in the warehouse?

The following figure shows a possible scenario for an inbound movement (goods receipt) in connection with a

Transfer Order (TO) This example shows what happens in the warehouse and in WM when goods are received.

Creating a Transfer Order without an IM Posting

___________________________________________________________________________________________

ADDITIONAL NOTES

Goods reception

Correct goods reception is a prerequisite for the efficient and error-free function of warehouse processes.

This places exacting demands on both personnel and tools in goods reception.

In Goods Reception incoming goods are registered and locations are found, before the articles are put on

stock. In small installations, with only a single zone, goods reception can be ignored, but in larger

installations it is recommended. Functions are:

The goods are registered, against an order from the Host system.

Quantities are controlled.

Locations are found and the articles can optionally be married to a barcode, for later identification.

Master data for the articles can be maintained.

At goods reception, incoming shipments are checked and registered. Often it is being checked whether the

right type of goods and the right quality is supplied, but not whether it is the right amount. And in these days

of small stocks and just-in-time deliveries an incomplete shipment has immediate consequences for the

production process. That costs money.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- M.E. (Mechanical - Heat Power Engineering) SyllabusDocument37 pagesM.E. (Mechanical - Heat Power Engineering) SyllabusKapil KotangaleNo ratings yet

- Basic-Engineering - Electrical EngineeringDocument227 pagesBasic-Engineering - Electrical EngineeringE-m FunaNo ratings yet

- Alimak AustraliancontractminingDocument5 pagesAlimak AustraliancontractminingmanudemNo ratings yet

- 2G Call FlowDocument71 pages2G Call Flowm191084No ratings yet

- NPC PrintPlay DeckDocument19 pagesNPC PrintPlay DeckBenjamin Pappa Bach FossumNo ratings yet

- Aspirasi MekoniumDocument17 pagesAspirasi MekoniumimanNo ratings yet

- The UFO MonthlyDocument21 pagesThe UFO MonthlySAB78No ratings yet

- Steam TurbineDocument25 pagesSteam TurbineIshan JunejaNo ratings yet

- Planning Installation and Configuration Guide For Windows PDFDocument228 pagesPlanning Installation and Configuration Guide For Windows PDFmmilovanmNo ratings yet

- Chapter 6 Exercises (Bonds & Interest)Document2 pagesChapter 6 Exercises (Bonds & Interest)Shaheera SuhaimiNo ratings yet

- CPE PRACTICE TEST 2 READINGDocument4 pagesCPE PRACTICE TEST 2 READINGHong Anh0% (1)

- RepairManual NEF M100 M150 P3D32N003E Mar06Document172 pagesRepairManual NEF M100 M150 P3D32N003E Mar06manuel segovia100% (1)

- Common Sense Renewed R. C. ChristianDocument276 pagesCommon Sense Renewed R. C. Christianwarhed76100% (3)

- GRT9165 Product GuideDocument23 pagesGRT9165 Product GuideEslamAldenAbdoNo ratings yet

- Greek MathemaDocument6 pagesGreek MathemaSebastian GhermanNo ratings yet

- Intelligence, Reasoning, Creativity, and WisdomDocument3 pagesIntelligence, Reasoning, Creativity, and WisdomSammy DeeNo ratings yet

- Overview of US Investment in NanotechnologyDocument19 pagesOverview of US Investment in NanotechnologyMaterials Research InstituteNo ratings yet

- Doctors Appointment - 4!14!17 Acid RefluxDocument11 pagesDoctors Appointment - 4!14!17 Acid RefluxRay Edwin Anderson IIINo ratings yet

- Reviewer On Nervous System Grade VIDocument4 pagesReviewer On Nervous System Grade VIKent Francis LayaguinNo ratings yet

- Casa Cook ArvindDocument65 pagesCasa Cook ArvindLEAN MauritiusNo ratings yet

- Djoko The Indonesian Mineral Mining Sector Prospects and ChallengesDocument42 pagesDjoko The Indonesian Mineral Mining Sector Prospects and ChallengesUmesh ShanmugamNo ratings yet

- Coyle Chapter 2 PowerPoint SlidesDocument33 pagesCoyle Chapter 2 PowerPoint SlidesKhaled Sheykh0% (1)

- Reservoir Engineering Handbook Tarek Ahmed Solution ManualDocument36 pagesReservoir Engineering Handbook Tarek Ahmed Solution ManualMohamad Hasen japerNo ratings yet

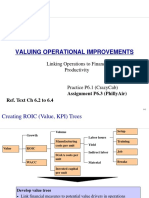

- 2 Linking Operations To Finance and ProductivityDocument14 pages2 Linking Operations To Finance and ProductivityAidan HonnoldNo ratings yet

- AR M205 BrochureDocument4 pagesAR M205 BrochurenickypanzeNo ratings yet

- CrankDocument9 pagesCrankKresna BayuNo ratings yet

- IRELAND - Rivers, Lakes and Mountains: Look at The Maps and Answer These QuestionsDocument2 pagesIRELAND - Rivers, Lakes and Mountains: Look at The Maps and Answer These QuestionsHannaNo ratings yet

- Wiper & Washer Circuit PDFDocument1 pageWiper & Washer Circuit PDFluis eduardo corzo enriquezNo ratings yet

- TOEFL Module 1 - ReadingDocument65 pagesTOEFL Module 1 - ReadingImam NurviyantoNo ratings yet

- Sri Lanka's Mineral Resources Can Enrich Country's CoffersDocument139 pagesSri Lanka's Mineral Resources Can Enrich Country's CoffersPrashan Francis100% (3)